specialty haulage solutions for construction and ... - Mega Corporation

specialty haulage solutions for construction and ... - Mega Corporation

specialty haulage solutions for construction and ... - Mega Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

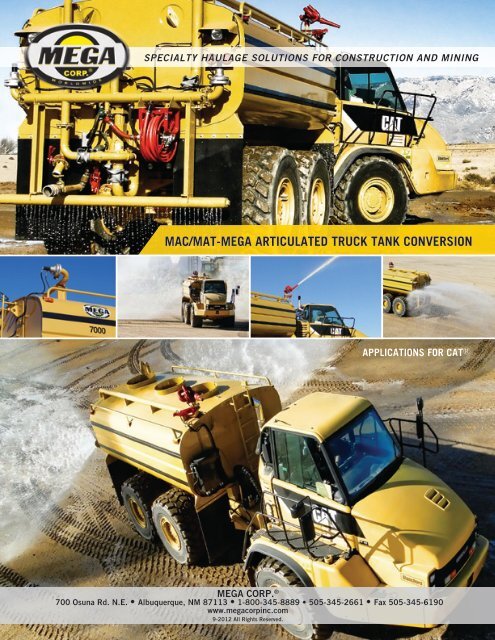

SPECIALTY HAULAGE SOLUTIONS FOR CONSTRUCTION AND MINING<br />

MAC/MAT-MEGA ARTICULATED TRUCK TANK CONVERSION<br />

APPLICATIONS FOR CAT®<br />

MEGA CORP. ®<br />

700 Osuna Rd. N.E. • Albuquerque, NM 87113 • 1-800-345-8889 • 505-345-2661 • Fax 505-345-6190<br />

www.megacorpinc.com<br />

9-2012 All Rights Reserved.

SPECIALTY HAULAGE SOLUTIONS FOR CONSTRUCTION AND MINING<br />

Table of Contents<br />

For over 35 years, <strong>Mega</strong> Corp. has been<br />

manufacturing premium products <strong>for</strong> <strong>specialty</strong><br />

<strong>haulage</strong> use in <strong>construction</strong> <strong>and</strong> mining<br />

applications around the world. From water tanks<br />

<strong>and</strong> coal haulers to <strong>specialty</strong> dumper bodies<br />

<strong>and</strong> equipment trailers, <strong>Mega</strong> has developed<br />

a reputation <strong>for</strong> building quality products <strong>and</strong><br />

providing outst<strong>and</strong>ing product support. Part of<br />

our support includes the sale <strong>and</strong> distribution<br />

of component parts <strong>and</strong> systems <strong>for</strong> <strong>Mega</strong><br />

products as well as <strong>for</strong> competitive br<strong>and</strong>s<br />

which are also available through our website @<br />

www.megacorpinc.com.<br />

You may also find our parts catalog under our<br />

product support page on our website <strong>and</strong> online<br />

parts ordering @ http://www.megacorpinc.com/<br />

parts/main.asp<br />

If you need assistance you can contact us toll<br />

free in the U.S. at 1.800.345.8889 or go to our<br />

contacts page at the end of this publication to<br />

reach any of our <strong>Mega</strong> sales representatives.<br />

We look <strong>for</strong>ward to serving you!<br />

Jim Kunz<br />

President<br />

MAC/MAT-MEGA ARTICULATED TRUCK TANK CONVERSION.... 3<br />

MEGA Anti-Surge Stabilization System (M.A.S.S.).................. 4<br />

MEGA STANDARD FEATURES.................................................. 5-11<br />

MEGA Spray System.......................................................... 5<br />

M3 Water Pump......................................................... 5<br />

MEGA Spray System Cab Control................................ 6<br />

MEGA Spray Heads............................................................ 7<br />

MEGA Hydraulic Spray Head....................................... 7<br />

Rear Spray Bar........................................................... 7<br />

Spray Capability........................................................ 8<br />

Self Loading Capability..................................................... 9<br />

Fill Port............................................................................. 10<br />

Access To Tank................................................................. 10<br />

Safety Grate...................................................................... 10<br />

Ladder & Safety Rails....................................................... 10<br />

LED Lighting & Utility Lights............................................. 11<br />

Direct Pin Mounting.......................................................... 11<br />

Flexible Front Mounting..................................................... 11<br />

Mud Flaps......................................................................... 11<br />

MEGA OPTIONAL FEATURES................................................... 12-15<br />

MEGA Water Cannon......................................................... 12<br />

MEGA Hydraulic Water Cannon.................................. 12<br />

MEGA Electric Water Cannon..................................... 12<br />

MEGA Foam Agent Fire Suppression System.............. 12<br />

MEGA Nozzles.................................................................... 13<br />

Tank Dump Options.......................................................... 14<br />

Spray Head Valve Options................................................. 14<br />

Hose Reel.......................................................................... 15<br />

Corrosion Resistant Options............................................. 15<br />

Fall Protection Tie Off Points............................................. 15<br />

