Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

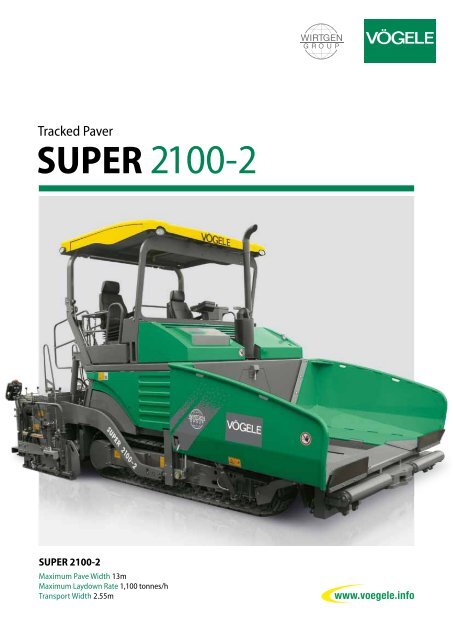

Tracked Paver<br />

<strong>SUPER</strong> <strong>2100</strong>-2<br />

<strong>SUPER</strong> <strong>2100</strong>-2<br />

Maximum Pave Width 13m<br />

Maximum Laydown Rate 1,100 tonnes/h<br />

Transport Width 2.55m

▲<br />

At a Glance<br />

Powerful, Economical, Low-Noise<br />

<strong>SUPER</strong> <strong>2100</strong>-2<br />

At a Glance<br />

▲<br />

▲<br />

▲<br />

▲<br />

▲<br />

▲<br />

▲<br />

▲<br />

▲<br />

Maximum pave width 13m<br />

Laydown rate up to 1,100 tonnes/h<br />

Maximum layer thickness 30cm<br />

Transport width 2.55m<br />

Pave speed up to 25m/min.<br />

Travel speed up to 4.5km/h<br />

Powerful DEUTZ engine rated at 182kW<br />

Easy-to-use ErgoPlus® operating concept<br />

Hardtop made of glass fibre reinforced<br />

polymer material<br />

The <strong>SUPER</strong> <strong>2100</strong>-2 is a real workhorse. This paver, one of the<br />

top models and great performer from the VÖGELE range of<br />

products, features a highly modern design and handles even<br />

largest contracts with excellence and ease, let alone its high<br />

cost-effectiveness.<br />

Given a maximum pave width of 13m, the <strong>SUPER</strong> <strong>2100</strong>-2 is<br />

a large player ideal for motorway construction in full-road<br />

width, surfacing large areas or taking up the challenge of<br />

airport projects. Thanks to various measures taken to minimize<br />

noise, <strong>SUPER</strong> <strong>2100</strong>-2 stands out through superquiet operation,<br />

a feature allowing application even in noise sensitive areas.<br />

It comes with a powerful engine developing 182kW.<br />

Conveyors and augers installed in the paver are so<br />

dimensioned as to transfer and spread even largest<br />

quantities of mix with effortless ease. No problem to<br />

place materials pretty hard to handle, such as water-bound<br />

base in thick layers, reliably and fast.<br />

A true highlight of <strong>SUPER</strong> <strong>2100</strong>-2 is ErgoPlus®, the innovative<br />

VÖGELE concept for paver handling. With ErgoPlus®, paver<br />

operation is child’s play. The operator enjoys a modern,<br />

ergonomical environment to work in that leaves nothing to<br />

be desired.<br />

The overall concept of the <strong>SUPER</strong> <strong>2100</strong>-2 unites ergonomics with<br />

