THOR Selection Guide - Kremlin Rexson Sames

THOR Selection Guide - Kremlin Rexson Sames

THOR Selection Guide - Kremlin Rexson Sames

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

tHOr<br />

RANGE<br />

SALES<br />

GUIDE<br />

Application Equipment for<br />

Single Component<br />

High-Viscosity Materials<br />

Experts in Finishing and Dispensing Solutions

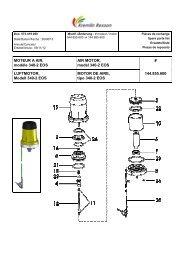

<strong>THOR</strong>: A COMPLETE RANGE TO MEET ALL NEEDS<br />

53.216<br />

7000<br />

82.216<br />

9000<br />

60.60<br />

3000<br />

34.106<br />

3000<br />

63.106<br />

5000<br />

32.207<br />

5000<br />

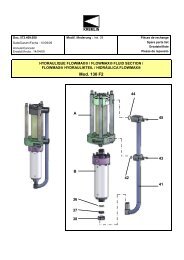

*First digit ‘60’ refers to Pump Pressure Ratio (e.g., 60:1)<br />

Second digit ‘60’ refers to Fluid Delivery in cc for one Cycle<br />

(or double stroke) of the hydraulic section (e.g., 60 cc).<br />

3000 designates the air motor size.<br />

KREMLIN REXSON <strong>THOR</strong> RANGE BRINGS<br />

INNOVATIVE SOLUTIONS TO THESE MARKETS<br />

■ AUTOMOTIVE INDUSTRY<br />

■ AGRICULTURAL MACHINERY<br />

■ RECREATIONAL VEHICLES<br />

■ SOLAR ENERGY<br />

■ TRAINS<br />

■ HOUSEHOLDS GOODS<br />

■ MARINE INDUSTRY<br />

■ BUILDING AND EARTH<br />

MOVING EQUIPMENT<br />

1

QUICK PUMP SELECTOR CHART<br />

1<br />

2<br />

3<br />

4<br />

What is the material output required for the application?<br />

What is the required flow rate? (or bead size and application time).<br />

What is the material viscosity?<br />

See product data sheet (TDS/MSDS), is it moisture sensitive?<br />

What is the container size?<br />

To determine the correct container size: 5 gal/20 l, 8 gal/30 l, 16 gal/60 l or 55 gal/200 l.<br />

What is the distance from the pump to the point of application?<br />

To determine the correct hose length.<br />

Once you know the required material flow rate (cc/min) and the material viscosity<br />

(cps) use the chart below to select the right pump. Each area is identified (C1, C2,<br />

etc.) that corresponds to a dedicated chapter in the guide where you will find all<br />

components required to build your complete system.<br />

FLOW RATE (cc/min)<br />

3 785<br />

(1 gal)<br />

C7<br />

32.207<br />

C3 34.106<br />

C5 63.106<br />

C8<br />

32.207<br />

Example:<br />

C4<br />

34.106<br />

To dispense a bead of sealant: a calculation of the bead volume shows that an<br />

output of 200cc/min is required. The material viscosity is 80,000 cps. Using<br />

the Pump Output vs. Viscosity chart (below), you will see that the two<br />

lines intersect under the Zone C2 60.60.<br />

C9<br />

53.216<br />

Turn to Chapter C2 and you will find details on the 60.60<br />

pump with a Twin Post Ram System. Please select the<br />

system according to the relevant drum size or<br />

application details.<br />

(For applications outside the scope of this<br />

chart please consult us).<br />

C10<br />

82.216<br />

C1<br />

60.60<br />

C2<br />

60.60<br />

C6<br />

63.106<br />

2<br />

VISCOSITY (CPS)

SALES GUIDE<br />

HIGH-VISCOSITY PRODUCTS<br />

For over 50 years, KREMLIN REXSON has<br />

been working in the fluid handling business,<br />

offering a wide range of equipment to industrial<br />

markets.<br />

At KREMLIN REXSON, we pride ourselves<br />

on being a complete supplier of equipment for<br />

single and plural component materials.<br />

We are committed to research and development,<br />

and are always looking for new ways to<br />

improve our equipment efficiency.<br />

Key to our equipment design is ease of use and<br />

simplicity, allowing materials to be pumped<br />

directly from contains with minimal material waste.<br />

In the pages that follow, you will find information<br />

about our product range.<br />

For additional information, please consult<br />

our web site www.exel-na.com.<br />

TABLE OF CONTENTS<br />

QUICK PUMP SELECTION CHART 2<br />

PUMP TECHNICAL SECTION<br />

C1 60.60 Pump – Single Post Ram 4–6<br />

C2 60.60 Pump – Twin Post Ram 7–9<br />

C3 34.106 Pump – Single Post Ram 10–12<br />

C4 34.106 Pump – Twin Post Ram 13–15<br />

C5 63.106 Pump – Single Post Ram 16–18<br />

C6 63.106 Pump – Twin Post Ram 19–21<br />

C7 32.207 Pump – Single Post Ram 22–24<br />

C8 32.207 Pump – Twin Post Ram 25–27<br />

C9 53.216 Pump – Twin Post Ram 28–30<br />

C10 82.216 Pump – Twin Post Ram 31–33<br />

RegSMART REGULATOR 34–35<br />

FEATURES AND BENEFITS 36–37<br />

SELECTION INFORMATION<br />

Ram 38<br />

Follower Plate 38<br />

Optional Equipment 39<br />

PRACTICAL INFORMATION 40–45<br />

3

C1<br />

60.60 PUMP - SINGLE POST RAM<br />

(5 gal/20 l) EXTRUSION UNIT<br />

The 60.60* pump is specially designed for pumping viscous materials.<br />

KREMLIN REXSON equipment can process a wide range of materials<br />

including oils, greases, adhesives and sealants.<br />

This equipment has proven itself over the years to be strong and reliable,<br />

and can process products up to 30,000 centipoise depending on<br />

specification.<br />

The system pumps directly from the original material container and is used<br />

on 5 gal (20 l) pails.<br />

The modular concept allows you to select an extrusion system comprised<br />

of an assembled pump, elevator and follower plate. Additional individual<br />

components are available including: filter, regulator, hose or gun<br />

to complete your system. Optional system accessories are available to<br />

suit your application.<br />

EVER<br />

Tough<br />

*First digit ‘60’ refers to Pump Pressure Ratio (e.g., 60:1)<br />

Second digit '60' refers to Fluid Delivery in cc for one Cycle (or double<br />

stroke) of the hydraulic section (e.g., 60 cc).<br />

FEATURES<br />

Modular design<br />

Air motor design enables<br />

precise control<br />

Direct pumping from 5 gal (20 l) pail<br />

Shovel pump technology<br />

Pneumatic-driven pump<br />

BENEFITS<br />

Wide range of options available<br />

to suit most applications<br />

The unique air motor design<br />

ensures a constant controlled<br />

flow rate with low noise and<br />

minimum icing risk<br />

Clean wipe of the material<br />

drum reducing material waste<br />

Can be used with a wide<br />

range of materials<br />

Safe for use near solvents and<br />

other flammable materials<br />

52.9<br />

44.1<br />

35.3<br />

26.4<br />

17.6<br />

8.8<br />

Air Motor Consumption<br />

(Cubic feet/min).<br />

87 psi - (6 bar)<br />

58 psi - (4 bar)<br />

29 psi - (2 bar)<br />

0 15 30 45 60<br />

Pump cycles per minute<br />

SPECIFICATIONS<br />

Pressure ratio 60:1<br />

Motor type 3000<br />

Fluid volume per cycle - cc 60<br />

Free flow rate at 60 cycles - gpm (l/min) .95 (3.6)<br />

Fluid output at 15 cycles - gpm (l/min) .24 (0.9)<br />

Maximum air inlet pressure - psi (bar) 87 (6)<br />

Maximum fluid pressure - psi (bar) 5290 (360)<br />

Maximum fluid temperature - °F (°C) 140 (60)<br />

Seal packings<br />

PTFE + PE<br />

Wetted parts<br />

Carbon steel<br />

Weight (bare pump) - lbs. (kg.) 42 (19)<br />

FITTINGS<br />

Fitting Air Inlet** 3/4'' F BSPP<br />

Fluid Outlet<br />

3/4'' F BSPP<br />

** Recommended air supply hose diameter 1/2”<br />

4

C1<br />

Pump/Ram Extrusion Packages<br />

w/60.60 Pump - Single Post Ram<br />

(For 5 gal/20 l Containers)<br />

PUMP<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

668-080-301 668-080-305 668-080-311 668-080-315<br />

60.60 extrusion pump with PTFE/PE seals ( II2G IIB T3)<br />

P/N: 151-040-000<br />

* * * *<br />

SINGLE POST RAM<br />

FOLLOWER PLATE<br />

Single post ram with air control (3000)<br />

P/N: 668-080-005<br />

* * * *<br />

Single post ram with air control (5000)<br />

P/N: 668-080-010<br />

Single Flat Wiper (Nitrile) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-100-100<br />

* *<br />

FOLLOWER PLATE - Teflon Coated<br />

CART<br />

Twin O-Ring (EPDM) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-102-200<br />

* *<br />

Cart kit<br />

P/N: 668-098-060 * *<br />

*<br />

= Included in pump package NOTE: Pump, Ram and Follower plate come assembled. Consult factory for other follower plate sizes not shown.<br />

+ + +<br />

System Components<br />

FILTER AND REGULATOR<br />

Part Number<br />

Option A : Regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-985<br />

Option B : Filter with fitting and mounting accessories (plate, fittings, hose...) 151-260-986<br />

