practical aspects of failure prevention in bonded joints on primary ...

practical aspects of failure prevention in bonded joints on primary ...

practical aspects of failure prevention in bonded joints on primary ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ANALES DE MECÁNICA DE LA FRACTURA Vol. 22 (2005)<br />

273<br />

PRACTICAL ASPECTS OF FAILURE PREVENTION IN BONDED JOINTS ON<br />

PRIMARY LOAD BEARING STRUCTURES<br />

Gary Savage.<br />

BAR Formula 1.<br />

Abstract.Adhesive b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g is a particularly effective method <str<strong>on</strong>g>of</str<strong>on</strong>g> assembl<str<strong>on</strong>g>in</str<strong>on</strong>g>g complex structures, especially<br />

those made from different materials. Provided the jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t is well designed, the adhesive b<strong>on</strong>d ought to be <strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

the str<strong>on</strong>gest <str<strong>on</strong>g>aspects</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> the structure and most certa<str<strong>on</strong>g>in</str<strong>on</strong>g>ly should not be the life limit<str<strong>on</strong>g>in</str<strong>on</strong>g>g factor. This <str<strong>on</strong>g>of</str<strong>on</strong>g> course<br />

pre-supposes that the jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t has been correctly executed. The major factors determ<str<strong>on</strong>g>in</str<strong>on</strong>g><str<strong>on</strong>g>in</str<strong>on</strong>g>g the <str<strong>on</strong>g>in</str<strong>on</strong>g>tegrity <str<strong>on</strong>g>of</str<strong>on</strong>g> an<br />

adhesive b<strong>on</strong>d are selecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the most appropriate adhesive, jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t design, preparati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

surfaces and strict quality c<strong>on</strong>trol <str<strong>on</strong>g>in</str<strong>on</strong>g> producti<strong>on</strong> and c<strong>on</strong>diti<strong>on</strong> m<strong>on</strong>itor<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>in</str<strong>on</strong>g> service. Adhesives have become<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>creas<str<strong>on</strong>g>in</str<strong>on</strong>g>gly important <str<strong>on</strong>g>in</str<strong>on</strong>g> assembl<str<strong>on</strong>g>in</str<strong>on</strong>g>g many <str<strong>on</strong>g>of</str<strong>on</strong>g> the multi-material structures which make up a c<strong>on</strong>temporary<br />

Formula 1 rac<str<strong>on</strong>g>in</str<strong>on</strong>g>g car. Structural fibre re<str<strong>on</strong>g>in</str<strong>on</strong>g>forced composite materials were <str<strong>on</strong>g>in</str<strong>on</strong>g>troduced <str<strong>on</strong>g>in</str<strong>on</strong>g>to Formula 1 motor<br />

rac<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>in</str<strong>on</strong>g> 1980. S<str<strong>on</strong>g>in</str<strong>on</strong>g>ce that time the cars have become <str<strong>on</strong>g>in</str<strong>on</strong>g>creas<str<strong>on</strong>g>in</str<strong>on</strong>g>gly dependent <strong>on</strong> these materials such that a<br />

c<strong>on</strong>temporary chassis may c<strong>on</strong>sist <str<strong>on</strong>g>of</str<strong>on</strong>g> up to 80% by weight <str<strong>on</strong>g>of</str<strong>on</strong>g> carb<strong>on</strong> fire re<str<strong>on</strong>g>in</str<strong>on</strong>g>forced epoxy res<str<strong>on</strong>g>in</str<strong>on</strong>g>s and the<br />

appropriate adhesives to facilitate fabricati<strong>on</strong>. One might argue therefore that a modern Formula 1 chassis<br />

c<strong>on</strong>sists <str<strong>on</strong>g>of</str<strong>on</strong>g> a series <str<strong>on</strong>g>of</str<strong>on</strong>g> “plastic” mould<str<strong>on</strong>g>in</str<strong>on</strong>g>gs held together with glue! Many <str<strong>on</strong>g>of</str<strong>on</strong>g> these structures are very highly<br />

stressed and required to operate <str<strong>on</strong>g>in</str<strong>on</strong>g> aggressive envir<strong>on</strong>ments, particularly high temperatures. The<br />

c<strong>on</strong>sequences <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>failure</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> “Class A” structures can be catastrophic to the operati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the vehicle and<br />

imp<str<strong>on</strong>g>in</str<strong>on</strong>g>ge <strong>on</strong> the safety <str<strong>on</strong>g>of</str<strong>on</strong>g> the driver. Although <str<strong>on</strong>g>in</str<strong>on</strong>g>creas<str<strong>on</strong>g>in</str<strong>on</strong>g>gly better understood, the science and eng<str<strong>on</strong>g>in</str<strong>on</strong>g>eer<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

adhesives is very much <str<strong>on</strong>g>in</str<strong>on</strong>g> its <str<strong>on</strong>g>in</str<strong>on</strong>g>fancy. C<strong>on</strong>sequently the design and operati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> comp<strong>on</strong>ents tends to<br />

be a c<strong>on</strong>stantly evolv<str<strong>on</strong>g>in</str<strong>on</strong>g>g, semi-quantitative process comb<str<strong>on</strong>g>in</str<strong>on</strong>g><str<strong>on</strong>g>in</str<strong>on</strong>g>g fracture and f<str<strong>on</strong>g>in</str<strong>on</strong>g>ite element analysis with<br />

<str<strong>on</strong>g>practical</str<strong>on</strong>g> experience. BAR have been particularly adept <str<strong>on</strong>g>in</str<strong>on</strong>g> the exploitati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesives over recent years.<br />

The process <str<strong>on</strong>g>of</str<strong>on</strong>g> “total quality management” (TQM) encompasses the whole operati<strong>on</strong> from R&D and design<br />

through materials procurement, comp<strong>on</strong>ent manufacture and c<strong>on</strong>diti<strong>on</strong> m<strong>on</strong>itor<str<strong>on</strong>g>in</str<strong>on</strong>g>g to ensure successful<br />

exploitati<strong>on</strong> up to the po<str<strong>on</strong>g>in</str<strong>on</strong>g>t <str<strong>on</strong>g>of</str<strong>on</strong>g> withdrawal from service.<br />

1. INTRODUCTION<br />

Adhesives are be<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>in</str<strong>on</strong>g>creas<str<strong>on</strong>g>in</str<strong>on</strong>g>gly employed <str<strong>on</strong>g>in</str<strong>on</strong>g> the<br />

assembly <str<strong>on</strong>g>of</str<strong>on</strong>g> complex comp<strong>on</strong>ents with<str<strong>on</strong>g>in</str<strong>on</strong>g> the Formula 1<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>dustry. In particular they are used to replace or<br />

augment more traditi<strong>on</strong>al jo<str<strong>on</strong>g>in</str<strong>on</strong>g><str<strong>on</strong>g>in</str<strong>on</strong>g>g techniques such as<br />

weld<str<strong>on</strong>g>in</str<strong>on</strong>g>g, mechanical fasten<str<strong>on</strong>g>in</str<strong>on</strong>g>gs and <str<strong>on</strong>g>in</str<strong>on</strong>g>terference fits etc.<br />

The driv<str<strong>on</strong>g>in</str<strong>on</strong>g>g force for the use <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesives is the<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>creas<str<strong>on</strong>g>in</str<strong>on</strong>g>g use <str<strong>on</strong>g>of</str<strong>on</strong>g> composite materials, although this has<br />

precipitated an <str<strong>on</strong>g>in</str<strong>on</strong>g>creas<str<strong>on</strong>g>in</str<strong>on</strong>g>g number <str<strong>on</strong>g>of</str<strong>on</strong>g> other applicati<strong>on</strong>s<br />

(1, 2). Adhesives may be quickly applied, possess<br />

excellent properties and are very cost effective. The<br />

many advantages <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesives <str<strong>on</strong>g>in</str<strong>on</strong>g>clude:<br />

1. The ability to jo<str<strong>on</strong>g>in</str<strong>on</strong>g> dissimilar materials.<br />

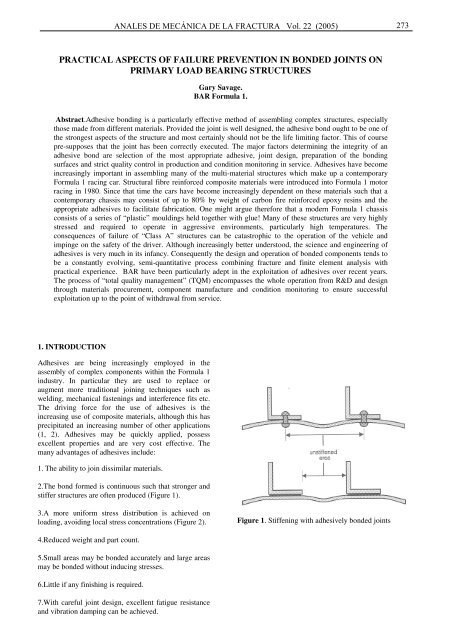

2.The b<strong>on</strong>d formed is c<strong>on</strong>t<str<strong>on</strong>g>in</str<strong>on</strong>g>uous such that str<strong>on</strong>ger and<br />

stiffer structures are <str<strong>on</strong>g>of</str<strong>on</strong>g>ten produced (Figure 1).<br />