TANK DIMENSIONS................................................................. 16-19<br />

MAC/MAT 5/6 Dimensions.......................................... 16<br />

MAC/MAT 6/7 Dimensions.......................................... 17<br />

MAC/MAT 7/8 Dimensions.......................................... 18<br />

MAC/MAT 8/9 Dimensions.......................................... 19<br />

CONTACTS.............................................................................. 22<br />

MEGA WARRANTY................................................................... 23

MAC/MAT-<strong>Mega</strong> Articulated Truck Tank Conversion<br />

Genuine <strong>Mega</strong> Design with Improved Cost Effectiveness <strong>and</strong> Per<strong>for</strong>mance<br />

MAC/MAT-<strong>Mega</strong> Articulated Conversion tanks are<br />

custom designed <strong>for</strong> the articulated dump truck<br />

chassis. The MAC model tank only kits are <strong>for</strong><br />

dealer installation <strong>and</strong> conversion of either a<br />

new or used chassis. MAC tank kits are shipped<br />

assembled as much as possible to reduce the<br />

amount of labor involved in installation to the<br />

truck chassis. Tank capacities range from 5,000<br />

gallons to 9,000 gallons <strong>and</strong> are available <strong>for</strong><br />

most br<strong>and</strong>s of tractor.<br />

MAT models are Caterpillar ® only tank <strong>and</strong> tractor<br />

combinations with the tractor provided by <strong>Mega</strong>.<br />

The tank <strong>and</strong> tractor are shipped fully assembled<br />

<strong>and</strong> tested at our facility in Albuquerque, NM.<br />

<strong>Mega</strong> Corp. maintains a full time Product<br />

Support staff <strong>for</strong> technical advice <strong>and</strong> after hours<br />

service. Emergency parts ordering is available<br />

after normal business hours via our Product<br />

Support team. Our website offers complete parts<br />

breakdown <strong>and</strong> availability <strong>for</strong> hundreds of our<br />

most common service items. For other tractor<br />

models <strong>and</strong> custom sizes please contact <strong>Mega</strong><br />

or your local dealer <strong>for</strong> more in<strong>for</strong>mation.<br />

Available <strong>Mega</strong> MAC/MAT Water Tanks <strong>for</strong> CATERPILLAR ®<br />

MEGA MODEL<br />

TANK SIZE<br />

CHASSIS CONFIGURATION<br />

3

MASS-MEGA Anti Surge System<br />

WHILE TANKS MAY LOOK SIMILAR ON THE OUTSIDE<br />

– IT’S WHAT’S INSIDE THAT COUNTS!<br />

MEGA Anti-Surge Stabilization System (M.A.S.S.)<br />

The <strong>Mega</strong> Anti Surge System (MASS) tank baffling<br />

design begins with a heavy duty spine that supports<br />

the rear pivot mounting. Line boring the rear pivot<br />

mounts ensures accurate direct pin installation of<br />

the tank. Heavy high strength steels in critical areas<br />

ensure long failure free life of the tank.<br />

Proper loading of the chassis frame ensures load<br />

stability, good machine h<strong>and</strong>ling, <strong>and</strong> long frame<br />

life of the chassis. Front spring type tie down mounts<br />

secure the front of the tank <strong>and</strong> adjustable body<br />

pads ensure that the chassis is properly loaded<br />

<strong>and</strong> balanced. The compartment style baffling built<br />

on top of the strong spine foundation controls the<br />

effects of surging water. Fully welded baffling,<br />

properly located <strong>and</strong> shaped baffles, <strong>and</strong> tightly<br />

controlled quality ensure that your <strong>Mega</strong> tank is<br />

the strongest, most stable, longest lasting tank<br />

available today.<br />

Fully featured spray controls with<br />

st<strong>and</strong>ard water level gauge <strong>and</strong><br />

accessory controls.<br />

Multiple access ports <strong>for</strong> tank filling <strong>and</strong> inspection.<br />

High output, direct coupled<br />

water pump capable of up to<br />

1000 gpm or 100 psi.<br />

Complete integration with tractor<br />

hydraulic system. The most durable<br />

hydraulic spray system on the market.<br />

4<br />

Fully compartmentalized baffling<br />

system <strong>for</strong> superior load stability<br />

<strong>and</strong> long tank life.<br />

Direct pin on mounting with<br />

no welding required.