ecological and economic aspects and was awarded the iF Product<br />

Design Award.<br />

2 VÖGELE <strong>SUPER</strong> Series <strong>SUPER</strong> <strong>2100</strong>-2 3

▲<br />

<strong>SUPER</strong> <strong>2100</strong>-2<br />

Tracked Paver <strong>SUPER</strong> <strong>2100</strong>-2<br />

4 VÖGELE <strong>SUPER</strong> Series <strong>SUPER</strong> <strong>2100</strong>-2 5

▲<br />

Drive<br />

The Drive Concept<br />

Powerful, Economical, Low-Noise<br />

▲<br />

High engine output of 182kW developed at just<br />

2,000 rpm, low noise levels and low exhaust emission<br />

(engine complying with exhaust standards COM 3a<br />

and EPA 3).<br />

▲<br />

ECO Mode (1,700 rpm) cuts operating cost and allows<br />

superquiet operation. Thanks to extra measures taken<br />

to minimize noise (sound insulated panels, for instance),<br />

the paver works very quietly, permitting operation also<br />

in environments sensitive to noise.<br />

▲<br />

A large cooler assembly with innovative air routing<br />

ensures perfect cooling of engine cooling liquid,<br />

hydraulic oil and charge air in every climatic zone<br />

the world over, no need to open panels. As a result,<br />

full engine performance is guaranteed and best<br />

conditions exist for longevity.<br />

▲<br />

High pave speed up to 25m/min. allows cost-effective<br />

operation and rapid completion of job sites.<br />

High power and economical operation are the main features<br />

of the DEUTZ engine installed in the <strong>SUPER</strong> <strong>2100</strong>-2. It already<br />

achieves its full power output of 182kW at just 2,000 rpm.<br />

The engine‘s noise levels are very low, and so are its exhaust<br />

emissions. The <strong>SUPER</strong> <strong>2100</strong>-2 complies with exhaust emissions<br />

standards COM 3a and EPA 3. Even when paving across large<br />

widths the paver can, in most of the cases, be operated in ECO<br />

Mode delivering 139kW at 1,800 rpm, which cuts operating<br />

costs and further reduces noise emissions.<br />

for instance, has been located so as to ensure a quiet intake<br />

of air. The hinged lateral panels, made of glass fibre reinforced<br />

plastic material, also add to noise insulation.<br />

A large cooler assembly and excellent air routing ensure perfect<br />

cooling of the engine coolant, hydraulic oil and charge air<br />

in every climatic zone the world over. As a result, full engine<br />

performance is guaranteed at all times, while also prolonging<br />

the engine‘s service life.<br />

▲<br />

▲<br />

Positive tracking when moving straight and accurate<br />

turning of radii due to separate drive and electronic<br />

control provided for each crawler track.<br />

The powerful transfer gearbox provides all hydraulic<br />

systems, such as conveyors and augers, with precisely<br />

the power required for the job in hand. All hydraulic<br />

pumps are clearly arranged on the transfer gearbox.<br />

In addition to the engine‘s particularly quiet ECO Mode, numerous<br />

additional measures have been taken to reduce the noise<br />

levels of the <strong>SUPER</strong> <strong>2100</strong>-2 to a minimum. The generator,<br />

Featuring extreme efficiency, high eco-friendliness and<br />

longevity, the drive concept of the <strong>SUPER</strong> <strong>2100</strong>-2 meets<br />

highest demands.<br />

6 VÖGELE <strong>SUPER</strong> Series <strong>SUPER</strong> <strong>2100</strong>-2 7

▲<br />

Feed with Mix<br />

▲<br />

Material Handling<br />

Large Material Hopper and Easy Feed with Mix<br />

Accurate Conveyance of Mix,<br />

High Laydown Rates<br />

▲<br />

The material hopper holding 14 tonnes is amply<br />

▲<br />

Proportional control provided for conveyors regulates<br />

dimensioned so that a sufficient quantity of mix<br />

flow rates to precisely match the requirement of mix<br />

is stored at all times, even when paver performance<br />

in front of the screed for excellent paving results.<br />

is high.<br />

▲<br />

Powerful, separate hydraulic drives installed for<br />

▲<br />

Easy feed with mix thanks to low material hopper<br />

conveyors and augers, thus permitting high laydown<br />

and hopper sides folding far down. Sturdy rubber<br />

rates up to 1,100 tonnes per hour.<br />

baffles fitted to the hopper front.<br />

The material feed and material handling concept of the<br />

<strong>SUPER</strong> <strong>2100</strong>-2 is designed for maximum performance.<br />

