working life - Wallenius Wilhelmsen Logistics

working life - Wallenius Wilhelmsen Logistics

working life - Wallenius Wilhelmsen Logistics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

outes<br />

wallenius wilhelmsen logistics magazine for employees<br />

#2.2007<br />

ford awards wwl top supplier price 12<br />

rune gisvold – the man who likes to be in control 15<br />

wwf and wwl join forces to save bluefin tuna 18<br />

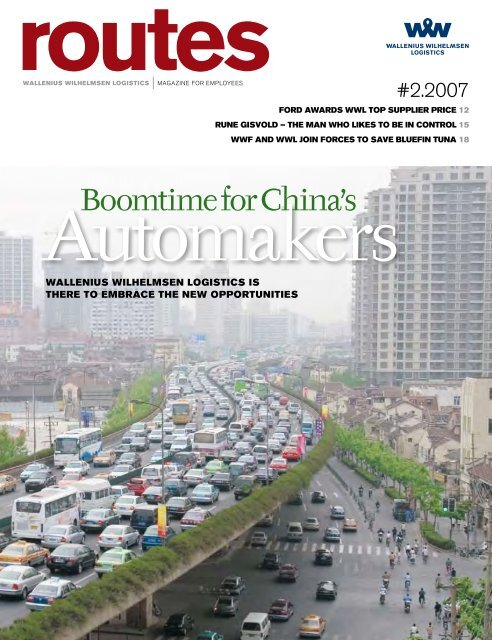

Boomtime for China’s<br />

Automakers<br />

wallenius wilhelmsen logistics is<br />

there to embrace the new opportunities

outes<br />

contents issue 2.2007<br />

THEME<br />

CHina’S BOOMing CaR<br />

indUSTRy dRivES lOgiSTiCS<br />

The demand for cars domestically in China is growing explosively.<br />

Production and sales are expected to double over the next five<br />

years. Mounting auto exports and imports are driving the need for<br />

improved logistics and supply chain management solutions of the<br />

kind delivered by <strong>Wallenius</strong> <strong>Wilhelmsen</strong> <strong>Logistics</strong>.<br />

04 inspiration<br />

WWL has signed a Lead <strong>Logistics</strong> pro-<br />

vider contract With BMW to deLiver its<br />

cars froM europe to austraLia and neW<br />

zeaLand. BMW has noW got a cutting<br />

edge soLution to suppLy the tWo Mar-<br />

kets More efficientLy and econoMicaLLy.<br />

ROUTES 2 2007<br />

8<br />

22 <strong>working</strong> <strong>life</strong><br />

22 the office: south africa<br />

23 knoWLedge schooL: ocean<br />

pLanning and reporting<br />

24 douBLe identity: MuLtiLinguaL<br />

MartiaL arts<br />

25 on the ocean: 75 years<br />

under sydney harBour Bridge<br />

1<br />

CUSTOMER CaSE<br />

gETTing THE RigHT<br />

CaR TO THE RigHT pORT<br />

<strong>Wallenius</strong> <strong>Wilhelmsen</strong> <strong>Logistics</strong> won a top award from Ford<br />

Australia for helping the carmaker develop and implement an<br />

innovative logistics solution. Dubbed ‘Right Car, Right Port’, WWL<br />

helped come up with a way to build flexibility into a supply chain<br />

that had been traditionally fairly rigid.<br />

26 our industry<br />

even Larger vesseLs in the pipeLine<br />

threatened the LiveLihood of the panaMa<br />

canaL. But the WaterWay has fought<br />

Back With innovative neW Ways to han-<br />

dLe the Bigger vesseLs expected in 2015.

18<br />

SUSTainaBiliTy<br />

gianT Of THE aTlanTiC<br />

ClOSE TO ExTinCTiOn<br />

WWF and <strong>Wallenius</strong> <strong>Wilhelmsen</strong> <strong>Logistics</strong> have joined forces<br />

to help save the giant bluefin tuna from extinction as a result<br />

of overfishing.<br />

puBLished By <strong>Wallenius</strong> <strong>Wilhelmsen</strong> <strong>Logistics</strong> AS, Box 38193, SE-100 64 Stockholm, Sweden<br />

editor Martha Thernsjö acting puBLisher responsiBLe under sWedish<br />

press LaW Martha Thernsjö editoriaL production Tidningskompaniet Stockholm<br />

environMentaL care This magazine is produced in accordance with the Nordic eco-labelling<br />

system, the Swan front cover Rush hour in Shanghai, China. Photo: Jackson Lowen.<br />

We Want your vieWs! Do you have any comments on Routes? Is there anything you would<br />

like to read about or are there things that you don’t like and would like to change? Send an e-mail<br />

to routes@2wglobal.com next issue September 2007 copyright Texts and images in Routes<br />

may not be republished without permission from the editor or publisher responsible.<br />

