Servicing #3 Gibb winches - BlueMoment

Servicing #3 Gibb winches - BlueMoment

Servicing #3 Gibb winches - BlueMoment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Gibb</strong> <strong>#3</strong> winch maintenance. Dec 2008.<br />

Problem : 1 Winch drum floppy on spindle<br />

2 Hex socket floppy within drum, and plastic sticking out of top.<br />

Loosen screw at bottom of winch handle hex socket, and lift complete drum and ratchet<br />

assembly clear of base and spindle.<br />

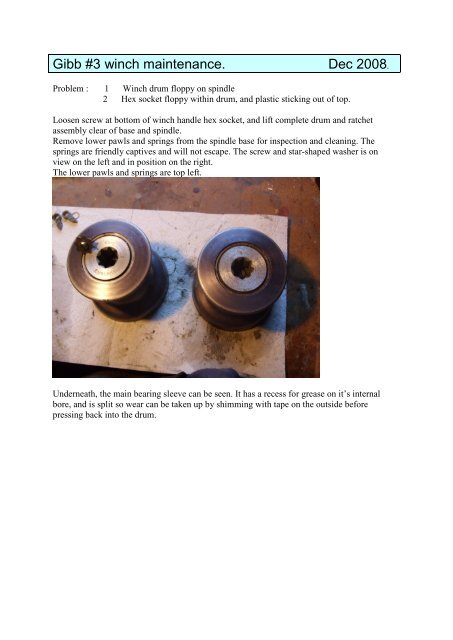

Remove lower pawls and springs from the spindle base for inspection and cleaning. The<br />

springs are friendly captives and will not escape. The screw and star-shaped washer is on<br />

view on the left and in position on the right.<br />

The lower pawls and springs are top left.<br />

Underneath, the main bearing sleeve can be seen. It has a recess for grease on it’s internal<br />

bore, and is split so wear can be taken up by shimming with tape on the outside before<br />

pressing back into the drum.

The stainless steel circlip needs to be prised out of it’s groove and “wound “out completely.<br />

And the top half of the plastic bearing for the hex drive prised out.

The stainless steel circlip needs to be.

And lift out the pawls and springs - not so captive this time!<br />

The upper plastic ring pre-greased,<br />

And lift out the pawls and springs - not so captive this time!

So that’s it in bits,<br />

Top left: upper pawls and springs, lower pawls with springs. circlip, upper and lower plastic<br />

sleeve.<br />

Bottom left: Drum, hex drive ratchet, screw and star-washer, main sleeve bearing .<br />

The solution was to swap upper and lower halves during re-assembly, there being enough of<br />

the flange left to secure both the upper pawls. The inner bearing surface was intact on all four<br />

parts.(two per winch)

After cleaning with paraffin, or citronella lamp oil if you prefer a fragrant winch, the unit is<br />

reassembled with lightly lubricated parts, in the reverse order to the above procedure.<br />

There are few “gotchas” : The upper pawl springs are a little fiddly and it is slightly<br />

unnerving having to press so hard to bed the upper plastic ratchet bearing, otherwise it’s a<br />

doddle.<br />

The upper plastic ring pre-greased,<br />

And the last bearing being persuaded to go home before fitting the circlip.

The batteries are camera-fodder - no electric <strong>winches</strong> on this boat!<br />

All that remains is to re-fit the lower pawls and assembly to the spindle and base, which<br />

remain on the boat.<br />

At that time shimming of the main bearing sleeve will be done little by little until satisfactory<br />

play is achieved.<br />

I hope this may be of use/encouragement to someone.<br />

Hook the spring onto it’s peg

and position the pawl on it’s

If there was play in the main bearing, - wobbly drum - then the split bearing can be tightened<br />

by adding tape to the outside before refitting into the drum.<br />

The internal groove should be full of grease

Squeeze the split bearing together and push into the drum. Then pop it back onto the spindle<br />

turning clockwise to set the pawls, and test for play. Add more tape as necessary - the slot can<br />

be widened using a hacksaw blade if more “shrink” is needed.<br />

Don’t forget to tighten down the retaining screw!<br />

Happy sailing.