PERFORMANCE TABLE CENTRIFUGAL PUMPS - in AISI 304 - Ebara

PERFORMANCE TABLE CENTRIFUGAL PUMPS - in AISI 304 - Ebara

PERFORMANCE TABLE CENTRIFUGAL PUMPS - in AISI 304 - Ebara

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

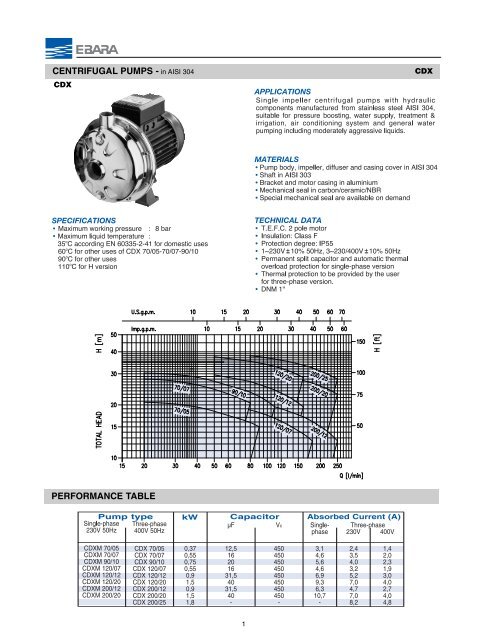

<strong>CENTRIFUGAL</strong> <strong>PUMPS</strong> - <strong>in</strong> <strong>AISI</strong> <strong>304</strong><br />

CDX<br />

CDX<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

1

<strong>CENTRIFUGAL</strong> <strong>PUMPS</strong> - TWIN IMPELLER <strong>in</strong> <strong>AISI</strong> <strong>304</strong><br />

2CDX<br />

APPLICATIONS<br />

2CDX<br />

MATERIALS<br />

SPECIFICATIONS<br />

TECHNICAL DATA<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

2

SELF PRIMING <strong>PUMPS</strong> <strong>in</strong> <strong>AISI</strong> <strong>304</strong><br />

JESX-JEX<br />

JESX-JEX<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

3

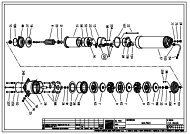

<strong>CENTRIFUGAL</strong> <strong>PUMPS</strong> <strong>in</strong> <strong>AISI</strong> <strong>304</strong><br />

