D5.4 - Leaflet about Retrofit - Fokker Services

D5.4 - Leaflet about Retrofit - Fokker Services

D5.4 - Leaflet about Retrofit - Fokker Services

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Several retrofitting technologies that could reduce emissions,<br />

increase passenger comfort and safety and/or improve punctuality<br />

also have a potential to be applied commercially. However, the<br />

Return On Investment (ROI) often becomes positive after a period<br />

of several years and the air transport industry seems reluctant to<br />

take this financial risk which proves to be a substantial barrier for<br />

retrofits. The EASA classification gives an indication of the certification<br />

requirements and the usage indicates how the retrofit has<br />

been applied up until now.<br />

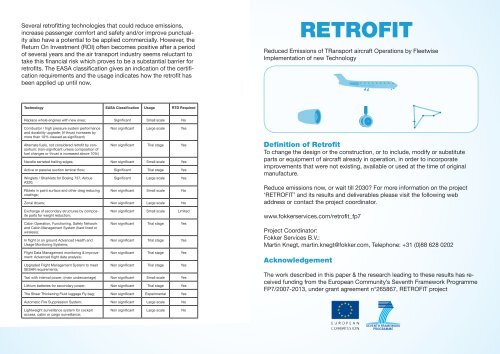

RETROFIT<br />

Reduced Emissions of TRansport aircraft Operations by Fleetwise<br />

Implementation of new Technology<br />

Technology EASA Classification Usage RTD Required<br />

Replace whole engines with new ones; Significant Small scale No<br />

Combustor / high pressure system performance<br />

and durability upgrade; (if thrust increases by<br />

more than 10% classed as significant)<br />

Alternate fuels, not considered retrofit by consortium;<br />

(non-significant unless composition of<br />

fuel changes or thrust is increased above 10%)<br />

Non significant Large scale Yes<br />

Non significant Trial stage Yes<br />

Nacelle serrated trailing edges; Non significant Small scale Yes<br />

Active or passive suction laminar flow; Significant Trial stage Yes<br />

Winglets / Sharklets for Boeing 737, Airbus<br />

A320;<br />

Riblets in paint surface and other drag reducing<br />

coatings;<br />

Significant Large scale Yes<br />

Non significant Small scale No<br />

Zonal dryers; Non significant Large scale No<br />

Exchange of secondary structures by composite<br />

parts for weight reduction;<br />

Cabin Operation, Functioning, Safety Network<br />

and Cabin Management System (hard lined or<br />

wireless);<br />

In flight or on ground Advanced Health and<br />

Usage Monitoring Systems;<br />

Flight Data Management monitoring & improvement:<br />

Advanced flight data analysis;<br />

Upgraded Flight Management System to meet<br />

SESAR requirements;<br />

Non significant Small scale Limited<br />

Non significant Trial stage Yes<br />

Non significant Trial stage Yes<br />

Non significant Trial stage Yes<br />

Non significant Trial stage Yes<br />

Taxi with internal power; (main undercarriage) Non significant Small scale Yes<br />

Lithium batteries for secondary power; Non significant Trial stage Yes<br />

The Shear Thickening Fluid luggage Fly bag; Non significant Experimental Yes<br />

Definition of <strong>Retrofit</strong><br />

To change the design or the construction, or to include, modify or substitute<br />

parts or equipment of aircraft already in operation, in order to incorporate<br />

improvements that were not existing, available or used at the time of original<br />

manufacture.<br />

Reduce emissions now, or wait till 2030? For more information on the project<br />

‘RETROFIT’ and its results and deliverables please visit the following web<br />

address or contact the project coordinator.<br />

www.fokkerservices.com/retrofit_fp7<br />

Project Coordinator:<br />

<strong>Fokker</strong> <strong>Services</strong> B.V.:<br />

Martin Knegt, martin.knegt@fokker.com, Telephone: +31 (0)88 628 0202<br />

Acknowledgement<br />

The work described in this paper & the research leading to these results has received<br />

funding from the European Community’s Seventh Framework Programme<br />

FP7/2007-2013, under grant agreement n°265867, RETROFIT project<br />

Automatic Fire Suppression System; Non significant Large scale No<br />

Lightweight surveillance system for cockpit<br />

access, cabin or cargo surveillance;<br />

Non significant Large scale No

Context<br />

Many new technologies are developed every day. Only if a large number of<br />

new technologies can be incorporated into the new design, will a new aircraft<br />

be developed. Typically the development time of a new aircraft program is at<br />

least five years. It may take another 10 years before a sizeable fleet of the new<br />

aircraft is in operation. This implies that it will take at least 15 years before the<br />

benefits of new technologies become noticeable on a global scale.<br />

Existing aircraft still have a long life to serve, but the operational environment<br />