St<strong>and</strong>ard Features<br />

<strong>Mega</strong> Spray System<br />

The <strong>Mega</strong> spray system begins with our high<br />

per<strong>for</strong>mance M3 water pump. Capable of over<br />

80 psi (551kPa) or over 800 gpm (3028 lpm).<br />

This pump can satisfy the water spraying needs of<br />

any size water tank. Our pump features a heavy<br />

shaft <strong>and</strong> dual bearing set <strong>for</strong> long life. The M3<br />

special features are lifting lugs, jacking points,<br />

rope packing, <strong>and</strong> shaft seal <strong>for</strong> ease of service<br />

<strong>and</strong> maintenance. A complete service <strong>and</strong> repair<br />

manual comes with each <strong>Mega</strong> M3 Water pump.<br />

<strong>Mega</strong> M3 Water Pump<br />

Water Pump Activation<br />

The water pump is actuated <strong>and</strong> operated with the<br />

chassis’ hydraulic hoist pump <strong>and</strong> valve system. When<br />

the water pump is turned on at the in-cab control, the<br />

hoist valve is actuated sending hydraulic oil to the water<br />

pump drive motor. <strong>Mega</strong> spray controls ensure proper<br />

integration with your tractor’s hoist valve <strong>and</strong> ECM.<br />

Return oil from the water pump drive motor drains into<br />

the tractor oil filtration <strong>and</strong> cooling system. <strong>Mega</strong> pump<br />

control systems include water pump soft start <strong>and</strong> shut<br />

down to ensure long pump <strong>and</strong> drive motor life.<br />

Complete specifications of our <strong>Mega</strong> M3 water pump<br />

is available on our website @ www.megacorpinc.com<br />

or by contacting us at 1.800.345.8889.<br />

5

St<strong>and</strong>ard Features<br />

Spray System Cab Control<br />

The <strong>Mega</strong> in-cab spray control module provides independent control of each spray head, water valves<br />

<strong>and</strong> selected options of your <strong>Mega</strong> water tank. Included in the cab control module is our LED water<br />

level gauge display. Our control module is built <strong>for</strong> rugged use in the harshest environments of mining<br />

<strong>and</strong> <strong>construction</strong>.<br />

Spray Control System: Electro - Hydraulic<br />

For the most dem<strong>and</strong>ing mining environments, <strong>and</strong> <strong>for</strong> tractors<br />

without a pneumatic system we provide our hydraulic spray<br />

control system. The cab control operates our proprietary<br />

hydraulic solenoid spray control module that individually<br />

actuates all spray heads <strong>and</strong> water valves on board.<br />

The solenoid module is housed in a weather tight steel housing<br />

(also available in optional stainless steel with our corrosion<br />

resistant package). All wiring/cabling is sealed against the<br />

elements by using high quality cables <strong>and</strong> water proof connectors.<br />

Spray system oil is filtered within the solenoid module housing.<br />

<strong>Mega</strong> fully supports these systems with spare parts <strong>and</strong> full<br />

time Product Support.<br />

Spray Control System: Electro - Pneumatic<br />

For tankers with available pneumatic systems, the water spray<br />

system can be controlled with the <strong>Mega</strong> electro-pneumatic spray<br />

control system. Individual spray heads <strong>and</strong> water control valves are<br />

actuated with regulated <strong>and</strong> filtered air pressure delivered by our<br />

solenoid control system. All wiring/cabling is sealed against the<br />

elements by using high quality cables <strong>and</strong> water proof connectors.<br />

<strong>Mega</strong> fully supports these systems with spare parts <strong>and</strong> full<br />

time Product Support.<br />

Water Level Gauges<br />

There are two LED type water level gauges st<strong>and</strong>ard on MAC/MAT<br />

units with electro-hydraulic spray control systems. One on the<br />

cab control <strong>and</strong> one on the solenoid control housing on the front<br />

bulkhead of the tank <strong>for</strong> easy viewing during tank filling. Both<br />

are reading water level from an electronic sensor mounted on the<br />

bottom of the front bulkhead of the tank.<br />

6<br />

MEGA SPRAY SYSTEM<br />

kits are available <strong>for</strong> application to older<br />

<strong>and</strong>/or competitve models.<br />

Call TODAY <strong>for</strong> more in<strong>for</strong>mation!

St<strong>and</strong>ard Features<br />

<strong>Mega</strong> Spray Head Valves<br />

<strong>Mega</strong> developed <strong>and</strong> patented its spray head valves in 1976<br />

<strong>and</strong> has continually improved them since. Each Genuine<br />

<strong>Mega</strong> spray head valve is fully adjustable <strong>for</strong> fan volume,<br />

width, <strong>and</strong> direction. Spray patterns over 90 feet (27 meters)<br />

wide are normal even with our smaller tanks. Precision<br />

water application is a simple matter of proper selection of<br />

spray head valve settings <strong>and</strong> the number of spray head<br />

valves activated. Optional intermittent spray allows <strong>for</strong><br />

wet-dry patch spray application.<br />

Our spray head valves are available in both pneumatic <strong>and</strong> hydraulic actuated models. St<strong>and</strong>ard<br />