Option C : Filter and regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-987<br />

5

C1<br />

System Components (Cont.)<br />

HOSES AND FITTINGS TO FEED GUN<br />

Fluid Hose Dia. Length Part Number<br />

Ø 3/8" PTFE hose 3/4" JIC fitting, 15' lg with all required fittings 3/8" 15' 668-260-980<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 15' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

1/2" + 3/8" 20' 668-260-981<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 25' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

1/2" + 3/8" 30' 668-260-982<br />

MANUAL GUN AND ACCESSORIES<br />

Part Number<br />

Extrusion gun 7251 psi (500 bar) (equipped - swivel, gun, nozzles) 668-110-500<br />

Plastic disposable nozzles (x10) 668-110-010<br />

Optional Accessories/Spare & Repair Parts<br />

3000 AIR MOTOR REPAIR KIT Part Number<br />

Air motor seal kit 146-310-090<br />

2 air motor silencer kit 146-310-091<br />

Distributor kit 146-310-092<br />

Pneumatic kit 146-320-094<br />

Safety valve 94 psi (6.5 bar) 903-080-401<br />

60 CC FLUID SECTION REPAIR KIT Part Number<br />

Standard seal kit (PTFE + PE) 144-200-090<br />

Repair kit 144-200-091<br />

Cylinder kit 144-200-092<br />

Optional maintenance kit (graphite-filled PTFE) 144-200-093<br />

Optional maintenance kit (PU + graphite-filled PTFE) 144-200-094<br />

FOLLOWER PLATE REPAIR (FLAT & DOUBLE) SEALS<br />

Part Number<br />

5 gal (20 l) flat seal - Nitrile (285 mm Ø) 150-048-301<br />

5 gal (20 l) double seal - EPDM O-ring seal (285 mm Ø) 150-048-306<br />

SINGLE POST RAM ELEVATOR ACCESSORIES & MAINTENANCE KITS<br />

Low level shut off kit 668-098-050<br />

Pail hold down kit 668-098-006<br />

Seal kit 668-080-090<br />

Manometer outlet back kit 151-080-091<br />

Command button kit 151-080-092<br />

Push button kit 151-080-093<br />

Base outlet manometer kit 151-080-094<br />

55 psi (3.8 bar) valve kit 903-080-403<br />

FILTER MAINTENANCE<br />

Part Number<br />

FKM (Viton) O-ring seal 80032<br />

Cartridge filter (25 mesh - 710 µ) 601084<br />

Cartridge filter (50 mesh - 350 µ) 601092<br />

Cartridge filter (80 mesh - 201 µ) 601287<br />

REGULATOR MAINTENANCE<br />

Part Number<br />

Repair Kit 8 mm 155-750-901<br />

8 mm Cartridge 155-750-904<br />

EXTRUSION GUN ACCESSORIES & MAINTENANCE<br />

Part Number<br />

Repair kit for 7251 psi (500 bar) extrusion gun 151-110-695<br />

Extrusion gun 7251 psi (500 bar) equipped 668-110-500<br />

Extrusion gun 7251 psi (500 bar) gun only 922-080-001<br />

Straight swivel 922-080-002<br />

Plastic disposable nozzles (x10) 668-110-010<br />

Max height 99.77"<br />

Min height 60.90"<br />

Stroke length 38.87"<br />

Total weight :<br />

475 lbs. / 215 kg.<br />

6

60.60 PUMP - TWIN POST RAM<br />

(5 gal/20 l - 55 gal/200 l) EXTRUSION UNIT<br />

C2<br />

The 60.60* pump is specially designed for pumping viscous materials.<br />

KREMLIN REXSON equipment can process a wide range of materials<br />

including oils, greases, adhesives and sealants.<br />

This equipment has proven itself over the years to be strong and reliable,<br />

and can process products up to 400,000 centipoise depending on specification.<br />

The system pumps directly from the original material container and can be<br />

used on 5 gal (20 l) pails up to 55 gal (200 l) drums.<br />

The modular concept allows you to select an extrusion system comprised<br />

of an assembled pump, elevator and follower plate. Additional<br />

individual components are available including: filter, regulator, hose or<br />

gun to complete your system. Optional system accessories are available<br />

to suit your application.<br />

EVER<br />

Tough<br />

* First digit ‘60’ refers to Pump Pressure Ratio (e.g., 60:1)<br />

Second digit '60' refers to Fluid Delivery in cc for one Cycle (or double<br />

stroke) of the hydraulic section (e.g., 60 cc).<br />

FEATURES<br />

Modular design<br />

Air motor design enables<br />

precise control<br />

Direct pumping from 55 gal drum<br />

Shovel pump technology<br />

Choice of double seal on<br />

follower plate<br />

Pneumatic driven pump<br />

BENEFITS<br />

Wide range of options available<br />

to suit most applications<br />

The unique air motor design<br />

ensures a constant controlled<br />

flow rate with low noise and<br />

minimum icing risk<br />

Clean wipe of the material<br />

drum reducing material waste<br />

Can be used with a wide<br />

range of materials<br />

Recommended for high-viscosity<br />

and moisture-sensitive materials<br />

Safe for use near solvents and<br />

other flammable materials<br />

Air Motor Consumption<br />

(Cubic feet/min).<br />

52.9<br />

44.1<br />

35.3<br />

26.4<br />

17.6<br />

8.8<br />

87 psi - (6 bar)<br />

58 psi - (4 bar)<br />

29 psi - (2 bar)<br />

0 15 30 45 60<br />

Pump cycles per minute<br />

SPECIFICATIONS<br />

Pressure ratio 60:1<br />

Motor type 3000<br />

Fluid volume per cycle - cc 60<br />

Free flow rate at 60 cycles - gpm (l/min) .95 (3.6)<br />

Fluid output at 15 cycles - gpm (l/min) .24 (0.9)<br />

Maximum air inlet pressure - psi (bar) 87 (6)<br />

Maximum fluid pressure - psi (bar) 5290 (360)<br />

Maximum fluid temperature - °F (°C) 140 (60)<br />

Seal packings<br />

PTFE + PE<br />

Wetted parts<br />

Carbon steel<br />

Weight (bare pump) - lbs. (kg.) 42 (19)<br />

FITTINGS<br />

Fitting Air Inlet** 3/4'' F BSPP<br />

Fluid Outlet<br />

3/4'' F BSPP<br />

** Recommended air supply hose diameter 1/2"<br />

7

C2<br />

Pump/Ram Extrusion Packages<br />

w/60.60 Pump - Twin Post Ram<br />

(For 5 gal/20 l - thru - 55 gal/200 l Containers)<br />

PUMP<br />

TWIN POST RAM<br />

FOLLOWER PLATE<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

668-090-301 668-090-305 668-090-312 668-090-314 668-090-315 668-090-317<br />

60.60 extrusion pump with PTFE/<br />

PE seals ( II2G IIB T3)<br />

P/N: 151-040-000 * * * * * *<br />

Twin post ram with air control<br />

(Short) P/N: 668-090-505 * * * *<br />

Twin post ram with air control<br />

(Long) P/N: 668-090-510 * *<br />

Single Flat Wiper (Nitrile) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-100-100<br />

*<br />

8 Gal/30L<br />

Consult Factory<br />

16 Gal /60L Ø14.17” (360 mm)<br />

P/N: 151-100-400<br />

*<br />

55 Gal /200L Ø22.48” (571 mm)<br />

P/N: 151-100-500<br />

*<br />

FOLLOWER PLATE - Teflon Coated<br />

*<br />

Twin O-Ring (EPDM) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-102-200<br />

*<br />

8 Gal/30L<br />

Consult Factory<br />

16 Gal /60L Ø14.17” (360 mm)<br />

P/N: 151-102-500<br />

*<br />

55 Gal /200L Ø22.48” (571 mm)<br />

P/N: 151-102-600<br />

*<br />

= Included in pump package NOTE: Pump, Ram and Follower plate come assembled. Consult factory for other follower plate sizes not shown.<br />

System Components<br />

+ + +<br />

FILTER AND REGULATOR<br />

Part Number<br />

Option A : Regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-985<br />

Option B : Filter with fitting and mounting accessories (plate, fittings, hose...) 151-260-986<br />

Option C : Filter and regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-987<br />

8

System Components (Cont.)<br />

HOSES AND FITTINGS TO FEED GUN<br />

Fluid Hose Dia. Length Part Number<br />

Ø 3/8" PTFE hose 3/4" JIC fitting, 15' lg with all required fittings 3/8" 15' 668-260-980<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 15' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

1/2" + 3/8" 20' 668-260-981<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 25' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

1/2" + 3/8" 30' 668-260-982<br />

Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 15' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

3/4" + 3/8" 20' 668-260-983<br />

Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 25' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

3/4" + 3/8" 30' 668-260-984<br />

MANUAL GUN AND ACCESSORIES<br />

Part Number<br />

Extrusion gun 7251 psi (500 bar) (equipped - swivel, gun, nozzles) 668-110-500<br />