3.A more uniform stress distributi<strong>on</strong> is achieved <strong>on</strong><br />

load<str<strong>on</strong>g>in</str<strong>on</strong>g>g, avoid<str<strong>on</strong>g>in</str<strong>on</strong>g>g local stress c<strong>on</strong>centrati<strong>on</strong>s (Figure 2).<br />

Figure 1. Stiffen<str<strong>on</strong>g>in</str<strong>on</strong>g>g with adhesively <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> jo<str<strong>on</strong>g>in</str<strong>on</strong>g>ts<br />

4.Reduced weight and part count.<br />

5.Small areas may be <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> accurately and large areas<br />

may be <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> without <str<strong>on</strong>g>in</str<strong>on</strong>g>duc<str<strong>on</strong>g>in</str<strong>on</strong>g>g stresses.<br />

6.Little if any f<str<strong>on</strong>g>in</str<strong>on</strong>g>ish<str<strong>on</strong>g>in</str<strong>on</strong>g>g is required.<br />

7.With careful jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t design, excellent fatigue resistance<br />

and vibrati<strong>on</strong> damp<str<strong>on</strong>g>in</str<strong>on</strong>g>g can be achieved.

274 ANALES DE MECÁNICA DE LA FRACTURA Vol. 22 (2005)<br />

Figure 2. Stress distributi<strong>on</strong> <str<strong>on</strong>g>in</str<strong>on</strong>g> a loaded jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t.<br />

(3). Good adhesi<strong>on</strong> requires very close c<strong>on</strong>tact. For an<br />

adhesive to b<strong>on</strong>d it is required to flow and wet the<br />

surface <str<strong>on</strong>g>of</str<strong>on</strong>g> the substrate. The surface energy (surface<br />

tensi<strong>on</strong> for liquids) <str<strong>on</strong>g>of</str<strong>on</strong>g> the adhesive must therefore be<br />

lower than that <str<strong>on</strong>g>of</str<strong>on</strong>g> the substrate to ensure good wett<str<strong>on</strong>g>in</str<strong>on</strong>g>g,<br />

the first stage <str<strong>on</strong>g>in</str<strong>on</strong>g> form<str<strong>on</strong>g>in</str<strong>on</strong>g>g an adhesive b<strong>on</strong>d. The sec<strong>on</strong>d<br />

stage is the generati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>in</str<strong>on</strong>g>tr<str<strong>on</strong>g>in</str<strong>on</strong>g>sic adhesi<strong>on</strong> forces across<br />

the <str<strong>on</strong>g>in</str<strong>on</strong>g>terface. The various forces which may be act<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

are known as the mechanisms <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesi<strong>on</strong>. There are<br />

three <strong>primary</strong> mechanisms <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesi<strong>on</strong> proposed (Figure<br />

3);<br />

It is very rare for the <str<strong>on</strong>g>failure</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> a <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t to <str<strong>on</strong>g>in</str<strong>on</strong>g>volve<br />

adhesive strength. Failures are generally due to poor<br />

design, <str<strong>on</strong>g>in</str<strong>on</strong>g>adequate preparati<strong>on</strong> and poor producti<strong>on</strong><br />

procedures. Successful exploitati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesives thus<br />

necessitates a thorough knowledge <str<strong>on</strong>g>of</str<strong>on</strong>g> all <str<strong>on</strong>g>aspects</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

materials science <str<strong>on</strong>g>of</str<strong>on</strong>g> the jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t as a complete system. A<br />

large variety <str<strong>on</strong>g>of</str<strong>on</strong>g> products are available which may be<br />

eng<str<strong>on</strong>g>in</str<strong>on</strong>g>eered to suit <str<strong>on</strong>g>in</str<strong>on</strong>g>dividual applicati<strong>on</strong>s. Nevertheless,<br />

the selecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesives can be overwhelm<str<strong>on</strong>g>in</str<strong>on</strong>g>gly<br />

complicated due to this enormous diversity.<br />

Am<strong>on</strong>g the limitati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesives which must be<br />

c<strong>on</strong>sidered are the follow<str<strong>on</strong>g>in</str<strong>on</strong>g>g:<br />

1.Durability is unpredictable and must be determ<str<strong>on</strong>g>in</str<strong>on</strong>g>ed<br />

experimentally for each applicati<strong>on</strong>.<br />

2.Surface preparati<strong>on</strong> is critical to the success <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

operati<strong>on</strong> and complete wett<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>of</str<strong>on</strong>g> the substrate must be<br />

ensured.<br />

3.Identificati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> defects by NDT requires a great deal<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> skill and experience and the tolerance to defects is<br />

impossible to predict <str<strong>on</strong>g>in</str<strong>on</strong>g> anyth<str<strong>on</strong>g>in</str<strong>on</strong>g>g but a semi-quantitative<br />

manner, given the present level <str<strong>on</strong>g>of</str<strong>on</strong>g> understand<str<strong>on</strong>g>in</str<strong>on</strong>g>g.<br />

4.Increas<str<strong>on</strong>g>in</str<strong>on</strong>g>g the service temperature decreases the b<strong>on</strong>d<br />

strength.<br />

5.Short term handleability is poor and <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> structures<br />

are <str<strong>on</strong>g>of</str<strong>on</strong>g>ten difficult to dismantle for <str<strong>on</strong>g>in</str<strong>on</strong>g>-service repair.<br />

6.Envir<strong>on</strong>mental resistance depends <strong>on</strong> the <str<strong>on</strong>g>in</str<strong>on</strong>g>tegrity <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

the adhesive.<br />

7.New and unfamiliar producti<strong>on</strong> and exploitati<strong>on</strong><br />

c<strong>on</strong>trols must be developed and implemented.<br />

That aside, even materials which are traditi<strong>on</strong>ally<br />

difficult to jo<str<strong>on</strong>g>in</str<strong>on</strong>g> can be <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> with adhesives, although<br />

some substrates may give rise to lower b<strong>on</strong>d strengths or<br />

limited durability.<br />

2. DEFINING THE ADHESIVE BOND<br />

Adhesi<strong>on</strong> is def<str<strong>on</strong>g>in</str<strong>on</strong>g>ed as the hold<str<strong>on</strong>g>in</str<strong>on</strong>g>g together <str<strong>on</strong>g>of</str<strong>on</strong>g> two<br />

surfaces by <str<strong>on</strong>g>in</str<strong>on</strong>g>terfacial forces that will resist separati<strong>on</strong><br />

Figure 3. Mechanisms <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesi<strong>on</strong>.<br />

1 .Mechanical <str<strong>on</strong>g>in</str<strong>on</strong>g>terlock<str<strong>on</strong>g>in</str<strong>on</strong>g>g or “key<str<strong>on</strong>g>in</str<strong>on</strong>g>g” occurs when<br />

cured adhesive becomes trapped <str<strong>on</strong>g>in</str<strong>on</strong>g> the irregular surface<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the substrate. It is however possible to show that the<br />

atta<str<strong>on</strong>g>in</str<strong>on</strong>g>ment <str<strong>on</strong>g>of</str<strong>on</strong>g> good adhesi<strong>on</strong> is possible between<br />

optically smooth surfaces (4, 5). The frequently<br />

observed <str<strong>on</strong>g>in</str<strong>on</strong>g>creases <str<strong>on</strong>g>in</str<strong>on</strong>g> measured jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t strengths with<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>creas<str<strong>on</strong>g>in</str<strong>on</strong>g>g substrate surface roughness are therefore<br />

c<strong>on</strong>sidered attributable to other factors such as the<br />

removal <str<strong>on</strong>g>of</str<strong>on</strong>g> weak surface material, improved wett<str<strong>on</strong>g>in</str<strong>on</strong>g>g and<br />

a larger exposed surface area for b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g.<br />