<strong>Mega</strong> spray head valves are constructed of a high quality aluminum alloy metal. We offer optional<br />

anodizing <strong>and</strong> hardening, as well as, stainless steel options to better resist corrosion <strong>and</strong> abrasion<br />

from harsh waters often found in mining environments. Request our spray head valve repair <strong>and</strong><br />

service manual <strong>for</strong> complete step by step service <strong>and</strong> rebuild instructions by calling our parts<br />

department at 1-800-345-8889 or visit our website at www.megacorpinc.com.<br />

<strong>Mega</strong> Hydraulic Spray Head Valves<br />

The <strong>Mega</strong> hydraulic spray head valve utilizes a custom made high quality<br />

heavy duty double acting hydraulic cylinder to open <strong>and</strong> close the valve<br />

portion of the spray head. This spray head valve is suitable <strong>for</strong> any<br />

heavy equipment prime mover <strong>and</strong> requires a hydraulic solenoid spray<br />

control system.<br />

Rear Spray Bar<br />

The st<strong>and</strong>ard <strong>Mega</strong> MAC/MAT rear spray bar on the rear of the tank features three or more Genuine<br />

<strong>Mega</strong> Spray head valves. The rear spray bar is constructed of four inch diameter pipe <strong>and</strong> covers<br />

the entire width of the rear of the tank. The st<strong>and</strong>ard rear spray bar is constructed of carbon<br />

steel pipe. Optional stainless steel spray bars <strong>and</strong> spray heads are available in our corrosion<br />

resistant package.<br />

7

St<strong>and</strong>ard Features<br />

Spray Capability<br />

One fully adjustable Genuine <strong>Mega</strong> spray head valve<br />

powered by the <strong>Mega</strong> M3 water pump will soak a<br />

path over 60 feet wide. The center spray head on<br />

the rear spray bar is the most often used spray.<br />

Additional water can be applied by activating<br />

either of the two st<strong>and</strong>ard outboard spray heads<br />

on the rear spray bar which can be adjusted <strong>for</strong><br />

both direction <strong>and</strong> angle of spray. Maximum spray<br />

width is over 90 feet <strong>and</strong> because of the high flow<br />

output of the M3 pump, 3 spray heads are easily<br />

operated simultaneously.<br />

MEGA SPRAY HEAD VALVES=<br />

MAXIMUM COVERAGE!<br />

Vertical Side Spray<br />

40 Feet<br />

(12 meters)<br />

8<br />

90+Feet<br />

(27 meters)

St<strong>and</strong>ard Features<br />

Self-Loading Capability<br />

All <strong>Mega</strong> MAC/MAT model water tanks feature self-loading ability via the discharge pump. Unique to<br />

<strong>Mega</strong> is a built in priming reservoir inside the water tank that floods the suction line with water when<br />

the valving is switched to load the tank. An auxiliary manual priming pump is also included. Optional<br />

suction hoses can be ordered separately.<br />

Fully adjustable <strong>Mega</strong> Spray Heads<br />

can be adjusted <strong>for</strong> fan width<br />

volume, watering hillsides, berms or<br />

<strong>for</strong> ground penetration <strong>and</strong> soaking.<br />

Swivel couplings allow <strong>for</strong> vertical adjustment of spray.<br />

Water pump discharge valving.<br />

Water pump intake valving.<br />

Manually operated priming pump <strong>for</strong><br />

suction hose.<br />

Suction Hose Connection.<br />

9

St<strong>and</strong>ard Features<br />

All <strong>Mega</strong> tanks are fully abrasive blasted prior to application of heavy anti-corrosive prime paint<br />

then top coated with dealer choice of one color. Tank color is most often matched to the tractor<br />

color. Custom coatings <strong>and</strong> graphics are available upon request.<br />

Fill Ports<br />

Over each tank compartment is a fill port with either a bolt in trash screen<br />

or safety block off to make maintenance of interior coating <strong>and</strong> access to the<br />

tank interior as easy <strong>and</strong> safe as possible.<br />

Safety Grate<br />

A bolt in trash screen safety grate cover is included in each fill port. Conical<br />

shaped fill ports, custom locations, <strong>and</strong> custom design fill ports are available<br />

as optional equipment.<br />

10<br />

Ladder <strong>and</strong> H<strong>and</strong> Rails<br />

All <strong>Mega</strong> tanks include access ladders to the top of the tank. Our st<strong>and</strong>ard<br />

ladder features tread grip rungs <strong>for</strong> a sure footed grip <strong>and</strong> h<strong>and</strong> rails at the top<br />

of the ladder <strong>for</strong> ease of access to the top of the tank. Optional customized<br />

safety railing is available upon request to meet your exact requirements.