This large paver achieves laydown rates up to 1,100 tonnes/h.<br />

Large job sites can thus be completed in considerably<br />

less time and more economically.<br />

▲<br />

▲<br />

Large oscillating push-rollers for easy and<br />

shock-free docking of feed vehicles.<br />

A hydraulically operated hopper front (option)<br />

prevents spills of mix when feed lorries change<br />

and permits the material hopper to be completely<br />

emptied, so no hand work with shovels required.<br />

The entirety of mix is properly conveyed in front<br />

Large auger blades (diameter 480mm) provide for<br />

an optimal head of mix in front of the screed and<br />

prevent segregation, even when paving across<br />

large widths.<br />

▲<br />

Optimally designed mix conveying system with<br />

conveyors ascending towards the rear avoids<br />

segregation and diminishes wear of conveyors and<br />

conveyor bearings.<br />

of the screed and cooling, which might promote<br />

conglomeration and affect pavement quality, is<br />

positively avoided.<br />

8 VÖGELE <strong>SUPER</strong> Series <strong>SUPER</strong> <strong>2100</strong>-2 9

▲<br />

Material Handling<br />

▲<br />

Maintenance<br />

Auger Height Adjustment Across the Full Pave Width<br />

Easy Servicing<br />

15cm<br />

The augers of the <strong>SUPER</strong> <strong>2100</strong>-2 are infinitely variable<br />