Plastic disposable nozzles (x10) 668-110-010<br />

C2<br />

Optional Accessories/Spare & Repair Parts<br />

3000 AIR MOTOR REPAIR KIT Part Number<br />

Air motor seal kit 146-310-090<br />

2 air motor silencer kit 146-310-091<br />

Distributor kit 146-310-092<br />

Pneumatic kit 146-320-094<br />

Safety valve 94 psi (6.5 bar) 903-080-401<br />

60 CC FLUID SECTION REPAIR KIT Part Number<br />

Standard seal kit (PTFE + PE) 144-200-090<br />

Repair kit 144-200-091<br />

Cylinder kit 144-200-092<br />

Optional maintenance kit (graphite-filled PTFE) 144-200-093<br />

Optional maintenance kit (PU + graphite-filled PTFE) 144-200-094<br />

FOLLOWER PLATE REPAIR (FLAT & DOUBLE) SEALS<br />

Part Number<br />

5 gal (20 l) flat seal - Nitrile (285 mm Ø) 150-048-301<br />

8 gal (30 l) flat seal - Nitrile call<br />

16 gal (60 l) flat seal - Nitrile (360 mm Ø) 150-048-304<br />

55 gal (200 l) flat seal - Nitrile (571 mm Ø) 150-048-305<br />

5 gal (20 l) double seal - EPDM O-ring seal (285 mm Ø) 150-048-306<br />

8 gal (30 l) double seal - EPDM O-ring seal call<br />

16 gal (60 l) double seal - EPDM O-ring seal (360 mm Ø) 150-048-309<br />

55 gal (200 l) double seal - EPDM O-ring seal (571 mm Ø) 150-048-310<br />

TWIN POST RAM ELEVATOR ACCESSORIES & MAINTENANCE KITS<br />

Low level shut off kit 668-098-055<br />

Pail hold down kit (5-8 gal) 668-098-006<br />

Drum locator kit 668-098-007<br />

Drum roller kit 668-098-100<br />

Seal kit 668-090-090<br />

Manometer outlet back kit 151-080-091<br />

Command button kit 151-080-092<br />

Push button kit 151-080-093<br />

Base outlet manometer kit 151-080-094<br />

55 psi (3.8 bar) valve kit 903-080-403<br />

FILTER MAINTENANCE<br />

Part Number<br />

FKM (Viton) O-ring seal 80032<br />

Cartridge filter (25 mesh - 710 µ) 601084<br />

Cartridge filter (50 mesh - 350 µ) 601092<br />

Cartridge filter (80 mesh - 201 µ) 601287<br />

REGULATOR MAINTENANCE<br />

Part Number<br />

Repair Kit 8 mm 155-750-901<br />

8 mm Cartridge 155-750-904<br />

EXTRUSION GUN ACCESSORIES & MAINTENANCE<br />

Part Number<br />

Repair kit for 7251 psi (500 bar) extrusion gun 151-110-695<br />

Extrusion gun 7251 psi (500 bar) equipped 668-110-500<br />

Extrusion gun 7251 psi (500 bar) gun only 922-080-001<br />

Straight swivel 922-080-002<br />

Plastic disposable nozzles (x10) 668-110-010<br />

Max height 99.77"<br />

Min height 60.90"<br />

Stroke length 38.87"<br />

Total weight :<br />

475 lbs. / 215 kg.<br />

9

C3<br />

34.106 PUMP - SINGLE POST RAM<br />

(5 gal/20 l) EXTRUSION UNIT<br />

The 34.106* pump is specially designed for pumping viscous materials.<br />

KREMLIN REXSON equipment can process a wide range of materials<br />

including oils, greases, adhesives and sealants.<br />

This equipment has proven itself over the years to be strong and reliable, and<br />

can process products up to 30,000 centipoise depending on specification.<br />

The system pumps directly from the original material container and is used<br />

on 5 gal (20 l) pails.<br />

The modular concept allows you to select an extrusion system comprised of<br />

an assembled pump, elevator and follower plate. Additional individual components<br />

are available including: filter, regulator, hose or gun to complete your<br />

system. Optional system accessories are available to suit your application.<br />

EVER<br />

Tough<br />

*First digit ‘34’ refers to Pump Pressure Ratio (e.g., 34:1)<br />

Second digit '106' refers to Fluid Delivery in cc for one Cycle (or double<br />

stroke) of the hydraulic section (e.g., 106 cc).<br />

FEATURES<br />

Modular design<br />

Air motor design enables precise<br />

control<br />

Direct pumping from 5 gal<br />

(20-60 l) pail<br />

Shovel pump technology<br />

Choice of double seal on<br />

follower plate<br />

Pneumatic driven pump<br />

BENEFITS<br />

Wide range of options available<br />

to suit most applications<br />

The unique air motor design<br />

ensures a constant controlled<br />

flow rate with low noise and<br />

minimum icing risk<br />

Clean wipe of the material<br />

drum reducing material waste<br />

Can be used with a wide range<br />

of materials<br />

Recommended for high-viscosity<br />

and moisture-sensitive materials<br />

Safe for use near solvents and<br />

other flammable materials<br />

Air Motor Consumption<br />

(Cubic feet/min).<br />

52.9<br />

44.1<br />

35.3<br />

26.4<br />

17.6<br />

8.8<br />

87 psi - (6 bar)<br />

58 psi - (4 bar)<br />

29 psi - (2 bar)<br />

0 15 30 45 60<br />

Pump cycles per minute<br />

SPECIFICATIONS<br />

Pressure ratio 34:1<br />

Motor type 3000<br />

Fluid volume per cycle - cc 106<br />

Free flow rate at 60 cycles - gpm (l/min) 1.7 (6.3)<br />

Fluid output at 15 cycles - gpm (l/min) .42 (1.6)<br />

Maximum air inlet pressure - psi (bar) 87 (6)<br />

Maximum fluid pressure - psi (bar) 2958 (204)<br />

Maximum fluid temperature - °F (°C) 140 (60)<br />

Seal packings<br />

PTFE + PE<br />

Wetted parts<br />

Carbon steel<br />

Weight (bare pump) - lbs. (kg.) 46 (21)<br />

FITTINGS<br />

Fitting Air Inlet** 3/4'' F BSPP<br />

Fluid Outlet<br />

3/4'' F BSPP<br />

** Recommended air supply hose diameter 1/2”<br />

10

C3<br />

Pump/Ram Extrusion Packages<br />

w/34.106 Pump - Single Post Ram<br />

(For 5 gal/20 l Containers)<br />

PUMP<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

668-080-321 668-080-325 668-080-331 668-080-335<br />

34.106 extrusion pump with PTFE/PE seals ( II2G IIB T3)<br />

P/N: 151-050-000<br />

* * * *<br />

SINGLE POST RAM<br />

FOLLOWER PLATE<br />

Single post ram with air control (3000)<br />

P/N: 668-080-005<br />

* * * *<br />

Single post ram with air control (5000)<br />

P/N: 668-080-010<br />

Single Flat Wiper (Nitrile) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-100-100<br />

* *<br />

FOLLOWER PLATE - Teflon Coated<br />

CART<br />

Twin O-Ring (EPDM) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-102-200<br />

* *<br />

Cart kit<br />

P/N: 668-098-060 * *<br />

*<br />

= Included in pump package NOTE: Pump, Ram and Follower plate come assembled. Consult factory for other follower plate sizes not shown.<br />

+ + +<br />

System Components<br />

FILTER AND REGULATOR<br />

Part Number<br />

Option A : Regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-985<br />

Option B : Filter with fitting and mounting accessories (plate, fittings, hose...) 151-260-986<br />

Option C : Filter and regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-987<br />

11

C3<br />

System Components (Cont.)<br />

HOSES AND FITTINGS TO FEED GUN<br />

Fluid Hose Dia. Length Part Number<br />

Ø 3/8" PTFE hose 3/4" JIC fitting, 15' lg with all required fittings 3/8" 15' 668-260-980<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 15' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

1/2" + 3/8" 20' 668-260-981<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 25' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

1/2" + 3/8" 30' 668-260-982<br />

Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 15' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

3/4" + 3/8" 20' 668-260-983<br />

Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 25' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

3/4" + 3/8" 30' 668-260-984<br />

MANUAL GUN AND ACCESSORIES<br />

Part Number<br />

Extrusion gun 3625 psi (250 bar) (equipped - swivel, gun, adapter, nozzles) 668-110-250<br />

Plastic disposable nozzles (x10) 668-110-010<br />

Optional Accessories/Spare & Repair Parts<br />

3000 AIR MOTOR REPAIR KIT Part Number<br />

Air motor seal kit 146-310-090<br />

2 air motor silencer kit 146-310-091<br />

Distributor kit 146-310-092<br />

Pneumatic kit 146-320-094<br />

Safety valve 94 psi (6.5 bar) 903-080-401<br />

106 CC FLUID SECTION REPAIR KIT Part Number<br />

Standard seal kit (PTFE + PE) 144-210-090<br />

Repair kit 144-210-091<br />

Cylinder kit 144-210-092<br />

Optional maintenance kit (graphite-filled PTFE) 144-210-093<br />

Optional maintenance kit (PU + graphite-filled PTFE) 144-210-094<br />

FOLLOWER PLATE REPAIR (FLAT & DOUBLE) SEALS<br />

Part Number<br />

5 gal (20 l) flat seal - Nitrile (285 mm Ø) 150-048-301<br />

5 gal (20 l) double seal - EPDM O-ring seal (285 mm Ø) 150-048-306<br />

SINGLE POST RAM ELEVATOR ACCESSORIES & MAINTENANCE KITS<br />

Low level shut off kit 668-098-050<br />

Pail hold down kit 668-098-006<br />

Seal kit 668-080-090<br />

Manometer outlet back kit 151-080-091<br />

Command button kit 151-080-092<br />

Push button kit 151-080-093<br />

Base outlet manometer kit 151-080-094<br />

55 psi (3.8 bar) valve kit 903-080-403<br />

FILTER MAINTENANCE<br />

Part Number<br />

FKM (Viton) O-ring seal 80032<br />

Cartridge filter (25 mesh - 710 µ) 601084<br />

Cartridge filter (50 mesh - 350 µ) 601092<br />

Cartridge filter (80 mesh - 201 µ) 601287<br />

REGULATOR MAINTENANCE<br />

Part Number<br />

Repair Kit 8 mm 155-750-901<br />

8 mm Cartridge 155-750-904<br />

EXTRUSION GUN ACCESSORIES & MAINTENANCE<br />

Part Number<br />

Repair kit for 3625 psi (250 bar) extrusion gun 151-110-690<br />

Extrusion gun 3625 psi (250 bar) equipped 668-110-250<br />

Extrusion gun 3625 psi (250 bar) gun only 151-110-200<br />

Straight swivel 922-080-002<br />

Retainer/Adapter nut 668-110-100<br />

Plastic disposable nozzles (x10) 668-110-010<br />

Max height 99.77"<br />

Min height 60.90"<br />

Stroke length 38.87"<br />

Total weight :<br />

190 lbs. / 86 kg.<br />

12

C4<br />

34.106 PUMP - TWIN POST RAM<br />

(5 gal/20 l - 55 gal/200 l) EXTRUSION UNIT<br />

The 34.106* pump is specially designed for pumping viscous materials.<br />

KREMLIN REXSON equipment can process a wide range of materials<br />

including oils, greases, adhesives and sealants.<br />

This equipment has proven itself over the years to be strong and reliable,<br />

and can process products up to 300,000 centipoise depending on specification.<br />