2. Adhesive and substrate may diffuse across the<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>terface. Similarly the adhesive may diffuse <str<strong>on</strong>g>in</str<strong>on</strong>g>to the<br />

surface <str<strong>on</strong>g>of</str<strong>on</strong>g> porous substrates and cure. The <str<strong>on</strong>g>in</str<strong>on</strong>g>terdiffusi<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the polymer cha<str<strong>on</strong>g>in</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> the adhesive requires the<br />

adhesive and substrate to be mutually soluble. Such<br />

c<strong>on</strong>diti<strong>on</strong>s are thought to occur <str<strong>on</strong>g>in</str<strong>on</strong>g> the solvent weld<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

polymers, but are not c<strong>on</strong>sidered capable <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>tribut<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

significantly to the <str<strong>on</strong>g>in</str<strong>on</strong>g>tr<str<strong>on</strong>g>in</str<strong>on</strong>g>sic strength <str<strong>on</strong>g>of</str<strong>on</strong>g> the b<strong>on</strong>d.<br />

Interdiffusi<strong>on</strong> can also be promoted <str<strong>on</strong>g>in</str<strong>on</strong>g> polymer/metal<br />

b<strong>on</strong>ds via pores and other surface defects <str<strong>on</strong>g>in</str<strong>on</strong>g> the<br />

substrates. This effect tends however to enhance the<br />

b<strong>on</strong>d by promot<str<strong>on</strong>g>in</str<strong>on</strong>g>g adsorpti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the adhesive rather<br />

than by the diffusi<strong>on</strong> process.<br />

3. Intimate c<strong>on</strong>tact between adhesive and substrate result<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g> adsorpti<strong>on</strong>, electrostatic and molecular attracti<strong>on</strong><br />

processes established between the atoms and molecules<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g> the surfaces <str<strong>on</strong>g>of</str<strong>on</strong>g> the adhesive and substrate. The most<br />

comm<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> these are van der Waal’s forces and, to a<br />

lesser extent, hydrogen b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g. These are referred to as

ANALES DE MECÁNICA DE LA FRACTURA Vol. 22 (2005)<br />

275<br />

“sec<strong>on</strong>dary b<strong>on</strong>ds”. Additi<strong>on</strong>ally, chemical b<strong>on</strong>ds may<br />

sometimes be formed across the <str<strong>on</strong>g>in</str<strong>on</strong>g>terface. The<br />

establishment <str<strong>on</strong>g>of</str<strong>on</strong>g> i<strong>on</strong>ic, covalent, or metallic b<strong>on</strong>ds is<br />

known as “chemisorpti<strong>on</strong>” or “<strong>primary</strong>” b<strong>on</strong>ds. The<br />

terms <strong>primary</strong> and sec<strong>on</strong>dary are fairly arbitrary<br />

descripti<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> the relative strengths <str<strong>on</strong>g>of</str<strong>on</strong>g> their attractive<br />

forces.<br />

Under specific circumstances, any or all <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

mechanisms may be resp<strong>on</strong>sible for the adhesive<br />

strength <str<strong>on</strong>g>of</str<strong>on</strong>g> a particular jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t. For the majority <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

eng<str<strong>on</strong>g>in</str<strong>on</strong>g>eer<str<strong>on</strong>g>in</str<strong>on</strong>g>g applicati<strong>on</strong>s however it is the adsorpti<strong>on</strong><br />

mechanism that dom<str<strong>on</strong>g>in</str<strong>on</strong>g>ates. Thus, provid<str<strong>on</strong>g>in</str<strong>on</strong>g>g there is<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>timate and c<strong>on</strong>t<str<strong>on</strong>g>in</str<strong>on</strong>g>uous molecular c<strong>on</strong>tact at the<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>terface <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesive and substrate, a b<strong>on</strong>d will be<br />

established due to the <str<strong>on</strong>g>in</str<strong>on</strong>g>teratomic forces between the<br />

materials.<br />

Adhesive strength is described as the force required to<br />

pull the adhesive cleanly away from the surface <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

substrate. A cured adhesive, <str<strong>on</strong>g>in</str<strong>on</strong>g> comm<strong>on</strong> with any other<br />

material, can also be characterised by its <str<strong>on</strong>g>in</str<strong>on</strong>g>ternal<br />

strength. Similarly, the third factor <str<strong>on</strong>g>in</str<strong>on</strong>g>fluenc<str<strong>on</strong>g>in</str<strong>on</strong>g>g the<br />

strength <str<strong>on</strong>g>of</str<strong>on</strong>g> the b<strong>on</strong>d is the <str<strong>on</strong>g>in</str<strong>on</strong>g>ternal strength <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

substrate(s). The term cohesive strength <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesives<br />

and substrates is used to differentiate from adhesi<strong>on</strong><br />

(Figure 4). Preferred design practice is to ensure that the<br />

life-limit<str<strong>on</strong>g>in</str<strong>on</strong>g>g factor <str<strong>on</strong>g>of</str<strong>on</strong>g> the jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t is the cohesive strength <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>on</strong>e or other <str<strong>on</strong>g>of</str<strong>on</strong>g> the substrates as this can be more<br />

accurately def<str<strong>on</strong>g>in</str<strong>on</strong>g>ed and guaranteed. Dur<str<strong>on</strong>g>in</str<strong>on</strong>g>g the executi<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> a b<strong>on</strong>d adhesives typically follow a flow phase when<br />

they are applied, spread and wet the surface, followed<br />

by a harden<str<strong>on</strong>g>in</str<strong>on</strong>g>g (cure) phase dur<str<strong>on</strong>g>in</str<strong>on</strong>g>g which their cohesive<br />

strength develops. Structural b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g is the term used to<br />

def<str<strong>on</strong>g>in</str<strong>on</strong>g>e a b<strong>on</strong>d where it performs a load bear<str<strong>on</strong>g>in</str<strong>on</strong>g>g functi<strong>on</strong>.<br />

This allows the forces with<str<strong>on</strong>g>in</str<strong>on</strong>g> a structure to be<br />

transmitted from <strong>on</strong>e member to another through the<br />

jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t. The purpose <str<strong>on</strong>g>of</str<strong>on</strong>g> the adhesive is to facilitate this<br />

load transfer. Despite an ever <str<strong>on</strong>g>in</str<strong>on</strong>g>creas<str<strong>on</strong>g>in</str<strong>on</strong>g>g amount <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

research aimed at def<str<strong>on</strong>g>in</str<strong>on</strong>g><str<strong>on</strong>g>in</str<strong>on</strong>g>g the properties <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

adhesively <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t, the majority <str<strong>on</strong>g>of</str<strong>on</strong>g> the data is<br />

qualitative at best, necessitat<str<strong>on</strong>g>in</str<strong>on</strong>g>g extensive test<str<strong>on</strong>g>in</str<strong>on</strong>g>g and<br />

prototype evaluati<strong>on</strong>.<br />

3. THE USE OF ADHESIVES IN FORMULA 1<br />

CAR CONSTRUCTION.<br />

Adhesives have been used <strong>on</strong> Formula 1 cars s<str<strong>on</strong>g>in</str<strong>on</strong>g>ce the<br />

late 1970s. Their firs major usage was <str<strong>on</strong>g>in</str<strong>on</strong>g> the chassis,<br />

b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>in</str<strong>on</strong>g>itially alum<str<strong>on</strong>g>in</str<strong>on</strong>g>ium and later carb<strong>on</strong> sk<str<strong>on</strong>g>in</str<strong>on</strong>g>s to<br />

h<strong>on</strong>eycomb material (1). Further development saw<br />

extensive use <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesives. One <str<strong>on</strong>g>of</str<strong>on</strong>g> the most excit<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

applicati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesives was <str<strong>on</strong>g>in</str<strong>on</strong>g> the producti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

composite suspensi<strong>on</strong> members. These were orig<str<strong>on</strong>g>in</str<strong>on</strong>g>ally<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>troduced by McLaren (6) follow<str<strong>on</strong>g>in</str<strong>on</strong>g>g an extensive<br />

period <str<strong>on</strong>g>of</str<strong>on</strong>g> test<str<strong>on</strong>g>in</str<strong>on</strong>g>g and development but are now used by<br />

all <str<strong>on</strong>g>of</str<strong>on</strong>g> the teams (Figure 5). The most recent <str<strong>on</strong>g>in</str<strong>on</strong>g>novati<strong>on</strong><br />