St<strong>and</strong>ard Features<br />

Technical Manuals<br />

Each <strong>Mega</strong> MAC/MAT water tank kit includes a technical manual which<br />

includes the Operators, Maintenance, Parts, Service <strong>and</strong> Kit Installation<br />

Guide/Instructions as well as service drawings <strong>and</strong> schematics. Extra sets of<br />

manuals can be purchased. Some of the manuals are available <strong>for</strong> download<br />

in the Product Support section on the <strong>Mega</strong> website at www.megacorpinc.com.<br />

LED Lighting & Utility Lights<br />

All clearance, stop, <strong>and</strong> tail lighting on <strong>Mega</strong> tanks are LED type <strong>for</strong> long life<br />

<strong>and</strong> low maintenance. Two high intensity utility lights are included on the rear<br />

bulkhead of the tank beneath the water shedders.<br />

Direct Pin Mounting With Line-Bored Holes<br />

<strong>Mega</strong> MAC/MAT tanks pin directly to the rear pivot mounts of the truck chassis.<br />

New pivot pins <strong>and</strong> shims are supplied with the tank. Mounting holes are line<br />

bored after welding, no field welding is necessary.<br />

Flexible Front Mounting<br />

The truck chassis is allowed to flex beneath the spring type front mounting tie<br />

downs. Body guides may be added <strong>for</strong> some models.<br />

Mud Flaps<br />

MAC/MAT tanks are equipped st<strong>and</strong>ard with mud flaps in front <strong>and</strong> behind of<br />

the drive tires.<br />

11

Optional Features<br />

Custom options available upon request.<br />

<strong>Mega</strong> Water Cannon<br />

<strong>Mega</strong> water cannons are designed <strong>for</strong> the severe<br />

duty environments of mining <strong>and</strong> <strong>construction</strong>. All<br />

<strong>Mega</strong> Water Cannons feature 2.5 inch (64mm)<br />

diameter stainless steel waterways <strong>and</strong> a unique<br />

permanently lubricated, swivel joint design.<br />

<strong>Mega</strong> Water Cannons are available in both electric<br />

drive (12 or 24 volt) <strong>and</strong> electro-hydraulic drive<br />

(24 volt only) models. We also offer a manually<br />

operated <strong>Mega</strong> Water Cannon suitable <strong>for</strong> both<br />

stationary <strong>and</strong> mobile applications. Kit options<br />

are available <strong>for</strong> the hydraulic <strong>and</strong> electric <strong>Mega</strong><br />

Water Cannons which are tank mounted with<br />

in-cab controls.<br />

Genuine <strong>Mega</strong> Water Cannon<br />

(Shown with Butterfly Valve & Nozzle)<br />

<strong>Mega</strong> Hydraulic Water Cannon<br />

Hydraulic drive motors provide the highest durability <strong>and</strong> very smooth<br />

travel. Our water cannon solenoid control module is dependable <strong>and</strong><br />

easily serviced. Adding an adjustable nozzle is as easy as connecting<br />

the nozzle <strong>and</strong> control lines.<br />

<strong>Mega</strong> Electric Water Cannon<br />

<strong>Mega</strong> Electric Drive Water Cannon Motors allows this water cannon<br />

to be used on nearly any tank with an available 12 or 24 volt power<br />

supply. This monitor allows <strong>for</strong> a wide selection of nozzles <strong>and</strong><br />

provides very smooth travel.<br />

Foam Agent Fire Suppression System<br />

The <strong>Mega</strong> foam agent system allows <strong>for</strong> additional fire<br />

suppression capability through the water cannon. The<br />

system includes 60 gallon (227 liters) or 120 gallon<br />

(454 liters) stainless steel foam agent tank imbedded into<br />

the main water tank, adjustable foam nozzle, <strong>and</strong> actuation<br />

controls. NOTE: system does not include foam agent.<br />

12

Optional Features<br />

Custom options available upon request.<br />

Nozzles<br />

For Specialty <strong>Mega</strong> Water Cannon<br />

Hydraulically Adjustable Nozzles For Hydraulic Drive <strong>Mega</strong> Water Cannon.<br />

Fog To Stream<br />

305875<br />

305876<br />

• Hydraulic Adjustment<br />

• Variable Fog Pattern<br />

• 150 feet stream reach<br />

Fog To Stream With Foam Eduction<br />

• Hydraulic Adjustment<br />

• Variable Fog Pattern<br />

• 150 feet stream reach<br />

• Adjustable fog pattern with foam (1, 3 <strong>and</strong> 6% proportioning)<br />

• System does not include foam agent<br />

• Requires foam agent system<br />

Electrically Adjustable Nozzles For <strong>Mega</strong> Electric Drive Water Cannon.<br />

Fan To Stream<br />

305151<br />

• 140 feet reach<br />

• Adjustable fan pattern<br />

Fog To Stream<br />

• 165 feet reach<br />

• Adjustable fog pattern<br />

305150<br />

Foam Eduction<br />

305149<br />

300656<br />

• 150 feet reach<br />

• Adjustable fog pattern with foam (1, 3 <strong>and</strong> 6% proportioning)<br />

• System does not include foam agent<br />

• Requires foam agent system<br />

Manual Adjustable Hydraulic Nozzle With Foam Eduction<br />

• Manually adjustable fog pattern<br />

• Foam eduction (1, 3 <strong>and</strong> 6% proportioning)<br />

• 150 feet stream reach<br />

• Adjustable fog pattern with foam (1, 3 <strong>and</strong> 6% proportioning)<br />