The system pumps directly from the original material container and can be<br />

used on 5 gal (20 l) pails up to 55 gal (200 l) drums.<br />

The modular concept allows you to select an extrusion system comprised<br />

of an assembled pump, elevator and follower plate. Additional individual<br />

components are available including: filter, regulator, hose or gun to complete<br />

your system. Optional system accessories are available to suit your<br />

application.<br />

EVER<br />

Tough<br />

*First digit ‘34’ refers to Pump Pressure Ratio (e.g., 34:1)<br />

Second digit '106' refers to Fluid Delivery in cc for one Cycle (or double<br />

stroke) of the hydraulic section (e.g., 106 cc).<br />

FEATURES<br />

Modular design<br />

Air motor design enables precise<br />

control<br />

Direct pumping from 55 gal (200 l)<br />

drum<br />

Shovel pump technology<br />

Choice of double seal on<br />

follower plate<br />

Pneumatic driven pump<br />

BENEFITS<br />

Wide range of options available<br />

to suit most applications<br />

The unique air motor design<br />

ensures a constant controlled<br />

flow rate with low noise and<br />

minimum icing risk<br />

Clean wipe of the material<br />

drum reducing material waste<br />

Can be used with a wide range of<br />

materials<br />

Recommended for high-viscosity<br />

and moisture-sensitive materials<br />

Safe for use near solvents and<br />

other flammable materials<br />

52.9<br />

44.1<br />

35.3<br />

26.4<br />

17.6<br />

8.8<br />

Air Motor Consumption<br />

(Cubic feet/min).<br />

87 psi - (6 bar)<br />

58 psi - (4 bar)<br />

29 psi - (2 bar)<br />

0 15 30 45 60<br />

Pump cycles per minute<br />

SPECIFICATIONS<br />

Pressure ratio 34:1<br />

Motor type 3000<br />

Fluid volume per cycle - cc 106<br />

Free flow rate at 60 cycles - gpm (l/min) 1.7 (6.3)<br />

Fluid output at 15 cycles - gpm (l/min) .42 (1.6)<br />

Maximum air inlet pressure - psi (bar) 87 (6)<br />

Maximum fluid pressure - psi (bar) 2958 (204)<br />

Maximum fluid temperature - °F (°C) 140 (60)<br />

Seal packings<br />

PTFE + PE<br />

Wetted parts<br />

Carbon steel<br />

Weight (bare pump) - lbs. (kg.) 46 (21)<br />

FITTINGS<br />

Fitting Air Inlet** 3/4'' F BSPP<br />

Fluid Outlet<br />

3/4'' F BSPP<br />

** Recommended air supply hose diameter 1/2”<br />

13

C4<br />

Pump/Ram Extrusion Packages<br />

w/34.106 Pump - Twin Post Ram<br />

(For 5 gal/20 l - thru - 55 gal/200 l Containers)<br />

PUMP<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

668-090-321 668-090-325 668-090-332 668-090-334 668-090-335 668-090-337<br />

34.106 extrusion pump with<br />

PTFE/PE seals ( II2G IIB T3)<br />

P/N: 151-050-000 * * * * * *<br />

TWIN POST RAM<br />

Twin post ram with air control<br />

(Short) P/N: 668-090-505 * * * *<br />

Twin post ram with air control<br />

(Long) P/N: 668-090-510<br />

* *<br />

FOLLOWER PLATE<br />

Single Flat Wiper (Nitrile) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-100-100<br />

*<br />

8 Gal/30L<br />

Consult Factory<br />

16 Gal /60L Ø14.17” (360 mm)<br />

P/N: 151-100-400<br />

*<br />

55 Gal /200L Ø22.48” (571 mm)<br />

P/N: 151-100-500<br />

*<br />

FOLLOWER PLATE - Teflon Coated<br />

*<br />

Twin O-Ring (EPDM) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-102-200<br />

*<br />

8 Gal/30L<br />

Consult Factory<br />

16 Gal /60L Ø14.17” (360 mm)<br />

P/N: 151-102-500<br />

*<br />

55 Gal /200L Ø22.48” (571 mm)<br />

P/N: 151-102-600<br />

*<br />

= Included in pump package NOTE: Pump, Ram and Follower plate come assembled. Consult factory for other follower plate sizes not shown.<br />

System Components<br />

+ + +<br />

FILTER AND REGULATOR<br />

Part Number<br />

Option A : Regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-985<br />

Option B : Filter with fitting and mounting accessories (plate, fittings, hose...) 151-260-986<br />

Option C : Filter and regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-987<br />

14

System Components (Cont.)<br />

C4<br />

HOSES AND FITTINGS TO FEED GUN<br />

Fluid Hose Dia. Length Part Number<br />

Ø 3/8" PTFE hose 3/4" JIC fitting, 15' lg with all required fittings 3/8" 15' 668-260-980<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 15' lg and PTFE Ø 3/8" whip<br />

end 3/4" JIC fitting, 5' lg with all required fittings<br />

1/2" + 3/8" 20' 668-260-981<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 25' lg and PTFE Ø 3/8" whip<br />

end 3/4" JIC fitting, 5' lg with all required fittings<br />

1/2" + 3/8" 30' 668-260-982<br />

Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 15' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

3/4" + 3/8" 20' 668-260-983<br />

Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 25' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

3/4" + 3/8" 30' 668-260-984<br />

MANUAL GUN AND ACCESSORIES<br />

Part Number<br />

Extrusion gun 3625 psi (250 bar) (equipped - swivel, gun, adapter, nozzles) 668-110-250<br />

Plastic disposable nozzles (x10) 668-110-010<br />

Optional Accessories/Spare & Repair Parts<br />

3000 AIR MOTOR REPAIR KIT Part Number<br />

Air motor seal kit 146-310-090<br />

2 air motor silencer kit 146-310-091<br />

Distributor kit 146-310-092<br />

Pneumatic kit 146-320-094<br />

Safety valve 94 psi (6.5 bar) 903-080-401<br />

106 CC FLUID SECTION REPAIR KIT Part Number<br />

Standard seal kit (PTFE + PE) 144-210-090<br />

Repair kit 144-210-091<br />

Cylinder kit 144-210-092<br />

Optional maintenance kit (graphite-filled PTFE) 144-210-093<br />

Optional maintenance kit (PU + graphite-filled PTFE) 144-210-094<br />

FOLLOWER PLATE REPAIR (FLAT & DOUBLE) SEALS<br />

Part Number<br />

5 gal (20 l) flat seal - Nitrile (285 mm Ø) 150-048-301<br />

8 gal (30 l) flat seal - Nitrile call<br />

16 gal (60 l) flat seal - Nitrile (360 mm Ø) 150-048-304<br />

55 gal (200 l) flat seal - Nitrile (571 mm Ø) 150-048-305<br />

5 gal (20 l) double seal - EPDM O-ring seal (285 mm Ø) 150-048-306<br />

8 gal (30 l) double seal - EPDM O-ring seal call<br />

16 gal (60 l) double seal - EPDM O-ring seal (360 mm Ø) 150-048-309<br />

55 gal (200 l) double seal - EPDM O-ring seal (571 mm Ø) 150-048-310<br />

TWIN POST RAM ELEVATOR ACCESSORIES & MAINTENANCE KITS<br />

Low level shut off kit 668-098-055<br />

Pail hold down kit (5-8 gal) 668-098-006<br />

Drum locator kit 668-098-007<br />

Drum roller kit 668-098-100<br />

Seal kit 668-090-090<br />

Manometer outlet back kit 151-080-091<br />

Command button kit 151-080-092<br />

Push button kit 151-080-093<br />

Base outlet manometer kit 151-080-094<br />

55 psi (3.8 bar) valve kit 903-080-403<br />

FILTER MAINTENANCE<br />

Part Number<br />

FKM (Viton) O-ring seal 80032<br />

Cartridge filter (25 mesh - 710 µ) 601084<br />

Cartridge filter (50 mesh - 350 µ) 601092<br />

Cartridge filter (80 mesh - 201 µ) 601287<br />

REGULATOR MAINTENANCE<br />

Part Number<br />

Repair Kit 8 mm 155-750-901<br />

8 mm Cartridge 155-750-904<br />

EXTRUSION GUN ACCESSORIES & MAINTENANCE<br />

Part Number<br />

Repair kit for 3625 psi (250 bar) extrusion gun 151-110-690<br />

Extrusion gun 3625 psi (250 bar) equipped 668-110-250<br />

Extrusion gun 3625 psi (250 bar) gun only 151-110-200<br />

Straight swivel 922-080-002<br />

Retainer/Adapter nut 668-110-100<br />

Plastic disposable nozzles (x10) 668-110-010<br />

Max height 99.77"<br />

Min height 60.90"<br />

Stroke length 38.87"<br />

Total weight :<br />

475 lbs. / 215 kg.<br />

15

C5<br />

63.106 PUMP - SINGLE POST RAM<br />

(5 gal/20 l) EXTRUSION UNIT<br />

The 63.106* pump is specially designed for pumping viscous materials.<br />

KREMLIN REXSON equipment can process a wide range of materials<br />

including oils, greases, adhesives and sealants.<br />

This equipment has proven itself over the years to be strong and reliable, and<br />

can process products up to 30,000 centipoise depending on specification.<br />

The system pumps directly from the original material container and is<br />

used on 5 gal (20 l) pails.<br />

The modular concept allows you to select an extrusion system comprised of<br />

an assembled pump, elevator and follower plate. Additional individual components<br />

are available including: filter, regulator, hose or gun to complete your<br />

system. Optional system accessories are available to suit your application.<br />

