PROGRESSING CAVITY PUMP SYSTEMS - National Oilwell Varco

PROGRESSING CAVITY PUMP SYSTEMS - National Oilwell Varco

PROGRESSING CAVITY PUMP SYSTEMS - National Oilwell Varco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>PROGRESSING</strong> <strong>CAVITY</strong> <strong>PUMP</strong> <strong>SYSTEMS</strong><br />

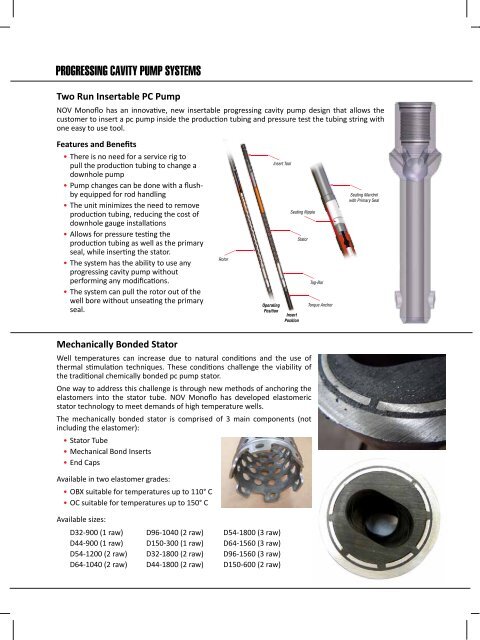

Two Run Insertable PC Pump<br />

NOV Monoflo has an innovative, new insertable progressing cavity pump design that allows the<br />

customer to insert a pc pump inside the production tubing and pressure test the tubing string with<br />

one easy to use tool.<br />

Features and Benefits<br />

• There is no need for a service rig to<br />

pull the production tubing to change a<br />

downhole pump<br />

• Pump changes can be done with a flushby<br />

equipped for rod handling<br />

• The unit minimizes the need to remove<br />

production tubing, reducing the cost of<br />

downhole gauge installations<br />

• Allows for pressure testing the<br />

production tubing as well as the primary<br />

seal, while inserting the stator.<br />

• The system has the ability to use any<br />

progressing cavity pump without<br />

performing any modifications.<br />

• The system can pull the rotor out of the<br />

well bore without unseating the primary<br />

seal.<br />

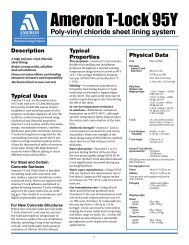

Mechanically Bonded Stator<br />

Well temperatures can increase due to natural conditions and the use of<br />

thermal stimulation techniques. These conditions challenge the viability of<br />

the traditional chemically bonded pc pump stator.<br />

One way to address this challenge is through new methods of anchoring the<br />

elastomers into the stator tube. NOV Monoflo has developed elastomeric<br />

stator technology to meet demands of high temperature wells.<br />

The mechanically bonded stator is comprised of 3 main components (not<br />

including the elastomer):<br />

• Stator Tube<br />

• Mechanical Bond Inserts<br />

• End Caps<br />

Available in two elastomer grades:<br />

• OBX suitable for temperatures up to 110° C<br />

• OC suitable for temperatures up to 150° C<br />

Available sizes:<br />

D32-900 (1 raw) D96-1040 (2 raw) D54-1800 (3 raw)<br />

D44-900 (1 raw) D150-300 (1 raw) D64-1560 (3 raw)<br />

D54-1200 (2 raw) D32-1800 (2 raw) D96-1560 (3 raw)<br />

D64-1040 (2 raw) D44-1800 (2 raw) D150-600 (2 raw)<br />

Rotor<br />

Operating<br />

Position<br />

Insert Tool<br />

Seating Nipple<br />

Insert<br />

Position<br />

Stator<br />

Tag-Bar<br />

Torque Anchor<br />

Seating Mandrel<br />

with Primary Seal