• System does not include foam agent<br />

• Requires foam agent system<br />

13

Optional Features<br />

Custom options available upon request.<br />

Dump Bar<br />

Tank Dump Options<br />

A dump bar (sometimes called a “drip” or “dribble bar”) is a horizontally<br />

arranged 4 inch diameter carbon steel pipe that is drilled along<br />

its bottom center line with a row of holes. The dump bar can be<br />

either pressurized or non-pressurized. Pressurized dump bars spray<br />

penetrating jets of water directly onto the ground surface the width of<br />

the tank.<br />

Non pressurized dump bars are gravity fed directly from the bottom<br />

of the water tank. An advantage of this tool is that water can be applied <strong>for</strong> dust suppression even in the<br />

event that the water pump is out of service.<br />

Dump Valve – Remote or Manual Operation<br />

The quick dump option is a large drain located at the bottom rear<br />

of the tank. This option is available either manually or hydraulically<br />

actuated in 4 inch (102mm) diameters.<br />

Anti-Siphon Fill Pipe<br />

The anti-siphon fill pipe is used with any pressurized water source.<br />

It is specifically designed to accommodate municipal water systems<br />

<strong>and</strong> fire hydrants requiring an air gap to prevent back siphoning<br />

of water into the supply.<br />

Spray Head Valve Options<br />

Vertical Side Spray<br />

Two spray heads mounted on the front quadrant of the tank with<br />

internal piping <strong>for</strong> spraying vertical fans of water. This spray is<br />

suitable <strong>for</strong> spraying hill sides, piles, <strong>and</strong> berms.<br />

14

Optional Features<br />

Custom options available upon request.<br />

Tank Interior Corrosion Resistance<br />

Epoxy Tank Lining<br />

Tank interior is blasted to a SP10 “near-white” condition, all sharp<br />

corners are rounded <strong>and</strong> voids are filled with special caulking prior to the<br />

tank being fully lined with high quality epoxy coating. This coating resists<br />

acids, salts, alkalis, <strong>and</strong> petroleum distillates.<br />

Moisture Cure Urethane Tank Lining<br />

Tank interior is blasted <strong>and</strong> fully lined with an aluminum filled moisture<br />

cure urethane coating. This is a very tough <strong>and</strong> flexible coating that is<br />

resistant to salty, acidic or alkaline water.<br />

NOTE: Coating data sheet <strong>and</strong> MSDS available upon request.<br />

Other Optional Features<br />

Factory Installation<br />

Water tank fully installed <strong>and</strong> tested at <strong>Mega</strong> Corp. factory in Albuquerque,<br />

New Mexico, U.S.A. (Requires transport of tractor to factory).<br />

Hose Reel - Manual Rewind<br />

Hose reels installed on <strong>Mega</strong> MAC/MAT models include high quality rubber<br />

water hose rated to 120 psi (827 kPa) <strong>and</strong> an adjustable fog to stream nozzle.<br />