<strong>on</strong> an F1 car is that <str<strong>on</strong>g>of</str<strong>on</strong>g> a composite gearbox (7). This<br />

device c<strong>on</strong>sists <str<strong>on</strong>g>of</str<strong>on</strong>g> a m<strong>on</strong>olithic carb<strong>on</strong> fibre re<str<strong>on</strong>g>in</str<strong>on</strong>g>forced<br />

epoxy “ma<str<strong>on</strong>g>in</str<strong>on</strong>g>case” <str<strong>on</strong>g>in</str<strong>on</strong>g>to which are <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> a number <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

titanium bulkheads to carry the “<str<strong>on</strong>g>in</str<strong>on</strong>g>ternals” (gear cluster<br />

and selectors etc) and “<str<strong>on</strong>g>in</str<strong>on</strong>g>serts” such as suspensi<strong>on</strong> and<br />

eng<str<strong>on</strong>g>in</str<strong>on</strong>g>e mounts etc. This device illustrates very<br />

graphically the strength and versatility <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesives,<br />

be<str<strong>on</strong>g>in</str<strong>on</strong>g>g a multi-material structure capable <str<strong>on</strong>g>of</str<strong>on</strong>g> transmitt<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g> excess <str<strong>on</strong>g>of</str<strong>on</strong>g> 900bhp whilst react<str<strong>on</strong>g>in</str<strong>on</strong>g>g severe suspensi<strong>on</strong><br />

loads, all at temperatures <str<strong>on</strong>g>of</str<strong>on</strong>g> up to (and sporadically<br />

exceed<str<strong>on</strong>g>in</str<strong>on</strong>g>g) 150 o C (Figure 6).<br />

Figure 5. B<strong>on</strong>ded composite suspensi<strong>on</strong> comp<strong>on</strong>ents<br />

Figure 4. Forces operat<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>in</str<strong>on</strong>g> an adhesive b<strong>on</strong>d<br />

Figure 6. Composite gearbox

276 ANALES DE MECÁNICA DE LA FRACTURA Vol. 22 (2005)<br />

4. JOINT DESIGN<br />

When c<strong>on</strong>sider<str<strong>on</strong>g>in</str<strong>on</strong>g>g an adhesively <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t it is<br />

important to appreciate that the optimum design will not<br />

be same as for traditi<strong>on</strong>al fix<str<strong>on</strong>g>in</str<strong>on</strong>g>g methods such as<br />

weld<str<strong>on</strong>g>in</str<strong>on</strong>g>g or mechanical fasteners. The characteristics <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

adhesives dictate that their mechanical resp<strong>on</strong>se to<br />

compressi<strong>on</strong>, shear and tensile load<str<strong>on</strong>g>in</str<strong>on</strong>g>g regimes is far<br />

superior to peel and cleavage (Figure 7). It is paramount<br />

that a comp<strong>on</strong>ent be designed such that the b<strong>on</strong>d will be<br />

strengthened by the geometry <str<strong>on</strong>g>of</str<strong>on</strong>g> the f<str<strong>on</strong>g>in</str<strong>on</strong>g>al artefact rather<br />

than be weakened or destroyed by it. The strength and<br />

durability <str<strong>on</strong>g>of</str<strong>on</strong>g> a jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t is a complex functi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the stress<br />

c<strong>on</strong>centrati<strong>on</strong>s set up by the applied loads and operat<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

c<strong>on</strong>diti<strong>on</strong>s. In a simple lap jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t made from th<str<strong>on</strong>g>in</str<strong>on</strong>g> metal<br />

sheets there are two types <str<strong>on</strong>g>of</str<strong>on</strong>g> stress: shear and peel. The<br />

shear stress varies al<strong>on</strong>g the length <str<strong>on</strong>g>of</str<strong>on</strong>g> the jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t with<br />

c<strong>on</strong>centrati<strong>on</strong>s at the ends. The peel stress acts at right<br />

angles to the lap jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t and is also maximised at the ends<br />

(Figure 8). The peel stress tends to distort the jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t and<br />

c<strong>on</strong>sequently weaken it. Similarly any deflecti<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

structure under load <str<strong>on</strong>g>in</str<strong>on</strong>g>crease the peel comp<strong>on</strong>ent and<br />

may lead to premature <str<strong>on</strong>g>failure</str<strong>on</strong>g>. Unsupported lap jo<str<strong>on</strong>g>in</str<strong>on</strong>g>ts<br />

are <strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> the weakest c<strong>on</strong>figurati<strong>on</strong>s and are seldom<br />

used <str<strong>on</strong>g>in</str<strong>on</strong>g> practise. A number <str<strong>on</strong>g>of</str<strong>on</strong>g> possible b<strong>on</strong>d geometries,<br />

both good and bad, are illustrated <str<strong>on</strong>g>in</str<strong>on</strong>g> Figure 9. Such<br />

jo<str<strong>on</strong>g>in</str<strong>on</strong>g>ts can be applied, either <str<strong>on</strong>g>in</str<strong>on</strong>g> isolati<strong>on</strong> or comb<str<strong>on</strong>g>in</str<strong>on</strong>g>ati<strong>on</strong>,<br />

to more complex geometries. The best results are clearly<br />

achieved by design<str<strong>on</strong>g>in</str<strong>on</strong>g>g the jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t such that the forces<br />

experienced tend to compress the adhesive or <str<strong>on</strong>g>in</str<strong>on</strong>g>duce<br />

shear loads whilst tak<str<strong>on</strong>g>in</str<strong>on</strong>g>g steps to elim<str<strong>on</strong>g>in</str<strong>on</strong>g>ate or at least<br />

m<str<strong>on</strong>g>in</str<strong>on</strong>g>imise peel and cleavage forces particularly at the<br />

vulnerable edges <str<strong>on</strong>g>of</str<strong>on</strong>g> the jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t.<br />

Figure 8. Stress distributi<strong>on</strong> <str<strong>on</strong>g>in</str<strong>on</strong>g> a simple lap shear jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t.<br />

Figure 9. Basic jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t geometries - <str<strong>on</strong>g>in</str<strong>on</strong>g> practice two or<br />

more may be used <str<strong>on</strong>g>in</str<strong>on</strong>g> c<strong>on</strong>juncti<strong>on</strong>.<br />

Figure 7. Types <str<strong>on</strong>g>of</str<strong>on</strong>g> load<str<strong>on</strong>g>in</str<strong>on</strong>g>g endured by adhesive jo<str<strong>on</strong>g>in</str<strong>on</strong>g>ts<br />

Structural adhesive layers are at their most efficient <str<strong>on</strong>g>in</str<strong>on</strong>g><br />

the thickness range 0.1-0.25mm. Too th<str<strong>on</strong>g>in</str<strong>on</strong>g> an adhesive<br />

layer will generally result <str<strong>on</strong>g>in</str<strong>on</strong>g> poor adhesi<strong>on</strong> due to n<strong>on</strong>uniform<br />

wett<str<strong>on</strong>g>in</str<strong>on</strong>g>g. Thicker b<strong>on</strong>ds, although attractive<br />

from a theoretical po<str<strong>on</strong>g>in</str<strong>on</strong>g>t <str<strong>on</strong>g>of</str<strong>on</strong>g> view, are not <str<strong>on</strong>g>practical</str<strong>on</strong>g><br />

because <str<strong>on</strong>g>of</str<strong>on</strong>g> the impossibility <str<strong>on</strong>g>of</str<strong>on</strong>g> execut<str<strong>on</strong>g>in</str<strong>on</strong>g>g them without<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>duc<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>in</str<strong>on</strong>g>tolerable levels <str<strong>on</strong>g>of</str<strong>on</strong>g> flaws and porosity.<br />

Experience has shown that optimum wett<str<strong>on</strong>g>in</str<strong>on</strong>g>g and relief<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the stress c<strong>on</strong>centrati<strong>on</strong>s at the edges is achieved by<br />

taper<str<strong>on</strong>g>in</str<strong>on</strong>g>g the b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g faces and, wherever possible,<br />

mach<str<strong>on</strong>g>in</str<strong>on</strong>g><str<strong>on</strong>g>in</str<strong>on</strong>g>g them to the required tolerance. It is advisable<br />

to jig the assembly <str<strong>on</strong>g>in</str<strong>on</strong>g> such a way as to ma<str<strong>on</strong>g>in</str<strong>on</strong>g>ta<str<strong>on</strong>g>in</str<strong>on</strong>g> a<br />

uniform b<strong>on</strong>d l<str<strong>on</strong>g>in</str<strong>on</strong>g>e. It goes without say<str<strong>on</strong>g>in</str<strong>on</strong>g>g that the design<br />

should maximise the area over which the load is<br />

distributed. C<strong>on</strong>siderati<strong>on</strong> must also be given to<br />

<str<strong>on</strong>g>practical</str<strong>on</strong>g> <str<strong>on</strong>g>aspects</str<strong>on</strong>g> such as ease and reproducibility <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

assembly. N<strong>on</strong> stressed comp<strong>on</strong>ents may be designed<br />

such that the adhesive b<strong>on</strong>ds are self jigg<str<strong>on</strong>g>in</str<strong>on</strong>g>g but<br />

structural b<strong>on</strong>ds must be assembled <strong>on</strong> purpose built jigs

