NEEDLE VALVES, TYPE ZWZ 11 and ZWZ 12

NEEDLE VALVES, TYPE ZWZ 11 and ZWZ 12

NEEDLE VALVES, TYPE ZWZ 11 and ZWZ 12

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>NEEDLE</strong> <strong>VALVES</strong>, <strong>TYPE</strong> <strong>ZWZ</strong> <strong>11</strong> <strong>and</strong> <strong>ZWZ</strong> <strong>12</strong><br />

APPLICATION AREA:<br />

The needle valves are used in measuring systems of level gauges, flow meters <strong>and</strong> other industrial automatic<br />

applications.<br />

For instance, they can be used to disconnect the measuring circuit right at the tank where fluid level is measured<br />

inside or cutoff the measuring tube.<br />

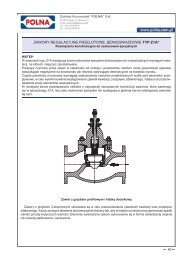

DESIGN:<br />

The bodies of cut-off valves are manufactured in two material variations:<br />

carbon steel (1.0570 – <strong>ZWZ</strong> <strong>11</strong> <strong>and</strong> <strong>ZWZ</strong> <strong>12</strong>) <strong>and</strong> acid-resistant steel<br />

(1.4571 – <strong>ZWZ</strong> <strong>11</strong>). In <strong>ZWZ</strong> <strong>11</strong> valves, the body is welded together with<br />

a bonnet, while in <strong>ZWZ</strong> <strong>12</strong> valves, the body with bonnet is made from a<br />

forging.<br />

Internal parts of cut-off valves in the carbon steel manufacture are made of<br />

stainless steel, <strong>and</strong> in acid-resistant valves, the parts directly coming into<br />

contact with an aggressive medium are made of acid-resistant steel, with<br />

the exception of the needle made of stainless steel, which is quenched<br />

<strong>and</strong> tempered.<br />

In <strong>ZWZ</strong> <strong>11</strong> valves in the steel version, the seat is padded with the use of<br />

an acid-resistant electrode, <strong>and</strong> in <strong>ZWZ</strong> <strong>12</strong> valves, the seat is made of<br />

acid-resistant steel, quenched <strong>and</strong> tempered, <strong>and</strong> then screwed in the<br />

body.<br />

The parts that are exposed to the risk of corrosion are protected by<br />

appropriate coatings. Ball endings of valves <strong>and</strong> connecting stubs<br />

are suitable for welding to pressurized pipes ∅<strong>12</strong> x 2 mm (<strong>ZWZ</strong> <strong>11</strong>)<br />

i ∅16 x 3 mm (<strong>ZWZ</strong> <strong>12</strong>). The ergonomic h<strong>and</strong>wheel are die pressed from<br />

steel sheets, which facilitates valve operation.<br />

TECHNICAL PARAMETERS:<br />

Working temperature: -10…+300 [°C] - for the steel body - S355J2G3 (1.0570),<br />

-196…+400 [°C] - for the acid resistant body - X6CrNiMoTi 17-<strong>12</strong>-2 (1.4571)<br />

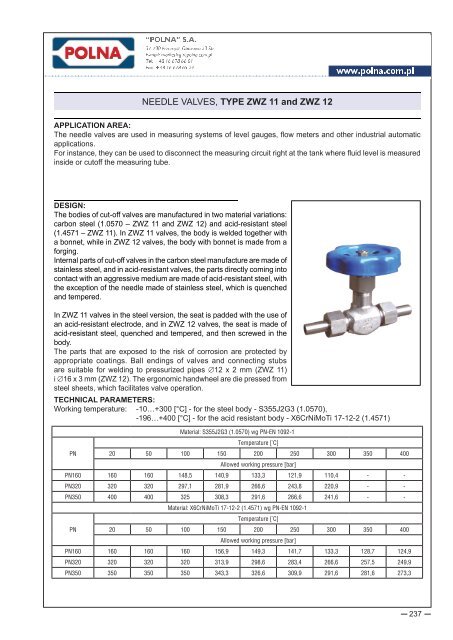

PN<br />

Material: S355J2G3 (1.0570) wg PN-EN 1092-1<br />

Temperature [°C]<br />

20 50 100 150 200 250 300 350 400<br />

Allowed working pressure [bar]<br />

PN160 160 160 148,5 140,9 133,3 <strong>12</strong>1,9 <strong>11</strong>0,4 - -<br />