EdiTORial: CREaTing valUE<br />

fOR OUR CUSTOMERS<br />

the first tWo Months in my<br />

new job as CEO has given me a<br />

number of opportunities to visit operations<br />

around the world, talk to many<br />

colleagues and<br />

better understand<br />

how we are<br />

able to live our<br />

ambitious factoryto-dealer<br />

strategy.<br />

this aLso<br />

coincided with<br />

our regional<br />

discussions on<br />

updating our long term strategy and<br />

deciding how we prioritise our initiatives<br />

to ensure we can deliver on<br />

the strategy and grow the business.<br />

a key factor here is obviously<br />

the tonnage situation, which will definitely<br />

change for the better as we<br />

go into 2008. We have a very close<br />

dialogue with our owners about our<br />

tonnage requirements for the period<br />

up to 2014. For the total of <strong>Wallenius</strong><br />

Lines and Wilh. <strong>Wilhelmsen</strong>, we<br />

now receive a new vessel from the<br />

yards almost every month.<br />

another key factor is how we<br />

manage to develop our global terminal<br />

network – both in terms of operational<br />

excellence, expansion of existing terminals<br />

and pursuit of new terminals to<br />

secure prioritised berthing, particularly<br />

in emerging markets.<br />

We need to Be excellent in Supply<br />

Chain Management in order to create<br />

that added value for our customers.<br />

We will target opportunities primarily<br />

with existing key customers to expand<br />

their outsourcing of finished vehicle<br />

logistics. This should help get their<br />

cargo quicker to its final destination,<br />

with better quality and at a lower cost.<br />

Last, But not<br />

least, we will<br />

continue to<br />

focus hard on<br />

minimising the<br />

impact our business<br />

has on the<br />

environment,<br />

with a specific<br />

focus on reducing<br />

total emissions. This will help<br />

maintain our leading position.<br />

“WE nEEd TO BE Ex-<br />

CEllEnT in SUpply<br />

CHain ManagEMEnT<br />

in ORdER TO CREaTE<br />

THaT addEd valUE<br />

fOR OUR CUSTOMERS.”<br />

i WiLL soon Launch my own blog<br />

on the corporate intranet. I hope you<br />

will use that opportunity to have a direct<br />

dialogue with me on issues you<br />

think are important for the growth<br />

and success of our great company.<br />

ariLd B. iversen<br />

Ceo<br />

wallenius wilhelmsen logistiCs<br />

anita arntzen<br />

ROUTES 2 2007

inspiration<br />

people who care about making a difference<br />

InSpIRIng landbRIdgE<br />

since late 2006 WWL has faced exploding volumes<br />

in several Global Trade Lanes with significant growth<br />

in the Asia-Europe segment. An inspiring ‘Landbridge’<br />

solution in the USA has helped to ease the pressure.<br />

Tonnage capacity has grown tight for cargo moving<br />

from Asia to North America, sparking the need for<br />

a creative solution to keep up with the volume growth<br />

and meet capacity demands from WWL customers.<br />

Together with the Trade and Commercial teams in<br />

Oslo, Tokyo, and Region Americas, Dave Minetti, head of<br />

Americas Trade Atlantic/Pacific/Oceania, and the Americas<br />

Trade Team agreed that ‘landbridging’ cargo from the<br />

US West Coast to end destinations across the USA would<br />

deliver key benefits. It would increase vessel capacity by<br />

shortening the overall voyage time and also deliver cargo<br />

to its final destination in the Mid West, South Atlantic, and<br />

US East Coast on, or before its original arrival date.<br />

“The first vessel for Landbridge was the M/V<br />

Tampere and the volume involved was impressive.<br />

But with the help of our friends at Vehicle Services<br />

Americas (VSA) and Pacific and Atlantic Vehicle<br />

Processors (PVP/AVP), we safely railed 1,175 GMDAT<br />

vehicles to Brunswick, Georgia and Port Newark,<br />

New Jersey, and trucked 401 Suzuki vehicles to PVP<br />

in Port Hueneme. We contracted Keen Transport to<br />

ROUTES 2 2007<br />

n who: John Felitto,<br />

Dave Minetti<br />

n what: Delivering innovative solutions<br />

n where: USA<br />

truck 389 excavators plus parts to various port and<br />

inland destinations. This was all achieved on, or before<br />

the intended delivery date at the original point of final<br />

destination,” says Dave.<br />

This challenging initiative required the support and<br />

coordination from several teams, including Customer<br />

Care, Cargo Management, Port Operations, Cargo Quality,<br />

Cargo Claims, Legal, Contract Management, Sales,<br />

Technical Services (VSA & PVP/AVP), Terminal Services,<br />

Inland Distribution and Trade. John Felitto, Senior<br />

Vice President Commercial, Region Americas, notes:<br />

“This Landbridge solution demonstrates WWL has the<br />

vast expertise to handle customer requirements at sea and<br />

on land. It represents WWL’s dedication to delivering integrated<br />

and seamless logistic solutions to our customers.”<br />

Dave believes the success of the project may<br />

lead to further opportunities for WWL’s customers to<br />

shorten transportation timelines via Landbridge.<br />

“Once again, our strongest asset, our people,<br />

delivered with excellence.”<br />

ThE SlEEpIng<br />

gIanT’S hOpE<br />

n who: Michael Doran<br />

n what: Driving Indian<br />

business<br />

n where: Mumbai, India<br />

india’s economy is booming.<br />

A report from investment bank<br />

Goldman Sachs says India could<br />

have the world’s fifth largest<br />

economy within a decade as its<br />

growth accelerates.<br />

WWL is taking its first key<br />

step to seize a slice of the action<br />

by opening an office in Mumbai,<br />

a vibrant Arabian Sea port and<br />

India’s commercial capital. Heading<br />

the new office in the bustling<br />

city of 13 million inhabitants will<br />

be Michael Doran, moving from<br />

WWL Australia to become Head<br />

of Business Development in India.<br />

“My main focus will be looking<br />

at opportunities for WWL across<br />

our five product offerings and<br />

building relationships,” Michael<br />

tells Routes. “We will focus on<br />

what our Corporate Accounts<br />

team will be doing in India in the<br />

short, medium, and long term.”<br />

Michael, who admits to being<br />

sales-focused, says the potential<br />

is huge.<br />

“India is a sleeping giant. I am<br />

very excited about the new job<br />

because India will offer us both<br />

opportunities and challenges<br />

in the field of factory to dealer<br />

vehicle logistics.”

managIng<br />

hIghER cOSTS<br />

n who: Konrad Kurz<br />

n what: Ready to meet<br />

change<br />

n where: Germany/Europe<br />

strict european union (EU)<br />

rules protecting workers by limiting<br />

the time a truck driver can spend<br />

on the road threaten to drive up<br />

the cost of transported goods, but<br />

WWL is geared up to meet the<br />

challenge.<br />

“We’ve equipped our trucks with<br />

costly new electronic equipment to<br />

monitor driver hours,” says Konrad<br />

Kurz, Managing Director WWL<br />

Germany. “A bonus is that monitoring<br />

work time online will help us to<br />

plan transport logistics better than<br />

ever before.”<br />

According to Konrad the regulations<br />

pose the biggest threat to<br />

Europe’s transport industry today.<br />

“Cutting the work week from<br />

today’s 60 hours to 48 will theoretically<br />

mean increasing the number<br />

of drivers by 25 percent. We<br />

believe the new rules could lead<br />

to a knock-on nine percent cost<br />

increase for road transportation.”<br />

Germany is the latest EU<br />

country to adopt similar recommendations<br />

for drivers, albeit less<br />

restrictive than in France, setting<br />

minimal standards for <strong>working</strong> time,<br />

driving and rest periods.<br />

dEvElOpIng TOp TalEnT<br />

n who: Eivind Garshol<br />

n what: Developing future<br />

management<br />

n where: Oslo, Norway<br />

when wwl launches a new<br />

15-month global trainee programme<br />

for nine young talents,<br />

it’s with a very clear agenda.<br />

Eivind Garshol, head of Global HR<br />

Policies and Practices explains the<br />

main objective in the programme:<br />

“It’s very important for a<br />

company like ours to develop<br />

future management and expert<br />

candidates with a global mindset<br />

and network.”<br />

The nine trainees, six women<br />

and three men, come from all<br />

four regions as well as the central<br />

office and they will work their<br />

way through the organisation<br />

and product areas. The goal is to<br />

offer employment to everyone at<br />

the end of the programme and to<br />

retain them within WWL long term.<br />

The first traineeship was successful.<br />

Valuable lessons were<br />

learned and are applied in this<br />

second program.<br />

“One main improvement for this<br />

second traineeship is that we have<br />

expressed clearly the ambition levels<br />

we have for each trainee – and<br />

what kind of position we want to<br />

offer them afterward. The trainees<br />

will be designated roles and tasks<br />

throughout the programme that are<br />

in line with their targeted future<br />

position,” says Eivind.<br />

With companies fighting for<br />

talent around the world, it’s vital<br />

to be an attractive employer,<br />

says Eivind:<br />

“A traineeship programme is<br />

a way to position ourselves in the<br />

labour market and in the minds of<br />

young talent.”<br />

aTTRacTIng<br />

cUSTOmERS<br />

n who: Fabio Mello<br />

n what: Customer<br />

net<strong>working</strong><br />

n where: Sao Paulo, Brazil<br />

for three days in April, the<br />

Brazilian city of Sao Paulo was<br />

the focus of the global logistics<br />

industry, hosting the InterModal<br />

Trade Fair, now in its 12th year.<br />

WWL – one of 400 participating<br />

companies – had a particularly<br />

successful time, attracting record<br />

numbers of customers to its<br />

stand, according to Fabio Mello,<br />

Manager South American Sales.<br />

“InterModal is Latin America’s<br />

most important trade show for<br />

logistics and transport markets.<br />

It is a great opportunity to network<br />

with customers and meet<br />

new contacts. It also provides a<br />

great opportunity for our customers<br />

to meet WWL team members<br />

<strong>working</strong> in operations, customer<br />

care and management.”<br />

Over 1,000 people a day visit<br />

the InterModal trade fair. WWL’s<br />

main goal at InterModal is to communicate<br />

and market its brand<br />

and promote its five products<br />

– Ocean Services, Terminal Services,<br />

Technical Services, Inland<br />

Distribution and Supply Chain<br />

Management – to customers.<br />

Fabio is ecstatic about WWL’s<br />

showing in 2007: “It was our best<br />

effort ever with between 70–100<br />

customers visiting the stand<br />

every day. We got to meet new<br />

customers and develop fresh<br />

business opportunities, all on the<br />

relaxing environment of the stand<br />

and helped by the WWL staff.”<br />

ROUTES 2 2007

inspiration<br />

IN THE CARGO<br />

kEEpIng TRack Of bmw<br />

for a great many drivers of all ages,<br />

a BMW is the ‘ultimate driving machine’.<br />

Founded in 1916, BMW prides itself on being<br />

one of the few manufacturers of automobiles<br />

and motorcycles worldwide that concentrates<br />

entirely on premium standards and<br />

outstanding quality.<br />

It is a quality-focused philosophy shared<br />

by <strong>Wallenius</strong> <strong>Wilhelmsen</strong> <strong>Logistics</strong> in delivering<br />

