Glasslined Pipes & Fittings - GMM Pfaudler Ltd

Glasslined Pipes & Fittings - GMM Pfaudler Ltd

Glasslined Pipes & Fittings - GMM Pfaudler Ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

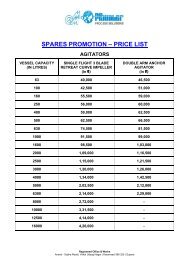

PE/10-<strong>GMM</strong>-12/06<br />

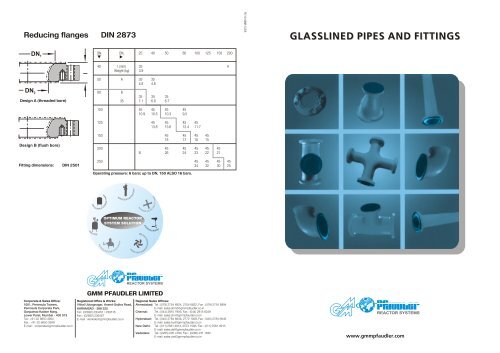

GLASSLINED PIPES AND FITTINGS<br />

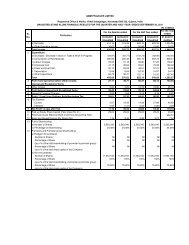

DN 1<br />

DN DN 25 40 50 80 100 125 150 200<br />

1 2<br />

40 I (mm) 35 A<br />

Weight (kg) 3.9<br />

50 A 35 35<br />

4.8 4.6<br />

DN 2<br />

<br />

80 B<br />

35 35 35<br />

35 7.1 6.8 6.7<br />

100 45 45 45 45<br />

10.9 10.5 10.3 9,5<br />

125 45 45 45 45<br />

13.8 13.6 12.4 11.7<br />

Design B (flush bore)<br />

<br />

150 45 45 45 45<br />

18 17 16 15<br />

200 45 45 45 45 45<br />

B 26 24 23 22 21<br />

250 45 45 45 45<br />

34 32 30 25<br />

<br />

<br />

OPTIMUM REACTOR<br />

SYSTEM SOLUTION<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

www.gmmpfaudler.com

glassed steel tubes are free of pin-holes, high voltage tested. Their significant advantage: these tubes hold high pressures up to 20<br />

bars, dependent on size and design.<br />

<br />

• As per ASME Code<br />

• Admissible operating pressure in the <strong>Pipes</strong> and <strong>Fittings</strong> -1/+6 bar<br />

0 0<br />

• Admissible operating temperature -25 /+250 C.<br />

• Dimensions according to DIN 2873.<br />

L<br />

<br />

DN mm 25 40 50 80 100 125 150 200 250<br />

I mm 180 210 230 270 310 350 390 520 630<br />

Weight kg 7.1 10.9 13.3 25.2 30.9 41.6 51.3 77.4 116.2<br />

<br />

<br />

All acceptance tests can be carried out in accordance with the relevant international standards, for example, ASME, TÜV, Stoomwezen, PED, etc.<br />

Every <strong>GMM</strong> <strong>Pfaudler</strong> product carries the ISO 9001 certificate.<br />

The certificate of quality reliability, safety & service. All requirements of the national and international standards to DIN/ISO 9001 are met.<br />

d<br />

DN mm 25 40 50 80 100 125 150 200 250<br />

d= Ø of glassed<br />

area mm 68 88 102 138 158 188 212 268 320<br />

Weight kg 1.4 2.3 5.1 5.9 5.7 8.4 10.4 16.4 24<br />

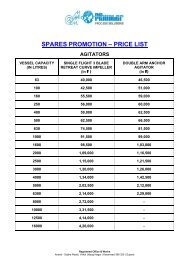

DN mm 25 40 50 80 100 125 150 200 250<br />

PN Standard flanges (bar) 6-20 6-20 6-16 6<br />

I= each length available to (mm) 1000 1500 2000 3000<br />

Flange connection dimensions according to DIN 2501. <strong>Pipes</strong> and flanges for higher pressure on request.<br />