in height up to 15cm while paving.<br />

▲<br />

▲<br />

▲<br />

Fast and easy adaptation to the desired layer thickness<br />

thanks to hydraulic adjustment of augers in height<br />

across the full pave width (hydraulic a an option).<br />

This provides for an optimal head of mix in front of<br />

the screed, even when placing thin layers or when<br />

layer thickness varies.<br />

The possibility of adjusting augers in height, complete<br />

with bearing boxes and limiting plates for the auger<br />

tunnel, allows to move the paver on the job site<br />

without a need for conversion, a benefit that saves<br />

time and money.<br />

▲<br />

▲<br />

▲<br />

▲<br />

▲<br />

Highly service-friendly paver design.<br />

All hydraulic pumps attached to the transfer gearbox.<br />

Their clear arrangement and easy access provides for<br />

service-friendliness at the highest level.<br />

Clear arrangement of power module, valves and<br />

flexible piping.<br />

All measuring points conveniently accessible.<br />

Centralized lubrication system installed as<br />

standard to automatically supply grease to<br />

the heavily strained bearings of conveyors<br />

and augers.<br />

The standardized service concept conceived for the “ dash 2“<br />

pavers means that servicing is quick and uncomplicated.<br />

Large hinged panels provide convenient access to all<br />

service points on the machine.<br />

10 VÖGELE <strong>SUPER</strong> Series <strong>SUPER</strong> <strong>2100</strong>-2 11

VÖGELE<br />

ErgoPlus ®<br />

The User-Friendly<br />

Operating System<br />

Even the best machine with the most advanced technology<br />

can only really show its strengths if it can be operated easily<br />

and as intuitively as possible, and offers to the operator a<br />

maximum of ergonomic comfort and workplace safety.<br />

Therefore, the ErgoPlus® operating concept focuses on the<br />

operator.<br />

The example diagrams on the following pages will provide<br />

you with additional information on the extensive functions<br />

of the ErgoPlus® operating concept. ErgoPlus® encompasses<br />

the operator‘s stand, the paver operator ‘s and screed consoles<br />

and NIVELTRONIC Plus®, the System for Automated Grade<br />

and Slope Control.<br />

The operating consoles are designed for optimum clarity,<br />

presenting all paver functions in logical groups. There‘s<br />

a place for everything and everything in its place on the<br />

operator‘s stand, and the paver operator has an excellent<br />

overview of all the key points of the paver.<br />

▲<br />

▲<br />

▲<br />

Operator platform of streamlined design<br />

All vital paver functions are clustered in logical<br />

groups on the paver operator‘s console. Their<br />

operation is easy to learn.<br />

The Strong Points of ErgoPlus®<br />

▲<br />

Easy operation of VÖGELE NIVELTRONIC Plus®,<br />

and well organized for a high level of safety<br />

the System for Automated Grade and Slope<br />

at work.<br />

Control, to achieve perfect paving results.<br />

The paver operator‘s seats and the operating<br />

The ErgoPlus® paver operator‘s console is of<br />

console adjust conveniently and easily in keeping<br />

modular design. This smart concept is not only<br />

with his personal needs. This provides a maximum<br />

ideal in practice, but also saves costs. In case<br />

of ergonomic comfort.<br />

of need, it offers the great advantage of easy<br />

▲<br />

replacement of single modules without having<br />

to replace the entire unit.<br />

All told, the ErgoPlus® operating concept enables the<br />

operator to respond to job site working processes and<br />

situations more quickly and accurately, giving him total<br />

control over the machine and the project.<br />

ErgoPlus® Paver Operator‘s Console ErgoPlus® Screed Console ErgoPlus® Operator Stand<br />

12 VÖGELE ErgoPlus®<br />

13

The ErgoPlus®<br />

Paver Operator‘s<br />

Console<br />

Full control for the machine operator

The ErgoPlus® Paver<br />

Operator‘s Console<br />

Clear and Logical Arrangement of Controls<br />

The ErgoPlus® paver operator‘s console has been designed<br />

according to practice-related principles. All controls are<br />

clearly arranged. Paver functions are clustered in logical<br />

goups so that operators find their controls where they<br />

suppose these should be.<br />

On the ErgoPlus® console, all push-buttons are easily<br />

identifiable by touch even when wearing work gloves.<br />

Once a button is pressed, off you go. This is due to the<br />

“Touch and Work” principle. This means that a function<br />

is executed directly – without a need to confirm.<br />

As darkness falls, the paver operator‘s console is back-lit<br />

automatically, as you have it in your car. This makes<br />

night-time work easy and relaxed.<br />

Module 1:<br />

Conveyors and Augers, Traction<br />

Module 2:<br />

Screed<br />

Module 3:<br />

Material Hopper and Steering<br />

Module 4:<br />

Display for set-up of vital paver functions on menu level 1.<br />

Secondary functions on menu level 2.<br />

Examples of Paver Functions<br />

Reversing Conveyor Movement<br />

In order to avoid mix dropping from the conveyors during<br />

a move of the paver on the job site, conveyor movement<br />

can be reversed at the push of a button. Reverse movement,<br />

transferring mix from the rear of the conveyor tunnel back<br />

inside, takes place for a short time only and stops automatically.<br />

Display of the Paver Operator‘s Console<br />

The large, easy-to-read display shows vital information on menu level 1 – such as<br />

the positions of the screed tow point rams or the pave speed. Set-up of further<br />

paver functions such as speeds for tamper and vibrators or feed rate for the<br />

conveyors can easily be made via the display, too. And the display gives access<br />

to machine-related information such as fuel consumption or service hours.<br />

No-Load Function<br />

The No-Load Function is provided for warm up or cleaning<br />

of conveyors, augers and tamper.<br />

Steering<br />

For turning a large radius, fine steering allows<br />

to pre-set a track position which is maintained<br />

automatically without a need for manual<br />

intervention by the operator.<br />

Automatic Functions<br />

For conveyors and augers, operators can easily select “Manual Mode”<br />

or “Automatic Mode”. When selecting “Automatic Mode” for the augers,<br />

sensors installed for the mix level in the auger tunnel provide that exactly<br />

the desired amount of mix is spread in front of the screed.<br />

Choice of Engine Speed Ranges<br />

For the engine, 3 modes exist to select from: MIN, ECO and MAX. To swap modes<br />

for engine rpm, all the operator needs to do is press the arrow buttons, up or down.<br />

