Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

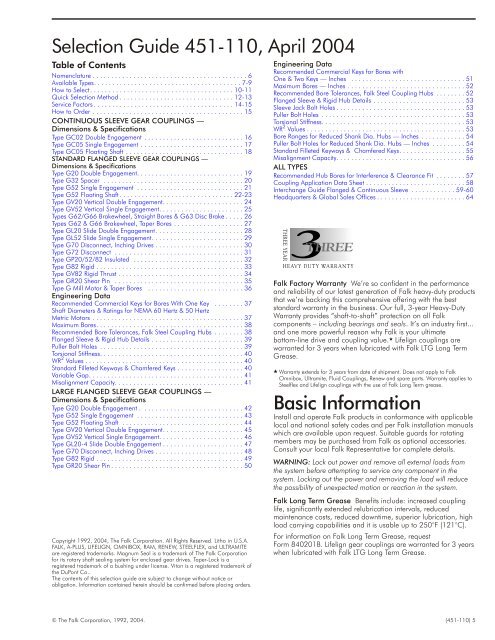

Selection Guide 451-110, April 2004<br />

Table of Contents<br />

Nomenclature ..........................................6<br />

Available Types. .......................................7-9<br />

How to Select. ......................................10-11<br />

Quick Selection Method ...............................12-13<br />

Service Factors ......................................14-15<br />

How to Order .........................................15<br />

CONTINUOUS SLEEVE GEAR <strong>COUPLINGS</strong> —<br />

Dimensions & Specifications<br />

Type GC02 Double Engagement ...........................16<br />

Type GC05 Single Engagement ............................17<br />

Type GC05 Floating Shaft ................................18<br />

STANDARD FLANGED SLEEVE GEAR <strong>COUPLINGS</strong> —<br />

Dimensions & Specifications<br />

Type G20 Double Engagement. ............................19<br />

Type G32 Spacer ......................................20<br />

Type G52 Single Engagement .............................21<br />

Type G52 Floating Shaft ...............................22-23<br />

Type GV20 Vertical Double Engagement. .....................24<br />

Type GV52 Vertical Single Engagement. ......................25<br />

Types G62/G66 Brakewheel, Straight Bores & G63 Disc Brake .....26<br />

Types G62 & G66 Brakewheel, Taper Bores ...................27<br />

Type GL20 Slide Double Engagement. .......................28<br />

Type GL52 Slide Single Engagement. ........................29<br />

Type G70 Disconnect, Inching Drives ........................30<br />

Type G72 Disconnect ...................................31<br />

Type GP20/52/82 Insulated ..............................32<br />

Type G82 Rigid . .......................................33<br />

Type GV82 Rigid Thrust . .................................34<br />

Type GR20 Shear Pin ...................................35<br />

Type G Mill Motor & Taper Bores ..........................36<br />

Engineering Data<br />

Recommended Commercial Keys for Bores With One Key ........37<br />

Shaft Diameters & Ratings for NEMA 60 Hertz & 50 Hertz<br />

Metric Motors .........................................37<br />

Maximum Bores. .......................................38<br />

Recommended Bore Tolerances, Falk Steel Coupling Hubs ........38<br />

Flanged Sleeve & Rigid Hub Details .........................39<br />

Puller Bolt Holes .......................................39<br />

Torsional Stiffness. ......................................40<br />

WR 2 Values ...........................................40<br />

Standard Filleted Keyways & Chamfered Keys ..................40<br />

Variable Gap. .........................................41<br />

Misalignment Capacity. ..................................41<br />

LARGE FLANGED SLEEVE GEAR <strong>COUPLINGS</strong> —<br />

Dimensions & Specifications<br />

Type G20 Double Engagement . ...........................42<br />

Type G52 Single Engagement .............................43<br />

Type G52 Floating Shaft .................................44<br />

Type GV20 Vertical Double Engagement. .....................45<br />

Type GV52 Vertical Single Engagement. ......................46<br />

Type GL20-4 Slide Double Engagement ......................47<br />

Type G70 Disconnect, Inching Drives ........................48<br />

Type G82 Rigid . .......................................49<br />

Type GR20 Shear Pin ....................................50<br />

Copyright 1992, 2004, The Falk Corporation. All Rights Reserved. Litho in U.S.A.<br />