PN320 320 320 297,1 281,9 266,6 243,8 220,9 - -<br />

PN350 400 400 325 308,3 291,6 266,6 241,6 - -<br />

PN<br />

Material: X6CrNiMoTi 17-<strong>12</strong>-2 (1.4571) wg PN-EN 1092-1<br />

Temperature [°C]<br />

20 50 100 150 200 250 300 350 400<br />

Allowed working pressure [bar]<br />

PN160 160 160 160 156,9 149,3 141,7 133,3 <strong>12</strong>8,7 <strong>12</strong>4,9<br />

PN320 320 320 320 313,9 298,6 283,4 266,6 257,5 249,9<br />

PN350 350 350 350 343,3 326,6 309,9 291,6 281,6 273,3<br />

237

Working pressures <strong>and</strong> nominal pressures for materials in table have been calculated interpolation method.<br />

Nominal pressure: 160 bar - <strong>ZWZ</strong> <strong>11</strong>,<br />

350 bar - <strong>ZWZ</strong> <strong>12</strong>-1,<br />

320 bar - <strong>ZWZ</strong> <strong>12</strong>-2,<br />

Diameter passage: 6 [mm]<br />

Weight: 0,4 [kg] - <strong>ZWZ</strong> <strong>11</strong>; 0,7 [kg] - <strong>ZWZ</strong> <strong>12</strong><br />

Design <strong>and</strong> dimensions of the valve<br />

Design options for the needle valve<br />

Material for the<br />

valve body<br />

Carbon steel<br />

Stainless steel<br />

Valve type<br />

(product code)<br />

<strong>ZWZ</strong> <strong>11</strong>-1<br />

<strong>ZWZ</strong> <strong>11</strong>-2<br />

<strong>ZWZ</strong> <strong>11</strong>-3<br />

Type of connecting nozzles<br />

Inlet<br />

Outlet<br />

with a ball ending <strong>and</strong> a nut<br />

for a ball ending<br />

with a ball ending <strong>and</strong> a nut<br />

for welding<br />

<strong>ZWZ</strong> <strong>11</strong>-4 for welding for welding<br />

<strong>ZWZ</strong> <strong>11</strong>-5 with internal thread NPT 1/4” with internal thread NPT 1/4”<br />

<strong>ZWZ</strong> <strong>12</strong>-1 with internal thread G 1/2” with internal thread G 1/2”<br />

<strong>ZWZ</strong> <strong>12</strong>-2 with a ball ending <strong>and</strong> a nut with a ball ending <strong>and</strong> a nut<br />

<strong>ZWZ</strong> <strong>11</strong>-1-KO<br />

with a ball ending <strong>and</strong> a nut<br />

<strong>ZWZ</strong> <strong>11</strong>-2-KO<br />

for a ball ending<br />

with a ball ending <strong>and</strong> a nut<br />

<strong>ZWZ</strong> <strong>11</strong>-3-KO<br />

for welding<br />

<strong>ZWZ</strong> <strong>11</strong>-4-KO for welding for welding<br />

<strong>ZWZ</strong> <strong>11</strong>-5-KO with internal thread NPT 1/4” with internal thread NPT 1/4”<br />

<strong>ZWZ</strong> <strong>12</strong>-1-KO with internal thread G 1/2”” with internal thread G 1/2””<br />

<strong>ZWZ</strong> <strong>12</strong>-2-KO with a ball ending <strong>and</strong> a nut with a ball ending <strong>and</strong> a nut<br />

ORDER PLACEMENT:<br />

Orders must contain full name of the valve <strong>and</strong> its product code, e.g. needle valve <strong>ZWZ</strong> <strong>11</strong> - 1 - KO<br />

238<br />

Revision: <strong>ZWZ</strong>/06/2013<br />

Valid until the next revision.