In ECO Mode, the engine delivers sufficient power for a great number of paving<br />

applications. Operating in ECO Mode reduces noise emission and fuel consumption<br />

considerably.<br />

Choice of Operating Modes for the Paver<br />

On the ErgoPlus® console, 4 different operating modes for the paver are available to select<br />

from. By pressing the arrow buttons, up or down, the operator changes modes in the order<br />

as follows: “Neutral“, “Job Site Mode“, “Positioning Mode“ and “Pave Mode“. A LED indicates<br />

the mode selected. When leaving “Pave Mode“, a smart Memory feature stores last settings<br />

for paver functions so that, when resuming work after a move of the paver on site, these settings<br />

are restored automatically.<br />

Screed Assist (Option)<br />

This button switches Screed Assist on (LED lights up) or off. Screed Assist pressure and<br />

balance can be set via the display. Screed Assist is active only when the screed floats.<br />

16 VÖGELE ErgoPlus® 19

The ErgoPlus®<br />

Screed Console<br />

Easy Operation Guaranteed<br />

Crucial for pavement quality is the screed. Therefore,<br />

easy and positive handling of all screed functions is of<br />

utmost importance for high-quality road construction.<br />

With ErgoPlus®, the screed operator has the process<br />

of paving at his fingertips. All functions are easily<br />

comprehensible and all controls are clearly arranged.<br />

The Screed Console<br />

The screed console is designed in keeping with the conditions prevailing on the job site. For the functions<br />

operated from the screed console, push-buttons are provided. These are watertight and enclosed<br />

in a perceptibly raised ring, so that they are identifiable blindfold simply by touch even when wearing<br />

work gloves. Important paver and screed data can be called up and adjusted from the screed console, too.<br />

The Display of the Screed Console<br />

The display of his console allows the screed operator to control and monitor both the left and the right<br />

side of the screed. Machine-related parameters such as tamper speed or conveyor speed can be adjusted<br />

conveniently via the display panel of the screed console. The clear menu structure, combined with easily<br />

understandable, self-explanatory symbols neutral in language, makes operating the display panel both<br />

simple and safe.<br />

Niveltronic Plus® (Option)<br />

NIVELTRONIC Plus®, the cutting-edge VÖGELE System for Automated Grade and Slope Control, is very<br />

easy to learn and achieves outstanding paving results. All important functions of NIVELTRONIC Plus®<br />

can be accessed directly on menu level 1. The operator is provided with a variety of information,<br />

such as the sensor currently selected or the specified and actual values for layer thickness.<br />

An electronic system installed in the screed tow point rams picks up the tow points‘ positions. Display<br />

of the current tow point positions and of the transverse slope on the screed console greatly facilitates<br />

set-up of the screed. All sensors connected are recognized automatically by NIVELTRONIC Plus® and can<br />

be monitored and controlled from either screed console. An open interface is provided for connection<br />

of a GPS system, thus permitting 3D paving.<br />

Automatic Mode for Augers, Reversing Auger Rotation<br />

Just like the paver operator, the screed operator, too, can select Manual Mode or Automatic Mode<br />

for conveyors and augers. Very useful and comfortable in practice is the function of “Reversing<br />