3 SERIES<br />

3 SERIES<br />

3 M F 4 H 40 200 3.0 M<br />

SIGLE PHASE<br />

MOTOR POWER [kW]<br />

IMPELLER<br />

NOMINAL DIAMETER<br />

DISCHARGE DIAMETER<br />

MECHANICAL SEAL TYPE<br />

4 POLE<br />

WITH OUT MOTOR<br />

M<br />

S<br />

P<br />

MONOBLOCK<br />

WITH STANDARD MOTOR<br />

PEDESTAL-FEXIBLE COUPLING<br />

SERIES 3<br />

4

SELECTION CHART<br />

2900 m<strong>in</strong> -1<br />

H<br />

[m]<br />

100<br />

80<br />

60<br />

U.S.g.p.m. 50 60 70 80 90100 120 140 160180200 250 300 350 400 500 600 700<br />

Imp.g.p.m. 40 50 60 70 80 90 100<br />

32-200/5.5<br />

120 140 160180200 250 300 350 400 500 600<br />

40-200/11<br />

30 0<br />

250<br />

200<br />

H<br />

[m]<br />

50<br />

40<br />

32-200/4.0<br />

32-200/3.0<br />

32-200/7.5<br />

40-200/7.5<br />

50-200/15 65-200/22<br />

50-200/11<br />

50-200/9.2<br />

65-200/18.5<br />

150<br />

30<br />

32-160/2.2<br />

40-200/5.5<br />

65-200/15 65-160/15<br />

100<br />

20<br />

32-160/1.5<br />

32-125/1.1<br />

40-160/4.0<br />

40-160/3.0<br />

40-125/2.2<br />

50-160/7.5<br />

50-160/5.5<br />

65-160/11<br />

65-160/9.2<br />

65-160/7.5<br />

75<br />

15<br />

50-125/4.0<br />

65-125/5.5<br />

65-125/7.5<br />

40-125/1.5<br />

40<br />

10<br />

9<br />

8<br />

7<br />

6<br />

50-125/2.2<br />

50-125/3.0<br />

65-125/4.0<br />

30<br />

25<br />

20<br />

5<br />

100<br />

120 150 200 250 300 400 500 600 700 800 1000 1200 1500 2000 2500 3000<br />

Q [I/m<strong>in</strong>]<br />

6 7 8 9 10 12 14 16 18 20 25 30 40 50 60 70 100 150<br />

Q [m3 /h]<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

Model<br />

3(L)M<br />

32-125/1.1 (M)<br />

32-160/1.5 (M)<br />

32-160/2.2 (M)<br />

32-200/3.0<br />

32-200/4.0<br />

32-200/5.5<br />

32-200/7.5<br />

40-125/1.5 (M)<br />

40-125/2.2 (M)<br />

40-160/3.0<br />

40-200/4.0<br />

40-200/5.5<br />

40-200/7.5<br />

40-200/11<br />

50-125/2.2 (M)<br />

50-125/3.0<br />

50-125/4.0<br />

50-160/5.5<br />

50-160/7.5<br />

50-200/9.2<br />

50-200/11<br />

50-200/15<br />

65-125/4.0<br />

65-125/5.5<br />

65-125/7.5<br />

65-160/7.5<br />

65-160/9.2<br />

65-160/11<br />

65-160/15<br />

65-200/15<br />

65-200/18.5<br />

65-200/22<br />

kW HP<br />

1,1<br />

1,5<br />

2,2<br />

3,0<br />

4,0<br />

5,5<br />

7,5<br />

1,5<br />

2,2<br />

3,0<br />

4,0<br />

5,5<br />

7,5<br />

11<br />

2,2<br />

3,0<br />

4,0<br />

5,5<br />

7,5<br />

9,2<br />

11<br />

15<br />

4<br />

5,5<br />

7,5<br />

7,5<br />

9,2<br />

11<br />

15<br />

15<br />

18,5<br />

22<br />

1,5<br />

234<br />

5,5<br />

7,5<br />

10<br />

2<br />

3<br />

4<br />

5,5<br />

7,5<br />

10<br />

15<br />

3<br />

4<br />

5,5<br />

7,5<br />

10<br />

12,5<br />

15<br />

20<br />

5,5<br />

7,5<br />

10<br />

10<br />

12,5<br />

15<br />

20<br />

20<br />

25<br />

30<br />

Abs. current (A)<br />

Q= Capacity<br />

230V<br />

Three-phase<br />

400V 690V<br />

I/m<strong>in</strong><br />

m 3 /h<br />

0<br />

0<br />

100<br />

6<br />

150<br />

9<br />

200<br />

12<br />

300<br />

18<br />

333<br />

20<br />

360<br />

22<br />

400<br />

24<br />

450<br />

27<br />

500<br />

30<br />

600<br />

36<br />

700<br />

42<br />

800<br />

48<br />

1000<br />

60<br />

1200<br />

72<br />

1500<br />

90<br />

1800<br />

108<br />

1900<br />

114<br />

2000<br />

120<br />

2100<br />

126<br />

2200<br />

132<br />

H= Total Head<br />

5,0<br />

5,9<br />

8,3<br />

11,8<br />

15,6<br />

-<br />

-<br />

5,9<br />

8,3<br />

11,8<br />

15,9<br />

-<br />

-<br />

-<br />

8,1<br />

11,8<br />

15,9<br />

-<br />

-<br />

-<br />

-<br />

-<br />

13,8<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

2,9<br />

3,4<br />

4,8<br />

6,8<br />

9,0<br />

11,8<br />

-<br />

3,4<br />

4,8<br />

6,8<br />

9,2<br />

11,1<br />

15,1<br />

20,0<br />

4,7<br />

6,8<br />

9,2<br />

11,5<br />

15,5<br />

17,4<br />

22,0<br />

31,3<br />

8<br />

11<br />

14,9<br />

14,9<br />

20,8<br />

27<br />

30,5<br />

30,5<br />

36,9<br />

40,8<br />

-<br />

---<br />

-<br />

6,8<br />

-<br />

-<br />

-<br />

-<br />

-<br />

6,4<br />

8,7<br />

11,6<br />

-<br />

-<br />

-<br />

6,6<br />

9,0<br />

10,0<br />

12,7<br />

18,0<br />

-<br />

6,3<br />

8,6<br />

8,6<br />

12,1<br />

15,6<br />

17,6<br />

17,6<br />

21,3<br />

23,5<br />

22,5<br />

29,5<br />

37<br />

44<br />

55<br />

70,5<br />

70,5<br />

20<br />

26,5<br />

31<br />

40<br />

47<br />

58<br />

72<br />

19<br />

22<br />

26,5<br />

33<br />

40<br />

53<br />

59<br />

72<br />

22,5<br />

27<br />

32<br />

32<br />

36,5<br />

40,5<br />

48<br />

54<br />

60,5<br />

67<br />

21<br />

28<br />

35,5<br />

42<br />

53,5<br />

69<br />

69<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

19,9<br />

26,5<br />

34<br />

40<br />

52<br />

67,5<br />

67,5<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

18,4<br />

24,5<br />

32<br />

37,5<br />

49,5<br />

65<br />

65<br />

19<br />

25,5<br />

29,5<br />

38,5<br />

45,5<br />

57<br />

71<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

14,1<br />

19,2<br />

27<br />

31<br />

43,5<br />

58,3<br />

58,3<br />

17,6<br />

24<br />

27,5<br />

37<br />

44<br />

55,5<br />

70<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

12<br />

17<br />

25<br />

28<br />

40,5<br />

-<br />

55,5<br />

17<br />

23,5<br />

27<br />

36<br />

43<br />

55<br />

70<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

38<br />

-<br />

53<br />

16,5<br />

23<br />

26,5<br />

35,5<br />

42,5<br />

54,5<br />

69,5<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

49<br />

15,7<br />

22<br />

25,5<br />

34,5<br />

41<br />

53,5<br />

68,5<br />

17,5<br />

20,5<br />

26<br />

31<br />

38,5<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

44<br />

14,5<br />

21<br />

24<br />

33<br />

39,5<br />

52,5<br />

67,5<br />

17<br />

20<br />

25,5<br />

30,5<br />

38<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

13,2<br />

19,5<br />

22,5<br />

32<br />

38<br />

51<br />

66<br />

16,3<br />

19,6<br />

25<br />

30<br />

37,5<br />

50<br />

56<br />

70<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

10,3<br />

16,4<br />

20<br />

29<br />

35<br />

47,5<br />

63<br />

14,9<br />

18,4<br />

24<br />

28,5<br />

36<br />

49<br />

55<br />

69<br />

20<br />

25<br />

30,5<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

7<br />

13<br />

17<br />

25,5<br />

31<br />

44<br />

59<br />

13,4<br />

17<br />

22,5<br />

27<br />

35<br />

17,5<br />

54<br />

68<br />

19,4<br />

24,5<br />

29,5<br />

30<br />

34,5<br />

38,5<br />

45,5<br />

51<br />

58,5<br />

65,5<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

11,7<br />

15,4<br />

21,5<br />

25,5<br />

33,5<br />

45,5<br />

52<br />

66<br />

18,5<br />

23,5<br />

29<br />

29<br />

34<br />

38<br />

45<br />

50<br />

57,5<br />

65<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

8<br />

11,8<br />

17,9<br />

22<br />

30<br />

40,5<br />

48<br />

62<br />

16,5<br />

21,5<br />

27<br />

27<br />

32<br />

36<br />

43<br />

48<br />

55,5<br />

63<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

8<br />

14<br />

18<br />

26<br />

34<br />

42<br />

57<br />

14,3<br />

19,1<br />

24,5<br />

25,5<br />

29,5<br />

34<br />

41<br />

45,5<br />

53<br />

60,5<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

10,7<br />

15,5<br />

21<br />

21,5<br />

26<br />

30,5<br />

37,5<br />

41<br />

49<br />

56,5<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

7<br />

11,7<br />

16,8<br />

17,5<br />

21,5<br />

26<br />

33,5<br />

36<br />

44<br />

52<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

10,4<br />

15,4<br />

16<br />

20<br />

24,5<br />

32<br />

34<br />

42,5<br />

50,5<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

14<br />

14,5<br />

18,6<br />

23<br />

30,5<br />

32<br />

40,5<br />

48,5<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

17<br />

21,5<br />

29<br />

30<br />

39<br />

47<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

20<br />

27<br />

-<br />

37<br />

45<br />

5

SELECTION CHART<br />

1450 m<strong>in</strong> -1<br />

U.S.g.p.m. 30 40 50 60 70 80 90 100 120 140 160 180200 250 300 350<br />

30<br />

Imp.g.p.m.<br />

20<br />

30<br />

40 50 60 70 80 90 100 120 140 160 180200 250 300<br />

H<br />

[m]<br />

20<br />

15<br />

32-200/0.75<br />

40-200/1.5<br />

50-200/2.2<br />

75<br />

50<br />

H<br />

[m]<br />

32-200/0.55<br />

40-200/1.1<br />

50-200/1.5<br />

65-200/3.0<br />

40<br />

10<br />

9<br />

8<br />

7<br />

32-200/0.55R<br />

32-160/0.37<br />

32-160/0.37R<br />

40-200/1.1R<br />

40-160/0.55<br />

50-200/1.5R<br />

50-160/1.1<br />

65-160/2.2<br />

65-200/2.2<br />

65-200/2.2R<br />

30<br />

25<br />

6<br />

5<br />

32-125/0.25<br />

40-160/0.55R<br />

40-125/0.37<br />

50-160/1.1R<br />

50-125/0.55<br />

65-160/1.1<br />

65-160/1.5<br />

65-160/1.1<br />

20<br />

15<br />

4<br />

40-125/0.37R<br />

50-125/0.55R<br />

3<br />

65-125/0.75<br />

10<br />

2<br />

65-125/0.55<br />

5<br />

1<br />

50<br />

60 80 100 120 150 200 250 300 400 500 600 700 800 1000 1200 1500<br />

Q [I/m<strong>in</strong>]<br />

3 4 5 6 7 8 9 10 12 14 16 18 20 25 30 40 50 60 70<br />

Q [m 3 /h]<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

Pump type<br />

3M<br />

32-125/0.25<br />

32-160/0.37R<br />

32-160/0.37<br />

32-200/0.55R<br />

32-200/0.55<br />

32-200/0.75<br />

40-125/0.37R<br />

40-125/0.37<br />

40-160/0.55R<br />

40-160/0.55<br />

40-200/1.1R<br />

40-200/1.1<br />

40-200/1.5<br />

50-125/0.55R<br />

50-125/0.55<br />

50-160/1.1R<br />

50-160/1.1<br />

50-200/1.5R<br />

50-200/1.5<br />

50-200/2.2<br />

65-125/0.55<br />

65-125/0.75<br />

65-125/1.1<br />

65-160/1.1<br />

65-160/1.5<br />

65-160/2.2<br />

65-200/2.2R<br />

65-200/2.2<br />

62-200/3.0<br />

kW<br />

0,25<br />

0,37<br />

0,37<br />

0,55<br />

0,55<br />

0,75<br />

0,37<br />

0,37<br />

0,55<br />

0,55<br />

1,1<br />

1,1<br />

1,5<br />

0,55<br />

0,55<br />

1,1<br />

1,1<br />

1,5<br />

1,5<br />

2,2<br />

0,55<br />

0,75<br />

1,1<br />

1,1<br />

1,5<br />

2,2<br />

2,2<br />

2,2<br />

3<br />

HP<br />

0,33<br />

0,5<br />

0,5<br />

0,75<br />

0,75<br />

1<br />

0,5<br />

0,5<br />

0,75<br />

0,75<br />

1,5<br />

1,5<br />

2<br />

0,75<br />

0,75<br />

1,5<br />

1,5<br />

2<br />

2<br />

3<br />

0,75<br />

1<br />

1,5<br />

1,5<br />

2<br />

3<br />

3<br />

3<br />

4<br />

Q= Capacity<br />

I/m<strong>in</strong> 50 100 160 200 250 300 350 400 500 600 650 800 950 1000 1050 1100 1200<br />

m 3 /h 3 6 9.6 12 15 18 21 24 30 36 39 48 57 60 63 66 72<br />

5,6<br />

7,2<br />

8,7<br />

10,5<br />

12<br />

17,3<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

4,9<br />

6,3<br />

8<br />

9,3<br />

11<br />

16,5<br />

4,5<br />

6,2<br />

7,2<br />

8,5<br />

11<br />

12,7<br />

17,8<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

3,3<br />

4,5<br />

6,7<br />

7<br />

9,2<br />

14,6<br />

4<br />

5,7<br />

6,7<br />

7,9<br />

10,5<br />

12,3<br />

17,4<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

H= Total manometric head <strong>in</strong> meters<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