ANALES DE MECÁNICA DE LA FRACTURA Vol. 22 (2005)<br />

277<br />

to ensure correct alignment throughout the cur<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

process.<br />

Estimati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the theoretical strength <str<strong>on</strong>g>of</str<strong>on</strong>g> a jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t is<br />

relatively straightforward us<str<strong>on</strong>g>in</str<strong>on</strong>g>g data which may be<br />

obta<str<strong>on</strong>g>in</str<strong>on</strong>g>ed from the adhesive manufacturer or (preferably)<br />

determ<str<strong>on</strong>g>in</str<strong>on</strong>g>ed experimentally. To a first approximati<strong>on</strong>, the<br />

load capacity <str<strong>on</strong>g>of</str<strong>on</strong>g> a jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t is simply the product <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

<str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> area and the shear strength <str<strong>on</strong>g>of</str<strong>on</strong>g> the adhesive. In<br />

<str<strong>on</strong>g>practical</str<strong>on</strong>g> applicati<strong>on</strong>s, a number <str<strong>on</strong>g>of</str<strong>on</strong>g> variables must be<br />

factored <str<strong>on</strong>g>in</str<strong>on</strong>g>. These <str<strong>on</strong>g>in</str<strong>on</strong>g>clude substrates and surface f<str<strong>on</strong>g>in</str<strong>on</strong>g>ish,<br />

b<strong>on</strong>d thickness (clearance), temperature, jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t geometry<br />

and envir<strong>on</strong>ment etc. Calculati<strong>on</strong>s must be verified by<br />

test<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>in</str<strong>on</strong>g> the laboratory. This programme is particularly<br />

important <str<strong>on</strong>g>in</str<strong>on</strong>g> the eventual success <str<strong>on</strong>g>of</str<strong>on</strong>g> the applicati<strong>on</strong><br />

s<str<strong>on</strong>g>in</str<strong>on</strong>g>ce it enables the identificati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> potential problems<br />

at an early stage. A variety <str<strong>on</strong>g>of</str<strong>on</strong>g> tests need to be<br />

c<strong>on</strong>sidered <str<strong>on</strong>g>in</str<strong>on</strong>g> order to determ<str<strong>on</strong>g>in</str<strong>on</strong>g>e any possible problems<br />

and achieve the follow<str<strong>on</strong>g>in</str<strong>on</strong>g>g objectives:<br />

design changes <str<strong>on</strong>g>in</str<strong>on</strong>g> the b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g geometry, tighten<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

producti<strong>on</strong> procedures, and/or selecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> an adhesive<br />

which is more suitable to the f<str<strong>on</strong>g>in</str<strong>on</strong>g>e detail <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

applicati<strong>on</strong>. The preferred <str<strong>on</strong>g>failure</str<strong>on</strong>g> mode is substrate<br />

<str<strong>on</strong>g>failure</str<strong>on</strong>g>. In such <str<strong>on</strong>g>in</str<strong>on</strong>g>stances the b<strong>on</strong>d is not the life-limit<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

factor <str<strong>on</strong>g>of</str<strong>on</strong>g> the jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t and should not therefore <str<strong>on</strong>g>in</str<strong>on</strong>g>fluence its<br />

l<strong>on</strong>g-term durability. It is recommended that all stressed<br />

jo<str<strong>on</strong>g>in</str<strong>on</strong>g>ts are designed such that ultimate <str<strong>on</strong>g>failure</str<strong>on</strong>g> occurs <str<strong>on</strong>g>in</str<strong>on</strong>g><br />

the substrate.<br />

1. Compare the properties and suitability <str<strong>on</strong>g>of</str<strong>on</strong>g> a group <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

adhesives.<br />

2. To act as a quality check for a batch <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesives.<br />

3. Verify the effectiveness and repeatability <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

preparati<strong>on</strong> techniques to be used.<br />

4. Measure the envir<strong>on</strong>mental effects (temperature,<br />

fluids, moisture etc.)<br />

5. Provide quantitative data <strong>on</strong> the jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t and adhesive.<br />

6. Analyse <str<strong>on</strong>g>failure</str<strong>on</strong>g> mechanisms.<br />

Some important criteria <str<strong>on</strong>g>of</str<strong>on</strong>g> an adhesive jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t may be<br />

determ<str<strong>on</strong>g>in</str<strong>on</strong>g>ed by visual observati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the parts follow<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

a <str<strong>on</strong>g>failure</str<strong>on</strong>g> dur<str<strong>on</strong>g>in</str<strong>on</strong>g>g a test. It is important to determ<str<strong>on</strong>g>in</str<strong>on</strong>g>e<br />

whether adhesive or cohesive <str<strong>on</strong>g>failure</str<strong>on</strong>g> has precipitated<br />

overall jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t <str<strong>on</strong>g>failure</str<strong>on</strong>g>, or if the <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> parts (substrates)<br />

have been destroyed (Figure 10). In the case <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesive<br />

<str<strong>on</strong>g>failure</str<strong>on</strong>g> the adhesive is observed to be completely<br />

separated from the face <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>on</strong>e substrate. This is the<br />

“worst case” scenario <str<strong>on</strong>g>in</str<strong>on</strong>g> that the weakest aspect <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t is the boundary layer between the <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> parts and<br />

the adhesive. This means that the jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t is pr<strong>on</strong>e to <str<strong>on</strong>g>failure</str<strong>on</strong>g><br />

without warn<str<strong>on</strong>g>in</str<strong>on</strong>g>g and at a load far lower than predicted.<br />

In such circumstances the causes are either that the<br />

material is unsuitable for b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g or the b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g surface<br />

was c<strong>on</strong>tam<str<strong>on</strong>g>in</str<strong>on</strong>g>ated and therefore <str<strong>on</strong>g>in</str<strong>on</strong>g>correctly prepared. In<br />

both cases the strength can be <str<strong>on</strong>g>in</str<strong>on</strong>g>creased by devot<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

more attenti<strong>on</strong> to the pre-treatment <str<strong>on</strong>g>of</str<strong>on</strong>g> the surface.<br />

Cohesive <str<strong>on</strong>g>failure</str<strong>on</strong>g> occurs when the adhesive itself breaks.<br />

The <str<strong>on</strong>g>failure</str<strong>on</strong>g> is characterised by rema<str<strong>on</strong>g>in</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> the adhesive<br />

be<str<strong>on</strong>g>in</str<strong>on</strong>g>g found <strong>on</strong> both substrates. This occurs because the<br />

adhesive is over stressed through external acti<strong>on</strong> such as<br />

temperature, age<str<strong>on</strong>g>in</str<strong>on</strong>g>g or <str<strong>on</strong>g>of</str<strong>on</strong>g>f-axis load<str<strong>on</strong>g>in</str<strong>on</strong>g>g due to<br />

misalignment or deflecti<strong>on</strong> etc. It can be remedied by<br />

Figure 10. Possible <str<strong>on</strong>g>failure</str<strong>on</strong>g> modes <str<strong>on</strong>g>in</str<strong>on</strong>g> adhesively <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g><br />

structures.<br />

5.SURFACE PREPARATION<br />

The advantages ga<str<strong>on</strong>g>in</str<strong>on</strong>g>ed through good design can <strong>on</strong>ly be<br />

exploited if the surfaces to be <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> are properly<br />

prepared. The surface thermodynamics <str<strong>on</strong>g>of</str<strong>on</strong>g> the majority<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> materials used <strong>on</strong> the race cars are extremely<br />

favourable to the adhesive b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g process and those<br />

few which are not may be treated with a primer with a<br />

modicum <str<strong>on</strong>g>of</str<strong>on</strong>g> success. This presupposes <str<strong>on</strong>g>of</str<strong>on</strong>g> course that the<br />

b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g surfaces are free from c<strong>on</strong>tam<str<strong>on</strong>g>in</str<strong>on</strong>g>ants. To ensure<br />

maximum strength <str<strong>on</strong>g>in</str<strong>on</strong>g> structural b<strong>on</strong>ds it is necessary to<br />

remove all traces <str<strong>on</strong>g>of</str<strong>on</strong>g> pa<str<strong>on</strong>g>in</str<strong>on</strong>g>ts, oxide films, dust, mould<br />

release agents and all other debris. There are four<br />

pr<str<strong>on</strong>g>in</str<strong>on</strong>g>cipal ways <str<strong>on</strong>g>of</str<strong>on</strong>g> prepar<str<strong>on</strong>g>in</str<strong>on</strong>g>g surfaces, which are used <str<strong>on</strong>g>in</str<strong>on</strong>g><br />

comb<str<strong>on</strong>g>in</str<strong>on</strong>g>ati<strong>on</strong>:<br />

1.Solvent degreas<str<strong>on</strong>g>in</str<strong>on</strong>g>g. This process removes any<br />

c<strong>on</strong>tam<str<strong>on</strong>g>in</str<strong>on</strong>g>ants that would adversely affect the adsorpti<strong>on</strong><br />

mechanism<br />

2. Mechanical abrasi<strong>on</strong> (grit blast<str<strong>on</strong>g>in</str<strong>on</strong>g>g etc.), removes any<br />

weak surface layers from the substrates and <str<strong>on</strong>g>in</str<strong>on</strong>g>creases the<br />

b<strong>on</strong>d area.