EVER<br />

Tough<br />

*First digit ‘63’ refers to Pump Pressure Ratio (e.g., 63:1)<br />

Second digit '106' refers to Fluid Delivery in cc for one Cycle (or double<br />

stroke) of the hydraulic section (e.g., 106 cc).<br />

FEATURES<br />

Modular design<br />

Air motor design enables precise<br />

control<br />

Direct pumping from 5 gal (20 l) pail<br />

Shovel pump technology<br />

Choice of double seal on<br />

follower plate<br />

Pneumatic driven pump<br />

BENEFITS<br />

Wide range of options available<br />

to suit most applications<br />

The unique air motor design<br />

ensures a constant controlled<br />

flow rate with low noise and<br />

minimum icing risk<br />

Clean wipe of the material<br />

drum reducing material waste<br />

Can be used with a wide range<br />

of materials<br />

Recommended for high-viscosity<br />

and moisture-sensitive materials<br />

Safe for use near solvents and<br />

other flammable materials<br />

Air Motor Consumption<br />

(Cubic feet/min).<br />

141<br />

124<br />

106<br />

88.3<br />

70.6<br />

52.9<br />

35.3<br />

17.6<br />

87 psi - (6 bar)<br />

58 psi - (4 bar)<br />

29 psi - (2 bar)<br />

0 10 20 30 40 50 60<br />

Pump cycles per minute<br />

SPECIFICATIONS<br />

Pressure ratio 63:1<br />

Motor type 5000<br />

Fluid volume per cycle - cc 106<br />

Free flow rate at 60 cycles - gpm (l/min) 1.7 (6.3)<br />

Fluid output at 15 cycles - gpm (l/min) .42 (1.6)<br />

Maximum air inlet pressure - psi (bar) 87 (6)<br />

Maximum fluid pressure - psi (bar) 5482i (378)<br />

Maximum fluid temperature - °F (°C) 140 (60)<br />

Seal packings<br />

PTFE + PE<br />

Wetted parts<br />

Carbon steel<br />

Weight (bare pump) - lbs. (kg.) 66 (30)<br />

FITTINGS<br />

Fitting Air Inlet** 3/4'' F BSPP<br />

Fluid Outlet<br />

3/4'' F BSPP<br />

** Recommended air supply hose diameter 1/2”<br />

16

C5<br />

Pump/Ram Extrusion Packages<br />

w/63.106 Pump - Single Post Ram<br />

(For 5 gal/20 l Containers)<br />

PUMP<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

668-080-341 668-080-345 668-080-351 668-080-355<br />

63.106 extrusion pump with PTFE/PE seals ( II2G IIB T3)<br />

P/N: 151-050-500<br />

* * * *<br />

SINGLE POST RAM<br />

FOLLOWER PLATE<br />

Single post ram with air control (3000)<br />

P/N: 668-080-005<br />

Single post ram with air control (5000)<br />

P/N: 668-080-010<br />

* * * *<br />

Single Flat Wiper (Nitrile) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-100-100<br />

* *<br />

FOLLOWER PLATE - Teflon Coated<br />

CART<br />

Twin O-Ring (EPDM) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-102-200<br />

* *<br />

Cart kit<br />

P/N: 668-098-060 * *<br />

*<br />

= Included in pump package NOTE: Pump, Ram and Follower plate come assembled. Consult factory for other follower plate sizes not shown.<br />

+ + +<br />

System Components<br />

FILTER AND REGULATOR<br />

Part Number<br />

Option A : Regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-985<br />

Option B : Filter with fitting and mounting accessories (plate, fittings, hose...) 151-260-986<br />

Option C : Filter and regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-987<br />

17

C5<br />

System Components (Cont.)<br />

HOSES AND FITTINGS TO FEED GUN<br />

Fluid Hose Dia. Length Part Number<br />

Ø 3/8" PTFE hose 3/4" JIC fitting, 15' lg with all required fittings 3/8" 15' 668-260-980<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 15' lg and PTFE Ø 3/8" whip<br />

end 3/4" JIC fitting, 5' lg with all required fittings<br />

1/2" + 3/8" 20' 668-260-981<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 25' lg and PTFE Ø 3/8" whip<br />

end 3/4" JIC fitting, 5' lg with all required fittings<br />

1/2" + 3/8" 30' 668-260-982<br />

Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 15' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

3/4" + 3/8" 20' 668-260-983<br />

Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 25' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

3/4" + 3/8" 30' 668-260-984<br />

MANUAL GUN AND ACCESSORIES<br />

Part Number<br />

Extrusion gun 7251 psi (500 bar) (equipped - swivel, gun, nozzles) 668-110-500<br />

Plastic disposable nozzles (x10) 668-110-010<br />

Optional Accessories/Spare & Repair Parts<br />

5000 AIR MOTOR REPAIR KIT Part Number<br />

Air motor seal kit 146-320-090<br />

Silencer kit 146-320-091<br />

Distributor kit 146-320-092<br />

Distributor seal kit 146-320-093<br />

Pneumatic kit 146-320-094<br />

Piston rod seal kit 146-320-095<br />

Safety valve 94 psi (6.5 bar) 903-080-401<br />

106 CC FLUID SECTION REPAIR KIT Part Number<br />

Standard seal kit (PTFE + PE) 144-210-090<br />

Repair kit 144-210-091<br />

Cylinder kit 144-210-092<br />

Optional maintenance kit (graphite-filled PTFE) 144-210-093<br />

Optional maintenance kit (PU + graphite-filled PTFE) 144-210-094<br />

FOLLOWER PLATE REPAIR (FLAT & DOUBLE) SEALS<br />

Part Number<br />

5 gal (20 l) flat seal - Nitrile (285 mm Ø) 150-048-301<br />

5 gal (20 l) double seal - EPDM O-ring seal (285 mm Ø) 150-048-306<br />

SINGLE POST RAM ELEVATOR ACCESSORIES & MAINTENANCE KITS<br />

Low level shut off kit 668-098-050<br />

Pail hold down kit 668-098-006<br />

Seal kit 668-080-090<br />

Manometer outlet back kit 151-080-091<br />

Command button kit 151-080-092<br />

Push button kit 151-080-093<br />

Base outlet manometer kit 151-080-094<br />

55 psi (3.8 bar) valve kit 903-080-403<br />

FILTER MAINTENANCE<br />

Part Number<br />

FKM (Viton) O-ring seal 80032<br />

Cartridge filter (25 mesh - 710 µ) 601084<br />

Cartridge filter (50 mesh - 350 µ) 601092<br />

Cartridge filter (80 mesh - 201 µ) 601287<br />

REGULATOR MAINTENANCE<br />

Part Number<br />

Repair Kit 8 mm 155-750-901<br />

8 mm Cartridge 155-750-904<br />

EXTRUSION GUN ACCESSORIES & MAINTENANCE<br />

Part Number<br />

Repair kit for 7251 psi (500 bar) extrusion gun 151-110-695<br />

Extrusion gun 7251 psi (500 bar) equipped 668-110-500<br />

Extrusion gun 7251 psi (500 bar) gun only 922-080-001<br />

Straight swivel 922-080-002<br />

Plastic disposable nozzles (x10) 668-110-010<br />

Max height 99.77"<br />

Min height 60.90"<br />

Stroke length 38.87"<br />

Total weight :<br />

216 lbs. / 98 kg.<br />

18

C6<br />

63.106 PUMP - TWIN POST RAM<br />

(5 gal/20 l - 55 gal/200 l) EXTRUSION UNIT<br />

The 63.106* pump is specially designed for pumping viscous materials.<br />

KREMLIN REXSON equipment can process a wide range of materials<br />

including oils, greases, adhesives and sealants.<br />

This equipment has proven itself over the years to be strong and reliable, and<br />

can process products up to 600,000 centipoise depending on specification.<br />

The system pumps directly from the original material container and can be<br />

used on 5 gal (20 l) pails up to 55 gal (200 l) drums.<br />

The modular concept allows you to select an extrusion system comprised of<br />

an assembled pump, elevator and follower plate. Additional individual components<br />

are available including: filter, regulator, hose or gun to complete your<br />

system. Optional system accessories are available to suit your application.<br />