3<br />

4,6<br />

5,7<br />

6,9<br />

9,6<br />

11,2<br />

16,2<br />

4,7<br />

5,6<br />

7,5<br />

8,8<br />

11,8<br />

12,7<br />

17,5<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

2,3<br />

3,8<br />

5<br />

6,2<br />

9<br />

10,4<br />

15,3<br />

4,4<br />

5,4<br />

7,2<br />

8,5<br />

11,5<br />

12,3<br />

17,2<br />

4,8<br />

6<br />

7,2<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

1,5<br />

3<br />

4,3<br />

5,4<br />

8,3<br />

9,4<br />

14,2<br />

4,2<br />

5,2<br />

6,9<br />

8,2<br />

11,1<br />

11,9<br />

16,8<br />

4,6<br />

5,8<br />

7<br />

8,1<br />

9,2<br />

11,3<br />

12,4<br />

13,9<br />

15,8<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

3,8<br />

4,9<br />

6,5<br />

7,8<br />

10,6<br />

11,5<br />

16,4<br />

4,4<br />

5,7<br />

6,8<br />

8,0<br />

9<br />

11,1<br />

12,2<br />

13,7<br />

15,6<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

3<br />

4,1<br />

5,6<br />

6,9<br />

9,5<br />

10,5<br />

15,4<br />

4,0<br />

5,2<br />

6,3<br />

7,4<br />

8,5<br />

10,6<br />

11,6<br />

13,0<br />

15,06<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

3,6<br />

5,2<br />

6,3<br />

7,5<br />

10,1<br />

11,9<br />

16,9<br />

4,9<br />

5,8<br />

7,7<br />

9<br />

12,1<br />

13<br />

17,7<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

2<br />

3,2<br />

4,5<br />

5,8<br />

8<br />

9,1<br />

14<br />

3,5<br />

4,6<br />

5,8<br />

7,0<br />

8<br />

10<br />

11<br />

12,4<br />

14,5<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

3,2<br />

4,4<br />

5,4<br />

6,6<br />

7,7<br />

9,8<br />

10,6<br />

12<br />

14,1<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

2,3<br />

3,5<br />

4,5<br />

5,7<br />

6,7<br />

8,8<br />

9,3<br />

10,8<br />

12,9<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

1,4<br />

2,5<br />

3,5<br />

4,6<br />

5,7<br />

7,6<br />

7,8<br />

9,3<br />

11,6<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

2,2<br />

3,2<br />

4,2<br />

5,3<br />

7,2<br />

7,3<br />

8,8<br />

11,1<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

2,8<br />

3,8<br />

4,9<br />

6,8<br />

6,8<br />

8,3<br />

10,6<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

4,5<br />

6,4<br />

-<br />

7,8<br />

10,1<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

5,5<br />

-<br />

-<br />

9<br />

6

<strong>CENTRIFUGAL</strong> <strong>PUMPS</strong> <strong>in</strong> <strong>AISI</strong> 316<br />

3L Series - wetted parts <strong>in</strong> <strong>AISI</strong> 316<br />

3LM<br />

3LS<br />

monobloc with extended motor shaft<br />

monobloc with standard motor<br />

and rigid coupl<strong>in</strong>g<br />

3L Series<br />

3LP<br />

pump on baseplate with<br />

standard motor and coupl<strong>in</strong>g<br />

3LS<br />

3LPF<br />

3LSF<br />

bareshaft pump<br />

1450 m<strong>in</strong> -1 1450 m<strong>in</strong> -1<br />

2900 m<strong>in</strong> -1<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

2900 m<strong>in</strong> -1<br />

7

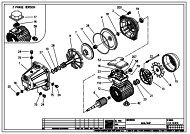

<strong>CENTRIFUGAL</strong> <strong>PUMPS</strong> - OPEN IMPELLER <strong>in</strong> <strong>AISI</strong> <strong>304</strong> DWO <strong>CENTRIFUGAL</strong> <strong>PUMPS</strong> - CLOSED IMPELLER <strong>in</strong> <strong>AISI</strong> <strong>304</strong> DWC<br />

DWO<br />

DWC<br />

APPLICATIONS<br />

• Chillers<br />

• Refrigeration<br />

• Condition<strong>in</strong>g and heat<strong>in</strong>g<br />

• Transferr<strong>in</strong>g of <strong>in</strong>dustrial<br />

liquids<br />

• Domestic and <strong>in</strong>dustrial<br />

water supply<br />

• Irrigation<br />

• Swimm<strong>in</strong>g pools<br />

• Wash<strong>in</strong>g systems<br />

• Dra<strong>in</strong>age<br />

FEATURES / BENEFIT<br />

• Hydraulic robust construction, enhance pump<strong>in</strong>g operation.<br />

• High performance and efficiency design, thus energy sav<strong>in</strong>g.<br />

• <strong>Ebara</strong> exclusive patent for hydraulic volute obta<strong>in</strong>ed from<br />

hydro-form<strong>in</strong>g process.<br />

• EPDM mechanical seal and elastomers as standard.<br />

• Connections: - Female thread G2<br />

- Hose-Union<br />

• Sta<strong>in</strong>less steel <strong>AISI</strong><strong>304</strong> for all wetted parts ensure long last<strong>in</strong>g<br />

operation.<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

8

PERIPHERAL TURBINE <strong>PUMPS</strong><br />

PRA<br />

PRA SWIMMING POOL <strong>PUMPS</strong> SWA<br />

SWA<br />

2900 m<strong>in</strong> -1 2900 m<strong>in</strong> -1<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

Pump type<br />

Versions<br />

50Hz<br />

Amp.<br />

HP<br />

Power<br />

kW<br />

PRA 050 M<br />

PRA 050 T<br />

PRA 080 M<br />

PRA 080 T<br />

PRA 100 M<br />

PRA 100 T<br />

PRA 150 M<br />

PRA 150 T<br />

PRA 200 M<br />

PRA 200 T<br />

1/230V<br />

3/415V<br />

1/230V<br />

3/415V<br />

1/230V<br />

3/415V<br />

1/230V<br />

3/415V<br />

1/230V<br />

3/415V<br />

2,5<br />

1<br />

4,9<br />

2,1<br />

5,6<br />

2,4<br />

10<br />

3,6<br />

10,9<br />

4,0<br />

0,5<br />

0,5<br />

0,8<br />

0,8<br />

1<br />

1<br />

1,5<br />

1,5<br />

2<br />

2<br />

0,37<br />

0,37<br />

0,59<br />

0,59<br />

0,74<br />

0,74<br />

1,1<br />

1,1<br />

1,5<br />

1,5<br />

9

HORIZONTAL MULTI-STAGE <strong>PUMPS</strong><br />

COMPACT<br />

COMPACT<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

10

COMPACT BOOSTER MODEL AM-PT<br />

COMPACT BOOSTER AM-PT<br />

COMPACT BOOSTER MODEL AM-PC<br />

COMPACT BOOSTER AM-PC<br />

Model : AM6-PT<br />

0.4kW<br />

Model : AM8-PC<br />

0.6kW<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

COMPACT BOOSTER type AM-PT<br />

Model<br />

kW<br />

*Application<br />

l/m<strong>in</strong><br />

m 3 /h<br />

Q = Capacity<br />

20 30 40 50 60 80<br />

1,2 1,8 2,4 3 3,6 4,8<br />

H = Total head (m)<br />

Connection<br />

AM 4-PT<br />

0.3<br />

20,5<br />

18,7<br />

16,7<br />

14,4<br />

11,9<br />

6<br />

1 ,, x 1 ,,<br />

AM 6-PT<br />

0.4<br />

Head <strong>in</strong> m<br />

30,7<br />

AM 8-PT 0.6<br />

39,7 36,1 32 27,4 22,4 10,5<br />

28,2<br />

25,2<br />

21,8<br />

18<br />

9<br />

1 ,, x 1 ,,<br />

1 ,, x 1 ,,<br />

COMPACT BOOSTER type AM-PC<br />

Model<br />

AM 6-PC<br />

kW<br />

0.4<br />

*Application<br />

l/m<strong>in</strong><br />

m 3 /h<br />

Q = Capacity<br />

20 30 40 50 60 80<br />

1,2 1,8 2,4 3 3,6 4,8<br />

H = Total head (m)<br />

Connection<br />

AM 4-PC 0.3<br />

20,5 18,7 16,7 14,4 11,9 6 1 ,, x 1 ,,<br />

Head <strong>in</strong> m<br />

30,7 28,2 25,2 21,8 18 9 1 ,, x 1 ,,<br />

AM 8-PC 0.6<br />

39,7 36,1 32 27,4 22,4 10,5<br />

1 ,, x 1 ,,<br />

11<br />

* For guidance only

PRA-BOOSTER & E-BOOSTER PUMP<br />

BOOSTER PUMP<br />

APPLICATION TYPE MODEL SERVICE* CONNECTION<br />

For average homes<br />

with modern<br />

applicances.<br />

PRA-<br />

BOOSTER<br />

0.37 kW 0.37 kW<br />

PRA-BOOSTER PT PRA-BOOSTER PC<br />

Max. Capacity:<br />

35 lit/m<strong>in</strong><br />

1” x 1”<br />

Large Double storey<br />

homes/ Semi-D/<br />

Bungalow<br />

E-BOOSTER<br />

9 series<br />

1 1 /4” x 1”<br />

COMFORTJET BOOSTER PUMP<br />

0.75 kW 0.75 kW<br />

E-BOOSTER 9010 PT E-BOOSTER 9010 PC<br />

Max. Capacity:<br />

120 lit/m<strong>in</strong><br />

*<br />

For guidance only.<br />

COMFORTJET<br />

Operative Features<br />

EBARA ComfortJet Booster<br />

• Quiet operation, thanks to EBARA design that makes this<br />

possible.<br />

• Fully automatic starts/stop when tap opened/closed.<br />

• Leakage-free design.<br />

• Ma<strong>in</strong>ta<strong>in</strong> pressure at a constant level dur<strong>in</strong>g operation,<br />

elim<strong>in</strong>at<strong>in</strong>g hot/cold shower fluctuations.<br />