278 ANALES DE MECÁNICA DE LA FRACTURA Vol. 22 (2005)<br />

3. Chemical etch<str<strong>on</strong>g>in</str<strong>on</strong>g>g and anodis<str<strong>on</strong>g>in</str<strong>on</strong>g>g. Promotes <strong>primary</strong><br />

and sec<strong>on</strong>dary b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g mechanisms.<br />

4. Use <str<strong>on</strong>g>of</str<strong>on</strong>g> primers and activators. Promotes <strong>primary</strong> and<br />

sec<strong>on</strong>dary b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g mechanisms and can be used to<br />

modify the cure k<str<strong>on</strong>g>in</str<strong>on</strong>g>etics <str<strong>on</strong>g>of</str<strong>on</strong>g> the adhesive.<br />

Provided the appropriate adhesive and surface<br />

preparati<strong>on</strong>s are used, almost any substrate can be<br />

<str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> as l<strong>on</strong>g as the operat<str<strong>on</strong>g>in</str<strong>on</strong>g>g c<strong>on</strong>diti<strong>on</strong>s are not too<br />

extreme<br />

6.DURABILITY OF ADHESIVE JOINTS<br />

Structural jo<str<strong>on</strong>g>in</str<strong>on</strong>g>ts are required to perform under a<br />

comb<str<strong>on</strong>g>in</str<strong>on</strong>g>ati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> service c<strong>on</strong>diti<strong>on</strong>s, which <str<strong>on</strong>g>in</str<strong>on</strong>g>clude both<br />

static and dynamically applied loads and exposure to<br />

hostile envir<strong>on</strong>ments, particularly temperature, moisture<br />

and solvents. It is paramount therefore to design a<br />

<str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> structure capable <str<strong>on</strong>g>of</str<strong>on</strong>g> operat<str<strong>on</strong>g>in</str<strong>on</strong>g>g under such<br />

c<strong>on</strong>diti<strong>on</strong>s and to develop processes to guarantee<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>tegrity over the entirety <str<strong>on</strong>g>of</str<strong>on</strong>g> their service life. Adhesives<br />

generally exhibit superior fatigue properties <str<strong>on</strong>g>in</str<strong>on</strong>g><br />

comparis<strong>on</strong> with competitive jo<str<strong>on</strong>g>in</str<strong>on</strong>g><str<strong>on</strong>g>in</str<strong>on</strong>g>g technologies as a<br />

c<strong>on</strong>sequence <str<strong>on</strong>g>of</str<strong>on</strong>g> a more even distributi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> stress.<br />

Nevertheless, the c<strong>on</strong>sequences <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>failure</str<strong>on</strong>g> are such that a<br />

great deal <str<strong>on</strong>g>of</str<strong>on</strong>g> work is necessary to m<str<strong>on</strong>g>in</str<strong>on</strong>g>imise the<br />

probability <str<strong>on</strong>g>of</str<strong>on</strong>g> such an event. When evaluat<str<strong>on</strong>g>in</str<strong>on</strong>g>g the<br />

fatigue performance <str<strong>on</strong>g>of</str<strong>on</strong>g> a jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t <strong>on</strong>e must c<strong>on</strong>sider a wide<br />

range <str<strong>on</strong>g>of</str<strong>on</strong>g> variables (9) (stress amplitude, mean stress,<br />

frequency, waveform, ambient and <str<strong>on</strong>g>in</str<strong>on</strong>g>ternal temperature<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the system etc.). Thus there are potentially more<br />

unknowns to c<strong>on</strong>sider than with a more “traditi<strong>on</strong>al”<br />

jo<str<strong>on</strong>g>in</str<strong>on</strong>g><str<strong>on</strong>g>in</str<strong>on</strong>g>g technique. The complex fatigue c<strong>on</strong>diti<strong>on</strong>s must<br />

be approximated to much simpler laboratory test<br />

c<strong>on</strong>diti<strong>on</strong>s <str<strong>on</strong>g>in</str<strong>on</strong>g> which many <str<strong>on</strong>g>of</str<strong>on</strong>g> the parameters are held<br />

c<strong>on</strong>stant. This presents a formidable task <str<strong>on</strong>g>in</str<strong>on</strong>g> that it is<br />

vital to identify those service c<strong>on</strong>diti<strong>on</strong>s which directly<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>fluence the life <str<strong>on</strong>g>of</str<strong>on</strong>g> a particular jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t. Failure to do this<br />

will render the test useless and any results not merely <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

no value, but may present too optimistic (or pessimistic)<br />

a predicti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the durability <str<strong>on</strong>g>of</str<strong>on</strong>g> a particular comp<strong>on</strong>ent.<br />

A number <str<strong>on</strong>g>of</str<strong>on</strong>g> load<str<strong>on</strong>g>in</str<strong>on</strong>g>g methods and specimen geometries<br />

have been reported <str<strong>on</strong>g>in</str<strong>on</strong>g> the literature (10, 11) for fatigue<br />

test<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesive jo<str<strong>on</strong>g>in</str<strong>on</strong>g>ts. In <str<strong>on</strong>g>practical</str<strong>on</strong>g> applicati<strong>on</strong>s<br />

however, the life limit<str<strong>on</strong>g>in</str<strong>on</strong>g>g factor <str<strong>on</strong>g>of</str<strong>on</strong>g> many jo<str<strong>on</strong>g>in</str<strong>on</strong>g>ts is the<br />

stress c<strong>on</strong>centrati<strong>on</strong> set up by the geometry <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

design. C<strong>on</strong>sequently, there is a tendency to test fullscale<br />

structures rather than standard test pieces (12).<br />

Whilst this approach provides the designer with<br />

c<strong>on</strong>fidence about a particular item, it does not generate<br />

basic materials data apposite to other applicati<strong>on</strong>s. The<br />

extreme competitive drive with<str<strong>on</strong>g>in</str<strong>on</strong>g> Formula 1 ensures that<br />

eng<str<strong>on</strong>g>in</str<strong>on</strong>g>eers use the very latest materials <str<strong>on</strong>g>in</str<strong>on</strong>g> novel<br />

applicati<strong>on</strong>s as they strive for improved performance.<br />

Thus, despite great advances <str<strong>on</strong>g>in</str<strong>on</strong>g> computer stress analysis<br />

and materials science, our ability to produce<br />

comp<strong>on</strong>ents more <str<strong>on</strong>g>of</str<strong>on</strong>g>ten than not leads our ability to fully<br />

understand them. The dynamic performance and l<strong>on</strong>gterm<br />

durability <str<strong>on</strong>g>of</str<strong>on</strong>g> such structures, particularly those<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>volv<str<strong>on</strong>g>in</str<strong>on</strong>g>g adhesive jo<str<strong>on</strong>g>in</str<strong>on</strong>g>ts with their <str<strong>on</strong>g>in</str<strong>on</strong>g>herent variability,<br />

can <strong>on</strong>ly be dem<strong>on</strong>strated by means <str<strong>on</strong>g>of</str<strong>on</strong>g> experiments with<br />

complete comp<strong>on</strong>ents and simulati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> actual operat<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

c<strong>on</strong>diti<strong>on</strong>s. The validity <str<strong>on</strong>g>of</str<strong>on</strong>g> accelerated durability tests<br />

depends <strong>on</strong> how closely the extrapolati<strong>on</strong> follows<br />

service c<strong>on</strong>diti<strong>on</strong>s an as such relies very str<strong>on</strong>gly <strong>on</strong> the<br />

experience <str<strong>on</strong>g>of</str<strong>on</strong>g> the team’s technical staff. Durability<br />

test<str<strong>on</strong>g>in</str<strong>on</strong>g>g may be carried out us<str<strong>on</strong>g>in</str<strong>on</strong>g>g calculated loads or<br />

service data collected from the test track to drive<br />

servohydraulic actuators which stress the comp<strong>on</strong>ents <strong>on</strong><br />

purpose built jigs (Figure 11) (13, 14). The digital<br />

operati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the equipment such as that manufactured by<br />

