Jetline marvel

This first issue is the beginning of our long journey which packed with striking Aviation reports , airlines reviews , articles,stories and most of all phenomenal imagery by reports from all over the globe about aviation & aerospace enthusiast people. Jetline Marvel is Synchronized by Aerospace Science Research Foundation(India) as well as Aerospace Science Club, Bengaluru.

This first issue is the beginning of our long journey which packed with striking Aviation reports , airlines reviews , articles,stories and most of all phenomenal imagery by reports from all over the globe about aviation & aerospace enthusiast people. Jetline Marvel is Synchronized by Aerospace Science Research Foundation(India) as well as Aerospace Science Club, Bengaluru.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

20<br />

JETLINE <strong>marvel</strong> I January 2015<br />

Did you know?<br />

How do they start jet engines on airplanes?<br />

Gas turbine engines come in many shapes and sizes. One type discussed in how turbine engines work<br />

includes a normal "jet" engine on an airplane. The hot gases produced by the burning fuel drive vanes in<br />

exactly the same way that wind turns a windmill. The vanes connect to a shaft that also spins the turbine's<br />

compressor. Another type of gas turbine engine, popular in tanks and helicopters, has one set of vanes<br />

for driving the compressor, as well as a separate set of vanes that drive the output shaft. In both of these<br />

types of engines, you need to get the main shaft spinning to start the engine.<br />

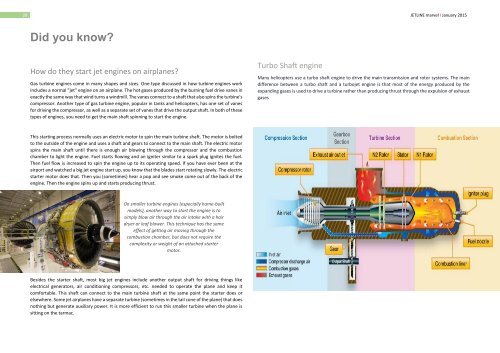

Turbo Shaft engine<br />

Many helicopters use a turbo shaft engine to drive the main transmission and rotor systems. The main<br />

difference between a turbo shaft and a turbojet engine is that most of the energy produced by the<br />

expanding gases is used to drive a turbine rather than producing thrust through the expulsion of exhaust<br />

gases<br />

This starting process normally uses an electric motor to spin the main turbine shaft. The motor is bolted<br />

to the outside of the engine and uses a shaft and gears to connect to the main shaft. The electric motor<br />

spins the main shaft until there is enough air blowing through the compressor and the combustion<br />

chamber to light the engine. Fuel starts flowing and an igniter similar to a spark plug ignites the fuel.<br />

Then fuel flow is increased to spin the engine up to its operating speed. If you have ever been at the<br />

airport and watched a big jet engine start up, you know that the blades start rotating slowly. The electric<br />

starter motor does that. Then you (sometimes) hear a pop and see smoke come out of the back of the<br />

engine. Then the engine spins up and starts producing thrust.<br />

On smaller turbine engines (especially home-built<br />

models), another way to start the engine is to<br />

simply blow air through the air intake with a hair<br />

dryer or leaf blower. This technique has the same<br />

effect of getting air moving through the<br />

combustion chamber, but does not require the<br />

complexity or weight of an attached starter<br />

motor.<br />

Besides the starter shaft, most big jet engines include another output shaft for driving things like<br />

electrical generators, air conditioning compressors, etc. needed to operate the plane and keep it<br />

comfortable. This shaft can connect to the main turbine shaft at the same point the starter does or<br />

elsewhere. Some jet airplanes have a separate turbine (sometimes in the tail cone of the plane) that does<br />

nothing but generate auxiliary power. It is more efficient to run this smaller turbine when the plane is<br />

sitting on the tarmac.