• Auto shuts off if dry-runn<strong>in</strong>g occurs.<br />

• IP68 electric motor used for weather-proof operation.<br />

• Outdoor <strong>in</strong>stallation possible.<br />

<strong>Ebara</strong> PC Controller<br />

<strong>Ebara</strong> Presscontrol (PC) is an electronic device ensur<strong>in</strong>g<br />

optimum control of automatic water pressure system.<br />

✓ Automatically control the pump efficiently.<br />

✓ Monitor both pressure and flow.<br />

✓ No adjustment of pressure sett<strong>in</strong>g is required.<br />

✓ Any risk of pumps damages as a result of dry runn<strong>in</strong>g is<br />

elim<strong>in</strong>ated, as the device will automatically cut-off when<br />

<strong>in</strong>com<strong>in</strong>g water supply is <strong>in</strong>sufficient.<br />

✓ Much more compact, absolutely quiet, durable and simple to <strong>in</strong>stall.<br />

Model<br />

kW<br />

*Application<br />

l/m<strong>in</strong> 20<br />

m 3 /h<br />

1.2<br />

Q = capacity<br />

30 40 60 80<br />

1.8 2.4 3.6 4.8<br />

H = Total head (m)<br />

Connection<br />

ComfortJet<br />

M08<br />

ComfortJet<br />

M12<br />

0.6<br />

0.9<br />

Head <strong>in</strong> m<br />

43.3<br />

-<br />

40.2<br />

45.6<br />

36.3<br />

44<br />

26.1<br />

38.8<br />

13.4<br />

32<br />

1 1 /4” x1 1 /4”<br />

1 1 /4” x1 1 /4”<br />

*<br />

For guidance only.<br />

12

MONOBLOC <strong>PUMPS</strong><br />

MD<br />

MD<br />

Total Head<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

Pump type kW Q= Capacity<br />

H=Total head[m]<br />

13

MONOBLOCK END SUCTION <strong>PUMPS</strong><br />

FSDA<br />

FSDA<br />

1500<br />

SELECTION CHART<br />

ft m 50Hz (Synchronous Speed: 1500m<strong>in</strong> -1 )<br />

70<br />

200<br />

60<br />

150<br />

50<br />

4LA530<br />

4LA575<br />

4LA555<br />

120<br />

40<br />

80X65 4KA511<br />

4LA522<br />

4LA545<br />

4KA537<br />

100<br />

80<br />

30<br />

80X65 4KA57.5<br />

80X65 4KA55.5<br />

4KA518.5<br />

4KA515<br />

4KA530<br />

4KA555<br />

4KA545<br />

Total Head<br />

20<br />

60<br />

50 15<br />

40<br />

4JA53.7<br />

4JA52.2<br />

4JA55.5<br />

4JA53.7<br />

4HA53.7<br />

4KA511<br />

4KA57.5<br />

4JA522<br />

4JA518.5<br />

4JA515<br />

4JA515<br />

4HA511<br />

4JA530<br />

4JA522<br />

4KA537<br />

4JA537<br />

30<br />

10<br />

4HA51.5<br />

4HA52.2<br />

4GA52.2<br />

4HA57.5<br />

4HA511<br />

4JA518.5 4JA518.5<br />

4JA515 4JA515<br />

8<br />

20<br />

6<br />

4GA5.75<br />

4GA51.5<br />

200X150<br />

4HA55.5<br />

4HA57.5<br />

15<br />

12<br />

4<br />

80X65 100X80 125X100 150X125 200X150<br />

0.04 0.06 0.1 0.2 0.3 0.4 0.6 0.8 1 2 3 4 6<br />

15 20 30 40 50 60 80 100 150 200 300 400 500 600<br />

800 1000 1500<br />

8 10 m 3 /m<strong>in</strong><br />

2000 US GPM<br />

10 15 20 30 40<br />

50<br />

60<br />

80<br />

100 150 200<br />

Capacity<br />

300<br />

400<br />

500 600<br />

800 1000<br />

1500 2000<br />

Imp. GPM<br />

14

300<br />

2HA52.2<br />

2JA522<br />

2GA57.5<br />

2KA5132<br />

END SUCTION VOLUTE <strong>PUMPS</strong><br />

FSA<br />

FSA<br />

f t<br />

200<br />

m<br />

100<br />

80<br />

80<br />

60<br />

150X100 4NA590<br />

4NA575<br />

4NA555<br />

150X125<br />

50HZ (Synchronous Speed 1500m<strong>in</strong> -1 )<br />

50<br />

125X100<br />

4LA575<br />

4NA5150<br />

4NA5132<br />

4NA5110<br />

4NA5335<br />

4NA5300<br />

4NA5260<br />

150<br />

4LA530<br />

4LA555<br />

4NA5225<br />

4NA5185<br />

4LA5150<br />

120<br />

40<br />

80X65<br />

4KA511<br />

4LA522<br />

4LA545<br />

4LA590<br />

4LA575<br />

4LA5132<br />

100<br />

30<br />

4KA57.5<br />

4KA518.5<br />

4KA537<br />

4KA555<br />

4LA5110<br />

Total Head<br />

80<br />

60<br />

50<br />

40<br />

20<br />

15<br />

4HA5.75<br />

80X65<br />

4JA52.2<br />

4JA51.5<br />

4KA55.5<br />

100X80<br />

4JA53.7<br />

4JA52.2<br />

4HA51.5<br />

4JA55.5<br />

4JA53.7<br />

4HA53.7<br />

4KA515<br />

4JCA511<br />

4JCA57.5<br />

4HCA55.5<br />

4JA522<br />

4JA518.5<br />

4JA515<br />

4HA515<br />

4KA530<br />

4HA511<br />

4JA530<br />

4JA522<br />

4JA518.5<br />

4KA545<br />

4KA537<br />

4LA590<br />

250x200<br />

30<br />

10<br />

4HA5.4<br />

4HCA53.7<br />

4HA57.5<br />

4HA511<br />

8<br />

4JA515<br />

4HA52.2<br />

4HA5.75<br />

4GA52.2<br />

4JCA55.5<br />

4GCA52.2<br />

4GA51.5<br />

4HA57.5<br />

20<br />

6<br />

4GA5.75<br />

4HA55.5<br />

(200X150)<br />

15<br />

65x50 80x65 100x80 125x100 150x125 200x150<br />

12<br />

4<br />

50x40<br />

0.04 0.06 0.1<br />

15 20 30<br />

40<br />

0.2 0.3 0.4 0.6 0.8 1 2 3 4 6 8 10 15 20 30 m 3 /mi<br />

50 60 80 100 150 200 300 400 500 600 800 1000 1500 2000 3000 4000 6000 8000 US GPM<br />