Auger Rotation”.<br />

20 VÖGELE ErgoPlus® 21

The ErgoPlus®<br />

Operator Stand<br />

Excellent All-Round Visibility<br />

▲<br />

▲<br />

The comfortable operator stand gives unobstructed view<br />

of all crucial areas on the paver such as material hopper,<br />

steering guide or screed. It allows the paver operator to<br />

closely monitor the paver‘s feed with mix and the process<br />

of paving.<br />

The seats swinging out to the sides and an operator stand<br />

of streamlined design provide for maximum visibility of the<br />

auger tunnel, thus permitting the paver operator to keep<br />

an eye on the head of mix in front of the screed at all times.<br />

Working Comfort<br />

▲<br />

▲<br />

A few adjustments are all it takes for the paver operator<br />

to position his console exactly in keeping with his personal<br />

needs. It can be displaced across the full width of the<br />

operator‘s stand, swivelled out to the sides and tilted.<br />

When working with the seat swung out, the paver operator‘s<br />

console can be swivelled out together with the operator’s seat.<br />

In this way, an ergonomically optimized workplace is set up<br />

in no time at all. A legroom kept warm adds to operator comfort<br />

during the cold season.<br />

A Place for Everything<br />

and Everything in its Place<br />

▲<br />

▲<br />

▲<br />

The operator‘s stand of streamlined design is well organized,<br />

so that the paver operator enjoys a professional workplace.<br />

The operator’s console can be protected by a shatter-proof<br />

cover to prevent wilful damage.<br />

Plenty of stowage space makes it easy to keep the machine<br />

tidy. Access to all vital service points on the machine has been<br />

designed to be extremely clear and ergonomic.<br />

Hardtop Gives Excellent Protection<br />

▲<br />

▲<br />

The modern hardtop made of glass fibre reinforced polymer<br />

material shelters the operator whether rain or shine.<br />

The hardtop, including exhaust pipe, raises up or lowers<br />

down quickly and with effortless ease by a manually operated<br />

hydraulic pump. Wide sunshades, extending easily, give the<br />

operator optimal protection when his seat is moved out.<br />

Six bright working lights are integrated into the hardtop.<br />

Raising the lights in this way floods the job site with light<br />

(Xenon lamps available as an option).<br />

22 VÖGELE ErgoPlus® 23

▲<br />

Screed Options<br />

Screeds to Meet all Needs<br />

Based on its enormous tractive power and the capability<br />

of handling highest laydown rates, the <strong>SUPER</strong> <strong>2100</strong>-2 is<br />

▲<br />

The SB 250 Fixed-Width Screed handles a maximum<br />

▲<br />

For the <strong>SUPER</strong> <strong>2100</strong>-2, VÖGELE AB 500-2 and AB 600-2<br />