on a Lead <strong>Logistics</strong> Provider (LLP) contract<br />

with BMW AG. Under the terms of the<br />

contract, WWL ships the automaker’s vehicles<br />

from five BMW Group factories in Europe, one<br />

factory in the USA and one factory in South<br />

Africa to Australia and New Zealand on the<br />

other side of the world.<br />

WWL exclusively developed its service for<br />

BMW tailored to the carmaker’s specific requirements.<br />

According to Joris Verhaag, <strong>Logistics</strong><br />

Contract Manager for Automotive Contracts<br />

Germany, WWL has provided BMW with a<br />

cutting edge solution in supplying the Australian<br />

and New Zealand market with their products.<br />

“Our ability to deliver LLP contracts<br />

through our global network is really a differentiator<br />

in the RoRo industry,” he says.<br />

bmw has been delighted by the joint effort<br />

with WWL to reduce the lead time by managing<br />

vehicle flow more efficiently. As a result<br />

BMW is able to significantly reduce capital lock<br />

up costs and achieve a shorter time to market.<br />

BMW’s vehicle offering encompasses<br />

Sedans and Estates, Coupés, Convertibles,<br />

Roadsters and Sports Activity Vehicles. With<br />

BMW Group at a glance<br />

BMW: Founded 1916<br />

Employees: 106,000 worldwide<br />

Sales: In the first quarter of 2007, the BMW<br />

Group delivered 333,276 BMW, MINI and<br />

Rolls-Royce brand automobiles<br />

Production: BMW Group manufactures at<br />

ROUTES 2 2007<br />

the three brands, BMW, MINI and Rolls-Royce<br />

Motor Cars, the BMW Group has established<br />

a widespread reputation for its pursuit of<br />

quality.<br />

the result of BMW’s firm focus on the<br />

premium sector of the international auto<br />

market is reflected in automobiles and motorcycles<br />

that fascinate people around the world.<br />

And win new admirers every day.<br />

Designed to save time and money for<br />

BMW, WWL’s contract resulted from several<br />

years of intensive concept studies. The<br />

research was aimed at developing a supply<br />

chain package that could efficiently keep<br />

track of the thousands of BMW and MINI<br />

vehicles shipped to Oceania each year.<br />

employing 106,000 people, BMW manufactures<br />

its models at 23 sites in 13 countries<br />

on four continents. The WWL contract<br />

encompasses cars being made at seven of<br />

BMW’s factories and destined for Australia<br />

and New Zealand.<br />

WWL is also saving BMW substantial<br />

management time by providing them with<br />

a one-stop solution in terms of only having<br />

to interact with one service provider rather<br />

than several along the supply chain. For example,<br />

as it is not possible to keep track<br />

of such a large volume of vehicles through<br />

an excel sheet, WWL’s order management<br />

system automates and speeds up the process,<br />

cutting out room for human error.<br />

alannah eames<br />

23 sites in 13 countries on four continents,<br />

including seven plants in Germany<br />

Model series: BMW 1 Series, 3 Series,<br />

5 Series, 6 Series, 7 Series, BMW X3,<br />

BMW X5, BMW Z4, MINI and Rolls-Royce<br />

Phantom<br />

photo: arnaud siquet

ROUTES 2 2007

Just 15 years ago, the bicycle was<br />

China’s main means of transport<br />

with only 5.7 vehicles for every<br />

1,000 people. The times have clearly<br />

changed – the figure today is<br />

33 vehicles per 1,000 people.<br />

ROUTES 2 2007<br />

photo: scanpix

China<br />

yesterday &<br />

tomorrow<br />

China is one of the world’s fastest growing<br />

economies. One sign is how Chinese<br />

citizens are swapping their bicycles for cars.<br />

With a foothold in China, WWL is geared to<br />

embrace the changes and emerging opportunities<br />

sweeping China into the future.<br />

WORdS alannah EamEs phOTO jackson lowEn<br />

Evening rush hour on<br />

the Chengdu elevated<br />

road in Shanghai, one of<br />

many Chinese cities that<br />

are rebuilding its roads<br />

to meet the increasing<br />

car traffic.<br />

ROUTES 2 2007

10 ROUTES 2 2007<br />

ChINa auTO marKET bOOmS<br />

WWL ServiceS<br />

in china<br />

Ocean services (China express;<br />

shuttle service twice monthly from<br />

Japan to China; direct service to<br />

Europe and North Africa, monthly service<br />

from Guangzhou to Europe). The<br />

plan now is to strengthen the ocean<br />

product from northern China outbound.<br />

Technical services: Pre Delivery Inspection<br />

(PDI) in Tianjin doing terminal<br />

handling and customer cleaning.<br />

Inland distribution: Managing Vehicle<br />

Distribution Centre (VDC) and vehicle<br />

distribution for BMW in southern China.<br />

Offices: Dalian, Tianjin, Shanghai,<br />

Guangzhou and Beijing.<br />

Ports: Tianjin, Shanghai and<br />

Guangzhou. Ad hoc from Dalian.<br />

Number of employees: 55.<br />

<strong>Wallenius</strong> <strong>Wilhelmsen</strong> <strong>Logistics</strong> has<br />

had a presence in China for over a<br />

century. Records show that Wilh.<br />

<strong>Wilhelmsen</strong> vessels called at Chinese<br />

ports in the late 1880s. In 1994,<br />

the company was registered as a wholly owned foreign<br />

enterprise.<br />

Recently, China’s economy has boomed. As Trond<br />

Tønjum, Managing Director of <strong>Wallenius</strong> <strong>Wilhelmsen</strong><br />

