165 - Magnet Service Binder

165 - Magnet Service Binder

165 - Magnet Service Binder

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

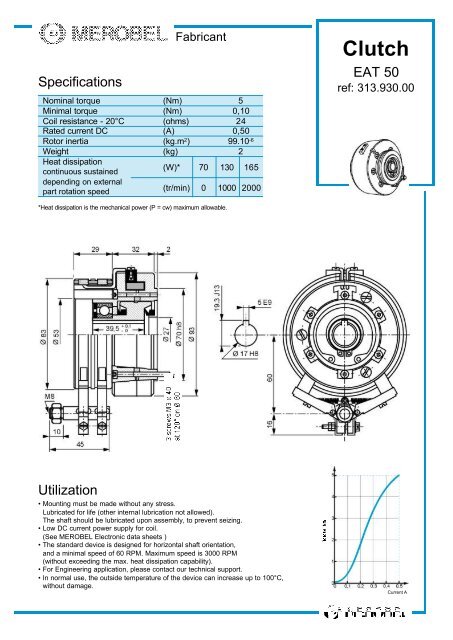

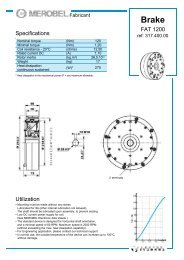

Specifications<br />

Fabricant<br />

Nominal torque (Nm) 5<br />

Minimal torque (Nm) 0,10<br />

Coil resistance - 20°C (ohms) 24<br />

Rated current DC (A) 0,50<br />

Rotor inertia (kg.m 2 ) 99.10 -6<br />

Weight (kg) 2<br />

Heat dissipation<br />

continuous sustained<br />

(W)* 70 130 <strong>165</strong><br />

depending on external<br />

part rotation speed (tr/min) 0 1000 2000<br />

Clutch<br />

EAT 50<br />

ref: 313.930.00<br />

*Heat dissipation is the mechanical power (P = cw) maximum allowable.<br />

Utilization<br />

• Mounting must be made without any stress.<br />

Lubricated for life (other internal lubrication not allowed).<br />

The shaft should be lubricated upon assembly, to prevent seizing.<br />

• Low DC current power supply for coil.<br />

(See MEROBEL Electronic data sheets )<br />

• The standard device is designed for horizontal shaft orientation,<br />

and a minimal speed of 60 RPM. Maximum speed is 3000 RPM<br />

(without exceeding the max. heat dissipation capability).<br />

• For Engineering application, please contact our technical support.<br />

• In normal use, the outside temperature of the device can increase up to 100°C,<br />

without damage.<br />

Current A

Safety<br />

• If the device is to be used in dusty, humid or corrosive environment,<br />

special protection needs to be considered.<br />

Maintenance<br />

• Two procedures are available:<br />

- Full inhouse maintenance servicing:<br />

Please call : +33 / 2 38 94 42 44<br />

- Spare parts or repair kits (depending on maintenance level)<br />

- Kit (powder, ball bearings, seals, felts) ref: 313.900.71<br />

- Coil ref: 313.920.05<br />

- Rotor ref: 313.900.03<br />

- Collector ref: 313.910.40<br />

- Equipped brush holder ref: 314.310.60<br />

- 10 brushes set ref: 314.310.62<br />

- In any case, our After Sales service is at your disposal.<br />

In line mounting<br />

EAT 50 - ref: 313.930.00<br />

In line mounting<br />

Parallel mounting<br />

M<br />

O<br />

T<br />

O<br />

R<br />

Elastic<br />

coupling<br />

Rotating<br />

shaft<br />

Rotating<br />

shaft<br />

Elastic<br />

coupling<br />

U<br />

TILIZATI<br />

O<br />

N<br />

M<br />

O<br />

T<br />

O<br />

R<br />

U<br />

T<br />

I<br />

L<br />

I<br />

Z<br />

A<br />

T<br />

I<br />

O<br />

N<br />

fly wheel<br />

fly wheel<br />

Zone industrielle - 45210 Ferrières - France<br />

Tel.: 33 2 38 94 42 44 - Fax: 33 2 38 94 42 45<br />

Internet Adress: http://www.merobel.com

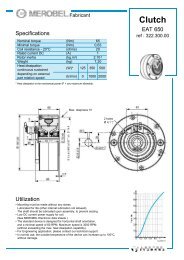

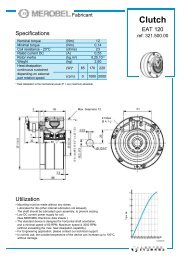

Specifications<br />

Fabricant<br />

Nominal torque (Nm) 5<br />

Minimal torque (Nm) 0,10<br />

Coil resistance - 20°C (ohms) 24<br />

Rated current DC (A) 0,50<br />

Rotor inertia (kg.m 2 ) 99.10 -6<br />

Rotor inertia (kg) 2,40<br />

Heat dissipation<br />

continuous sustained<br />

(W)* 100 275 360<br />

depending on external<br />

part rotation speed (tr/min) 0 1000 2000<br />

Clutch<br />

ERAT 50<br />

ref: 313.935.00<br />

*Heat dissipation is the mechanichal power (P = cw) maximum allowable.<br />

Utilization<br />

• Mounting must be made without any stress.<br />

Lubricated for life (other internal lubrication not allowed).<br />

The shaft should be lubricated upon assembly, to prevent seizing.<br />

• Low DC current power supply for coil.<br />

(See MEROBEL Electronic data sheets)<br />

• The standard device is designed for horizontal shaft orientation,<br />

and a minimal speed of 60 RPM. Maximum speed is 3000 RPM.<br />

(without exceeding the max. heat dissipation capability).<br />

• For application Engineering, please contact our technical support.<br />

• In normal use, the outside temperature of the device can increase up to 100°C,<br />

without damage.<br />

Current A

Safety<br />

• If the device is to be used in dusty, humid or corrosive environment,<br />

special protection needs to be considered.<br />

Maintenance<br />

• Two procedures are available:<br />

- Full inhouse maintenance servicing:<br />

Please call : +33 / 2 38 94 42 44<br />

- Spare parts or repair kits (depending on maintenance level)<br />

- Kit (powder, ball bearings, seals, felts) ref: 313.900.71<br />

- Coil ref: 313.920.05<br />

- Rotor ref: 313.900.03<br />

- Collector ref: 313.910.40<br />

- Equipped brush holder ref: 314.310.60<br />

- 10 brushes set ref: 314.310.62<br />

- In any case, our After Sales service is at your disposal.<br />

Recommended mounting principles<br />

ERAT 50 - ref: 313.935.00<br />

In line mounting<br />

Parallel mounting<br />

M<br />

O<br />

T<br />

O<br />

R<br />

Elastic<br />

coupling<br />

Rotating<br />

shaft<br />

Rotating<br />

shaft<br />

Elastic<br />

coupling<br />

U<br />

T<br />

ILI<br />

Z<br />

A<br />

T<br />

I<br />

O<br />

N<br />

M<br />

O<br />

T<br />

O<br />

R<br />

U<br />

TILIZATI<br />

O<br />

N<br />

fly wheel<br />

fly wheel<br />

Zone industrielle - 45210 Ferrières - France<br />

Tel.: 33 2 38 94 42 44 - Fax: 33 2 38 94 42 45<br />

Internet Adress: http://www.merobel.com