Effects of Ground Granulated Blast Furnace Slag in Portland Cement ...

Effects of Ground Granulated Blast Furnace Slag in Portland Cement ...

Effects of Ground Granulated Blast Furnace Slag in Portland Cement ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

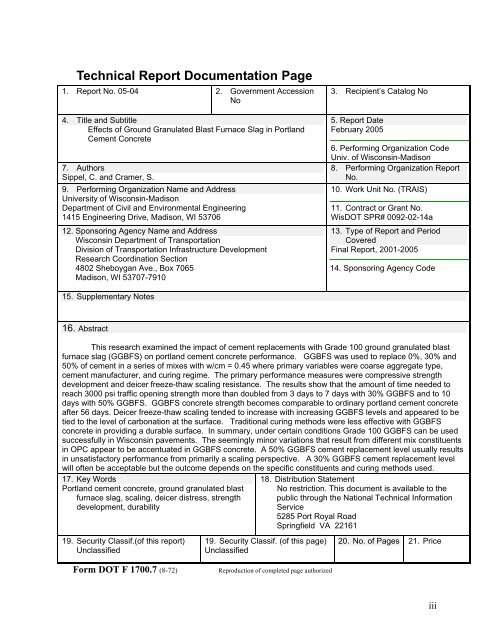

Technical Report Documentation Page<br />

1. Report No. 05-04 2. Government Accession<br />

No<br />

4. Title and Subtitle<br />

<strong>Effects</strong> <strong>of</strong> <strong>Ground</strong> <strong>Granulated</strong> <strong>Blast</strong> <strong>Furnace</strong> <strong>Slag</strong> <strong>in</strong> <strong>Portland</strong><br />

<strong>Cement</strong> Concrete<br />

7. Authors<br />

Sippel, C. and Cramer, S.<br />

9. Perform<strong>in</strong>g Organization Name and Address<br />

University <strong>of</strong> Wiscons<strong>in</strong>-Madison<br />

Department <strong>of</strong> Civil and Environmental Eng<strong>in</strong>eer<strong>in</strong>g<br />

1415 Eng<strong>in</strong>eer<strong>in</strong>g Drive, Madison, WI 53706<br />

12. Sponsor<strong>in</strong>g Agency Name and Address<br />

Wiscons<strong>in</strong> Department <strong>of</strong> Transportation<br />

Division <strong>of</strong> Transportation Infrastructure Development<br />

Research Coord<strong>in</strong>ation Section<br />

4802 Sheboygan Ave., Box 7065<br />

Madison, WI 53707-7910<br />

3. Recipient’s Catalog No<br />

5. Report Date<br />

February 2005<br />

6. Perform<strong>in</strong>g Organization Code<br />

Univ. <strong>of</strong> Wiscons<strong>in</strong>-Madison<br />

8. Perform<strong>in</strong>g Organization Report<br />

No.<br />

10. Work Unit No. (TRAIS)<br />

11. Contract or Grant No.<br />

WisDOT SPR# 0092-02-14a<br />

13. Type <strong>of</strong> Report and Period<br />

Covered<br />

F<strong>in</strong>al Report, 2001-2005<br />

14. Sponsor<strong>in</strong>g Agency Code<br />

15. Supplementary Notes<br />

16. Abstract<br />

This research exam<strong>in</strong>ed the impact <strong>of</strong> cement replacements with Grade 100 ground granulated blast<br />

furnace slag (GGBFS) on portland cement concrete performance. GGBFS was used to replace 0%, 30% and<br />

50% <strong>of</strong> cement <strong>in</strong> a series <strong>of</strong> mixes with w/cm = 0.45 where primary variables were coarse aggregate type,<br />

cement manufacturer, and cur<strong>in</strong>g regime. The primary performance measures were compressive strength<br />

development and deicer freeze-thaw scal<strong>in</strong>g resistance. The results show that the amount <strong>of</strong> time needed to<br />

reach 3000 psi traffic open<strong>in</strong>g strength more than doubled from 3 days to 7 days with 30% GGBFS and to 10<br />

days with 50% GGBFS. GGBFS concrete strength becomes comparable to ord<strong>in</strong>ary portland cement concrete<br />

after 56 days. Deicer freeze-thaw scal<strong>in</strong>g tended to <strong>in</strong>crease with <strong>in</strong>creas<strong>in</strong>g GGBFS levels and appeared to be<br />

tied to the level <strong>of</strong> carbonation at the surface. Traditional cur<strong>in</strong>g methods were less effective with GGBFS<br />

concrete <strong>in</strong> provid<strong>in</strong>g a durable surface. In summary, under certa<strong>in</strong> conditions Grade 100 GGBFS can be used<br />

successfully <strong>in</strong> Wiscons<strong>in</strong> pavements. The seem<strong>in</strong>gly m<strong>in</strong>or variations that result from different mix constituents<br />

<strong>in</strong> OPC appear to be accentuated <strong>in</strong> GGBFS concrete. A 50% GGBFS cement replacement level usually results<br />

<strong>in</strong> unsatisfactory performance from primarily a scal<strong>in</strong>g perspective. A 30% GGBFS cement replacement level<br />

will <strong>of</strong>ten be acceptable but the outcome depends on the specific constituents and cur<strong>in</strong>g methods used.<br />

17. Key Words<br />

<strong>Portland</strong> cement concrete, ground granulated blast<br />

furnace slag, scal<strong>in</strong>g, deicer distress, strength<br />

development, durability<br />

19. Security Classif.(<strong>of</strong> this report)<br />

Unclassified<br />

18. Distribution Statement<br />

No restriction. This document is available to the<br />

public through the National Technical Information<br />

Service<br />

5285 Port Royal Road<br />

Spr<strong>in</strong>gfield VA 22161<br />

19. Security Classif. (<strong>of</strong> this page)<br />

Unclassified<br />

20. No. <strong>of</strong> Pages 21. Price<br />

Form DOT F 1700.7 (8-72)<br />

Reproduction <strong>of</strong> completed page authorized<br />

iii