<strong>Logistics</strong> China says:<br />

“What we have seen in China is that the domestic<br />

market’s demand for vehicles is growing tremendously.<br />

For the next five years we estimate that it will double<br />

both in production and sales. Exports and imports are<br />

also growing, but with a moderate volume compared<br />

to mature markets. We expect these areas to triple during<br />

the same period.”<br />

During the 1980s and 1990s, western vehicle manufacturers<br />

rushed to set up joint ventures with local Chinese<br />

companies, the majority of which focused on sales in<br />

the domestic market. The export of western brands from<br />

these joint ventures has been low, due to the domestic<br />

focus and Chinese legislation. However, exports of Chinese<br />

brands such as Chery, FAW, Great Wall, Brilliance<br />

and SAIC are growing, mainly to the Middle East, North<br />

Africa, Russia, South East Asia and South America.<br />

in 2006, china ExportEd around 200,000 built-up,<br />

finished cars. According to Trond, trucks and buses<br />

are showing large export growth and will be very important<br />

for WWL China in the future.<br />

“Good sustainable logistics solutions will be increasingly<br />

important for the Chinese manufacturers<br />

as they enter western markets. Western demands are<br />

much more complex than those<br />

currently found in their own mar-<br />

ket. The Chinese need to get their<br />

supply chain management right to<br />

succeed,” Trond states.<br />

Meanwhile, within the domestic<br />

market, there is also a need for<br />

improved supply chains. Today,<br />

most Chinese manufacturers are<br />

strong in their local provinces and<br />

transport vehicles by truck from<br />

plant to dealer. As they start to<br />

expand their sales reach, there is a<br />

need to diversify distribution methods<br />

from being heavily dependent<br />

on road transportation to better use<br />

of river, coast and rail transport. Increased<br />

use of distribution hubs will<br />

be essential to improve domestic<br />

logistics.<br />

“WWL’s strategy is to cater for<br />

Vivian Zhang, team leader, Karl Yang and Liu Jun,<br />

<strong>Logistics</strong> Co-ordinators, carry out inspection for<br />

customs clearance on GEFCO import vehicles in Tianjin.<br />

exports and imports. However, understanding the<br />

domestic market is key when we procure land based<br />

distribution services on behalf of our customers,”<br />

Trond emphasises.<br />

It has not been difficult for WWL to win the trust of Chinese<br />

manufacturers to handle their shipments overseas.<br />

“We exported 70 percent of Chery’s finished vehicles<br />

last year,” says Trond. “It is a challenge to provide<br />

ocean capacity but we are building up our product<br />

offerings in China. It is a growing market and we will<br />

grow even more as we have a good position in the market<br />

based on our global reach.”<br />

However, at the same time he admits that, “Some<br />

customers have never even seen a RoRo vessel,<br />

others limit their logistics to truck transportation.<br />

We help them see the benefits of securing the quality<br />

and optimal solutions they need to expand their sales<br />

nationally and internationally.”<br />

thE pErsEvErancE and hard work is paying off and<br />

the contracts are increasing. The BMW contract has<br />

been renewed and WWL will distribute BMW vehicles<br />

in south China.<br />

“We see great potential to secure more contracts<br />

in this area, and are currently <strong>working</strong> with several<br />

manufacturers to come up with smart solutions to<br />

match their needs,” says Trond.<br />

While WWL’s products are developing in China, several<br />

challenges in this booming economy still remain.<br />

“In China, development can go very quickly, while<br />

other things can take time. This is not surprising as it<br />

is an emerging market and many things are done for<br />

the first time. To know and be part of the culture is the<br />

only way,” Trond explains.<br />

photo: richard ma

����������������������<br />

������������������<br />

�������������<br />

��<br />

��<br />

�<br />

�<br />

�<br />

�<br />

�<br />

����������������������<br />

�������� �����<br />

����<br />

����<br />

����<br />

����<br />

����<br />

����<br />

����<br />

����<br />

����<br />

����<br />

���������������������<br />

�������������������<br />

���������������<br />

�������<br />

���<br />

�����������<br />

���<br />

�����<br />

��<br />

������������<br />

��� ������<br />

���<br />

���������<br />

��������������<br />

�����<br />

���<br />

��������<br />

���<br />

�������������������������������������������������������������������<br />

Trond Tønjum, managing<br />

Director, WWL in<br />

China and Qi Yumin,<br />

President of brilliance<br />

auto, exchanging<br />

gifts in February this<br />

year at the loading of<br />

the first 500 brilliance<br />

cars in Dalian, destined<br />

for Europe.<br />

average auto<br />

sales growth in<br />

China over 5 year<br />

period 2007–2012<br />

= %<br />

photo: richard ma<br />

ROUTES 2 2007 11

Right car to the<br />

right port<br />

You live in Melbourne, Australia. You have<br />

just purchased a new Ford Focus that is<br />

built in South Africa around 10,000 kilometres<br />

away. Neither you, nor Ford, want you<br />

to wait unnecessarily for your shiny new car<br />

to be delivered, which is where <strong>Wallenius</strong><br />

<strong>Wilhelmsen</strong> <strong>Logistics</strong> enters the picture.<br />

WORDS DAVID NOBLE PHOTOS EAmON gALLAghEr<br />

12 ROUTES 2 2007<br />

WWL’s Craig Heron<br />

has helped Ford drive<br />

its ‘Right Car, Right<br />

Port’ project forward<br />

successfully.<br />

When companies talk about getting<br />

their supply chains right what<br />

they are talking about is getting<br />

products to customers in the most<br />

efficient and cost effective way<br />

possible. For Ford Australia that translates into getting<br />

Ford Focus cars and other vehicles in its ranges from<br />

their production facilities in Europe, South Africa,<br />

Asia and elsewhere to end customers around the globe.<br />

Ensuring supply chain logistics function in a reliable,<br />

efficient and timely manner is no easy task in<br />

today’s global marketplace. It demands knowledge and<br />

science to constantly improve ways of moving products<br />

in response to customers’ changing needs. For Ford<br />

this means not only moving cars from one continent to<br />

another, but also across the continents themselves and<br />

not always to the original projected destination.<br />

But what can appear a logistics nightmare to some

is a vision of possibility for WWL. In fact, so successful<br />

has the company been in delivering innovative<br />

logistics solutions that Ford Australia recently gave<br />

WWL membership of its family of elite suppliers.<br />

ThE FOrD mOTOr COmpANy in Australia awarded<br />

WWL a 2006 Ford Supplier Excellence Silver Award<br />

that recognises “suppliers who not only achieve the<br />

highest levels of cost, quality and delivery, but also<br />

who embrace the vision to build on Ford’s legacy and<br />

drive innovation to new heights”.<br />

Sam Casabene, Vice President Purchasing, Ford<br />

Motor Company Australia explains that WWL won the<br />

prestigious accolade because it had been proactive in<br />

the technological and planning aspects of sea transportation<br />

and during 2006 piloted a key supply chain<br />

program with Ford Australia.<br />

“During 2006 <strong>Wallenius</strong> <strong>Wilhelmsen</strong> <strong>Logistics</strong><br />

saving FoRd time and money<br />

“Ford immediately liked the look of<br />

the ‘Right Car, Right Port’ proposal<br />

so much they asked us to implement<br />

a pilot programme.”<br />

piloted a programme with Ford Australia called ‘Right<br />

Car, Right Port’,” says Casabene. “This programme<br />

provides the ability to change destination at origin or<br />

in transit and reduces land-based transfer costs within<br />

Australia. This obviously reduces logistics costs and<br />

provides flexibility for Ford and its dealers to meet<br />

changing vehicle supply and demand in Australia.”<br />

Designed to build some flexibility into the Ford supply<br />

chain after a vehicle has left production, the ‘Right<br />

Car, Right Port’ logistics solution directly tackles the<br />

problem that once a car is manufactured it is immediately<br />

assigned to a discharge port. Currently, should<br />

the final point of sale of a vehicle differ to its discharge<br />

port, logistics time and money is lost by trucking vehicles<br />

by road across Australia to the final point of sale.<br />

ThE ‘rIghT CAr, rIghT pOrT’ solution instead monitors<br />

the progress of a vehicle through the supply chain<br />

from the time it leaves the factory in South Africa<br />

(and in the future potentially Asia and Europe), right<br />

through to the port of discharge and arrival in Australia.<br />

The solution assigns the correct port of discharge,<br />

should this differ from the original instruction, just<br />

prior to the vessel arriving in Australia.<br />

The innovative approach allows WWL to coordinate<br />

the discharge of other shipping lines servicing Ford<br />

Australia, to potentially discharge vehicles earlier or<br />

later than first intended – helping to reduce the need<br />

and cost of inland transportation.<br />

<strong>Wallenius</strong> <strong>Wilhelmsen</strong> <strong>Logistics</strong> has been a Ford<br />