EVER<br />

Tough<br />

*First digit ‘63’ refers to Pump Pressure Ratio (e.g., 63:1)<br />

Second digit '106' refers to Fluid Delivery in cc for one Cycle (or double<br />

stroke) of the hydraulic section (e.g., 106 cc).<br />

FEATURES<br />

Modular design<br />

Air motor design enables precise<br />

control<br />

Direct pumping from 55 gal (200 l)<br />

drum<br />

Shovel pump technology<br />

Choice of double seal on<br />

follower plate<br />

Pneumatic driven pump<br />

BENEFITS<br />

Wide range of options available<br />

to suit most applications<br />

The unique air motor design<br />

ensures a constant controlled<br />

flow rate with low noise and<br />

minimum icing risk<br />

Clean wipe of the material<br />

drum reducing material waste<br />

Can be used with a wide range<br />

of materials<br />

Recommended for high-viscosity<br />

and moisture-sensitive materials<br />

Safe for use near solvents and<br />

other flammable materials<br />

Air Motor Consumption<br />

(Cubic feet/min).<br />

141<br />

124<br />

106<br />

88.3<br />

70.6<br />

52.9<br />

35.3<br />

17.6<br />

87 psi - (6 bar)<br />

58 psi - (4 bar)<br />

29 psi - (2 bar)<br />

0 10 20 30 40 50 60<br />

Pump cycles per minute<br />

SPECIFICATIONS<br />

Pressure ratio 63:1<br />

Motor type 5000<br />

Fluid volume per cycle - cc 106<br />

Free flow rate at 60 cycles - gpm (l/min) 1.7 (6.3)<br />

Fluid output at 15 cycles - gpm (l/min) .42 (1.6)<br />

Maximum air inlet pressure - psi (bar) 87 (6)<br />

Maximum fluid pressure - psi (bar) 5482 (378)<br />

Maximum fluid temperature - °F (°C) 140 (60 )<br />

Seal packings<br />

PTFE + PE<br />

Wetted parts<br />

Carbon steel<br />

Weight (bare pump) - lbs. (kg.) 66 (30)<br />

FITTINGS<br />

Fitting Air Inlet** 3/4'' F BSPP<br />

Fluid Outlet<br />

3/4'' F BSPP<br />

** Recommended air supply hose diameter 1/2”<br />

19

C6<br />

Pump/Ram Extrusion Packages<br />

w/63.106 Pump - Twin Post Ram<br />

(For 5 gal/20 l - thru - 55 gal/200 l Containers)<br />

*<br />

PUMP<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

668-090-341 668-090-345 668-090-352 668-090-354 668-090-355 668-090-357<br />

63.106 extrusion pump with<br />

PTFE/PE seals ( II2G IIB T3)<br />

P/N: 151-050-500 * * * * * *<br />

TWIN POST RAM<br />

Twin post ram with air control<br />

(Short) P/N: 668-090-505<br />

* * * *<br />

Twin post ram with air control<br />

(Long) P/N: 668-090-510<br />

* *<br />

FOLLOWER PLATE<br />

Single Flat Wiper (Nitrile) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-100-100<br />

*<br />

8 Gal/30L<br />

Consult Factory<br />

16 Gal /60L Ø14.17” (360 mm)<br />

P/N: 151-100-400<br />

*<br />

55 Gal /200L Ø22.48” (571 mm)<br />

P/N: 151-100-500<br />

*<br />

FOLLOWER PLATE - Teflon Coated<br />

Twin O-Ring (EPDM) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-102-200<br />

*<br />

8 Gal/30L<br />

Consult Factory<br />

16 Gal /60L Ø14.17” (360 mm)<br />

P/N: 151-102-500<br />

*<br />

55 Gal /200L Ø22.48” (571 mm)<br />

P/N: 151-102-600<br />

*<br />

= Included in pump package NOTE: Pump, Ram and Follower plate come assembled. Consult factory for other follower plate sizes not shown.<br />

System Components<br />

+ + +<br />

FILTER AND REGULATOR<br />

Part Number<br />

Option A : Regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-985<br />

Option B : Filter with fitting and mounting accessories (plate, fittings, hose...) 151-260-986<br />

Option C : Filter and regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-987<br />

20

System Components (Cont.)<br />

C6<br />

HOSES AND FITTINGS TO FEED GUN<br />

Fluid Hose Dia. Length Part Number<br />

Ø 3/8" PTFE hose 3/4" JIC fitting, 15' lg with all required fittings 3/8" 15' 668-260-980<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 15' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 25' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 15' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 25' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

MANUAL GUN AND ACCESSORIES<br />

1/2" + 3/8" 20' 668-260-981<br />

1/2" + 3/8" 30' 668-260-982<br />

3/4" + 3/8" 20' 668-260-983<br />

3/4" + 3/8" 30' 668-260-984<br />

Part Number<br />

Extrusion gun 7251 psi (500 bar) (equipped - swivel, gun, nozzles) 668-110-500<br />

Plastic disposable nozzles (x10) 668-110-010<br />

Optional Accessories/Spare & Repair Parts<br />

5000 AIR MOTOR REPAIR KIT Part Number<br />

Air motor seal kit 146-320-090<br />

Silencer kit 146-320-091<br />

Distributor kit 146-320-092<br />

Distributor seal kit 146-320-093<br />

Pneumatic kit 146-320-094<br />

Piston rod seal kit 146-320-095<br />

Safety valve 94 psi (6.5 bar) 903-080-401<br />

106 CC FLUID SECTION REPAIR KIT Part Number<br />

Standard seal kit (PTFE + PE) 144-210-090<br />

Repair kit 144-210-091<br />

Cylinder kit 144-210-092<br />

Optional maintenance kit (graphite-filled PTFE) 144-210-093<br />

Optional maintenance kit (PU + graphite-filled PTFE) 144-210-094<br />

FOLLOWER PLATE REPAIR (FLAT & DOUBLE) SEALS<br />

Part Number<br />

5 gal (20 l) flat seal - Nitrile (285 mm Ø) 150-048-301<br />

8 gal (30 l) flat seal - Nitrile call<br />

16 gal (60 l) flat seal - Nitrile (360 mm Ø) 150-048-304<br />

55 gal (200 l) flat seal - Nitrile (571 mm Ø) 150-048-305<br />

5 gal (20 l) double seal - EPDM O-ring seal (285 mm Ø) 150-048-306<br />

8 gal (30 l) double seal - EPDM O-ring seal call<br />

16 gal (60 l) double seal - EPDM O-ring seal (360 mm Ø) 150-048-309<br />

55 gal (200 l) double seal - EPDM O-ring seal (571 mm Ø) 150-048-310<br />

TWIN POST RAM ELEVATOR ACCESSORIES & MAINTENANCE KITS<br />

Low level shut off kit 668-098-055<br />

Pail hold down kit (5-8 gal) 668-098-006<br />

Drum locator kit 668-098-007<br />

Drum roller kit 668-098-100<br />

Seal kit 668-090-090<br />

Manometer outlet back kit 151-080-091<br />

Command button kit 151-080-092<br />

Push button kit 151-080-093<br />

Base outlet manometer kit 151-080-094<br />

55 psi (3.8 bar) valve kit 903-080-403<br />

FILTER MAINTENANCE<br />

Part Number<br />

FKM (Viton) O-ring seal 80032<br />

Cartridge filter (25 mesh - 710 µ) 601084<br />

Cartridge filter (50 mesh - 350 µ) 601092<br />

Cartridge filter (80 mesh - 201 µ) 601287<br />

REGULATOR MAINTENANCE<br />

Part Number<br />

Repair Kit 8 mm 155-750-901<br />

8 mm Cartridge 155-750-904<br />

EXTRUSION GUN ACCESSORIES & MAINTENANCE<br />

Part Number<br />

Repair kit for 7251 psi (500 bar) extrusion gun 151-110-695<br />

Extrusion gun 7251 psi (500 bar) equipped 668-110-500<br />

Extrusion gun 7251 psi (500 bar) gun only 922-080-001<br />

Straight swivel 922-080-002<br />

Plastic disposable nozzles (x10) 668-110-010<br />

Max height 99.77"<br />

Min height 60.90"<br />

Stroke length 38.87"<br />

Total weight :<br />

498 lbs. / 226 kg.<br />

21

C7<br />

32.207 PUMP - SINGLE POST RAM<br />

(5 gal/20 l) EXTRUSION UNIT<br />

The 32.207* pump is specially designed for pumping viscous materials.<br />

KREMLIN REXSON equipment can process a wide range of materials<br />

including oils, greases, adhesives and sealants.<br />

This equipment has proven itself over the years to be strong and reliable,<br />

and can process products up to 30,000 centipoise depending on specification.<br />