FALK, A-PLUS, LIFELIGN, OMNIBOX, RAM, RENEW, STEELFLEX, and ULTRAMITE<br />

are registered trademarks. Magnum Seal is a trademark of The Falk Corporation<br />

for its rotary shaft sealing system for enclosed gear drives. Taper-Lock is a<br />

registered trademark of a bushing under license. Viton is a registered trademark of<br />

the DuPont Co..<br />

The contents of this selection guide are subject to change without notice or<br />

obligation. Information contained herein should be confirmed before placing orders.<br />

Engineering Data<br />

Recommended Commercial Keys for Bores with<br />

One & Two Keys — Inches ...............................51<br />

Maximum Bores — Inches ................................52<br />

Recommended Bore Tolerances, Falk Steel Coupling Hubs ........52<br />

Flanged Sleeve & Rigid Hub Details . ........................53<br />

Sleeve Jack Bolt Holes ...................................53<br />

Puller Bolt Holes .......................................53<br />

Torsional Stiffness. ......................................53<br />

WR 2 Values ...........................................53<br />

Bore Ranges for Reduced Shank Dia. Hubs — Inches ............54<br />

Puller Bolt Holes for Reduced Shank Dia. Hubs — Inches .........54<br />

Standard Filleted Keyways & Chamfered Keys. .................55<br />

Misalignment Capacity. ..................................56<br />

ALL TYPES<br />

Recommended Hub Bores for Interference & Clearance Fit ........57<br />

Coupling Application Data Sheet ...........................58<br />

Interchange Guide Flanged & Continuous Sleeve ............59-60<br />

Headquarters & Global Sales Offices ........................64<br />

Falk Factory Warranty We’re so confident in the performance<br />

and reliability of our latest generation of Falk heavy-duty products<br />

that we’re backing this comprehensive offering with the best<br />

standard warranty in the business. Our full, 3-year Heavy-Duty<br />

Warranty provides “shaft-to-shaft” protection on all Falk<br />

components – including bearings and seals. It’s an industry first...<br />

and one more powerful reason why Falk is your ultimate<br />

bottom-line drive and coupling value. Lifelign couplings are<br />

warranted for 3 years when lubricated with Falk LTG Long Term<br />

Grease.<br />

Warranty extends for 3 years from date of shipment. Does not apply to Falk<br />

Omnibox, Ultramite, Fluid Couplings, Renew and spare parts. Warranty applies to<br />

Steelflex and Lifelign couplings with the use of Falk Long Term grease.<br />

Basic Information<br />

Install and operate Falk products in conformance with applicable<br />

local and national safety codes and per Falk installation manuals<br />

which are available upon request. Suitable guards for rotating<br />

members may be purchased from Falk as optional accessories.<br />

Consult your local Falk Representative for complete details.<br />

WARNING: Lock out power and remove all external loads from<br />

the system before attempting to service any component in the<br />

system. Locking out the power and removing the load will reduce<br />

the possibility of unexpected motion or reaction in the system.<br />

Falk Long Term Grease Benefits include: increased coupling<br />

life, significantly extended relubrication intervals, reduced<br />

maintenance costs, reduced downtime, superior lubrication, high<br />

load carrying capabilities and it is usable up to 250°F (121°C).<br />

For information on Falk Long Term Grease, request<br />

Form 840201B. Lifelign gear couplings are warranted for 3 years<br />

when lubricated with Falk LTG Long Term Grease.<br />

© The Falk Corporation, 1992, 2004. (451-110) 5