supplier for many years, offering its full range of<br />

logistics capabilities and moving tens of thousands<br />

of vehicles for Ford Australia such as imports from<br />

Europe to all major Australian ports. However, the<br />

prestigious supplier excellence award was the direct<br />

result of a request from Ford Australia for WWL to act<br />

as consultants in a supply chain evaluation project.<br />

“We recommended several changes and Ford immediately<br />

liked the look of the ‘Right Car, Right Port’ proposal<br />

so much they asked us to implement a pilot programme<br />

together with them,” recalls Craig Heron, Business Development<br />

Manager at the time, who headed the project.<br />

He underlines the project has been a joint effort<br />

between Ford Australia and the WWL Oceania Commercial<br />

and <strong>Logistics</strong> team, supported by IS&T.<br />

q<br />

ROUTES 2 2007 13

saving FoRd time and money<br />

the aim of the<br />

‘Right Car, Right<br />

Port’ project was<br />

to create a flexible,<br />

agile supply chain<br />

solution as a multitrade,<br />

multi-region<br />

application – saving<br />

resources, time<br />

and money.<br />

14 ROUTES 2 2007<br />

The project was handled by a core team including<br />

Craig, IT Senior Solutions Architect, Allan Hird, and<br />

Runhild Persensky, a member of the Oceania Business<br />

Development team at the time. Craig comments,<br />

“Our task in a nutshell was to come up with a<br />

way to build flexibility into a supply chain that traditionally<br />

has been fairly rigid.”<br />

The solution development process progressed<br />

amazingly quickly, according to Craig, encompassing<br />

less than three months from start to finish in mid-<br />

2006. In fact, WWL’s Melbourne team are now into<br />

a second phase involving Ford vehicles being moved<br />

from Europe to Australia by WWL.<br />

ALLAN sAys ThE ability to leverage the company’s wide<br />

experience and global know-how in developing similar<br />

IT applications speeded the effort to deliver on Ford’s<br />

requirements.<br />

“From the very start we set out to develop a flexible,<br />

agile supply chain solution as a multi-trade,<br />

multi-region application from the start that could<br />

also cater to non-WWL carriers needs,” says Allan.<br />

Kevin Moore, Vice President, Commercial, WWL<br />

HoW to get tHe CaR to tHe RigHt PoRt<br />

2 WWL sends a<br />

request through to Ford<br />

S.A. to issue change of<br />

stow if unit is still at the<br />

terminal. If vehicle is on<br />

water, WWL issues a<br />

change of destination<br />

request with carrier.<br />

Oceania, underlines that the ‘Right Car, Right Port’<br />

enables Ford to better manage the distribution of its<br />

vehicles by getting them to market as quickly and efficiently<br />

as possible.<br />

“The programme saves equipment resources, time<br />

and money and it is also good for the environment as<br />

it cuts down unnecessary logistics movements,” says<br />

Kevin.<br />

Craig has no doubt about the possibilities that the<br />

success of the project holds for the future: “The ‘Right<br />

Car, Right Port’ solution has exciting future potential<br />

because it is a true supply chain innovation allowing<br />

customers to handle their logistics better, faster and<br />

cheaper than ever before,” says Craig.<br />

THIS IS FORD AUSTRALIA<br />

FOrD CArs hAVE BEEN sold in Australia since 1904<br />

with Ford Australia being formed in 1925.<br />

Ford Australia is the longest established and largest<br />

automotive manufacturer in Australia and the only such<br />

company that wholly designs as well as develops and<br />

builds a range of vehicles locally – the Falcon/Fairmont/<br />

Fairlane/LTD range.<br />

Ford Australia’s headquarters are located at<br />

Broadmeadows, in suburban Melbourne, along with the<br />

assembly facilities for the Ford Falcon range, Fairlane<br />

Ghia and LTD passenger vehicles, and the Falcon light<br />

commercial range.<br />

Facilities at Broadmeadows also include the Customer<br />

Service Division, a training centre and a research<br />

and design centre. Ford Australia has almost 1,500<br />

suppliers and 246 dealers in the country.<br />

3 Unit is discharged in<br />

the optimal port relative<br />

to the dealer.<br />

1 Ford Australia sends<br />

WWL a daily file to reconcile<br />

ports booked with<br />

optimal ports per unit.<br />

Product<br />

Communication

Moving<br />

the business<br />

forward<br />

Meet the man who likes to be in control – Rune Gisvold<br />

q<br />

q<br />

ROUTES 2 2007 15

16 ROUTES 2 2007<br />

The one thing executives worldwide<br />

hate is surprise – good or bad. It’s<br />

the job of <strong>Wallenius</strong> <strong>Wilhelmsen</strong><br />

<strong>Logistics</strong>’ chief financial officer<br />

Rune Gisvold to keep top managers<br />

playing their cheerleader game efficiently<br />

by delivering predictability.<br />

WORdS DaviD Noble phOTOS aNita arNtzeN<br />

Making sure <strong>Wallenius</strong> <strong>Wilhelmsen</strong><br />

<strong>Logistics</strong> has what it takes<br />

to compete in the international<br />

marketplace at a time of turbulent<br />

economic transformation involves<br />

many different disciplines. But one key success factor<br />

is putting in place financial systems, processes and<br />

procedures giving management the ability to steer the<br />

company with a degree of predictability over the short<br />

to medium term.<br />

“All managers and executives hate surprises,” says<br />

Rune Gisvold with deep conviction.“Bad surprises<br />

are terrible, and positive surprises aren’t much better<br />

either because that demonstrates lack of control and<br />

predictability – which damages our credibility both<br />

within the company and externally among customers<br />

and competitors.”<br />

Against the above background,<br />

unsurprisingly, Rune admits to<br />

being completely focused on delivering<br />

on what he – and his team<br />

– promise.<br />

“My business philosophy very<br />

much encompasses the notion that<br />

it is better to ‘under promise and<br />

over deliver’.”<br />

Rune also believes passionately<br />

in management by objectives.<br />

“It was a management theory<br />

back when I was young, but is still<br />

very relevant. It is all about agreeing<br />

as a team on what needs to be<br />

done and then getting on with<br />

the deliverables as an individual.<br />

Although I like being in control<br />

and am meticulous about follow-<br />

As a young man, Rune Gisvold<br />

worked his way around the<br />

world on a cruise ship – and<br />

got the chance to show off his<br />

traditional folk clothes.<br />

ing up what’s been agreed, I don’t<br />

like getting involved in every little<br />

implementation detail.<br />

“I’m pretty much hands-off<br />

unless asked for advice or support,<br />

very<br />

mucH<br />

some-<br />

times<br />

Not<br />

at all<br />

THE SCALE OF<br />

Sets objectives<br />

or until something goes badly wrong. ”<br />

Globalisation is impacting the world economy.<br />

And while it puts more goods in front of more people<br />

at better prices, it also increases the pressure on Rune<br />

and his finance and strategic development team.<br />

“We have to make sure everyone steering WWL<br />

towards our vision of offering a competitive seamless<br />

ocean and land-based logistics network can rely on us<br />

to deliver the resources they need,” Rune explains.<br />

He believes tHe two functions of finance and strategic<br />

development tie in well together in a global company<br />

like <strong>Wallenius</strong> <strong>Wilhelmsen</strong> <strong>Logistics</strong> with its 65 vessels<br />

sailing the world’s oceans, transporting 3.3 million<br />

cars and rolling equipment on sea and land and<br />

26 strategically sited technical service centres.<br />

“Strategy today is about building your business and<br />

to do that you must have your finances firmly rooted.

