Effects of Ground Granulated Blast Furnace Slag in Portland Cement ...

Effects of Ground Granulated Blast Furnace Slag in Portland Cement ...

Effects of Ground Granulated Blast Furnace Slag in Portland Cement ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

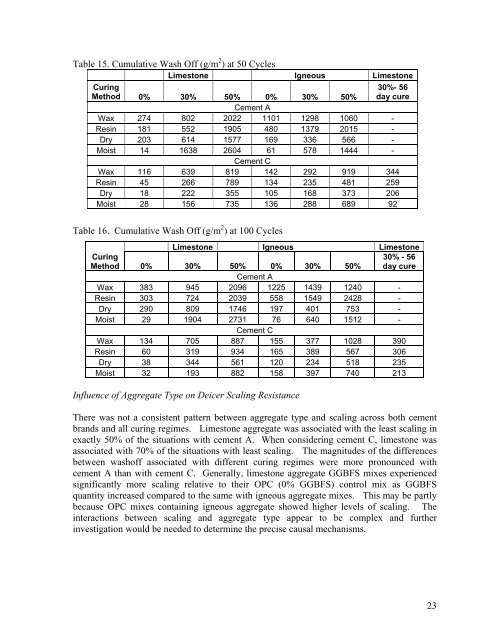

Table 15. Cumulative Wash Off (g/m 2 ) at 50 Cycles<br />

Limestone Igneous Limestone<br />

Cur<strong>in</strong>g<br />

Method 0% 30% 50% 0% 30% 50%<br />

30%- 56<br />

day cure<br />

<strong>Cement</strong> A<br />

Wax 274 802 2022 1101 1298 1060 -<br />

Res<strong>in</strong> 181 552 1905 480 1379 2015 -<br />

Dry 203 614 1577 169 336 566 -<br />

Moist 14 1638 2604 61 578 1444 -<br />

<strong>Cement</strong> C<br />

Wax 116 639 819 142 292 919 344<br />

Res<strong>in</strong> 45 266 789 134 235 481 259<br />

Dry 18 222 355 105 168 373 206<br />

Moist 28 156 735 136 288 689 92<br />

Table 16. Cumulative Wash Off (g/m 2 ) at 100 Cycles<br />

Limestone Igneous Limestone<br />

Cur<strong>in</strong>g<br />

Method 0% 30% 50% 0% 30% 50%<br />

30% - 56<br />

day cure<br />

<strong>Cement</strong> A<br />

Wax 383 945 2096 1225 1439 1240 -<br />

Res<strong>in</strong> 303 724 2039 558 1549 2428 -<br />

Dry 290 809 1746 197 401 753 -<br />

Moist 29 1904 2731 76 640 1512 -<br />

<strong>Cement</strong> C<br />

Wax 134 705 887 155 377 1028 390<br />

Res<strong>in</strong> 60 319 934 165 389 567 306<br />

Dry 38 344 561 120 234 518 235<br />

Moist 32 193 882 158 397 740 213<br />

Influence <strong>of</strong> Aggregate Type on Deicer Scal<strong>in</strong>g Resistance<br />

There was not a consistent pattern between aggregate type and scal<strong>in</strong>g across both cement<br />

brands and all cur<strong>in</strong>g regimes. Limestone aggregate was associated with the least scal<strong>in</strong>g <strong>in</strong><br />

exactly 50% <strong>of</strong> the situations with cement A. When consider<strong>in</strong>g cement C, limestone was<br />

associated with 70% <strong>of</strong> the situations with least scal<strong>in</strong>g. The magnitudes <strong>of</strong> the differences<br />

between wash<strong>of</strong>f associated with different cur<strong>in</strong>g regimes were more pronounced with<br />

cement A than with cement C. Generally, limestone aggregate GGBFS mixes experienced<br />

significantly more scal<strong>in</strong>g relative to their OPC (0% GGBFS) control mix as GGBFS<br />

quantity <strong>in</strong>creased compared to the same with igneous aggregate mixes. This may be partly<br />

because OPC mixes conta<strong>in</strong><strong>in</strong>g igneous aggregate showed higher levels <strong>of</strong> scal<strong>in</strong>g. The<br />

<strong>in</strong>teractions between scal<strong>in</strong>g and aggregate type appear to be complex and further<br />

<strong>in</strong>vestigation would be needed to determ<strong>in</strong>e the precise causal mechanisms.<br />

23