The system pumps directly from the original material container and is used<br />

on 5 gal (20 l) pails<br />

The modular concept allows you to select an extrusion system comprised<br />

of an assembled pump, elevator and follower plate. Additional individual<br />

components are available including: filter, regulator, hose or gun to complete<br />

your system. Optional system accessories are available to suit your<br />

application.<br />

EVER<br />

Tough<br />

*First digit ‘32’ refers to Pump Pressure Ratio (e.g., 32:1)<br />

Second digit '207 ' refers to Fluid Delivery in cc for one Cycle (or double<br />

stroke) of the hydraulic section (e.g., 207 cc).<br />

FEATURES<br />

Modular design<br />

Air motor design enables precise<br />

control<br />

Direct pumping from 5 gal (20 l) pail<br />

Shovel pump technology<br />

Choice of double seal on<br />

follower plate<br />

Pneumatic driven pump<br />

BENEFITS<br />

Wide range of options available<br />

to suit most applications<br />

The unique air motor design<br />

ensures a constant controlled<br />

flow rate with low noise and<br />

minimum icing risk<br />

Clean wipe of the material<br />

drum reducing material waste<br />

Can be used with a wide range<br />

of materials<br />

Recommended for high-viscosity<br />

and moisture-sensitive materials<br />

Safe for use near solvents and<br />

other flammable materials<br />

Air Motor Consumption<br />

(Cubic feet/min).<br />

141<br />

124<br />

106<br />

88.3<br />

70.6<br />

52.9<br />

35.3<br />

17.6<br />

87 psi - (6 bar)<br />

58 psi - (4 bar)<br />

29 psi - (2 bar)<br />

0 10 20 30 40 50 60<br />

Pump cycles per minute<br />

SPECIFICATIONS<br />

Pressure ratio 32:1<br />

Motor type 5000<br />

Fluid volume per cycle - cc 207<br />

Free flow rate at 60 cycles - gpm (l/min) 3.3 (12.4)<br />

Fluid output at 15 cycles - gpm (l/min) .82 (3.1)<br />

Maximum air inlet pressure - psi (bar) 87 (6)<br />

Maximum fluid pressure - psi (bar) 2784 (192)<br />

Maximum fluid temperature - °F (°C) 140 (60)<br />

Seal packings<br />

PTFE + PE<br />

Wetted parts<br />

Carbon steel<br />

Weight (bare pump) - lbs. (kg.) 69.4 (31.5)<br />

FITTINGS<br />

Fitting Air Inlet** 3/4'' F BSPP<br />

Fluid Outlet<br />

3/4'' F BSPP<br />

** Recommended air supply hose diameter 1/2”<br />

22

C7<br />

Pump/Ram Extrusion Packages<br />

w/32.207 Pump - Single Post Ram<br />

(For 5 gal/20 l Containers)<br />

PUMP<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

668-080-361 668-080-365 668-080-371 668-080-375<br />

*<br />

32.207 extrusion pump with PTFE/PE seals ( II2G IIB T3)<br />

P/N: 151-060-000<br />

* * * *<br />

SINGLE POST RAM<br />

FOLLOWER PLATE<br />

Single post ram with air control (3000)<br />

P/N: 668-080-005<br />

Single post ram with air control (5000)<br />

P/N: 668-080-010<br />

* * * *<br />

Single Flat Wiper (Nitrile) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-100-100<br />

* *<br />

FOLLOWER PLATE - Teflon Coated<br />

CART<br />

Twin O-Ring (EPDM) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-102-200<br />

* *<br />

Cart kit<br />

P/N: 668-098-060 * *<br />

= Included in pump package NOTE: Pump, Ram and Follower plate come assembled. Consult factory for other follower plate sizes not shown.<br />

+ + +<br />

System Components<br />

FILTER AND REGULATOR<br />

Part Number<br />

Option A : Regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-985<br />

Option B : Filter with fitting and mounting accessories (plate, fittings, hose...) 151-260-986<br />

Option C : Filter and regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-987<br />

23

C7<br />

System Components (Cont.)<br />

HOSES AND FITTINGS TO FEED GUN<br />

Fluid Hose Dia. Length Part Number<br />

Ø 3/8" PTFE hose 3/4" JIC fitting, 15' lg with all required fittings 3/8" 15' 668-260-980<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 15' lg and PTFE Ø 3/8" whip<br />

end 3/4" JIC fitting, 5' lg with all required fittings<br />

1/2" + 3/8" 20' 668-260-981<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 25' lg and PTFE Ø 3/8" whip<br />

end 3/4" JIC fitting, 5' lg with all required fittings<br />

1/2" + 3/8" 30' 668-260-982<br />

Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 15' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

3/4" + 3/8" 20' 668-260-983<br />

Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 25' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

3/4" + 3/8" 30' 668-260-984<br />

MANUAL GUN AND ACCESSORIES<br />

Part Number<br />

Extrusion gun 3625 psi (250 bar) (equipped - swivel, gun, adapter, nozzles) 668-110-250<br />

Plastic disposable nozzles (x10) 668-110-010<br />

Optional Accessories/Spare & Repair Parts<br />

5000 AIR MOTOR REPAIR KIT Part Number<br />

Air motor seal kit 146-320-090<br />

Silencer kit 146-320-091<br />

Distributor kit 146-320-092<br />

Distributor seal kit 146-320-093<br />

Pneumatic kit 146-320-094<br />

Piston rod seal kit 146-320-095<br />

Safety valve 94 psi (6.5 bar) 903-080-401<br />

207 CC FLUID SECTION REPAIR KIT Part Number<br />

Standard seal kit (PTFE + PE) 144-220-090<br />

Repair kit 144-220-091<br />

Cylinder kit 144-220-092<br />

Optional maintenance kit (graphite-filled PTFE) 144-220-093<br />

Optional maintenance kit (PU + graphite-filled PTFE) 144-220-094<br />

FOLLOWER PLATE REPAIR (FLAT & DOUBLE) SEALS<br />

Part Number<br />

5 gal (20 l) flat seal - Nitrile (285 mm Ø) 150-048-301<br />

5 gal (20 l) double seal - EPDM O-ring seal (285 mm Ø) 150-048-306<br />

SINGLE POST RAM ELEVATOR ACCESSORIES & MAINTENANCE KITS<br />

Low level shut off kit 668-098-050<br />

Pail hold down kit 668-098-006<br />

Seal kit 668-080-090<br />

Manometer outlet back kit 151-080-091<br />

Command button kit 151-080-092<br />

Push button kit 151-080-093<br />

Base outlet manometer kit 151-080-094<br />

55 psi (3.8 bar) valve kit 903-080-403<br />

FILTER MAINTENANCE<br />

Part Number<br />

FKM (Viton) O-ring seal 80032<br />

Cartridge filter (25 mesh - 710 µ) 601084<br />

Cartridge filter (50 mesh - 350 µ) 601092<br />

Cartridge filter (80 mesh - 201 µ) 601287<br />

REGULATOR MAINTENANCE<br />

Part Number<br />

Repair Kit 8 mm 155-750-901<br />

8 mm Cartridge 155-750-904<br />

EXTRUSION GUN ACCESSORIES & MAINTENANCE<br />

Part Number<br />

Repair kit for 3625 psi (250 bar) extrusion gun 151-110-690<br />

Extrusion gun 3625 psi (250 bar) equipped 668-110-250<br />

Extrusion gun 3625 psi (250 bar) gun only 151-110-200<br />

Straight swivel 922-080-002<br />

Retainer/Adapter nut 668-110-100<br />

Plastic disposable nozzles (x10) 668-110-010<br />

Max height 99.77"<br />

Min height 60.90"<br />

Stroke length 38.87"<br />

Total weight :<br />

220 lbs. / 100 kg.<br />

24

C8<br />

32.207 PUMP - TWIN POST RAM<br />

(5 gal/20 l - 55 gal/200 l) EXTRUSION UNIT<br />

The 32.207* pump is specially designed for pumping viscous materials.<br />

KREMLIN REXSON equipment can process a wide range of materials<br />

including oils, greases, adhesives and sealants.<br />

This equipment has proven itself over the years to be strong and reliable,<br />

and can process products up to 300,000 centipoise depending on<br />

specification.<br />

The system pumps directly from the original material container and<br />

can be used on 5 gal (20 l) pails up to 55 gal (200 l) drums.<br />

The modular concept allows you to select an extrusion system comprised<br />

of an assembled pump, elevator and follower plate. Additional individual<br />

components are available including: filter, regulator, hose or gun to complete<br />

your system. Optional system accessories are available to suit your<br />

application.<br />

EVER<br />

Tough<br />

*First digit ‘32’ refers to Pump Pressure Ratio (e.g., 32:1)<br />

Second digit '207 ' refers to Fluid Delivery in cc for one Cycle (or double<br />

stroke) of the hydraulic section (e.g., 207 cc).<br />

FEATURES<br />

Modular design<br />

Air motor design enables precise<br />

control<br />

Direct pumping from 55 gal (200 l)<br />

drum<br />

Shovel pump technology<br />

Choice of double seal on<br />

follower plate<br />

Pneumatic driven pump<br />

BENEFITS<br />

Wide range of options available<br />

to suit most applications<br />

The unique air motor design<br />

ensures a constant controlled<br />

flow rate with low noise and<br />

minimum icing risk<br />

Clean wipe of the material<br />

drum reducing material waste<br />

Can be used with a wide range of<br />

materials<br />

Recommended for high-viscosity<br />

and moisture-sensitive materials<br />

Safe for use near solvents and<br />

other flammable materials<br />

Air Motor Consumption<br />

(Cubic feet/min).<br />

141<br />

124<br />

106<br />

88.3<br />

70.6<br />

52.9<br />

35.3<br />

17.6<br />

87 psi - (6 bar)<br />

58 psi - (4 bar)<br />

29 psi - (2 bar)<br />

0 10 20 30 40 50 60<br />

Pump cycles per minute<br />

SPECIFICATIONS<br />

Pressure ratio 32:1<br />

Motor type 5000<br />

Fluid volume per cycle - cc 207<br />

Free flow rate at 60 cycles - gpm (l/min) 3.3 (12.4)<br />

Fluid output at 15 cycles - gpm (l/min) .82 (3.1)<br />

Maximum air inlet pressure - psi (bar) 87 (6)<br />

Maximum fluid pressure - psi (bar) 2784 (192)<br />

Maximum fluid temperature - °F (°C) 140 (60)<br />

Seal packings<br />

PTFE + PE<br />

Wetted parts<br />

Carbon steel<br />

Weight (bare pump) - lbs. (kg.) 69.4 (31.5)<br />

FITTINGS<br />

Fitting Air Inlet** 3/4'' F BSPP<br />

Fluid Outlet<br />

3/4'' F BSPP<br />

** Recommended air supply hose diameter 1/2”<br />

25

C8<br />

Pump/Ram Extrusion Packages<br />

w/32.207 Pump - Twin Post Ram<br />

(For 5 gal/20 l - thru - 55 gal/200 l Containers)<br />

*<br />

PUMP<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

Part<br />

Number<br />

668-090-361 668-090-365 668-090-372 668-090-374 668-090-375 668-090-377<br />

32.207 extrusion pump with<br />

PTFE/PE seals ( II2G IIB T3)<br />

P/N: 151-060-000 * * * * * *<br />

TWIN POST RAM<br />

Twin post ram with air control<br />

(Short) P/N: 668-090-505 * * * *<br />

Twin post ram with air control<br />

(Long) P/N: 668-090-510<br />

* *<br />

FOLLOWER PLATE<br />

Single Flat Wiper (Nitrile) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-100-100<br />