Fall Protection Tie Off Points<br />

Optional custom fall protection tie off points are available upon request.<br />

15

MAC-MAT5/6<br />

MAC-MAT5/6<br />

725 ADT SWB-St<strong>and</strong>ard Wheel Base<br />

MAC/MAT5 – 5,000 gallons<br />

(18,925 Liters)<br />

All weights <strong>and</strong> dimensions are subject to change.<br />

725 LWB-Long Wheel Base<br />

MAC/MAT6 – 6,000 gallons<br />

(22,710 Liters)<br />

A Overall Length 405 in 10,287 mm 450 in 11,430 mm<br />

B Overall Height 169 in 4,292 mm 169 in 4,292 mm<br />

C Overall Width 112 in 2,845 mm 112 in 2,845 mm<br />

Tank Kit Weight 9,950 lb 4,513 kg 13,704 lb 6,216 kg<br />

Tank Only Overall Length 220 in 5,588 mm 265 in 6,731 mm<br />

Tank Only Overall Height 95 in 2,413 mm 82 in 2,083 mm<br />

Tank Only Overall Width 114 in 2,896 mm 117 in 2,972 mm<br />

B<br />

A<br />

16<br />

C

MAC-MAT6/7<br />

MAC-MAT6/7<br />

730 ADT SWB-St<strong>and</strong>ard Wheel Base<br />

MAC6 – 6,000 gallons<br />

(22,710 Liters)<br />

All weights <strong>and</strong> dimensions are subject to change.<br />

730 LWB-Long Wheel Base<br />

MAC7 – 7,000 gallons<br />

(26,495 Liters)<br />

A Overall Length 410 in 10,414 mm 469 in 11,887 mm<br />

B Overall Height 170 in 4,318 mm 170 in 4,318 mm<br />

C Overall Width 114 in 2,896 mm 114 in 2,896 mm<br />

Tank Kit Weight 10,650 lb 4,831 kg 13,500 lb 6,124 kg<br />

Tank Only Overall Length 220 in 5,588 mm 278 in 7,062 mm<br />

Tank Only Overall Height 107 in 2,718 mm 107 in 2,718 mm<br />

Tank Only Overall Width 117 in 2,972 mm 117 in 2,972 mm<br />

B<br />

A<br />

C<br />

17

MAC-MAT 7/8<br />

MAC-MAT 7/8<br />

735 ADT SWB-St<strong>and</strong>ard Wheel Base<br />

MAC/MAT7 – 7,000 gallons<br />

(26,495 Liters)<br />

735 LWB-Long Wheel Base<br />

MAC/MAT8 – 8,000 gallons<br />

(30,280 Liters)<br />

A Overall Length 441 in 11,202 mm 512 in 13,005 mm<br />

B Overall Height 185 in 4,699 mm 185 in 4,699 mm<br />

C Overall Width 135 in 3,429 mm 135 in 3,429 mm<br />

Tank Kit Weight 13,000 lb 5,897 kg 15,000 lb 6,804 kg<br />

Tank Only Overall Length 224 in 5,690 mm 295 in 7,493 mm<br />

Tank Only Overall Height 110 in 2,794 mm 110 in 2,794 mm<br />

Tank Only Overall Width 135 in 3,429 mm 135 in 3,429 mm<br />

All weights <strong>and</strong> dimensions are subject to change.<br />

B<br />

A<br />

18<br />

C

MAC-MAT8/9<br />

MAC-MAT 8/9<br />

740 ADT SWB-St<strong>and</strong>ard Wheel Base<br />

MAC/MAT8 – 8,000 gallons<br />

(30,280 Liters)<br />

740 LWB-Long Wheel Base<br />

MAC/MAT9 – 9,000 gallons<br />

(34,065 Liters)<br />

A Overall Length 441 in 11,202 mm 523 in 13,284 mm<br />

B Overall Height 194 in 4,928 mm 194 in 4,928 mm<br />

C Overall Width 135 in 3,429 mm 135 in 3,429 mm<br />

Tank Kit Weight 13,800 lb 6,260 kg 17,500 lb 7,938 kg<br />

Tank Only Overall Length 226 in 5,740 mm 308 in 7,823 mm<br />

Tank Only Overall Height 119 in 3,023 mm 119 in 3,023 mm<br />

Tank Only Overall Width 135 in 2,429 mm 135 in 3,429 mm<br />

All weights <strong>and</strong> dimensions are subject to change.<br />

B<br />

A<br />

C<br />

19

Global Product Support<br />

Parts <strong>and</strong> Product Support available 24 hours a day, seven days a week.<br />

<strong>Mega</strong>’s product support team provides full-time technical support<br />

including parts sales, on-site field assistance, training <strong>and</strong><br />

after-hours emergency parts service. <strong>Mega</strong> maintains a complete<br />

inventory of repair <strong>and</strong> maintenance parts <strong>for</strong> all of its products<br />

including accessory kits, <strong>and</strong> support packages <strong>for</strong><br />

immediate shipment. <strong>Mega</strong> parts are also available at<br />

Caterpillar ® dealer’s parts counters<br />

worldwide through the Caterpillar®<br />

ANTARES SM parts network. Call today<br />

<strong>for</strong> more in<strong>for</strong>mation on ordering parts or<br />

visit our website:<br />

Se Habla Español!<br />

www.megacorpinc.com<br />

Recommended Support Parts Package<br />

Out in the field? Need parts? Our spare parts package can be custom configured <strong>for</strong> single<br />

tanks to entire fleets. Please contact us at 1-800-345-8889 or your sales representative<br />

<strong>for</strong> more in<strong>for</strong>mation.<br />

20<br />

VISIT OUR WEBSITE FOR MORE INFORMATION ON OUR PARTS AT WWW.MEGACORPINC.COM!

We Reach Out Globally to Take Care Of You<br />

We are the world’s leading manufacturer<br />

of <strong>specialty</strong> <strong>haulage</strong> equipment <strong>for</strong> the<br />

<strong>construction</strong> & mining industry. For over 35<br />

years, <strong>Mega</strong> has been responsible <strong>for</strong> the<br />

design, development, manufacture, marketing<br />

<strong>and</strong> sale of products used in surface mining<br />

<strong>and</strong> <strong>construction</strong> projects worldwide.<br />

<strong>Mega</strong>’s products include all varieties of<br />

water <strong>haulage</strong> equipment, 34 yard elevating<br />

scrapers, coal haulers, bottom-dump trailers,<br />

equipment transports, <strong>specialty</strong> dumper bodies,<br />

mobile pumps, <strong>and</strong> st<strong>and</strong> tanks, as well as<br />

parts service <strong>and</strong> technical support. <strong>Mega</strong>’s<br />

products are manufactured at its headquarters<br />

in Albuquerque, New Mexico, U.S.A. as well<br />

as by its partners in South Africa, Columbia,<br />

United Kingdom <strong>and</strong> Chile.<br />

Support Material<br />

MEGA offers a full-line of publications <strong>for</strong> its products including<br />

operator, service, parts <strong>and</strong> maintenance manuals as well as<br />

drawings <strong>for</strong> installation guides <strong>and</strong> schematics.<br />