<strong>Fittings</strong><br />

•<br />

•<br />

•<br />

•<br />

•<br />

Made of steel, glassed over the flanges like the pipes.<br />

Connection dimensions according to DIN 2501.<br />

Pressures correspond to those of pipes (see above).<br />

Dimensions according to DIN.<br />

All pipes are supplied including split flanges.<br />

s<br />

DN<br />

d<br />

<br />

DN mm 25 40 50 80 100 125 150 200 250<br />

d mm 68 88 102 138 158 185 210 265 320<br />

Weight kg 10 0.25 0.37 0.45 0.75 0.9 1.1 1.3 1.7 2.3<br />

15 0.35 0.55 0.7 1.15 1.3 1.6 1.9 2.6 3.4<br />

20 0.5 0.75 0.9 1.5 1.8 2.2 2.5 3.4 4.6<br />

25 0.6 0.0 1.1 2.2 2.7 2.7 3.2 4.4 5.8<br />

30 0.75 1.1 1.4 2.3 2.7 3.3 3.8 5.2 6.9<br />

40 1.0 1.4 1.8 3.0 3.6 4.4 5.0 6.9 9.3<br />

<br />

All weights include standard split flanges.<br />

DN<br />

e<br />

DN<br />

e<br />

e<br />

DN<br />

e<br />

<br />

<br />

DN mm 25 40 50 80 100 125 150 200 250<br />

e mm 60 70 80 95 105 125 150 180 220<br />

Weight kg 2.5 4.2 5.1 9.5 12.4 16.5 22.3 33.7 48.7<br />

<br />

<br />

DN mm 25 40 50 80 100 125 150 200 250<br />

e mm 90 105 115 135 155 175 195 260 315<br />

Weight mm 2.8 4.4 5.5 11.3 13.4 19 23 36 54.4<br />

<br />

DN mm 25 40 50 80 100 125 150 200 250<br />

I mm 180 210 230 270 310 350 390 520 630<br />

Weight mm 4.2 6.9 9.4 16.9 21.7 30.8 39.2 63.2 93.1<br />

e = 1/2 (With differing outlets also available)<br />

I<br />

DN 2<br />

DN 1<br />

b 2<br />

b 1<br />

DN b b DN 25 40 50 80 100 125 150 200<br />

1 1 2 2<br />

I (mm)= 140<br />

(kg) 3,0 Weight (kg)<br />

40 31 140<br />

3.2<br />

50 32 140 140<br />

3.6 4.3<br />

160 160<br />

80 35 7.2 7.5<br />

100 37 175 175 175<br />

8.5 8.7 10.9<br />

125 37 200 200 200<br />

11.5 13.9 14.6<br />

150 37 225 225 225<br />

16.5 17.1 19.3<br />

200 39 250 250 250 250<br />

21.1 22.1 24 25.4<br />

250 41 300 300 300 300<br />

29.7 32.6 33.9 36.2<br />

<br />

DIAPHRAGM VALVES<br />

e<br />

DN<br />

<br />

DN mm 25 40 50 80 100 125 150 200 250<br />

I mm 180 210 230 270 310 350 390 520 630<br />

Weight kg 6.2 9.7 12 24.7 29.2 40.4 49.1 76.7 114<br />

e = 1/2 (With differing outlets also available, and with sight glass)<br />

L<br />

NB<br />

C<br />

B<br />

A<br />

N d<br />

T<br />

H<br />

Size NB A B C Nxd L H T<br />

mm mm mm mm holes mm mm mm<br />

25 115 80 65 4-16 127 105 16<br />

40 140 98 85 4-16 159 140 16<br />

50 165 121 100 4-18 191 150 18<br />

75 200 153 135 4-18 254 205 20<br />

100 230 190 165 8-18 305 270 22<br />

150 280 241 212 8-22 406 357 24