*<br />

8 Gal/30L<br />

Consult Factory<br />

16 Gal /60L Ø14.17” (360 mm)<br />

P/N: 151-100-400<br />

*<br />

55 Gal /200L Ø22.48” (571 mm)<br />

P/N: 151-100-500<br />

*<br />

FOLLOWER PLATE - Teflon Coated<br />

Twin O-Ring (EPDM) Seal<br />

5 gal /20 l Ø11.25” (285 mm)<br />

P/N: 151-102-200<br />

*<br />

8 Gal/30L<br />

Consult Factory<br />

16 Gal /60L Ø14.17” (360 mm)<br />

P/N: 151-102-500<br />

*<br />

55 Gal /200L Ø22.48” (571 mm)<br />

P/N: 151-102-600<br />

*<br />

= Included in pump package NOTE: Pump, Ram and Follower plate come assembled. Consult factory for other follower plate sizes not shown.<br />

System Components<br />

+ + +<br />

FILTER AND REGULATOR<br />

Part Number<br />

Option A : Regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-985<br />

Option B : Filter with fitting and mounting accessories (plate, fittings, hose...) 151-260-986<br />

Option C : Filter and regulator with fitting and mounting accessories (plate, fittings, hose...) 151-260-987<br />

26

System Components (Cont.)<br />

HOSES AND FITTINGS TO FEED GUN<br />

Fluid Hose Dia. Length Part Number<br />

Ø 3/8" PTFE hose 3/4" JIC fitting, 15' lg with all required fittings 3/8" 15' 668-260-980<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 15' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

1/2" + 3/8" 20' 668-260-981<br />

Ø 1/2" PTFE hose 7/8" JIC fitting, 25' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

1/2" + 3/8" 30' 668-260-982<br />

Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 15' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

3/4" + 3/8" 20' 668-260-983<br />

Ø 3/4" PTFE hose 1" 1/16 JIC fitting, 25' lg and PTFE Ø 3/8" whip end<br />

3/4" JIC fitting, 5' lg with all required fittings<br />

3/4" + 3/8" 30' 668-260-984<br />

MANUAL GUN AND ACCESSORIES<br />

Part Number<br />

Extrusion gun 3625 psi (250 bar) (equipped - swivel, gun, adapter, nozzles) 668-110-250<br />

C8<br />

Plastic disposable nozzles (x10) 668-110-010<br />

Optional Accessories/Spare & Repair Parts<br />

5000 AIR MOTOR REPAIR KIT Part Number<br />

Seal motor kit 146-320-090<br />

Silencer kit 146-320-091<br />

Distributor kit 146-320-092<br />

Distributor seal kit 146-320-093<br />

Pneumatic kit 146-320-094<br />

Piston rod seal kit 146-320-095<br />

Safety valve 94 psi (6.5 bar) 903-080-401<br />

207 CC FLUID SECTION REPAIR KIT Part Number<br />

Standard seal kit (PTFE + PE) 144-220-090<br />

Repair kit 144-220-091<br />

Cylinder kit 144-220-092<br />

Optional maintenance kit (graphite-filled PTFE) 144-220-093<br />

Optional maintenance kit (PU + graphite-filled PTFE) 144-220-094<br />

FOLLOWER PLATE REPAIR (FLAT & DOUBLE) SEALS<br />

Part Number<br />

5 gal (20 l) flat seal - Nitrile (285 mm Ø) 150-048-301<br />

8 gal (30 l) flat seal - Nitrile call<br />

16 gal (60 l) flat seal - Nitrile (360 mm Ø) 150-048-304<br />

55 gal (200 l) flat seal - Nitrile (571 mm Ø) 150-048-305<br />

5 gal (20 l) double seal - EPDM O-ring seal (285 mm Ø) 150-048-306<br />

8 gal (30 l) double seal - EPDM O-ring seal call<br />

16 gal (60 l) double seal - EPDM O-ring seal (360 mm Ø) 150-048-309<br />

55 gal (200 l) double seal - EPDM O-ring seal (571 mm Ø) 150-048-310<br />

TWIN POST RAM ELEVATOR ACCESSORIES & MAINTENANCE KITS<br />

Low level shut off kit 668-098-055<br />

Pail hold down kit (5-8 gal) 668-098-006<br />

Drum locator kit 668-098-007<br />

Drum roller kit 668-098-100<br />

Seal kit 668-090-090<br />

Manometer outlet back kit 151-080-091<br />

Command button kit 151-080-092<br />

Push button kit 151-080-093<br />

Base outlet manometer kit 151-080-094<br />

55 psi (3.8 bar) valve kit 903-080-403<br />

FILTER MAINTENANCE<br />

Part Number<br />

FKM (Viton) O-ring seal 80032<br />

Cartridge filter (25 mesh - 710 µ) 601084<br />

Cartridge filter (50 mesh - 350 µ) 601092<br />

Cartridge filter (80 mesh - 201 µ) 601287<br />

REGULATOR MAINTENANCE<br />

Part Number<br />

Repair Kit 8 mm 155-750-901<br />

8 mm Cartridge 155-750-904<br />

EXTRUSION GUN ACCESSORIES & MAINTENANCE<br />

Part Number<br />

Repair kit for 3625 psi (250 bar) extrusion gun 151-110-690<br />

Extrusion gun 3625 psi (250 bar) equipped 668-110-250<br />

Extrusion gun 3625 psi (250 bar) gun only 151-110-200<br />

Straight swivel 922-080-002<br />

Retainer/Adapter nut 668-110-100<br />

Plastic disposable nozzles (x10) 668-110-010<br />

Max height 99.77"<br />

Min height 60.90"<br />

Stroke length 38.87"<br />

Total weight :<br />

500 lbs. / 227 kg.<br />

27

C9<br />

53.216 PUMP - TWIN POST RAM<br />

(5 gal/20 l - 55 gal/200 l) EXTRUSION UNIT<br />

The 53.216* pump is specially designed for pumping viscous materials.<br />

KREMLIN REXSON equipment can process a wide range of materials including<br />

oils, greases, adhesives and sealants.<br />

This equipment has proven itself over the years to be strong and reliable,<br />

and can process products up to 500-000 centipoise depending on specification.<br />

The system pumps directly from the original material container and can be<br />

used on 5 gal (20 l) pails up to 55 gal (200 l) drums.<br />

The modular concept allows you to select an extrusion system comprised of<br />

an assembled pump, elevator and follower plate. Additional individual components<br />

are available including: filter, regulator, hose or gun to complete your<br />

system. Optional system accessories are available to suit your application.<br />

EVER<br />

Tough<br />

*First digit ‘53’ refers to Pump Pressure Ratio (e.g., 53:1)<br />

Second digit '216 ' refers to Fluid Delivery in cc for one Cycle (or double<br />

stroke) of the hydraulic section (e.g., 216 cc).<br />

FEATURES<br />

Modular design<br />

Air motor design enables precise<br />

control<br />

Direct pumping from 55 gal (200 l)<br />

drum<br />

Shovel pump technology<br />

Choice of double seal on<br />

follower plate<br />

Pneumatic driven pump<br />

BENEFITS<br />

Wide range of options available<br />

to suit most applications<br />

The unique air motor design<br />

ensures a constant controlled<br />

flow rate with low noise and<br />

minimum icing risk<br />

Clean wipe of the material<br />

drum reducing material waste<br />

Can be used with a wide range<br />

of materials<br />

Recommended for high-viscosity<br />

and moisture-sensitive materials<br />

Safe for use near solvents and<br />

other flammable materials<br />

Air Motor Consumption<br />

(Cubic feet/min).<br />

141<br />

124<br />

106<br />

88.3<br />

70.6<br />

52.9<br />

35.3<br />

17.6<br />

87 psi - (6 bar)<br />

58 psi - (4 bar)<br />

29 psi - (2 bar)<br />

0 10 20 30 40 50 60<br />

Pump cycles per minute<br />

SPECIFICATIONS<br />

Pressure ratio 53:1<br />

Motor type 7000<br />

Fluid volume per cycle - cc 216<br />

Free flow rate at 60 cycles - gpm (l/min) 3.4 (12.9)<br />

Fluid output at 15 cycles - gpm (l/min) .87 (3.3)<br />

Maximum air inlet pressure - psi (bar) 87 (6)<br />

Maximum fluid pressure - psi (bar) 4612 (318)<br />

Maximum fluid temperature - °F (°C) 140 (60)<br />

Seal packings<br />

PTFE + PE<br />

Wetted parts<br />

Carbon steel<br />

Weight (bare pump) - lbs. (kg.) 112 (51)<br />

FITTINGS<br />

Fitting Air Inlet** 3/4'' F BSPP<br />

Fluid Outlet<br />

1'' F BSPP<br />