Full-time Quality Control Inspection Staff<br />

• Inspection of weldment to AWS D1.1 st<strong>and</strong>ard during<br />

<strong>and</strong> after fabrication.<br />

• Compliance with applicable SAE ISO, <strong>and</strong> DOT st<strong>and</strong>ards.<br />

• Complete product documentation including drawings, parts<br />

<strong>and</strong> operation manuals.<br />

• Fully functional 60+ minute operation of all installed products prior to shipment.<br />

• Compliance with Caterpillar® hydraulic cleanliness specifications including use of Caterpillar®<br />

hydraulic kidney system <strong>and</strong> particle inspection of hydraulic oil samples.<br />

21

MEET YOUR MEGA SALES TEAM!<br />

PLEASE CONTACT US WITH<br />

ANY INQUIRIES OR QUESTIONS.<br />

Claudio Córdova M.<br />

Independent Sales Representative<br />

Latin America<br />

ccordova@megacorpinc.cl<br />

011-56996476128<br />

Norm Redenshek<br />

Product Support Manager<br />

Regional Sales Manager<br />

nredenshek@megacorpinc.com<br />

505-341-6987<br />

Paul Dornberger<br />

Independent Sales Representative-<br />

Europe/Africa/Middle East<br />

pdornberger@megacorpinc.com<br />

+41 22 751 0020<br />

Jeff Linn<br />

Director-Sales, Marketing<br />

& Product Support<br />

jlinn@megacorpinc.com<br />

505-345-2661<br />

John Stubbs<br />

Parts Sales Manager<br />

Regional Sales Manager<br />

jstubbs@megacorpinc.com<br />

505-259-5975<br />

Jennifer Gockley<br />

Sales Administrator<br />

jgockley@megacorpinc.com<br />

505-341-6998<br />

Bill Taylor<br />

Product Support Sales Representative<br />

btaylor@megacorpinc.com<br />

505-341-6988<br />

David Holly<br />

Product Support Technician<br />

dholly@megacorpinc.com<br />

505-341-6990<br />

Jose Barraza<br />

Parts Sales<br />

jbarraza@megacorpinc.com<br />

505-341-6969<br />

Miguel Galaviz<br />

Parts Sales<br />

mgalaviz@megacorpinc.com<br />

505-341-6986

Warranty Coverage For Your <strong>Mega</strong> Equipment<br />

Protecting your investment.<br />

<strong>Mega</strong> provides a full one year warranty,<br />

unlimited hours against defects in materials <strong>and</strong> workmanship.

CHECK US OUT ON THE WEB Optional @ Features<br />

Custom options available upon request.<br />

WWW.MEGACORPINC.COM<br />

ONLINE PARTS ORDERING IS NOW AVAILABLE!<br />

In response to customer requests, <strong>Mega</strong> has added online<br />

ordering capability to our website. Customers can browse<br />

through approximately 700 of our most commonly-ordered<br />

parts <strong>and</strong> place orders using both PO's <strong>and</strong> credit cards.<br />

Customers will need to register on-line to access this service.<br />

Pricing on the web, including any applicable discounts <strong>and</strong><br />

shipping, will be the same as if the order were placed via<br />

telephone. Along with parts ordering, <strong>Mega</strong> has refreshed<br />

the look <strong>and</strong> functionality of the website to improve its use.<br />

Check us out at: www.megacorpinc.com.<br />

Order Parts!<br />

Illustrated Parts<br />

Breakdowns!<br />

Set up your account<br />

TODAY!<br />

MEGA Corp. <strong>and</strong> its respective logos as well as corporate <strong>and</strong> product identity used<br />

herein, are trademarks of <strong>Mega</strong> Corp. <strong>and</strong> may not be used without permission.<br />

© 2012 <strong>Mega</strong> Corp. All rights reserved.<br />

For more in<strong>for</strong>mation please visit us on the<br />

web at www.megacorpinc.com<br />

MEGA retains all copyrights in any text, graphic images, <strong>and</strong> content owned by<br />

MEGA Corp. <strong>and</strong> hereby authorizes you to electronically copy documents published<br />

herein solely <strong>for</strong> the purpose of transmitting or viewing the in<strong>for</strong>mation.<br />

You may not mirror, modify or otherwise alter any files <strong>for</strong> rebroadcast, or print the<br />

in<strong>for</strong>mation contained therein, without written permission from MEGA Corp.<br />

Materials <strong>and</strong> specifications are subject to change without notice. Featured machines<br />

in photos may include additional equipment. See your dealer <strong>for</strong> available options. 24