▲<br />

Electric Screed Heating<br />

a tough performer when it comes to working across large<br />

pave width of 13m and is ideally suited to use on<br />

Extending Screeds are available in TV version (with tamper<br />

- Homogeneous surface texture thanks to uniform<br />

pave widths and achieving high compacting results.<br />

large-scale job sites. High performance and cost-effective<br />

and vibrators) for standard compaction or in TP1 or TP2<br />

heating of screed plates, tamper bars and pressure bar(s).<br />

VÖGELE offer a variety of screed options and screed versions<br />

paving are its strengths. The SB 250 in TVP2 version<br />

versions (with 1 or 2 pressure bars) for high compaction.<br />

- Even with the paver‘s engine running at minimum rpm,<br />

to combine with <strong>SUPER</strong> <strong>2100</strong>-2.<br />

equipped with the full package of compacting systems<br />

For paving binder course and base course achieving highest<br />

the time required for the screed to reach its operating<br />

achieves a maximum degree of density. Thanks to<br />

precompaction, the paver can be combined with the<br />

temperature is reduced substantially thanks to an<br />

75cm hydraulic bolt-on extensions, the pave width is<br />

AB 600-2 Extending Screed in TP2 Plus version.<br />

intelligent Generator Management.<br />

infinitely variable within a range of 1.5m.<br />

- With paver functions set to automatic, the Generator<br />

▲<br />

Transverse Pavement Profiles<br />

Management activates Alternating Mode for screed<br />

▲<br />

AB 500-2 and AB 600-2 Extending Screeds, standing out<br />

- Positive and negative crown can be paved with all screed<br />

heating (heats the screed alternately to left and right),<br />

through high adaptability, are ideal for paving in varying<br />

types.<br />

a feature which is easy on the engine and reduces fuel<br />

widths. Their sturdy single-tube telescoping system allows<br />

- The AB screeds‘ extending units adjustable in height and<br />

consumption considerably.<br />

screed width control with highest precision. Even with the<br />

spindles provided on either side of each extending unit<br />

screed set to its maximum width, the telescoping tubes<br />

allow the Extending Screeds to be set up to a variety of<br />

are extended by no more than half, thus providing for<br />

additional special profiles.<br />

superb screed stability and zero flexing.<br />

24 VÖGELE <strong>SUPER</strong> Series <strong>SUPER</strong> <strong>2100</strong>-2 25

▲<br />

Screed Options<br />

Screed Options for <strong>SUPER</strong> <strong>2100</strong>-2<br />

AB 500-2<br />

Example: AB 500-2 TV built up to maximum pave width<br />

Pave Widths<br />

- Infinitely variable range from 2.55m to 5m.<br />

- Larger widths by addition of bolt-on extensions<br />

up to a maximum of 8.5m.<br />

Screed Versions<br />

2,550mm<br />

- AB 500-2 TV with tamper and vibrators<br />

- AB 500-2 TP1 with tamper and 1 pressure bar<br />

- AB 500-2 TP2 with tamper and 2 pressure bars<br />

5,000mm<br />

8,500mm<br />

AB 600-2<br />

Example: AB 600-2 TV built up to maximum pave width<br />

Pave Widths<br />

- Infinitely variable range from 3m to 6m.<br />

- Larger widths by addition of bolt-on extensions<br />

up to a maximum of 9.5m.<br />

Screed Versions<br />

- AB 600-2 TV with tamper and vibrators<br />

3,000mm<br />

- AB 600-2 TP1 with tamper and 1 pressure bar<br />

- AB 600-2 TP2 with tamper and 2 pressure bars<br />

- AB 600-2 TP2 Plus with tamper and 2 pressure bars<br />

for highest precompaction<br />

6,000mm<br />

9,500mm<br />

SB 250<br />

Example: SB 250 TV built up to maximum pave width<br />

Pave Widths<br />

- Basic width 2.5m. Larger widths by addition<br />

of bolt-on extensions up to a maximum of 13m.<br />

- Thanks to 75cm hydraulic bolt-on extensions,<br />

pave width is infinitely variable within a range of 1.5m.<br />

2,500mm<br />

Screed Versions<br />

- SB 250 TV with tamper and vibrators<br />

- SB 250 TP1 with tamper and 1 pressure bar<br />

1,500mm<br />

500mm<br />

1,500mm<br />

1,500mm 1,500mm 1,500mm 1,500mm<br />

500mm<br />

- SB 250 TP2 with tamper and 2 pressure bars<br />

- SB 250 TVP2 with tamper, vibrators and 2 pressure bars<br />

250mm<br />

13,000mm<br />

250mm<br />

26 VÖGELE <strong>SUPER</strong> Series <strong>SUPER</strong> <strong>2100</strong>-2 27