Instr<strong>on</strong>, enables the programm<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>of</str<strong>on</strong>g> safety factors with<br />

relative ease. The effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>in</str<strong>on</strong>g>creased temperature <strong>on</strong><br />

durability is to <str<strong>on</strong>g>in</str<strong>on</strong>g>crease the rate <str<strong>on</strong>g>of</str<strong>on</strong>g> strength loss. This<br />

can be modelled by <str<strong>on</strong>g>in</str<strong>on</strong>g>corporat<str<strong>on</strong>g>in</str<strong>on</strong>g>g some form <str<strong>on</strong>g>of</str<strong>on</strong>g> heat<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

chamber <str<strong>on</strong>g>in</str<strong>on</strong>g>to the test rig. The time c<strong>on</strong>stra<str<strong>on</strong>g>in</str<strong>on</strong>g>ts imposed<br />

due to the nature <str<strong>on</strong>g>of</str<strong>on</strong>g> the sport make more l<strong>on</strong>g-term<br />

envir<strong>on</strong>mental effects such as moisture uptake difficult<br />

to simulate. Given time <strong>on</strong>e would carry out tests us<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

relative humidity cab<str<strong>on</strong>g>in</str<strong>on</strong>g>ets etc. Instead envir<strong>on</strong>mental<br />

test<str<strong>on</strong>g>in</str<strong>on</strong>g>g tends to be an “over-kill” such as a 24 hour<br />

c<strong>on</strong>diti<strong>on</strong> exposure to, for example, hydraulic fluid prior<br />

to the durability tests. One has to be very careful when<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>terpret<str<strong>on</strong>g>in</str<strong>on</strong>g>g the results from this type <str<strong>on</strong>g>of</str<strong>on</strong>g> test. In the<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>terests <str<strong>on</strong>g>of</str<strong>on</strong>g> expediency there is a great potential to<br />

produce mislead<str<strong>on</strong>g>in</str<strong>on</strong>g>g results. Too harsh an envir<strong>on</strong>ment<br />

compared to reality may result <str<strong>on</strong>g>in</str<strong>on</strong>g> premature <str<strong>on</strong>g>failure</str<strong>on</strong>g> (and<br />

subsequent anxiety) over a mechanism which would<br />

never occur <str<strong>on</strong>g>in</str<strong>on</strong>g> practice. Similarly, if the envir<strong>on</strong>ment is<br />

not simulated <str<strong>on</strong>g>in</str<strong>on</strong>g> such a way as to at least provide<br />

subjective results, there is likely to be a degree <str<strong>on</strong>g>of</str<strong>on</strong>g> overc<strong>on</strong>fidence<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g> the comp<strong>on</strong>ent. There is a tendency<br />

therefore for b<strong>on</strong>ds to be over designed but this is<br />

obviously preferable to a <str<strong>on</strong>g>failure</str<strong>on</strong>g>.<br />

Figure 11. 6-axis test rig used to test a complete corner<br />

suspensi<strong>on</strong> assembly<br />

7.FATIGUE MECHANISMS<br />

Fatigue is generally c<strong>on</strong>sidered to <str<strong>on</strong>g>in</str<strong>on</strong>g>volve <str<strong>on</strong>g>in</str<strong>on</strong>g>itiati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a<br />

crack and its subsequent propagati<strong>on</strong>. Most studies

ANALES DE MECÁNICA DE LA FRACTURA Vol. 22 (2005)<br />

279<br />

however tend to neglect the <str<strong>on</strong>g>in</str<strong>on</strong>g>itiati<strong>on</strong> phase and focus<br />

up<strong>on</strong> growth <str<strong>on</strong>g>of</str<strong>on</strong>g> a crack <str<strong>on</strong>g>of</str<strong>on</strong>g> microscopic proporti<strong>on</strong>s,<br />

s<str<strong>on</strong>g>in</str<strong>on</strong>g>ce it is this porti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the <str<strong>on</strong>g>failure</str<strong>on</strong>g> mechanism which<br />

actually determ<str<strong>on</strong>g>in</str<strong>on</strong>g>es the fatigue life. This is an acceptable<br />

practice s<str<strong>on</strong>g>in</str<strong>on</strong>g>ce the <str<strong>on</strong>g>in</str<strong>on</strong>g>itiati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a crack is difficult if not<br />

impossible to model, and any calculated lifetime will be<br />

somewhat c<strong>on</strong>servative which is generally preferred by<br />

designers. Studies <strong>on</strong> carb<strong>on</strong> fibre composites <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g><br />

us<str<strong>on</strong>g>in</str<strong>on</strong>g>g epoxy adhesives show fatigue <str<strong>on</strong>g>failure</str<strong>on</strong>g> to occur due<br />

to crack growth with<str<strong>on</strong>g>in</str<strong>on</strong>g> the adhesive (15). A similar<br />

process is observed when b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g composite to metal<br />

(Figure 12). The c<strong>on</strong>cept <str<strong>on</strong>g>of</str<strong>on</strong>g> fatigue crack growth <str<strong>on</strong>g>in</str<strong>on</strong>g><br />

adhesive jo<str<strong>on</strong>g>in</str<strong>on</strong>g>ts is a great c<strong>on</strong>cern, but little work has<br />

been has been reported to enable a fundamental<br />

understand<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>of</str<strong>on</strong>g> the mechanisms <str<strong>on</strong>g>in</str<strong>on</strong>g>volved. It is<br />

therefore very difficult establish design criteria and<br />

develop quantitative methodologies for predict<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

service lives. The nature <str<strong>on</strong>g>of</str<strong>on</strong>g> the damage which<br />

accumulates at the crack tip, and causes the<br />

load<str<strong>on</strong>g>in</str<strong>on</strong>g>g/unload<str<strong>on</strong>g>in</str<strong>on</strong>g>g cycle to be so deleterious, has not<br />

been identified. Furthermore, the affects <str<strong>on</strong>g>of</str<strong>on</strong>g> chang<str<strong>on</strong>g>in</str<strong>on</strong>g>g the<br />

various load<str<strong>on</strong>g>in</str<strong>on</strong>g>g and envir<strong>on</strong>mental parameters up<strong>on</strong> the<br />

rate <str<strong>on</strong>g>of</str<strong>on</strong>g> crack growth is all but unknown.<br />

adhesives themselves. A perfectly elastic material will<br />

rema<str<strong>on</strong>g>in</str<strong>on</strong>g> at the temperature <str<strong>on</strong>g>of</str<strong>on</strong>g> the test envir<strong>on</strong>ment<br />

throughout a fatigue test s<str<strong>on</strong>g>in</str<strong>on</strong>g>ce no energy is dissipated<br />

with<str<strong>on</strong>g>in</str<strong>on</strong>g> the specimen. Polymeric materials however are<br />

viscoelastic and exhibit mechanical hysteresis even at<br />

relatively low applied stra<str<strong>on</strong>g>in</str<strong>on</strong>g>s. Under cyclic load<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

some <str<strong>on</strong>g>of</str<strong>on</strong>g> this deformati<strong>on</strong> energy will be dissipated as<br />

heat dur<str<strong>on</strong>g>in</str<strong>on</strong>g>g each load<str<strong>on</strong>g>in</str<strong>on</strong>g>g cycle. The adhesive’s<br />

temperature will rise as a c<strong>on</strong>sequence, until the heat<br />

generated per cycle is equal to the heat dissipated by<br />

c<strong>on</strong>ducti<strong>on</strong> and radiati<strong>on</strong>. It is theoretically possible for<br />

the adhesive to heat up quite quickly to relatively high<br />

temperatures. The affect, if any, is difficult to predict;<br />

the elevated temperature may s<str<strong>on</strong>g>of</str<strong>on</strong>g>ten the adhesive<br />

caus<str<strong>on</strong>g>in</str<strong>on</strong>g>g blunt<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>of</str<strong>on</strong>g> the crack tip, hence act as a<br />

toughen<str<strong>on</strong>g>in</str<strong>on</strong>g>g mechanism, or may result <str<strong>on</strong>g>in</str<strong>on</strong>g> a loss <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

strength by waken<str<strong>on</strong>g>in</str<strong>on</strong>g>g the adhesive. Thermal effects<br />

result<str<strong>on</strong>g>in</str<strong>on</strong>g>g from fatigue load<str<strong>on</strong>g>in</str<strong>on</strong>g>g may well be very<br />

significant <str<strong>on</strong>g>in</str<strong>on</strong>g> determ<str<strong>on</strong>g>in</str<strong>on</strong>g><str<strong>on</strong>g>in</str<strong>on</strong>g>g the l<strong>on</strong>g term performance <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

a jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t under load, but are frequently far too complex to<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>terpret. This then is yet another factor mak<str<strong>on</strong>g>in</str<strong>on</strong>g>g the<br />

fatigue resp<strong>on</strong>se <str<strong>on</strong>g>of</str<strong>on</strong>g> adhesives difficult to quantify.<br />

8.DEFECTS IN BONDED STRUCTURES<br />

Figure 12 Fatigue <str<strong>on</strong>g>failure</str<strong>on</strong>g> <str<strong>on</strong>g>in</str<strong>on</strong>g> metal to composite jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t<br />