10<br />

15<br />

20<br />

30<br />

40<br />

50<br />

60<br />

80<br />

100<br />

150<br />

200 300 400 500 600<br />

Capacity<br />

800 1000<br />

1500<br />

2000<br />

3000<br />

4000<br />

6000<br />

8000<br />

Imp. G<br />

ft<br />

500<br />

m<br />

160<br />

140<br />

100X65<br />

50HZ (Synchronous Speed 3000m<strong>in</strong> -1 )<br />

150X100<br />

400<br />

120<br />

2KA575<br />

150X100<br />

300<br />

100<br />

100<br />

100X80<br />

2KA555<br />

2KA5110<br />

80<br />

2JA515<br />

2JA545<br />

2KA590<br />

2JA537<br />

2KA575<br />

Total Head<br />

200<br />

150<br />

120<br />

60<br />

50<br />

40<br />

2HA55.5<br />

2HA53.7<br />

2JA511<br />

2HA57.5<br />

2HA55.5<br />

2JA516.5<br />

2HA515<br />

2HA511<br />

2JA530<br />

2HA522<br />

2HA518.5<br />

2GA515<br />

100X80<br />

125X100<br />

2JCA555<br />

2JCA545<br />

2JCA537<br />

2HCA530<br />

100<br />

30<br />

2GA57.5<br />

2HCA522<br />

2GA511<br />

80<br />

2HA3.7<br />

2GA55.5<br />

2GCA518.5<br />

2GCA515<br />

125X100<br />

20<br />

60<br />

4HA51.5<br />

65X50<br />

80X65<br />

100X80<br />

50<br />

15<br />

40<br />

50X40<br />

10<br />

10<br />

0.1 0.2 0.3 0.4 0.6 0.8 1 1.5 2 3 4 6 8<br />

30 40 50 60 80<br />

150 200 300 400 500 600 800 1000 1500 2000<br />

m 3 /m<strong>in</strong><br />

US GPM<br />

20 30 40 50 60 80 100 150 200 300 400 500 600 800 1000 1200 1500<br />

Imp. GPM<br />

15

STAINLESS STEEL VOLUTE PUMP - 316SS Version<br />

FSSA<br />

FSSA<br />

<strong>PERFORMANCE</strong> CHART<br />

16

END SUCTION VOLUTE <strong>PUMPS</strong><br />

FS<br />

END SUCTION VOLUTE <strong>PUMPS</strong><br />

S<br />

FS<br />

S<br />

SELECTION CHART<br />

2 Pole 50 Hz (Synchronous Speed : 3000 m<strong>in</strong> -1 )<br />

SELECTION CHART<br />

50 Hz (Synchronous Speed : 1500 m<strong>in</strong> -1 )<br />

4 Pole<br />

50 Hz (Synchronous Speed : 1500 m<strong>in</strong> -1 )<br />

17

END SUCTION VOLUTE <strong>PUMPS</strong><br />

IBL<br />

VERTICAL IN-LINE <strong>PUMPS</strong><br />

LPD<br />

IBL<br />

LPD<br />

SELECTION CHART<br />

SELECTION CHART<br />

2 Pole 3000 m<strong>in</strong> -1 3000 m<strong>in</strong> -1<br />

4 Pole 1500 m<strong>in</strong> -1<br />

18

STAINLESS STEEL VERTICAL IN-LINE <strong>PUMPS</strong> <strong>in</strong> <strong>AISI</strong> <strong>304</strong><br />

LPS<br />

LPS<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

19

VERTICAL IN-LINE <strong>PUMPS</strong><br />

ELINE / ELINE-D<br />

ELINE / ELINE-D<br />

SELECTION CHART<br />

(*) Model available <strong>in</strong> s<strong>in</strong>gle and tw<strong>in</strong> executions.<br />

(*) Model available <strong>in</strong> s<strong>in</strong>gle and tw<strong>in</strong> executions.<br />

(**) Model only available <strong>in</strong> tw<strong>in</strong> execution.<br />

20

END SUCTION <strong>CENTRIFUGAL</strong> PUMP<br />

ENR<br />

ENR<br />

EBARA ENR pump is designed for pump<strong>in</strong>g water or fluid accord<strong>in</strong>g to DIN<br />

24255 (EN733) standard. The B.P.O design of the pump allows the<br />

complete drive unit to be removed from the cas<strong>in</strong>g without disturb<strong>in</strong>g the<br />

attached pipe work.<br />

FEATURES OF ENR:<br />

• S<strong>in</strong>gle-stage end suction centrifugal pump.<br />

• Volute pump cas<strong>in</strong>g with cast pump feet.<br />

• Bear<strong>in</strong>g support with foot.<br />

• Axial suction and radial discharge upwards.<br />

• Totally enclosed radial impeller.<br />

• Hydraulic balance by means of wear<strong>in</strong>g r<strong>in</strong>g and balanc<strong>in</strong>g holes.<br />

• Lifetime lubricated ball bear<strong>in</strong>gs.<br />

• Mechanical shaft seal accord<strong>in</strong>g to DIN 24960.<br />

(Gland pack<strong>in</strong>g optional)<br />

APPLICATIONS<br />

• Water supply duties for municipalities and <strong>in</strong>dustries.<br />

• Irrigation<br />

• Dra<strong>in</strong>age<br />

• Heat<strong>in</strong>g and air condition<strong>in</strong>g.<br />

• Hot and chilled water.<br />

• Fresh and sea water.<br />

• Fire protection.<br />

SELECTION CHART<br />

at 1.450 r.p.m.<br />

100<br />

80<br />

60<br />

H<br />

50<br />

[m]<br />

40<br />

10<br />

10<br />

20<br />

20<br />

40<br />

40<br />

60<br />

60<br />

80<br />

80<br />

100<br />

100<br />

200<br />

200<br />

400<br />

400<br />

80-400 100-400<br />

600<br />

800<br />

1000<br />

1500<br />

2000<br />

3000<br />

600<br />

800<br />

1000<br />

1500<br />

2000<br />

3000 4000<br />

150-500 200-500 250-<br />

500<br />

125-<br />

400<br />

150-<br />

400 200-<br />

400<br />

Imp.gal/m<strong>in</strong><br />

US gal./m<strong>in</strong><br />

300-500<br />

300<br />

250<br />

200<br />

150<br />

30<br />

20<br />

32-250<br />

40-315<br />

40-<br />

250<br />

50-315<br />

50-250 65-250<br />

80-<br />

315<br />

65-<br />

315<br />

80-<br />

250<br />

100-<br />

315<br />

125-<br />

315<br />

100-<br />

250<br />

150-<br />

315<br />

150-250<br />

125-<br />

250<br />

200-<br />

315<br />

300-<br />

400<br />

250-<br />

315<br />

250-<br />

300<br />

250-<br />

400<br />

100<br />

80<br />

60<br />

10<br />

5<br />

32-200A<br />

40-<br />

200<br />

32-<br />

200B<br />

50-<br />

200<br />

65-<br />

200<br />

32-160A 32-<br />

160B<br />

40-<br />

160 50-160 65-<br />

160<br />

80-<br />

200<br />

100-<br />

200<br />

125-<br />

200<br />

100-<br />

160<br />

80-<br />

160<br />

150-<br />

200<br />

200-<br />

250<br />

40<br />

30<br />

20<br />

4<br />

32-125<br />

40-125 50-125 65-125<br />

3<br />

10<br />

2<br />

2<br />

3<br />

4<br />

5<br />

10 20<br />

30<br />

40<br />

50<br />

100 200<br />

300 400 500<br />

1000<br />

2000<br />

Q [m 3 /h]<br />

SELECTION CHART<br />

at 2.900 r.p.m.<br />

150<br />

10<br />

10<br />

20<br />

20<br />

40 60 80 100<br />

40 60 80 100<br />

200<br />

200<br />

400 600 1000 1500 2000 3000<br />

400 600 800 1000 1500 2000 3000<br />

Imp.gal/m<strong>in</strong><br />

US gal./m<strong>in</strong><br />

450<br />

100<br />

H<br />

[m]<br />

40-315 50-315<br />

65-<br />

315<br />

80-<br />

315<br />

400<br />

H<br />

300<br />

[ft]<br />

32-250 40-250<br />

50-250<br />

65-250<br />

80-<br />

250<br />

100-<br />

250<br />

200<br />

50<br />

40<br />

32-200A<br />

32-<br />

200B<br />

40-<br />

200<br />

50-<br />

200<br />

65-<br />

200<br />

80-<br />

200<br />

100-<br />

200<br />

125-<br />

200<br />

150<br />

30<br />

32-160A 40-160<br />

32-<br />

160B<br />

50-<br />

160<br />

65-<br />

160<br />

80-<br />

160<br />

100<br />

80<br />

20<br />

100-<br />

160<br />

32-125 40-125<br />

50-125<br />

65-<br />

125<br />

60<br />

40<br />

10<br />

2 3 4 5 10 20<br />

40<br />

30 50<br />

100 200<br />

300 400 500<br />

1000<br />

2000<br />

Q[m 3 /h]<br />

21

VERTICAL MULTI-STAGE <strong>PUMPS</strong><br />

MULTIGO<br />

MULTIGO<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

22

VERTICAL MULTI-STAGE <strong>CENTRIFUGAL</strong> PUMP<br />

CVM<br />

Vertical multistage centrifugal pumps manufactured with the great experience of EBARA <strong>in</strong> design and production of<br />

pumps. Reliable and quiet <strong>in</strong> operation.<br />

APPLICATION<br />

• Civil/Domestic Uses / Industrial:<br />

Water supply systems<br />

Pressure boost<strong>in</strong>g<br />

Water treatment plants (filtrations)<br />

Water supply systems<br />

Wash<strong>in</strong>g plants<br />

Transfer of non-aggressive liquids<br />

• Agriculture:<br />

Irrigation<br />

SPECIFICATIONS<br />

Liquid Handled<br />

Construction<br />

Pipe connection<br />

Material<br />

Applicable standard of test<br />

PUMP<br />

Type of liquid<br />

Clean water<br />

Max temperature 40<br />

Impeller<br />

Closed centrifugal type<br />

Shaft seal Type<br />

Mechanical seal<br />

Bear<strong>in</strong>g<br />

Sealed ball bear<strong>in</strong>g<br />

Suction G 1 1/4 UNI ISO 228<br />

Discharge G 1 1/4 UNI ISO 228<br />

Cas<strong>in</strong>g<br />

Cast iron<br />

Impeller<br />

PPO mod. glass fibre re<strong>in</strong>forced<br />

External pump cas<strong>in</strong>g <strong>AISI</strong> <strong>304</strong><br />

