A COMPREHENSIVE APPROACH. CAPABILITY ... - SSI Schäfer

A COMPREHENSIVE APPROACH. CAPABILITY ... - SSI Schäfer

A COMPREHENSIVE APPROACH. CAPABILITY ... - SSI Schäfer

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

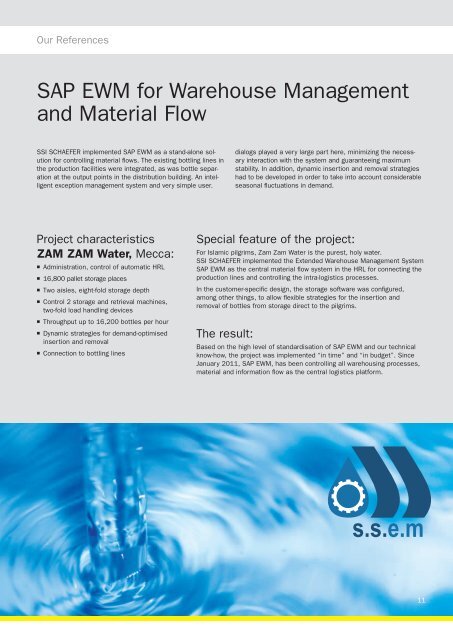

Our References<br />

SAP EWM for Warehouse Management<br />

and Material Flow<br />

<strong>SSI</strong> SCHAEFER implemented SAP EWM as a stand-alone solution<br />

for controlling material flows. The existing bottling lines in<br />

the production facilities were integrated, as was bottle separation<br />

at the output points in the distribution building. An intelligent<br />

exception management system and very simple user.<br />

dialogs played a very large part here, minimizing the necessary<br />

interaction with the system and guaranteeing maximum<br />

stability. In addition, dynamic insertion and removal strategies<br />

had to be developed in order to take into account considerable<br />

seasonal fluctuations in demand.<br />

Project characteristics<br />

ZAM ZAM Water, Mecca:<br />

• Administration, control of automatic HRL<br />

• 16,800 pallet storage places<br />

• Two aisles, eight-fold storage depth<br />

• Control 2 storage and retrieval machines,<br />

two-fold load handling devices<br />

• Throughput up to 16,200 bottles per hour<br />

• Dynamic strategies for demand-optimised<br />

insertion and removal<br />

• Connection to bottling lines<br />

Special feature of the project:<br />

For Islamic pilgrims, Zam Zam Water is the purest, holy water.<br />

<strong>SSI</strong> SCHAEFER implemented the Extended Warehouse Management System<br />

SAP EWM as the central material flow system in the HRL for connecting the<br />

production lines and controlling the intra-logistics processes.<br />

In the customer-specific design, the storage software was configured,<br />

among other things, to allow flexible strategies for the insertion and<br />

removal of bottles from storage direct to the pilgrims.<br />

The result:<br />

Based on the high level of standardisation of SAP EWM and our technical<br />

know-how, the project was implemented “in time” and “in budget”. Since<br />

January 2011, SAP EWM, has been controlling all warehousing processes,<br />

material and information flow as the central logistics platform.<br />

11