RunE GiSvOLd<br />

Strategist detail freak deliverer Loves surprises<br />

Managers need to know where the money flows are<br />

coming from and where they are going. Our job is to<br />

manage and coordinate the strategic process being<br />

evolved by our folks in the field, our customers and the<br />

external world.”<br />

What does he view as the most important steps<br />

needing to be taken over the next eighteen months?<br />

“We must not lose sight of the fact we are actually<br />

developing five products within two business areas at the<br />

same time. One business area is our Ocean Services, which<br />

is all about asset managing three billion dollars worth of<br />

floating vessels that need to always be in the right place<br />

at the right time. Our other business area, encompassing<br />

terminals, technical services and inland distribution procurement,<br />

is about cost management and more of a nickel<br />

and dimes business with millions of small transactions,<br />

many with low value and low margins.<br />

“The biggest challenge now is managing these<br />

“My business<br />

philosophy very<br />

much encompasses<br />

the notion<br />

that it is better to<br />

‘under promise<br />

and over deliver’.”<br />

Evolution of<br />

a numbErs guy<br />

norway’s Vikings carved a<br />

ferocious image for themselves.<br />

So what would they have made<br />

of Rune Gisvold playing the distinctively<br />

non-aggressive game<br />

of cricket in England?<br />

“I was <strong>working</strong> for a Norwegian<br />

company in northern England.<br />

I thought it vital to get to know<br />

English culture, so I joined the<br />

company’s cricket team!”<br />

Such ‘out of the box’ thinking<br />

is integral to Rune’s approach to<br />

<strong>life</strong>. For example, after getting a<br />

Bachelors Degree in Business Administration,<br />

the travel bug bit him.<br />

“i decided to travel the world<br />

as an assistant purser on a<br />

Norwegian cruise ship. It was<br />

such fun I decided to go around<br />

again, but the only job available<br />

was as a lowly utility hand.”<br />

Back ashore, Rune returned<br />

to university in the USA, getting<br />

his MBA in 1981. He worked for<br />

several well-known companies<br />

in various parts of the world and<br />

even ran his own successful<br />

business for a time before joining<br />

WWL in 2002. Rune says<br />

he has never regretted making<br />

that decision.<br />

two businesses in parallel successfully. We are moving<br />

in the right direction but there is still a huge need for<br />

managers who can handle both cost management and<br />

asset management at the same time.”<br />

Rune stresses the need to balance cost management<br />

with huge investments.<br />

“If we cannot do that we will<br />

not succeed with our strategy for<br />

the reason that we will not make<br />

money any other way.<br />

“My job is to make sure we have<br />

control of the resources available<br />

to move with the world, so that<br />

our assets and services can be in<br />

the right place at the right time<br />

with the right capacity and ability<br />

to deliver on our promises to our<br />

customers.”<br />

ROUTES 2 2007 17

sustainability<br />

Giant of the Atlantic<br />

18 ROUTES 2 2007<br />

The bluefin tuna is one of the most magnificent fish living<br />

in the world’s oceans. However, it’s also considered to<br />

make the world’s finest sushi, which has contributed to<br />

it being on a path to extinction. A catastrophe that WWF,<br />

the global conservation organisation, supported by WWL,<br />

is now doing everything in its power to prevent.<br />

T<br />

he Atlantic bluefin is the tuna species to be<br />

most negatively affected by last century’s<br />

large-scale industrial fishing. The number<br />

of adult fish currently amounts to only<br />

10 percent of the 1975 level which, even<br />

then, was considerably depleted. A large proportion of<br />

Atlantic bluefin tuna is exported to Asia, but increasingly<br />

also to northern Europe, as the sushi trend expands.<br />

Measuring up to 4 metres in length and weighing 680<br />

kg, bluefin tuna is the most valuable of all the fish in<br />

the sea, with a record specimen having been sold at the<br />

Tokyo fish market for USD 173,600!<br />

In the Mediterranean, where fishing of the Atlantic<br />

bluefin tuna has been most widespread, the species<br />

may disappear entirely as early as this year. Something<br />

that would be disastrous for<br />

“Removing a top predator<br />

like the tuna can<br />

lead to a domino effect,<br />

where other species<br />

further down the<br />

chain are affected.”<br />

WORdS SuSanna w. ahlForS pHOTO GettY iMaGeS<br />

biodiversity, but also for the<br />

ecological balance, says WWF<br />

marine biologist Sergi Tudela:<br />

“Removing a top predator like<br />

the tuna can lead to a domino effect,<br />

where other species further<br />

down the chain are affected.”<br />

In the Mediterranean, this<br />

may mean a sharp increase in the<br />

number of squid which, in its<br />

turn, would result in a reduction<br />

in the sardine population. “What we’re witnessing now<br />

is the same situation as with the cod stocks off Newfoundland.<br />

Since they collapsed in the 1990s, they have<br />

not been able to recover,” Tudela adds.<br />

So what can be done in order to prevent a collapse? In<br />

November last year, ICCAT, the main body for managing<br />

Atlantic bluefin tuna, held a meeting in Croatia.<br />

At that meeting, ICCAT’s own scientists proposed a<br />

reduction in the catch quota from 32,000 to 15,000 metric<br />

tonnes per year in the Mediterranean as a necessary<br />

measure to save the species from almost certain extinc-<br />

tion. But the proposal that was<br />

finally agreed upon was that<br />

put forward by the EU delegation,<br />

which involves<br />

a reduction merely from<br />

32,000 to 29,500 tonnes<br />

in 2007, along with a ban on<br />

fishing only from July to the end<br />

of the year. This, despite the fact<br />

that up to 60 percent of all the Atlantic<br />

bluefin caught in the Mediterranean is<br />

fished while spawning in June.<br />

“The EU calls this a recovery plan, but we call<br />

it a collapse plan”, says Tudela.<br />

the conSiderable commercial value of the catch<br />

means that governments are subjected to enormous<br />

pressure from the fishing industry. This reduces the<br />

political will for a sustainable management system on<br />

the part of states such as France, Spain and Italy. Together,<br />

these three countries are responsible for more<br />

than 50 percent of the total legal catch of bluefin tuna<br />

in the Mediterranean.<br />

In order to prevent an immediate collapse of the<br />

species, WWF has asked all states with an allocation<br />

for fishing not to accept ICCAT’s proposal of a quota of<br />

29,500 tonnes, but to reduce their catch quota by half.<br />

So far, only Norway has responded to WWF’s request.<br />

“As an immediate action, we are asking retailers,<br />

especially supermarkets in Europe, to support our<br />

call to cut bluefin tuna quotas by half in the Mediterranean,<br />

and more than a dozen retailers have joined so far.”<br />

The fate of the Atlantic bluefin tuna is also a terrifying<br />

indication of what could happen to all tuna<br />

species, according to Tudela.<br />

“We have to start looking at fish as more than just<br />

food. If we could see the tuna migration that passes<br />

through the Straits of Gibraltar every year, it would be as<br />

thrilling as watching the lions in the African Serengeti!”

close to extinction<br />

What can you do?<br />

When you are at your sushi restaurant, at your fishmonger’s<br />

or in the store:<br />

Ask where the bluefin tuna comes from. If it is from the<br />

Mediterranean, WWF recommends not to buy it, unless<br />

the seller can prove that it has been sustainably fished.<br />

Buying tuna in tins for salads and sandwiches is,<br />

on the other hand, not a problem for bluefin tuna, as it<br />

almost never ends up in a tin. The best choice here is<br />

yellowfin tuna from the East Pacific Ocean.<br />

For more information visit www.panda.org/tuna<br />

<strong>Wallenius</strong> <strong>Wilhelmsen</strong> <strong>Logistics</strong><br />

is the sole sponsor of<br />

WWF’s High Seas Conservation<br />

Programme, supporting<br />

WWF in its work to improve<br />

high seas conservation and<br />

governance.<br />

ROUTES 2 2007 19

wwl oN site<br />

a process from a to Z<br />

a smooth car trip<br />

In 2004, WWL signed a Lead <strong>Logistics</strong> Provider (LLP)<br />

contract with BMW AG for the shipment of all vehicles from<br />

seven BMW Group factories to Australia and New Zealand.<br />

Here’s how WWL manages to get the vehicles from<br />

the factory to the final destination successfully.<br />

20 ROUTES 2 2007<br />

Words AlAnnAh eAmes<br />

photos BArBArA hArtmAnn<br />

ArnAud siquet<br />

eAmon gAllAgher<br />

1 NotificatioN messages<br />

Bremen, germAny. renée Liebig, <strong>Logistics</strong> Coordinator,<br />

has got a message from BMW by Electronic data<br />

Integration (EdI) to WWL’s order management system<br />

that a vehicle will need to be picked up soon from a<br />

production plant in Germany. When the vehicle reaches<br />

the endofline point in the factory, WWL gets another<br />

message that the vehicle must be picked up within<br />

a short time frame. the selected trucking company<br />

receives a message to pick up a vehicle load and is<br />

given a reference number.<br />

2 pickiNg up the vehicle<br />

regensBurg, germAny. the trucking company confirms<br />

the load and picks up the vehicle within the agreed<br />

time frame at the production facility. If, for any reason, a<br />

vehicle is not moving according to plan, WWL <strong>Logistics</strong><br />

Coordinators receive alert messages from the order<br />

management system.

3at<br />

the port<br />

ZeeBrugge, Belgium. the<br />

trucking company delivers the<br />

vehicle to the terminal where it has<br />

already been assigned to a voyage through the<br />

order Management system. there are two different<br />

sailings to oceania from Zeebrugge – one is via the<br />

Us and panama Canal to Australia, the other is via south<br />

Africa. Both trips take around 40 days. Urgent cars are<br />

given a red priority sticker.<br />

5arriviNg<br />

iN australia<br />

melBourne, AustrAliA. the car is discharged. Urgent cars<br />

are the first to be moved to the Vehicle processing Centre<br />

(VpC), where they are washed, inspected and made ready for<br />

delivery. WWL can change the port of destination during the<br />

shipment, should the need arise for BMW to have a vehicle<br />

shipped to a different part of Australia.<br />

4 the voyage to oceaNia<br />

At seA. From the moment the vehicle is picked up by WWL<br />

to the moment it is dispatched at the destination, BMW and<br />

their dealerships can see what they have ordered through the<br />

web visibility tool, 2vu. BMW can type in details such as a<br />

dealer name and see how many vehicles have been loaded in<br />

Zeebrugge for this dealer. status messages from WWL are<br />

displayed in BMW’s system.<br />

6fiNal<br />

destiNatioN<br />

melBourne, AustrAliA. Before the car’s final transport to the<br />

dealer, a transport order is sent from the system to the selected<br />

trucking company. When delivered, WWL receives confirmation<br />

in real time into its system from the trucking company. the same<br />

information is available in WWL’s web visibility tool.<br />

ROUTES 2 2007 21

<strong>working</strong> <strong>life</strong><br />

ThE OfficE: dURban<br />

A major tourist centre of three million people and the busiest port in<br />

Africa, Durban is the South African city where CAT-WWL <strong>Logistics</strong> operates.<br />

Two years ago, WWL had only one person on site in South Africa.<br />

Today, the CAT-WWL <strong>Logistics</strong> team consists of more than 80 people in<br />

