contact angle meter surftens 300 wh - OEG

contact angle meter surftens 300 wh - OEG

contact angle meter surftens 300 wh - OEG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

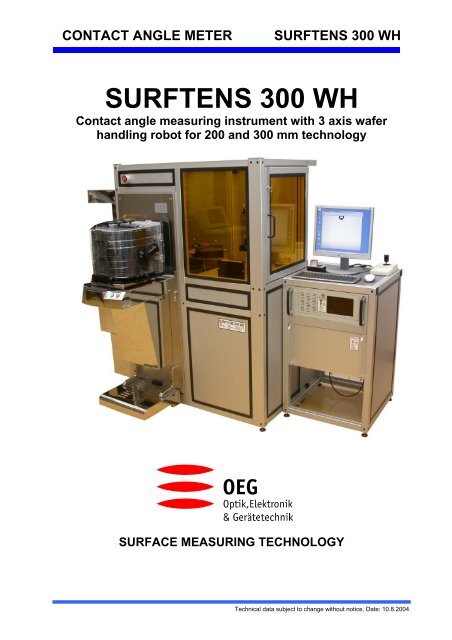

CONTACT ANGLE METER SURFTENS <strong>300</strong> WH<br />

SURFTENS <strong>300</strong> WH<br />

Contact <strong>angle</strong> measuring instrument with 3 axis wafer<br />

handling robot for 200 and <strong>300</strong> mm technology<br />

SURFACE MEASURING TECHNOLOGY<br />

Technical data subject to change without notice, Date: 10.8.2004

CONTACT ANGLE METER SURFTENS <strong>300</strong> WH<br />

GENERAL SOFTWARE<br />

- implementation of user levels in software<br />

- connection to SPC via network interface card<br />

- operating system Windows 2000<br />

- automatic loadport recognition<br />

- automatic recognition of slot occupancy<br />

- automatic measurement recipes assigned to certain load port (recipe mix up between different wafer<br />

sizes is avoided)<br />

- slot integrity is warranted<br />

- notching before measurement<br />

- Measurement data will be stored on local disc – any backup storage on network server will be organized<br />

by customer<br />

- LAN compatible<br />

- Client software for result evaluation on office PC is included<br />

- Manual operation mode (via joystick)<br />

MEASUREMENT GENERAL<br />

- Dispense System<br />

- Syringe or other dispense system for one media (DI-water)<br />

- Tank with 10 ml media stock<br />

- Programmable droplet size<br />

- Automatic placement of the droplet on the wafer, movement for droplet placement is programmable<br />

- Easy disassembly/cleaning of the dispense system<br />

- System capable for measurements with second liquid<br />

MEASUREMENT<br />

- Tool/Software supports free definable measurement maps<br />

- The <strong>wh</strong>ole wafer surface for 12“ must be in reach for the dispense system (excluding edge area)<br />

- Complete automatic measurement (FOUP -> droplet placement -> measurement -> droplet removal -><br />

FOUP)<br />

- <strong>contact</strong> <strong>angle</strong>s between 85° and 95° will be excluded from measurement range of the tool<br />

GENERAL HARDWARE<br />

- Wafer handling capability for 12“ wafer<br />

- System guarantees slot integrity<br />

- Manual focus system <strong>OEG</strong> provides detailed instruction for focus adjustment<br />

- <strong>OEG</strong> provides concept for maintenance, spare parts, complete users guide<br />

- <strong>OEG</strong> provides instruction for change of syringe<br />

- Wafer chuck only defined by measurement characteristics<br />

- Air pressure, vacuum, exhaust is provided by customer<br />

- Customer provides <strong>300</strong>mm wafers plus FOUPs for development system setup<br />

- After measurement liquid will be evaporated by hotplate<br />

- Work place contains keyboard and mouse<br />

Technical data subject to change without notice, Date: 10.8.2004

CONTACT ANGLE METER SURFTENS <strong>300</strong> WH<br />

TOOL CONFIGURATION<br />

Configuration - unit description:<br />

No Item Description<br />

3-axis wafer handling robot<br />

FOUP opening system <strong>300</strong>mm<br />

1 Wafer handling system Loadport 200mm<br />

Laser scanner<br />

Vacuum endeffector<br />

3-axis-step motor<br />

stepping motor driven wafer table<br />

automatic dispense system<br />

automatic droplet positioning (teachable)<br />

2 SURFTENS automatic illumination system<br />

CCD camera<br />

Frame grabber<br />

Software package<br />

3 Hotplate<br />

4 PC<br />

ACCEPTANCE CRITERIA<br />

for liquid removal<br />

PC, Flatscreen, keyboard, mouse<br />

- All relevant documents have to be present<br />

- Software will be accepted according to specifications<br />

- Handlingtest with “empty“ recipe: 50 wafers have to be handled without interruption<br />