Despite a lack <str<strong>on</strong>g>of</str<strong>on</strong>g> hard evidence, a number <str<strong>on</strong>g>of</str<strong>on</strong>g> studies<br />

have suggested an endurance or fatigue limit <str<strong>on</strong>g>in</str<strong>on</strong>g> adhesive<br />

systems (analogous to observed with ferrous alloys) <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

35-45% <str<strong>on</strong>g>of</str<strong>on</strong>g> ultimate strength (16). Experimental<br />

evidence suggests that a safety factor <str<strong>on</strong>g>of</str<strong>on</strong>g> 3 or more to a<br />

jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t will all but elim<str<strong>on</strong>g>in</str<strong>on</strong>g>ate purely mechanical fatigue<br />

problems (this does not <str<strong>on</strong>g>of</str<strong>on</strong>g> course negate envir<strong>on</strong>mental<br />

degradati<strong>on</strong> and the effect <str<strong>on</strong>g>of</str<strong>on</strong>g> defects). Regardless <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

anecdotal evidence, the work <str<strong>on</strong>g>of</str<strong>on</strong>g> Lewis et al is<br />

c<strong>on</strong>sidered to over-simplify the problem and make far<br />

too many assumpti<strong>on</strong>s such that any agreement between<br />

calculated life and general design practice is far more<br />

likely to be a fortunate co<str<strong>on</strong>g>in</str<strong>on</strong>g>cidence and is certa<str<strong>on</strong>g>in</str<strong>on</strong>g>ly not<br />

an established phenomen<strong>on</strong> (17).<br />

A number <str<strong>on</strong>g>of</str<strong>on</strong>g> possible sources <str<strong>on</strong>g>of</str<strong>on</strong>g> weakness have been<br />

identified with<str<strong>on</strong>g>in</str<strong>on</strong>g> adhesively <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> jo<str<strong>on</strong>g>in</str<strong>on</strong>g>ts. These occur<br />

with<str<strong>on</strong>g>in</str<strong>on</strong>g> the adhesive itself, at the adhesive/substrate<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>terface and progressively due to <str<strong>on</strong>g>in</str<strong>on</strong>g>-service<br />

degradati<strong>on</strong>. The strength <str<strong>on</strong>g>of</str<strong>on</strong>g> the jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t depends <strong>on</strong> how<br />

successfully the loads are transmitted by each part <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

structure. Any weak l<str<strong>on</strong>g>in</str<strong>on</strong>g>k will therefore lead to premature<br />

<str<strong>on</strong>g>failure</str<strong>on</strong>g>. The most comm<strong>on</strong> defects found <str<strong>on</strong>g>in</str<strong>on</strong>g> adhesively<br />

<str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> jo<str<strong>on</strong>g>in</str<strong>on</strong>g>ts are shown schematically <str<strong>on</strong>g>in</str<strong>on</strong>g> Figure 13<br />

(18). Porosity results from trapped gasses (perhaps<br />

dur<str<strong>on</strong>g>in</str<strong>on</strong>g>g mix<str<strong>on</strong>g>in</str<strong>on</strong>g>g) and volatiles associated with the cur<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

process. Voids may be formed by the coalescence <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

porosity, entrapment <str<strong>on</strong>g>of</str<strong>on</strong>g> air dur<str<strong>on</strong>g>in</str<strong>on</strong>g>g applicati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

adhesive or by <str<strong>on</strong>g>in</str<strong>on</strong>g>sufficient adhesive be<str<strong>on</strong>g>in</str<strong>on</strong>g>g applied.<br />

Incorrect cure is caused by the presence <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

c<strong>on</strong>tam<str<strong>on</strong>g>in</str<strong>on</strong>g>ants, bad formulati<strong>on</strong>, or poor mix<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

adhesive. It may occur locally <str<strong>on</strong>g>in</str<strong>on</strong>g> small pockets but is<br />

more likely to occur throughout the whole <str<strong>on</strong>g>of</str<strong>on</strong>g> the b<strong>on</strong>d<br />

l<str<strong>on</strong>g>in</str<strong>on</strong>g>e. Cracks with<str<strong>on</strong>g>in</str<strong>on</strong>g> the adhesive are generally associated<br />

with cur<str<strong>on</strong>g>in</str<strong>on</strong>g>g and thermal shr<str<strong>on</strong>g>in</str<strong>on</strong>g>kage dur<str<strong>on</strong>g>in</str<strong>on</strong>g>g manufacture,<br />

particularly when us<str<strong>on</strong>g>in</str<strong>on</strong>g>g high temperature adhesives<br />

which can sometimes be quite brittle at room<br />

temperature.<br />

A further complicati<strong>on</strong> <str<strong>on</strong>g>in</str<strong>on</strong>g> understand<str<strong>on</strong>g>in</str<strong>on</strong>g>g the fatigue<br />

behaviour <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> jo<str<strong>on</strong>g>in</str<strong>on</strong>g>ts arises from the nature <str<strong>on</strong>g>of</str<strong>on</strong>g> the

280 ANALES DE MECÁNICA DE LA FRACTURA Vol. 22 (2005)<br />

Any lif<str<strong>on</strong>g>in</str<strong>on</strong>g>g predicti<strong>on</strong>s will thus have to be qualitative<br />

based up<strong>on</strong> experience and laboratory test<str<strong>on</strong>g>in</str<strong>on</strong>g>g.<br />

9.TOTAL QUALITY MANAGEMENT<br />

Figure 13 Potential defects <str<strong>on</strong>g>in</str<strong>on</strong>g> adhesive b<strong>on</strong>ds (18)<br />

A weak or n<strong>on</strong>-existent b<strong>on</strong>d generally results from a<br />

c<strong>on</strong>tam<str<strong>on</strong>g>in</str<strong>on</strong>g>ated substrate surface or if the adhesive is used<br />

too l<strong>on</strong>g after mix<str<strong>on</strong>g>in</str<strong>on</strong>g>g. The result<str<strong>on</strong>g>in</str<strong>on</strong>g>g total lack <str<strong>on</strong>g>of</str<strong>on</strong>g> b<strong>on</strong>d,<br />

or disb<strong>on</strong>d <str<strong>on</strong>g>of</str<strong>on</strong>g> zero volume at the <str<strong>on</strong>g>in</str<strong>on</strong>g>terface, can be<br />

detected us<str<strong>on</strong>g>in</str<strong>on</strong>g>g NDT techniques albeit with a degree <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

difficulty. Their significance <strong>on</strong> the performance <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

jo<str<strong>on</strong>g>in</str<strong>on</strong>g>t is however very difficult to predict. Specific<br />

b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g problems can arise with the “peel plies” (19)<br />

which are frequently used when jo<str<strong>on</strong>g>in</str<strong>on</strong>g><str<strong>on</strong>g>in</str<strong>on</strong>g>g composite<br />

materials. In practice these c<strong>on</strong>sumables are not<br />

removed until just prior to b<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g. It is not uncomm<strong>on</strong><br />

for the release agents used <str<strong>on</strong>g>in</str<strong>on</strong>g> formulat<str<strong>on</strong>g>in</str<strong>on</strong>g>g the peel ply to<br />

migrate <str<strong>on</strong>g>in</str<strong>on</strong>g>to the surface <str<strong>on</strong>g>of</str<strong>on</strong>g> the composite substrate<br />

which may lead to a weaken<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>of</str<strong>on</strong>g> the subsequent b<strong>on</strong>d.<br />

Hot cured epoxy adhesives <str<strong>on</strong>g>of</str<strong>on</strong>g>fer an advantage <str<strong>on</strong>g>in</str<strong>on</strong>g> such<br />

applicati<strong>on</strong>s <str<strong>on</strong>g>in</str<strong>on</strong>g> that they can dissolve some <str<strong>on</strong>g>of</str<strong>on</strong>g> the surface<br />

c<strong>on</strong>tam<str<strong>on</strong>g>in</str<strong>on</strong>g>ati<strong>on</strong>. In the l<strong>on</strong>g-term, dispens<str<strong>on</strong>g>in</str<strong>on</strong>g>g with peel<br />

plies <str<strong>on</strong>g>in</str<strong>on</strong>g> favour <str<strong>on</strong>g>of</str<strong>on</strong>g> the “wet blast<str<strong>on</strong>g>in</str<strong>on</strong>g>g” preparati<strong>on</strong><br />

technique <str<strong>on</strong>g>of</str<strong>on</strong>g>fers many advantages.<br />

As previously discussed, adhesively <str<strong>on</strong>g>b<strong>on</strong>ded</str<strong>on</strong>g> jo<str<strong>on</strong>g>in</str<strong>on</strong>g>ts are<br />

particularly susceptible to attack by aggressive<br />