Comminution - Ausenco

Comminution - Ausenco

Comminution - Ausenco

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

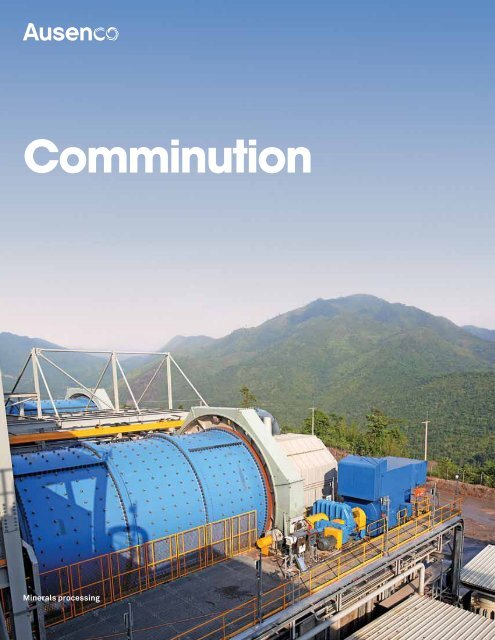

<strong>Comminution</strong><br />

Minerals processing

<strong>Comminution</strong><br />

<strong>Ausenco</strong> is a leading global provider<br />

of engineering and project management<br />

services to the resource and energy sectors.<br />

We combine ingenuity with insight to deliver<br />

effective end-to-end solutions for our clients.<br />

Our professionals offer expertise across every<br />

aspect of the resource and energy sectors<br />

— in areas including mineral processing;<br />

pipelines; transportation systems; ports and<br />

terminals; infrastructure; and conventional,<br />

renewable and alternative energies. We’re also<br />

experts in optimising performance through<br />

tailored operations and maintenance solutions,<br />

and in providing environmental and<br />

sustainability strategies that deliver benefits<br />

for projects, communities and the environment.<br />

We’re skilled in every phase of the project<br />

lifecycle. From initial concept through to<br />

operation, our people can assess, plan, cost,<br />

design and construct ingenious solutions<br />

that add value and support your return<br />

on investment.<br />

<strong>Ausenco</strong> is recognised for our level of<br />

expertise in all aspects of comminution.

Lumwana Copper Project,<br />

North Western Province, Zambia<br />

Solutions for the full project lifecycle<br />

Our experience and expertise in developing<br />

effective comminution solutions for our clients<br />

sets us apart from the rest.<br />

At <strong>Ausenco</strong>, we offer quality services for each<br />

comminution project, including high-level<br />

process engineering expertise, management<br />

of feasibility studies, and complete services<br />

through trusted alliances and joint ventures.<br />

We also have extensive experience in delivering<br />

large EPC and EPCM projects and have the<br />

ability, knowledge and expertise to manage<br />

our clients’ projects on their behalf, in a timely<br />

manner and within the allocated budget.<br />

Our clients know that an EPCM contract with<br />

<strong>Ausenco</strong> will ensure that their project is<br />

managed consistently and carefully to meet<br />

their needs.<br />

World-class comminution methodologies<br />

<strong>Ausenco</strong> is recognised for our high level of<br />

expertise in all aspects of comminution, from<br />

initial test work program development through<br />

all stages of study to design, construction<br />

supervision, start-up, commissioning and plant<br />

optimisation.<br />

<strong>Ausenco</strong> personnel have a wide range of<br />

experience in conventional stage crushing<br />

and SAG milling circuit designs, and are at<br />

the forefront of modelling and engineering of<br />

comminution circuits based on high pressure<br />

grinding rolls (HPGR) technology.<br />

Our people also have extensive experience in<br />

the determination of mill power requirements<br />

and mill sizing including large mills with<br />

gearless drives.<br />

We can offer our clients a range of comminution<br />

services over the full project lifecycle and a<br />

global network for design and delivery including:<br />

• sample selection, metallurgical test<br />

work program design, management and<br />

results interpretation<br />

• consulting:<br />

• process modelling and simulation<br />

(JKSimMet and in-house power model)<br />

• independent review of process designs<br />

• review of existing operations and<br />

performance enhancement<br />

• energy efficiency assessments<br />

• trade-off options, optimisation and circuit/<br />

technology selection studies:<br />

• SAG<br />

• HPGR<br />

• stage crushing<br />

• scoping, prefeasibility and feasibility studies<br />

• basic and detailed design<br />

• construction support<br />

• commissioning assistance<br />

• operator training and operations support.<br />

Additionally, we are experts in the<br />

application of various ore characterisation<br />

methodologies including:<br />

• JKSimMet<br />

• JKDWT<br />

• SMC<br />

• SPI<br />

• Bond<br />

• Starkey.

Our experience<br />

Project<br />

Sepon Copper Project<br />

Location<br />

Laos, South East Asia<br />

Client<br />

Oxiana Resources Limited<br />

Year<br />

2008<br />

Description<br />

The Sepon Copper Project uses<br />

a patented copper leaching<br />

process comprising crushing,<br />

grinding in acid, acidic<br />

flotation, pressure oxidation<br />

and a solvent extraction<br />

electrowinning circuit.<br />

<strong>Ausenco</strong>’s scope was for<br />

the full EPCM for the project.<br />

The grinding circuit comprises<br />

a 2 MW variable speed<br />

single-stage grate discharge<br />

ball mill operating in closed<br />

circuit with hydrocyclones,<br />

with a capacity of 1.34 Mt/y.<br />

The circuit is designed to scrub<br />

and grind the copper-rich clay<br />

ore to a P80 of 106 μm. Milling<br />

is conducted in a warm acid<br />

recycle solution to avoid<br />

excessive dilution of the<br />

copper tenor in subsequent<br />

leaching. The mill internals are<br />

clad with SAF 2205 and rubber<br />

lined to protect the carbon<br />

steel shell and end plates.<br />

Project<br />

Cadia East Project<br />

Location<br />

New South Wales, Australia<br />

Client<br />

Newcrest Mining Ltd<br />

Year<br />

2010–2011<br />

Description<br />

<strong>Ausenco</strong> designed a new<br />

comminution circuit for the<br />

existing concentrator to allow<br />

for the treatment of much<br />

harder ore. We created an<br />

innovative circuit incorporating<br />

High Pressure Grinding Rolls<br />

(HPGR) technology prior to the<br />

Semi-Autogenous Grinding<br />

(SAG) mill to improve efficiency<br />

and increase throughput of<br />

the concentrator.<br />

For this upgrade, <strong>Ausenco</strong><br />

was awarded Contractor of<br />

the Year from the 2012<br />

Annual Australian Mining<br />

Prospect Awards.<br />

Project<br />

Lumwana Copper Project<br />

Location<br />

North Western Province,<br />

Zambia<br />

Client<br />

Equinox Minerals<br />

Year<br />

2006–2008<br />

Description<br />

Located in the North Western<br />

Province of Zambia, Lumwana<br />

is the largest copper project of<br />

its kind in Africa.<br />

<strong>Ausenco</strong>’s scope included the<br />

design, supply, construction<br />

and commissioning of the<br />

20 Mt/y copper concentrator<br />

including associated on-site<br />

and off-site infrastructure,<br />

water and waste-management<br />

systems, dams, diversion<br />

channels, and associated<br />

facilities. This project uses<br />

a SAB circuit with pebble<br />

recycle, using a gearless drive<br />

18 MW SAG mill and a gearless<br />

drive 16 MW ball mill.<br />

To learn more about our comminution experience, contact us via<br />

email business.development@ausenco.com or visit our website www.ausenco.com<br />

AUS0717_11_C_V1_26.03.13