DIN 17350

DIN 17350

DIN 17350

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

40 Каталог марок сталей<br />

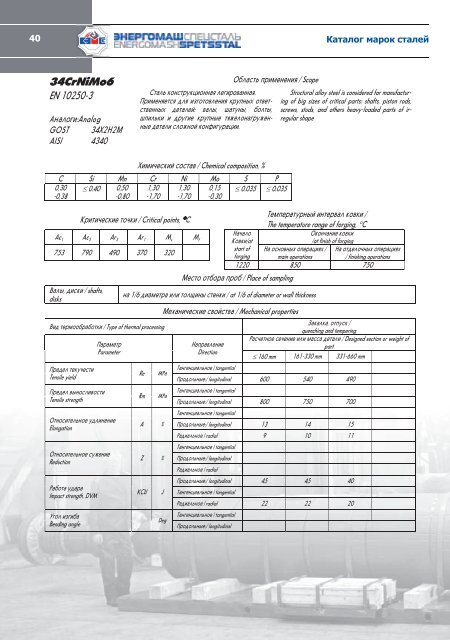

34CrNiMo6<br />

EN 10250-3<br />

Àíàëîãè:Analog<br />

GOST 34Õ2Í2Ì<br />

AISI 4340<br />

Ñòàëü êîíñòðóêöèîííàÿ ëåãèðîâàííàÿ.<br />

Ïðèìåíÿåòñÿ äëÿ èçãîòîâëåíèÿ êðóïíûõ îòâåòñòâåííûõ<br />

äåòàëåé: âàëû, øàòóíû, áîëòû,<br />

øïèëüêè è äðóãèå êðóïíûå òÿæåëîíàãðóæåííûå<br />

äåòàëè ñëîæíîé êîíôèãóðàöèè.<br />

Õèìè÷åñêèé ñîñòàâ / Chemical composition, %<br />

Îáëàñòü ïðèìåíåíèÿ / Scope<br />

Ñ Si Mn Cr Ni Mo S P<br />

0,30<br />

-0,38<br />

� 0.40 0,50<br />

-0,80<br />

1,30<br />

-1,70<br />

1,30<br />

-1,70<br />

0,15<br />

-0,30<br />

� 0.035 � 0.035<br />

Êðèòè÷åñêèå òî÷êè / Critical points, �Ñ<br />

Ac 1 Ac 3 Ar 3 Ar 1 M s M f<br />

753 790 490 370 320<br />

Âàëû, äèñêè / shafts,<br />

disks<br />

Âèä òåðìîîáðàáîòêè / Type of thermal processing<br />

Ïðåäåë òåêó÷åñòè<br />

Tensile yield<br />

Ïðåäåë âûíîñëèâîñòè<br />

Tensile strength<br />

Ïàðàìåòð<br />

Parameter<br />

Îòíîñèòåëüíîå óäëèíåíèå<br />

Elongation<br />

Îòíîñèòåëüíîå ñóæåíèå<br />

Reduction<br />

Ðàáîòà óäàðà<br />

Impact strength, DVM<br />

Óãîë èçãèáà<br />

Bending angle<br />

Structural alloy steel is considered for manufacturing<br />

of big sizes of critical parts: shafts, piston rods,<br />

screws, studs, and others heavy-loaded parts of irregular<br />

shape<br />

Òåìïåðàòóðíûé èíòåðâàë êîâêè /<br />

The temperature range of forging, �Ñ<br />

Íà÷àëî<br />

Îêîí÷àíèå êîâêè<br />

Êîâêè/at<br />

/at finish of forging<br />

start of Íà îñíîâíûõ îïåðàöèÿõ / Íà îòäåëî÷íûõ îïåðàöèÿõ<br />

forging main operations<br />

/ finishing operations<br />

1220 850 750<br />

Ìåñòî îòáîðà ïðîá / Place of sampling<br />

íà 1/6 äèàìåòðà èëè òîëùèíû ñòåíêè / at 1/6 of diameter or wall thickness<br />

Re MÐà<br />

Rm MÐà<br />

A %<br />

Z %<br />

KCU J<br />

Ìåõàíè÷åñêèå ñâîéñòâà / Mechanical properties<br />

Deg<br />

Íàïðàâëåíèå<br />

Direction<br />

Òàíãåíöèàëüíîå | tangential<br />

Çàêàëêà, îòïóñê /<br />

quenching and tempering<br />

Ðàñ÷åòíîå ñå÷åíèå èëè ìàññà äåòàëè / Designed section or weight of<br />

part<br />

� 160 mm 161-330 mm 331-660 mm<br />

Ïðîäîëüíûå:/ longitudinal 600 540 490<br />

Òàíãåíöèàëüíîå | tangential<br />

Ïðîäîëüíûå:/ longitudinal 800 750 700<br />

Òàíãåíöèàëüíîå | tangential<br />

Ïðîäîëüíûå:/ longitudinal 13 14 15<br />

Ðàäèàëüíîå | radial 9 10 11<br />

Òàíãåíöèàëüíîå | tangential<br />

Ïðîäîëüíûå:/ longitudinal<br />

Ðàäèàëüíîå | radial<br />

Ïðîäîëüíûå:/ longitudinal 45 45 40<br />

Òàíãåíöèàëüíîå | tangential<br />

Ðàäèàëüíîå | radial 22 22 20<br />

Òàíãåíöèàëüíîå | tangential<br />

Ïðîäîëüíûå:/ longitudinal