three different locations, and with a lot of growing potential.<br />

n Olga Maqizana, Supply<br />

Chain Co-ordinator. The<br />

most precious thing on Olga’s<br />

desk is the photo of her son,<br />

who was tragically shot dead<br />

last year. She now lives with<br />

her son’s friend and carries on<br />

strongly with her <strong>life</strong> – <strong>working</strong>,<br />

socialising and doing things<br />

she enjoys. The office does<br />

not just comprise hard<strong>working</strong><br />

people. She says: “We’re more<br />

of a family, with everyone<br />

cherishing each other.”<br />

Outside work hours, Olga likes<br />

to work out in the gym.<br />

22 ROUTES 2 2007<br />

n Jacques Landman, Depot<br />

Manager. The office’s main<br />

objective in recent months has<br />

been to get the new facility running<br />

efficiently, which has meant a lot of<br />

hard work. It has also meant there<br />

hasn’t been enough time to socialise.<br />

But one good thing stemming<br />

from this is the great teamwork.<br />

“The hard situations we have<br />

experienced have helped us to<br />

bond strongly,” says Jacques.<br />

When not <strong>working</strong>, he likes to<br />

join his son for some motocrossing<br />

– and enjoying a cold beer or two.<br />

n Juan Gorgas, Operations Manager. Juan moved from Argentina<br />

with his wife in 2006 to work with Volkswagen’s South Africa<br />

project. He oversees the distribution of finished vehicles throughout<br />

South Africa and the surrounding countries, according to lead times<br />

set by Renault South Africa and Volkswagen South Africa.<br />

“There hasn’t been much leisure time lately. If there was,<br />

I‘d play my acoustic guitar and be more with the family.”<br />

n Deon Arnolds, <strong>Logistics</strong> Co-ordinator.<br />

An upcoming winner of a reality show like<br />

Survivor or The Amazing Race? That is Deon’s<br />

dream. Maybe it will come true one day soon,<br />

but in the meantime he is happy pursuing his<br />

main hobbies – supporting his country’s rugby<br />

team and doing something called ‘vleisbraai’,<br />

the traditional South African barbeque.<br />

On his desk he keeps a miniature of<br />

the Eiffel Tower in Paris.<br />

“It reminds me of where I want to go<br />

one day,” Deon says.<br />

n Luvuyo Hobo, Supply<br />

Chain Manager. Managing<br />

the supply chain for Volkswagen<br />

South Africa (VWSA)<br />

from the time the vehicles<br />

leave the plant to the time<br />

they get to the dealers can be<br />

challenging and stressful.<br />

“Right now, I spend most of my<br />

time at work. Because of this,<br />

it’s only fair to my family that I try<br />

to keep work<strong>life</strong> and my spare<br />

time separate,” says Luvuyo.<br />

Because of a heavy workload,<br />

there has been little chance for<br />

afterwork activities at the office.<br />

n Rune Loew, Managing Director,<br />

CAT-WWL <strong>Logistics</strong>, is not in the picture<br />

but he was standing behind the camera<br />

when the two rhino’s passed by in Hluhluwi<br />

National Game Reserve Park, two years ago.

kNOWLEDGE ScHOOL<br />

OcEan planning and REpORTing<br />

STRATA is a new system providing a complete overview of<br />

WWL’s ocean results. It is available to the global commercial,<br />

trade performance and voyage calculation teams. This<br />

web-based solution enables users to compile information<br />

and report on ocean budgeting, forecasting and actual<br />

results. Reporting from STRATA is enabled by Cognos 8.<br />

Voyage Results<br />

(budgeting and forecasting)<br />

This screen calculaTes the overall result of a<br />

specific voyage, from a cost and revenue perspective.<br />

Voyage results are based on volume and<br />

revenue input, as well as cost management and<br />

allocations. The results for a voyage can be viewed<br />

on both a prorated and nonprorated basis.<br />

“This screen includes more uptodate actual<br />

costs from coda, the accounting system, making it<br />

possible to combine estimated results with actual<br />

results for a more accurate and updated ocean<br />

result,” says Monica.<br />

The greatest overall advantage of the new system is that<br />

budgets, forecasts and estimates will be more accurate<br />

and provide far greater opportunities for analysis. All areas<br />

of the organisation will be <strong>working</strong> on this one common<br />

platform which provides greatly enhanced opportunities<br />

for collaboration and information sharing.<br />

Terminal Results<br />

(analysis of results)<br />

Volume and Revenue Input<br />

(budgeting and forecasting)<br />

This screen provides information on turnover<br />

defined by either customer or cargo segment.<br />

By alternating between rows and columns in the<br />

Total customer and Total cargo Segment tabs, data<br />

specifying the monthly revenue per customer and<br />

cargo segment can be accessed.<br />

“The main improvement in this application is that<br />

the previous forecast is always available to the user<br />

and will form the basis for new input. This will result in<br />

less duplicated work and more comparable information,”<br />

says Monica Trøen Volden, Project Manager<br />

STRATA.<br />

The loading Terminal Spec tab shows the vital statistics for a specific loading<br />

terminal. Average rates for “All customers” and for “All cargo segments” can be measured.<br />

customer and/or cargo segment will be selected when specific rates apply.<br />

“costs can now be entered in greater detail, providing significantly more accurate<br />

calculations of cargorelated costs, given that the lowest level is used as the cost<br />

basis,” Monica explains.<br />

For more information on STRATA, contact your regional super-user:<br />

americas: Diane Moyse, James Sloan europe: Marcus Hallberg, Björn<br />

Jungbeck asia: Yoshihisa Obataa, Shinya Soutome oceania: John Doherty,<br />

Jason Clifford or Global Business System responsible for Strata, Donal Duggan.<br />

ROUTES 2 2007 23

<strong>working</strong> <strong>life</strong><br />

DOuBLE IDENTITy<br />

MUlTilingUal MaRTial aRTS<br />

Ineta Liaudinskaite, five times Lithuanian<br />

National Champion & European Silver-<br />

Medalist in Karate<br />

“i sTarTed Taking karate lessons in Lithuania<br />

at the age of ten. My cousin was practising<br />

wushu, a form of chinese<br />

martial arts, and she was<br />

so strong. I wanted to<br />

be stronger and more<br />

selfconfident at<br />

school and be able<br />

to defend myself.<br />

Initially, it didn’t even<br />

occur to me that<br />

I would compete.”<br />

Ineta Liaudinskaite<br />

started entering local competitions<br />

and, within a year,<br />

she was competing internationally.<br />

In 1995, at the age of 17,<br />

she became Lithuanian National<br />

champion, a title she held for five<br />

years. Ineta was also awarded a<br />

silver medal at the European championships<br />

the same year. She stopped<br />

competing in 2000 for health reasons.<br />

“After I started competing internationally,<br />

I was travelling abroad nearly every month, to<br />

Germany, Poland, France and other countries.<br />

Back then, the only people in Lithuania who were<br />

allowed to travel were politicians, diplomats and<br />

sportsmen, so I was incredibly fortunate and really<br />

appreciated it. The travelling also fostered my interest<br />

in foreign languages and cultures,” she explains.<br />

“I had to give up karate due to poor eyesight.<br />

If I started again now, I could never reach the<br />

same levels, so it wouldn’t be satisfying. I have<br />

been offered a job as a karate instructor and I am<br />

considering it but my new hobby is latin dancing.<br />

Both are great for releasing excess energy, in very<br />

different ways. But salsa dancing is a hobby, where<br />

karate used to be my <strong>life</strong>.”<br />

phoTo: rodrigo diaz Wichmann<br />

24 ROUTES 2 2007<br />

Ineta Liaudinskaite, <strong>Logistics</strong> Operator,<br />

<strong>Wallenius</strong> <strong>Wilhelmsen</strong> <strong>Logistics</strong> Ibérica<br />