Shaft seal<br />

Ceramic/Carbon/NBR<br />

Shaft <strong>AISI</strong> 416<br />

Bracket<br />

Cast iron<br />

ISO 9906 Annex A<br />

SELECTION CHART<br />

CVM A - CVM B<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

23

VERTICAL MULTI-STAGE STAINLESS STEEL <strong>PUMPS</strong><br />

EVM<br />

APPLICATIONS<br />

• Civil, Industrial, farm<strong>in</strong>g, fire-fight<strong>in</strong>g, boost<strong>in</strong>g systems<br />

• Water treatment plants (reverse osmosis, filtrations)<br />

• Irrigation system<br />

• Wash<strong>in</strong>g system<br />

• Movement of hot and cold water for heat<strong>in</strong>g, cool<strong>in</strong>g and air-condition<strong>in</strong>g system.<br />

• Boiler feed<strong>in</strong>g<br />

• Movement of moderately aggressive chemical liquids without solids.<br />

MATERIALS<br />

• Impeller, diffusers, cas<strong>in</strong>g cover, outer cas<strong>in</strong>g, shaft sleeve, coupl<strong>in</strong>g covers,<br />

fix<strong>in</strong>g <strong>in</strong> contact with liquid: <strong>AISI</strong> <strong>304</strong> sta<strong>in</strong>less steel<br />

• Bottom cas<strong>in</strong>g: <strong>AISI</strong> <strong>304</strong> sta<strong>in</strong>less steel (EVM) - cast iron (EVMG),<br />

<strong>AISI</strong> 316L (EVML)<br />

• Motor bracket and base: cast iron (not <strong>in</strong> contact with the pumped liquid)<br />

• Bear<strong>in</strong>gs (<strong>in</strong> contact with liquid): tungsten carbide<br />

• Mechanical seal: Silicon carbide/carbon/Viton<br />

• Shaft: <strong>AISI</strong> 316 sta<strong>in</strong>less steel<br />

• Tie rods and fix<strong>in</strong>gs not contact with liquid: z<strong>in</strong>c coated sta<strong>in</strong>less steel<br />

STANDARD SPECIFICATION - EVM(G)<br />

Model type 3 5 10 18 32 45 64<br />

Application<br />

Water supply, Light Industrial (boiler feed, wash<strong>in</strong>g, coolant etc.)<br />

Temperature range -15 to +120 o C<br />

Flow / head 80 m 3 /hr (max); 300m (max)<br />

Max. work<strong>in</strong>g pressure<br />

1.6/2.5MPa (16Bar/25Bar)<br />

1.6/2.5/3.0Mpa (16/25/30Bar)<br />

Seal<strong>in</strong>g 16Bar:Mechanical-seal - accord<strong>in</strong>g to DIN Cartridge type Mechanical-seal<br />

25bar:Cartridge Mechanical-seal - accord<strong>in</strong>g to DIN - accord<strong>in</strong>g to DIN<br />

Connect<strong>in</strong>g flange<br />

OVAL OR DIN TYPE<br />

DIN TYPE<br />

Material Impeller <strong>AISI</strong> <strong>304</strong><br />

Stage cas<strong>in</strong>g <strong>AISI</strong> <strong>304</strong><br />

Bottom cas<strong>in</strong>g Cast iron<br />

Head cover Cast iron<br />

Outer sleeve <strong>AISI</strong> <strong>304</strong><br />

Shaft <strong>AISI</strong> 316<br />

Cas<strong>in</strong>g r<strong>in</strong>g EPDM-<strong>AISI</strong>316<br />

Rubber/O-r<strong>in</strong>g EPDM<br />

Mechanical seal Silicon Carbide / Carbon / FPM<br />

Motor No. of Poles 2P (3000rpm:50Hz -- Synchronous speed)<br />

Flange Mount IM B14 (up to 4KW); IM B5 (above 5.5KW)<br />

Voltage/Hz 380V/415V:50Hz (or 400V:50Hz)<br />

OPTIONAL SPECIFICATIONS<br />

Material of Construction<br />

All wetted parts <strong>in</strong> SS<strong>304</strong> available upon request.<br />

Connect<strong>in</strong>g flange<br />

Vitaulic coupl<strong>in</strong>g only for <strong>AISI</strong>316 pump<br />

DIN Round Flange for 16Bar range<br />

Motor No. of Poles IEC 4P model<br />

STANDARD SPECIFICATION - EVM(L)<br />

Model type 3 5 10 18 32 45 64<br />

Application<br />

Water supply, R.O., D.I. Water, ultra-filter systems, process water, etc.<br />

Temperature range<br />

o<br />

-15 to +120 C<br />

Flow / head 80 m 3 /hr (max); 300m (max)<br />

Max. work<strong>in</strong>g pressure 1.6/2.5MPa (16Bar/25Bar) 1.6/2.5/3.0Mpa (16/25/30Bar)<br />

Connect<strong>in</strong>g flange<br />

OVAL OR DIN TYPE<br />

DIN TYPE<br />

Material Impeller <strong>AISI</strong> 316L<br />

Stage cas<strong>in</strong>g <strong>AISI</strong> 316L<br />

Bottom cas<strong>in</strong>g <strong>AISI</strong> 316L stamped <strong>AISI</strong> 316 cast<strong>in</strong>g<br />

Head cover piece <strong>AISI</strong> 316L<br />

Outer sleeve <strong>AISI</strong> 316L<br />

Shaft <strong>AISI</strong> 316<br />

Cas<strong>in</strong>g r<strong>in</strong>g<br />

PTFE(Teflon)-<strong>AISI</strong>316<br />

Rubber/O-r<strong>in</strong>g Viton<br />

Mechanical seal Silicon Carbide/Carbon/FPM (OPTION: SiC vs SiC)<br />

Motor No. of Poles 2P (3000rpm:50Hz -- Synchronous speed)<br />

Flange Mount IM B14 (up to 4 KW); IM B5 (above 5.5 KW)<br />

Voltage/Hz<br />

380V/415V:50Hz (or 400V:50Hz)<br />

OPTIONAL SPECIFICATIONS<br />

Connect<strong>in</strong>g flange<br />

Vitaulic coupl<strong>in</strong>g only for <strong>AISI</strong>316 pump<br />

DIN Round Flange for 16Bar range<br />

Motor No. of Poles IEC 4P model<br />

24

VERTICAL MULTI-STAGE STAINLESS STEEL <strong>PUMPS</strong><br />

EVM<br />

EBARA Corporation was established <strong>in</strong> 1912 as a pump manufacturer and today EBARA is the world's foremost manufacturer<br />

of pumps and pump system. EBARA is proudly present<strong>in</strong>g Vertical Multi-stage pump type EVM, manufacture with great<br />

experience of EBARA <strong>in</strong> design and production of stamped sta<strong>in</strong>less steel pumps. EBARA EVM pumps offer technically advance<br />

designs to meet most market demands, <strong>in</strong>clud<strong>in</strong>g pump<strong>in</strong>g of aggressive liquid.<br />

Two standard pump options are available to satisfy most of the market requirements:<br />

- EVM(G): Bottom cas<strong>in</strong>g <strong>in</strong> cast iron, other liquid contact parts <strong>in</strong> SS<strong>304</strong> sta<strong>in</strong>less steel for general<br />

water supply usage<br />

- EVM(L): All wetted contact parts <strong>in</strong> SS316 sta<strong>in</strong>less steel for aggressive liquid pump<strong>in</strong>g operation.<br />