is changing. Airlines are confronted with emission trading, new noise legislation,<br />

increasing fuel prices and new safety and security demands. Aircraft<br />

need to operate in a new Air traffic Management (ATM) environment in which<br />

older aircraft do not comply with the new ATM standards. Also the passengers<br />

expect to be provided with high levels of comfort, communication and safety<br />

possible. Integration of new technologies on existing aircraft provides an opportunity<br />

for stakeholders and society to benefit from new technologies much<br />

earlier.<br />

The goal of the RETROFIT project is to analyze the possibilities and attractiveness<br />

of retrofitting the large fleet of commercial airliners with new technical<br />

solutions in order to satisfy todays and tomorrow’s commercial, environmental<br />

and safety demands.<br />

The RETROFIT project is a Coordination and Support Action (CSA) within the<br />

Seventh Framework Programme co-funded by the European Commission.<br />

(Grant agreement n°265867)<br />

The RETROFIT project first addressed the stakeholder requirements and<br />

investigated current and future technology options for retrofitting existing aircraft.<br />

Next, it investigated the need for research and integration activities to<br />

make retrofits attractive. It selected specific research activities that could be<br />

called for in the near-to-medium term in the RTD Framework Program of the<br />

European Commission. It also performed a cost benefit analysis on integrating<br />

selected mature (high Technology Readiness Level (TRL)) technologies<br />

on existing airline fleets. Finally, it investigated the possibilities for funding of<br />

retrofits and the possible role the European<br />

Commission could play. The results of the project will be widely disseminated.<br />

Promising cases can lead to a substantial economic activity in many<br />

European countries.<br />

The project provides recommendations to the European Commission with<br />

respect to Research and Technology Development (RTD) for retrofit to be incorporated<br />

in Framework Programme FP7 as well as for Horizon 2020. It also<br />

suggested that the Commission could create incentives for an early application<br />

of retrofits in the air transport fleet.<br />

Technology TRL Level RTD Required<br />

Cost-efficient implementation of Single European Sky ATM Research requirements<br />

(SESAR) on existing aircraft, e.g., through a validated and certifiable uniform SESAR box<br />

to be interfaced with existing avionics suites.<br />

Feasibility and implementation of advanced, stand-alone (i.e., not tied into main avionics)<br />

Health and Usage Monitoring Systems (HUMS) for structures and none-critical systems<br />

on existing aircraft, supported by RTD on air-ground communication and more advanced<br />

data communication (integrated data-power, wireless transmission) in existing aircraft.<br />

Wireless data communication in existing aircraft for integrated configurable network<br />

solutions for, e.g., advanced In-Flight Entertainment and Connectivity, cabin management<br />

and safety.<br />

3 YES Level 0/1<br />

4-6 YES Level 1<br />

4-5 YES Level 2<br />

Approach<br />

In the RETROFIT project, <strong>Fokker</strong> <strong>Services</strong> B.V., ADSE Consulting and Engineering,<br />

the National Aerospace Laboratory NLR, AD CUENTA B.V., PARA-<br />

GON S.A. and L-UP SAS worked together to analyze the possibilities and<br />

attractiveness of retrofitting the large fleet of commercial airliners with new<br />

technical solutions in order to satisfy today’s and tomorrow’s commercial,<br />

environmental and safety demands.<br />

Air-ground and at-gate communication in existing aircraft, e.g., for Advanced Health and<br />

Usage Monitoring System (AHUMS), black boxes, turn-around operations, connectivity<br />

with maintenance base and IRU fault detection.<br />

Engine systems and components retrofit development, rig testing, demonstration, and<br />

flight qualification such as combustion chamber retrofit for Nitrogen Oxide reduction.<br />

Development of a retrofit kit for nacelle and composite fan casing, for weight reduction,<br />

aerodynamics benefits (laminar flow) and potentially also reduction of noise.<br />

The long term performance of alternative, non-drop-in fuels (incl. synthetic fuel and<br />

biofuel) in existing engines without (major) modifications on existing aircraft, such as the<br />

effect on the gas path, the effect on the engine maintenance on the long term, and the<br />

effect on the engine washing.<br />

Integration and validation of new parts for the exchange of secondary structures by<br />

composite parts, for weight reduction and other structural benefits.<br />

5 YES Level 1<br />

5-6 YES Clean Sky<br />

CFC 7-8<br />

NC 1<br />

YES Clean Sky<br />

4-9 YES Clean Sky<br />

8-9 No<br />

Feasibility of a glass cockpit replacing analogue instruments in existing aircraft. 8-9 YES Per Type<br />

Alternatives to main engine based taxiing for existing aircraft, such as taxiing on internal<br />

power using electric motors in the main undercarriage, to allow main engines on idle<br />

setting or switched off during taxiing.<br />

4 YES Clean Sky