Dimensions in mm<br />

L* = Dependent on Screed Type (see Specification)<br />

Power Unit<br />

Engine:<br />

6-cylinder DEUTZ diesel engine, liquid-cooled<br />

Type:<br />

TCD 2013 L06 2V<br />

Output:<br />

Nominal: 182kW at 2,000 rpm (according to DIN)<br />

ECO Mode: 169kW at 1,700 rpm<br />

Fuel Tank:<br />

450 litres<br />

Electrical System: 24 V<br />

Undercarriage<br />

Crawler Tracks: provided with rubber pads<br />

Ground Contact: 3,060mm x 305mm<br />

Suspension:<br />

rigid<br />

Track Tension Adjuster: spring assembly<br />

Track Rollers:<br />

lifetime grease lubricated<br />

Traction Drive: hydraulic, separate drive and electronic control<br />

provided for each crawler track<br />

Speeds:<br />

- Paving: up to 25m/min., infinitely variable<br />

- Travel: up to 4.5km/h, infinitely variable<br />

Steering:<br />

by alteration of track running speeds<br />

Service Brake: hydrostatic<br />

Parking Brake: spring-loaded multiple-disk brake, maintenance-free<br />

Material Hopper<br />

Hopper Capacity: 14 tonnes<br />

Width:<br />

3,265mm<br />

Feed Height:<br />

615mm (bottom of material hopper)<br />

Push-Rollers:<br />

oscillating, displaceable forwards by 100mm<br />

Conveyors and Augers<br />

Conveyors:<br />

2, with replaceable feeder bars, conveyor movement<br />

reversible for a short time<br />

Drive: hydraulic, separate drive provided for each conveyor<br />

Speed: up to 33m/min., infinitely variable (manual or automatic)<br />

Augers:<br />

2, with replaceable auger blades, auger rotation reversible<br />

Diameter: 480mm<br />

Drive: hydraulic, separate drive provided for each auger<br />

Speed: up to 60 revs/min., infinitely variable (manual or automatic)<br />

Auger Height:<br />

- Standard: infinitely variable by 15cm, mechanical<br />

- Option: infinitely variable by 15cm, hydraulic<br />

Lubrication:<br />

Centralized Lubrication System with electrically driven<br />

grease pump for conveyor and auger bearings<br />

Screed Options<br />

SB 250:<br />

basic width 2.5m, maximum width (TV/TP1) 13m<br />

AB 500-2:<br />

basic width 2.55m, infinitely variable range 2.55m to 5m<br />

maximum width (TV/TP1/TP2) 8.5m<br />

AB 600-2:<br />

basic width 3m, infinitely variable range 3m to 6m<br />

maximum width (TV/TP1/TP2) 9.5m<br />

Screed Versions: TV, TP1, TP2, TP2 Plus (AB 600-2), TVP2 (SB 250)<br />

Layer Thickness: up to 30cm<br />

Screed Heating: electric by heating rods<br />

Power Supply: three-phase A.C. generator<br />

Dimensions and Weights<br />

Length:<br />

Tractor Unit and Screed in Transport Position:<br />

- SB 250 TV/TP1/TP2/TVP2: 6.55m<br />

- AB 500-2/AB 600-2 TV: 6.6m<br />

- AB 500-2/AB 600-2 TP1/TP2: 6.75m<br />

Weights:<br />

Tractor Unit with AB 500-2 Screed in TV Version:<br />

- Pave Widths up to 5m: 21.4 tonnes<br />

- Pave Widths up to 8.5m: 24.7 tonnes<br />

Optional Equipment Hydraulic hopper front. Xenon lamps for working lights.<br />

Hardtop of glass fibre reinforced polymer material. Sonic sensors<br />

to monitor head of mix in front of the screed. Automated Steering<br />

Control. Washdown system. NIVELTRONIC Plus® for Automated<br />

Grade and Slope Control (various sensors available).<br />

For more optional extras please contact your VÖGELE partner.<br />

Key: T = equipped with Tamper P1 = equipped with 1 Pressure Bar SB = Fixed-Width Screed Technical alterations reserved.<br />

V = equipped with Vibrators P2 = equipped with 2 Pressure Bars AB = Extending Screed<br />

ErgoPlus, InLine Pave, NIVELTRONIC, NIVELTRONIC Plus, NAVITRONIC, NAVITRONIC Plus, RoadScan and V-TRONIC are registered Community Trademarks of JOSEPH VÖGELE AG, Ludwigshafen, Germany. PCC is a registered<br />

German ® Trademark of JOSEPH VÖGELE AG, Ludwigshafen, Germany. NIVELTRONIC Plus and NAVITRONIC Plus are trademarks registered in the US Patent and Trademark Office to JOSEPH VÖGELE AG, Ludwigshafen,<br />

Germany. Legally binding claims cannot be derived from written information or pictures contained in this brochure. Pictures may include optional extras. We reserve the right of technical or design alterations.<br />

JOSEPH VÖGELE AG<br />

Joseph-Vögele-Straße 1<br />

67075 Ludwigshafen · Germany<br />

marketing@voegele.info<br />

Telephone: +49 (0)621 8105 0<br />

Fax: +49 (0)621 8105 461<br />

www.voegele.info<br />

2066034 EN/04.10