Optional materials available upon request: All wetted contact parts <strong>in</strong> SS<strong>304</strong> sta<strong>in</strong>less steel for <strong>in</strong>dustrial<br />

pump<strong>in</strong>g applications.<br />

1. Quality motor used.<br />

Standard IEC motors used for EVM pump; thus<br />

ensure realiability <strong>in</strong> pump operation.<br />

2. Spacer coupl<strong>in</strong>g for<br />

user-friendly servic<strong>in</strong>g.<br />

For 11kW & above models, uniquely<br />

designed 'split' type spacer coupl<strong>in</strong>g are<br />

used to permit easy assembly/disassembly<br />

works without dismantl<strong>in</strong>g pipework and<br />

motor.<br />

Spacer<br />

coupl<strong>in</strong>g<br />

Normal Operation<br />

4. Wide selection options.<br />

Two (2) pump types are available as<br />

standard i.e. EVMG (Cast iron bottom<br />

cas<strong>in</strong>g; other wetted parts <strong>in</strong><br />

SUS<strong>304</strong>) and EVML (All wetted parts<br />

<strong>in</strong> SUS316L).<br />

• All wetted parts <strong>in</strong> SUS<strong>304</strong><br />

available as option.<br />

EVM(G) Version<br />

FC/SUS<strong>304</strong><br />

Option:<br />

EVM Version<br />

SUS<strong>304</strong><br />

EVM(L) Version<br />

SUS316<br />

5. High efficiency hydraulic<br />

design.<br />

EBARA owned R&D has resulted <strong>in</strong><br />

the newly developed hydraulic parts<br />

for EVM, particularly impellers and<br />

<strong>in</strong>termediate cas<strong>in</strong>g that provide high<br />

efficiency operation.<br />

2D S/S impeller<br />

Dur<strong>in</strong>g Servic<strong>in</strong>g<br />

3D S/S impeller<br />

Guide vane<br />

<strong>in</strong>termediate cas<strong>in</strong>g<br />

Cartridge<br />

seal<br />

Spacer<br />

coupl<strong>in</strong>g<br />

6. Bottom cas<strong>in</strong>g support.<br />

For EVM 45 and 64, unique bottom<br />

cas<strong>in</strong>g bear<strong>in</strong>g is used to enhance<br />

longer operat<strong>in</strong>g life of the pumps.<br />

3. Cartridge mechanical seal.<br />

Cartridge mechanical seal is<br />

used for all pump models, except<br />

EVM 3-18 (16Bar). Thus permit<br />

easy ma<strong>in</strong>tenance works at site.<br />

Tungsten carbide<br />

Bottom Bear<strong>in</strong>g.<br />

25

<strong>PERFORMANCE</strong> <strong>TABLE</strong> (EVM 3, 5, 10, 18, 32, 45, 64)<br />

EVM<br />

400<br />

16 Bar<br />

25 Bar<br />

30 Bar<br />

50Hz<br />

300<br />

14-30<br />

14-3-30<br />

200<br />

150<br />

26-3.7<br />

22-2.2<br />

18-2.2<br />

24-5.5<br />

22-4.0<br />

22-4.0<br />

22-11<br />

20-7.5<br />

18-7.5<br />

16-7.5<br />

15-5.5<br />

16-15<br />

15-15<br />

14-15<br />

13-30<br />

13-3-30<br />

12-22<br />

12-3-22<br />

11-22<br />

11-3-22<br />

12-11<br />

10-18.5<br />

10-3-18.5<br />

9-18.5<br />

9-3-18.5<br />

8-15<br />

10-37<br />

10-2-37<br />

9-37<br />

9-2-30<br />

8-30<br />

8-2-30 6-37<br />

7-30<br />

7-2-30<br />

6-22<br />

7-1-37<br />

7-2-37<br />

7-3-37<br />

6-1-37<br />

6-2-30<br />

15-1.5<br />

18-4.0<br />

16-3.0<br />

14-5.5<br />

12-5.5<br />

10-11<br />

8-3-15<br />

7-15<br />

6-2-22<br />

6-3-30<br />

5-30<br />

100<br />

13-1.5<br />

14-3.0<br />

11-4.0<br />

7-3-15<br />

6-11<br />

5-18.5<br />

5-2-18.5<br />

5-1-30<br />

5-2-30<br />

5-3-30<br />

11-1.1<br />

12-2.2<br />

11-2.2<br />

10-4.0<br />

8-7.5<br />

7-7.5<br />

6-5.5<br />

6-3-11<br />

5-11<br />

4-15<br />

4-22<br />

4-1-22<br />

4-2-18.5<br />

70<br />

9-1.1<br />

10-2.2<br />

8-3.0<br />

5-3-11<br />

4-7.5<br />

4-2-15<br />

3-11<br />

4-3-18.5<br />

3-18.5<br />

3-1-15<br />

50<br />

7-0.75<br />

6-0.75<br />

8-1.5<br />

7-1.5<br />

6-1.1<br />

6-2.2<br />

5-2.2<br />

5-5.5<br />

4-4.0<br />

4-3-7.5<br />

3-5.5<br />

3-2-11<br />

2-7.5<br />

3-2-15<br />

3-3-15<br />

2-11<br />

Total Head (m)<br />

30<br />

20<br />

5-0.55<br />

4-0.55<br />

3-0.37<br />

5-1.1<br />

4-0.75<br />

3-0.55<br />

4-1.5<br />

3-1.1<br />

3-3.0<br />

2-2.2<br />

3-3-5.5<br />

2-4.0<br />

2-2-3.0<br />

2-2-5.5<br />

1-4.0<br />

2-1-11<br />

2-2-7.5<br />

1-5.5<br />

15<br />

2-0.37<br />

2-0.37<br />

2-0.75<br />

1-2.2<br />

1-1-3.0<br />

1-1-4.0<br />

10<br />

EVM 3 EVM 5 EVM 10 EVM 18 EVM 32 EVM 45 EVM 64<br />

5<br />

0.01 0.015 0.02 0.03<br />

0.05<br />

0.07 0.1 0.15 0.2 0.3<br />

0.5 0.7 1.5 2<br />

3<br />

Capacity (m /m<strong>in</strong>)<br />

MODEL CODE<br />

EVM ( ) 5 8 - N 1.5 (E)<br />

Model Series<br />

E: for <strong>in</strong>verted drive only<br />

M: for S<strong>in</strong>gle Phase only<br />

(G): Cast tron Bottom Cas<strong>in</strong>g<br />

(L): 316 SS Version<br />

( ): <strong>304</strong> SS Version Power output <strong>in</strong> kW<br />

Nom<strong>in</strong>al Capacity (m 3 /hr)<br />

N : Oval Flanges F: Round Flanges<br />

No. of Impellers<br />

no. of reduced impellers (only for EVM 32/45/64)<br />

26

<strong>PERFORMANCE</strong> <strong>TABLE</strong> (EVM 2, 4, 8,16, 30, 60)<br />

EVM<br />

1-Phase<br />

3-Phase<br />

3-Phase<br />

27

VERTICAL MUITL-STAGE <strong>PUMPS</strong><br />

EVMK<br />

MULTI-STAGE <strong>PUMPS</strong><br />

HTM<br />

EVMK<br />

HTM<br />

SELECTION CHART<br />

SELECTION CHART<br />

2900 rpm<br />

50Hz 2 Pole<br />

EVMK<br />

35/40<br />

EVMK<br />

45/70/90<br />

EVMK<br />

125/175<br />

*<br />

EVM3<br />

EVM5<br />

*<br />

EVM10<br />

*<br />

EVM18<br />

*<br />

EVM 32/45/64<br />

*<br />

50Hz 4 Pole<br />

* Please refer to pg 24 & 26 for EVM details.<br />

28

MULTI-STAGE <strong>PUMPS</strong><br />

FM (2 Pole motor drive)<br />

FM MULTI-STAGE <strong>PUMPS</strong> MS 410<br />

MS 410 (4 Pole motor drive)<br />

SELECTION CHART<br />

SELECTION CHART<br />

29

MULTI-STAGE VOLUTE <strong>PUMPS</strong><br />

MS210•220•230<br />

MS210•220•230<br />

SELECTION CHART<br />

Notes: The encircled numbers <strong>in</strong> the areas enclosed by unbroken l<strong>in</strong>es <strong>in</strong>dicate the number of stages, and the other numbers <strong>in</strong> the areas enclosed by<br />

broken l<strong>in</strong>es <strong>in</strong>dicate the motor capacity <strong>in</strong> kW.<br />

30

MULTI-STAGE VOLUTE <strong>PUMPS</strong><br />

MS420<br />

MS420 MULTI-STAGE TURBINE <strong>PUMPS</strong> MSS<br />

MSS<br />

SELECTION CHART<br />

SELECTION CHART<br />

Notes: The encircled numbers <strong>in</strong> the areas enclosed by unbroken l<strong>in</strong>es <strong>in</strong>dicate the number of<br />

stages, and the other numbers <strong>in</strong> the areas enclosed by broken l<strong>in</strong>es <strong>in</strong>dicate the motor<br />

capacity <strong>in</strong> kW.<br />

Notes: Numbers <strong>in</strong> bold type <strong>in</strong>dicate the number of stages, and number <strong>in</strong> f<strong>in</strong>e type <strong>in</strong>dicate<br />

motor capacity <strong>in</strong> kW.<br />

31

SELF PRIMING REGENERATIVE RQ & RQD SELF PRIMING VOLUTE <strong>PUMPS</strong> SQ<br />