- For check of measurement accuracy <strong>contact</strong> <strong>angle</strong> standard (provided by <strong>OEG</strong>) will be used<br />

- Measured values have to be within +/- 0,2° compared to standard<br />

- 25 wafer have to be handled and measured automatically without interruption using recipe set up<br />

according customer requirements<br />

- For acceptance Customer has to provide sufficient number of primed wafers<br />

Technical Para<strong>meter</strong>s for <strong>contact</strong> <strong>angle</strong> measurement<br />

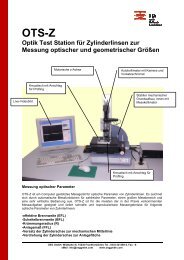

Contact <strong>angle</strong> measuring device SURFTENS <strong>300</strong> WH for the fully automatic measurement of the wetting<br />

behavior of solids (e.g. wafers or glass substrates for flat panel displays) under clean-room conditions, as<br />

well as for series tests and systematic analysis. The SURFTENS automatic enables the reduction of<br />

subjective factors and time involved for <strong>contact</strong> <strong>angle</strong> measurements in research, quality- and production<br />

inspection.<br />

For the software-controlled measurement and analysis of:<br />

- the static and dynamic <strong>contact</strong> <strong>angle</strong> according to the Sessile Drop method;<br />

- the wetting behavior on solid surfaces<br />

- the surface free energy of solids and their components<br />

The SURFTENS automatic consists of the basic instrument with the following technical equipment:<br />

- Single needle support with vertical and horizontal positioning;<br />

- Measuring stage, for fully automatic accurate sample positioning;<br />

- telecentric measuring lens;<br />

- Video measuring system with high-resolution CCD-camera;<br />

- High-performance video digitizing board (frame grabber) for the PC;<br />

Technical data subject to change without notice, Date: 10.8.2004

CONTACT ANGLE METER SURFTENS <strong>300</strong> WH<br />

- Illumination with continuously adjustable intensity for a homogeneous back lighting;<br />

- Control and measuring electronics for the teach-in procedure, graphic display with keyboard and video<br />

display<br />

- Power supply by PC<br />

- The 32-bit software SURFTENS developed for Windows NT/98/XP®;<br />

- Control of the sample position in X-, Y-direction, the needle position in Z-direction,<br />

- Static and dynamic <strong>contact</strong> <strong>angle</strong> measurement according to the Sessile drop method<br />

- Calculation of the surface and interfacial tension from the sessile drops<br />

- Calculation of the surface free energy of solids and their components according to the theorie of Wu,<br />

- Statistics and measurement error analysis<br />

- 3 axis wafer handling robot<br />

- Loadport for <strong>300</strong>mm wafer<br />

- scanner for slot occupacy<br />

- housing<br />

Technical data for conatct <strong>angle</strong> measurement<br />

- sample size: <strong>300</strong> mm Si-Wafer<br />

- Position accuracy ± 0.05 mm in the sample level;<br />

- Range of <strong>contact</strong> <strong>angle</strong> measurement 0 … 180° ; ± 0.2° measuring accuracy of the video system<br />

(excluded is the <strong>contact</strong> <strong>angle</strong> range of 85°...95°<br />

- Range of surface and interfacial tension 1·10-2 … 2·103 mN/m; resolution: min. ± 0.05 mN/m<br />

- CCD-camera with a resolution of max. 752 x 582 pixels<br />

- Video system: High-performance image processing system with 132 MBytes/s data transfer rate<br />

(compatible to European standard CCIR and US standard RS-170) , up to 50 images/s digitizing speed<br />

- Measuring methods: Sessile Drop method<br />

- Clean-room classification: 100<br />

<strong>OEG</strong> GmbH<br />

Wildbahn 8b<br />

D-15236 Frankfurt<br />

Germany<br />

Tel.: +49 335 5213894<br />

Fax: +49 335 5213896<br />

www.oeg-instruments.com<br />

info@oeg-instruments.com<br />

Representative<br />

Contact <strong>angle</strong> <strong>meter</strong><br />

Thin film stress measurement<br />

End point detection<br />

Micro diamond scriber<br />

Technical data subject to change without notice, Date: 10.8.2004