“i joined WWl in Barcelona in July 2006.<br />

I am responsible for logistics management<br />

of inland automotive transport in the Eastern<br />

Europe Development Department. My role<br />

is basically to sell loads to subcontractors<br />

and to find loads for subcontractors with<br />

available capacity.”<br />

“I think I got this job primarily<br />

because of my mother tongue,<br />

Lithuanian. Last year, Lithuanian<br />

operators accounted for 70 percent<br />

of WWL Ibérica’s overall land transport<br />

volumes. I manage the daily dealings<br />

with Lithuanian and other operators,<br />

which means selling loads, as well as<br />

expanding our subcontractor network<br />

and developing new routes and new<br />

load combinations.”<br />

Ineta grew up in kaunas, Lithuania. She<br />

studied Sports & Tourism Management and<br />

first came to Spain in 1998 to work, as part of<br />

her studies. In 2002, she returned to complete<br />

her MBA thesis and decided to stay. She<br />

joined Spanish automotive manufacturer<br />

SEAT’s service department, dealing with importers<br />

in 64 countries. Ineta Liaudinskaite<br />

speaks six languages: Lithuanian, English,<br />

Spanish, Italian, catalan and Russian. She<br />

also admits to understanding German and<br />

French, but not fluently.<br />

“Since early childhood I was very<br />

interested in languages. At the age<br />

of five, I started asking my mother to<br />

teach me English words! The best<br />

thing about my job is the dynamic<br />

international atmosphere and the opportunity<br />

to use my languages.<br />

I communicate in Lithuanian,<br />

Spanish, Italian and English every<br />

single day.” isabelle kliger

ON THE OcEAN<br />

75yEaRS Of ThE SydnEy haRbOUR bRidgE<br />

On March 18, 2007, WWL participated<br />

in the 75th anniversary celebrations<br />

of the famous Sydney Harbour Bridge<br />

in Australia. When the bridge was<br />

first opened in 1932, Wilh. Wilhemsen’s<br />

MV Temeraire was one of the first<br />

vessels to pass under it as part of<br />

the opening ceremony. In 2007,<br />

the honour instead fell to <strong>Wallenius</strong><br />

Wilhemsen <strong>Logistics</strong> MV Texas.<br />

“We were asked to participate in the celebrations<br />

and, fortunately, our schedule happened<br />

to have us in Sydney on that particular<br />

day,” comments Bjørnar Larssen, captain<br />

onboard the MV Texas. “Furthermore, a<br />

<strong>Wilhelmsen</strong> ship had led the inbound convoy<br />

when the bridge was opened 75 years ago.<br />

We prepared by touching up the paintwork<br />

on the side of the ship and the names, and<br />

then we hoisted signal<br />

flags, which is a common<br />

custom in the shipping<br />

industry when celebrating.<br />

We also assisted<br />

local representatives in<br />

arranging fireworks and<br />

other effects when we<br />

passed by.”<br />

Bjørnar Larssen.<br />

The MV Texas is a RoRo vessel that<br />

carries High and Heavy cargo, such as<br />

machinery and vehicles used in construction<br />

and agriculture, motor vehicles and break<br />

bulk. Back in the days of the MV Temeraire,<br />

shipping was a very different business.<br />

The MV Temeraire was<br />

delivered to Wilh. Willhelmsen<br />

from St. Nazaire, South<br />

Africa, in December 1927.<br />

In 1958 it was renamed MV<br />

Vogesen and sold<br />

to Germany.<br />

The vessels of today are considerably larger<br />

and faster and the time spent in port is significantly<br />

shorter, with staff <strong>working</strong> round<br />

the clock. At the time of the bridge opening in<br />

1932, Australia was an export market for products<br />

such as foodstuffs and wool, whereas<br />

The MV Temeraire was 138<br />

meter long, compared to the<br />

162 meter length of MV Texas.<br />

Temeraire also had a gross<br />

tonnage of 6465 MT – less than<br />

a tenth of that of MV Texas.<br />

When MV Texas passed<br />

under the Sydney Harbour<br />

Bridge on March 18 it was<br />

repeating history.<br />

it is now primarily an import market, with<br />

WWL carrying predominantly High and<br />

Heavy products and vehicles into the country.<br />

Gregory and Joan Richardson were two of<br />

six siblings who were onboard the MV Temeraire<br />

when the Sydney Harbour Bridge was<br />

officially opened in 1932. Their father worked<br />

for a woolbuying firm, which was one of<br />

<strong>Wallenius</strong> Wilhemsen <strong>Logistics</strong>’ customers<br />

back when wool was a major export product.<br />

They remember sailing from Woolloomooloo<br />

and travelling under the bridge before returning<br />

to port. There was a ‘Punch and Judy’<br />

show onboard and the children were each<br />

given icecream.<br />

“We were still in the depression at<br />

the time, so icecream was a big treat!”<br />

comments Gregory Richardson.<br />

isabelle kliger<br />

ROUTES 2 2007 25

our industry<br />

canal innovation<br />

waTERway Of ThE fUTURE<br />

The pressure on the Panama Canal continues to build. To meet market<br />

demand, Panama is extending its waterway. In a referendum last year, 78 percent<br />

of Panamanians voted in favour of the extension. Now the rebuilding<br />

is underway and when the canal lies ready in 2015 the amount of<br />

tonnage transiting will be double that of today.<br />

“If we faIl to extend our canal it will drive<br />

traffic to the Suez canal, despite the longer<br />

journey and high bunker costs,” says Jorge<br />

Quijano, project director at autoridad del canal<br />

de Panamá (acP).<br />

the canal is also competing with intermodal<br />

transport between the USa’s east and west<br />

coasts.<br />

Good availability of water is vital for the canal.<br />

in the existing locks, built in 1914, water runs<br />

straight into the sea when they are opened.<br />

in the new locks being built, some 60 percent<br />

of the water is reclaimed in adjacent basins.<br />

the system has already proved itself along<br />

Germany’s Rhine River waterway.<br />

During the dry season there is a shortage of<br />

water in the country, so during the rainy season<br />

water is stored in the Gatún and the alhajuela<br />

lakes. the water used in the canal comes from<br />

these water reservoirs, and Gatún is also part of<br />

the canal waterway.<br />

Stanley Heckadon, a researcher at the<br />

Smithsonian institution, (Smithsonian analysed<br />

the environmental consequences when the first<br />

canal was constructed), says the institution is<br />

very pleased with the planned extension. in the<br />

original plans dating back to 1999–2000, three<br />

modified streams that ran into three artificial<br />

lakes would have collected the water.<br />

“today’s plan is very different and more sympathetic,”<br />

he says expressing satisfaction with the<br />

decision to recycle water by storing it in basins.<br />

customers will benefit from the expansion.<br />

today, almost 90 percent of the canal’s capacity<br />

is used. Without an expansion, the delays and<br />

wwl Through ThE CaNal<br />

WWL ranks among the ten largest customers<br />

in the Panama canal with almost 200 passages<br />

each year, an average of 15 per month:<br />

n 3 to Australia from North America & Europe<br />

n 6 to USA East Coast from Asia<br />

n 6 to USA West Coast from Europe<br />

Source: WWL<br />

26 ROUTES 2 2007<br />

the<br />

waiting<br />

NEw loCks<br />

times will<br />

increase. With the<br />

new locks the waiting 4<br />

times will be reduced and<br />

hence the estimated arrival time to<br />

the next port of call will be predictable.<br />

another consequence of reduced waiting<br />

times is less air pollution.<br />

on the downsIde, the extension means the cost<br />

of using the canal will rise. January saw the acP<br />

announce a hefty increase in fees, but also asking<br />

the shipping companies what they thought, to<br />

which WWl has responded. Despite the efforts<br />

from several industrial bodies, as well as WWl’s<br />

separate initiative, the acP will introduce the<br />

new pricing system, starting July 1 this year with<br />

tolls increasing by eight percent. next year the<br />

increase will be another 11 percent and by 2009<br />

it will be a further 7 percent. WWl is engaged in<br />

keeping costs down sufficiently. the fee increase<br />

impacts all of the shipping lines using the canal.<br />

the ongoing mounting pressure on world<br />

tonnage is leading to bigger vessels. For more<br />

and more shipbuilders, the Panama canal is<br />

increasingly viewed as providing limited options.<br />

the result is they must look at multi-hull options,<br />

which lead to reduced ballast water requirements.<br />

Both technical departments at <strong>Wallenius</strong> Marine<br />

and <strong>Wilhelmsen</strong> Maritime Services are currently<br />

exploring new broader vessels. there are many<br />

benefits with such vessels, including their ability<br />

to carry more loads, and that in turn reduces the<br />

environmental impact per transported unit.<br />

UlrIka hallIn<br />

ATLANTIC OCEAN<br />

5<br />

6<br />

ExIsTINg loCks

GATUN<br />

LAKE<br />

1<br />

3<br />

ThE Canal in nUmbERS<br />

n Panamax ship dimensions: max length 294.13 metres.<br />

Postpanamax ship dimensions: max length 366 metres.<br />

n 14,194 vessels transited in 2006, split up as follows:<br />

container vessels (26%), dry bulk (22%), tankers (14%),<br />

vehicle carriers (6%) and others (32%).<br />

n During the first quarter of 2007, the number of vessels<br />

passing through the canal increased by eight percent<br />

and 87 percent of the canal’s capacity was used.<br />

n some 40 percent of world fleet transport from North-<br />

East asia and the usa move via the Panama Canal.<br />

Source: ACP<br />

= New channel<br />

= Dredging<br />

3<br />

1<br />

2<br />

Canal faCTS<br />

1<br />

Two new channels are being<br />

built – deeper and wider than the<br />

existing ones.<br />

The first major excavation work<br />

2 will get underway just behind the<br />

Miraflores lock on the Pacific side of<br />

the channel. But first, archaeologists will<br />

search the site for ancient remains.<br />

Meeting the demands of post-<br />

3 panamax vessels also requires<br />

modernisation of parts of the existing<br />

canal, including dredging. in some sections<br />

underwater blasting will be required.<br />

Two new locks are being con-<br />

4 structed, one on the atlantic side,<br />

and one on the Pacific. the old locks,<br />

33.5 metres wide (from which the term<br />

‘panamax’ stems) are to be replaced by<br />

new ones measuring 55 metres across.<br />

“thanks to the extra width the canal<br />