SQ<br />

SELECTION CHART<br />

SELECTION CHART<br />

1500 mim -1<br />

32

SELF PRIMING <strong>PUMPS</strong><br />

FQ & FQD SELF PRIMING MULTI-STAGE <strong>PUMPS</strong> FMQ<br />

FMQ<br />

SELECTION CHART<br />

SELECTION CHART<br />

3000 m<strong>in</strong> -1<br />

33

SELF PRIMING <strong>PUMPS</strong><br />

SQPB<br />

SQPB<br />

34

-1<br />

MIXED FLOW <strong>PUMPS</strong><br />

SZ<br />

SZ<br />

SELECTION CHART<br />

ft<br />

60<br />

50<br />

40<br />

m<br />

20<br />

15<br />

200 SZ<br />

250 0SZ<br />

400 SZ<br />

500 SZ<br />

30<br />

10<br />

8<br />

-1<br />

-1<br />

-1<br />

Total Head<br />

20<br />

15<br />

6<br />

5<br />

-1<br />

-1<br />

4<br />

10<br />

3<br />

8<br />

-1<br />

7<br />

6<br />

2<br />

-1<br />

-1<br />

5<br />

1<br />

1.5 2 3 4 5 6 8 10 15 20 30 40 50 60 m 3 /m<strong>in</strong><br />

400<br />

500<br />

600<br />

800<br />

1000<br />

1500<br />

2000<br />

3000<br />

4000<br />

5000 6000<br />

8000<br />

10000<br />

15000<br />

USGPM<br />

400 500 600 800 1000 1500<br />

2000 3000 4000 5000 6000 8000 10000<br />

Capacity<br />

35<br />

IMP.GPM

HORIZONTAL SPLIT CASING <strong>PUMPS</strong><br />

CS/CN<br />

CS/CN<br />

36

HORIZONTAL SPLIT CASING <strong>PUMPS</strong><br />

CSA/CNA<br />

CSA/CNA<br />

1450 m<strong>in</strong> -1<br />

37

HORIZONTAL DOUBLE SUCTION VOLUTE <strong>PUMPS</strong><br />

CN<br />

CN 200~500 mm<br />

CN 600~1000 mm<br />

SELECTION CHARTS<br />

CN Bore 600~1000mm<br />

High speed<br />

Low speed<br />

(NOTE) • Pump rat<strong>in</strong>g not <strong>in</strong> the<br />

chart are also available.<br />

38

SUBMERSIBLE SUMP <strong>PUMPS</strong> <strong>in</strong> <strong>AISI</strong> <strong>304</strong><br />

BEST ZERO<br />

BEST ZERO<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

Note: Best Zero SG is pump without automatic float switch.<br />

39

SUBMERSIBLE SUMP <strong>PUMPS</strong> <strong>in</strong> <strong>AISI</strong> <strong>304</strong><br />

BEST ONE<br />

BEST ONE<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

40

SUBMERSIBLE SUMP <strong>PUMPS</strong> <strong>in</strong> <strong>AISI</strong> <strong>304</strong> BEST 2-3-4-5<br />

BEST 2-3-4-5<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

Pump type kW Capacitor Absorbed Current (A) Q=Capacity<br />

three-phase<br />

F Vc<br />

1~ 3~ l/m<strong>in</strong> 20 80 120<br />

400V 50Hz<br />

m 3 /h 1,2 4,8 7,2<br />

- BEST 5<br />

1,5<br />

-<br />

- - 3,3<br />

18,4 16,1 14,5<br />

H=Total head<br />

BEST 2<br />

0,55<br />

16<br />

450<br />

4,4 2,0<br />

12,2 9,8 8,3<br />

BEST 3<br />

0,75<br />

20<br />

450<br />

5,6 2,4<br />

13,6 11,1 9,5<br />

BEST 4<br />

1,1<br />

31,5<br />

450<br />

7,3 3,0<br />

17,4 15 13,4<br />

S<strong>in</strong>gle-phase<br />

230V 50Hz<br />

BEST 2 M<br />

BEST 3 M<br />

BEST 4 M<br />

170<br />

10,2<br />

6,3<br />

7,6<br />

11,3<br />

12,5<br />

260<br />

15,6<br />

280<br />

16,8<br />

330<br />

19,8<br />

360<br />

21,6<br />

2,9 - - -<br />

4 3,2 - --5<br />

7,5 6,7 4,6<br />

9 8 6<br />

41

SUBMERSIBLE <strong>PUMPS</strong> for dirty water <strong>in</strong> <strong>AISI</strong> <strong>304</strong><br />

RIGHT<br />

RIGHT<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

42

SUBMERSIBLE <strong>PUMPS</strong> for dirty / sewage water <strong>in</strong> <strong>AISI</strong> <strong>304</strong><br />

DW-DW VOX<br />

DW-DW VOX<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

43

5”SUBMERSIBLE MULTI-STAGE <strong>PUMPS</strong> <strong>in</strong> <strong>AISI</strong> <strong>304</strong><br />

IDROGO<br />

IDROGO<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

44

4” BORE HOLE <strong>PUMPS</strong> <strong>in</strong> <strong>AISI</strong> <strong>304</strong> 4 BHS<br />

4 BHS<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

45

6” SUBMERSIBLE DEEP WELL <strong>PUMPS</strong> <strong>in</strong> <strong>AISI</strong> <strong>304</strong> 6 BHS<br />

6 BHS<br />

<strong>PERFORMANCE</strong> <strong>TABLE</strong><br />

46

SUBMERSIBLE <strong>PUMPS</strong> FOR DEEP WELLS<br />

BHS<br />

BHS<br />

SELECTION CHART 2900 mim -1<br />

emarks<br />

e performance curves and<br />

mensions displayed represent the<br />

ximum, number of possible<br />

ges for a given motor output.<br />

r <strong>in</strong>termediate or higher curves,<br />

ase contact the manufacturer or<br />

ur local dealer.<br />

For 6” or larger well<br />

For 8” or larger well<br />

For 10” or larger well<br />

For 12” or larger well<br />

47

4” STAINLESS STEEL SUBMERSIBLE MOTOR<br />

OPM / T<br />

OPM / T<br />

6” STAINLESS STEEL SUBMERSIBLE MOTOR<br />

OY6<br />

48

SUBMERSIBLE DEWATERING ES & EA HEAVY DUTY SAND <strong>PUMPS</strong> ENZ2<br />

ES & EA<br />

ENZ2<br />

SELECTION CHART<br />

SELECTION CHART<br />

(for ES Model) 3000 m<strong>in</strong> -1<br />

1500 m<strong>in</strong> -1<br />

(for EA Model) 3000 m<strong>in</strong> -1<br />

49

SUBMERSIBLE SUMP <strong>PUMPS</strong><br />

DS<br />

DS<br />

3000 m<strong>in</strong> -1<br />

50

SUBMERSIBLE SEMI-VORTEX SEWAGE <strong>PUMPS</strong><br />

DVS<br />

DVS<br />

SELECTION CHART 3000 m<strong>in</strong> -1<br />

Total head : m<br />

Capacity : m 3 /m<strong>in</strong><br />

43 51

SUBMERSIBLE SEWAGE <strong>PUMPS</strong> (With Cutter) DF SUBMERSIBLE SEWAGE PUMP (With Cutter) DL Cutter<br />

DF<br />

DL Cutter<br />

SELECTION CHART<br />

SELECTION CHART<br />

1500 m<strong>in</strong> -1<br />

52

EXPLOSION-PROOF SUBMERSIBLE<br />

<strong>PUMPS</strong> EExdII T3 protection<br />

RW<br />

STAINLESS STEEL SUBMERSIBLE<br />

<strong>PUMPS</strong> <strong>in</strong> <strong>AISI</strong> 316<br />

RWI<br />

RW<br />

RWI<br />

SELECTION CHART<br />

SELECTION CHART<br />

40<br />

30<br />

20<br />

H<br />

RW3000<br />

RW4000<br />

MODEL<br />

RWI 2010.2MS<br />

RWI 2010.2T<br />

RWI 2015.2MS<br />

RWI 2015.2T<br />

RWI 2025.2T<br />

RWI 2030.2T<br />

RWI 2015.4T<br />

kW cv m3/h 0<br />

0,75<br />

0,75<br />

1<br />

1<br />

1,1 1,5<br />

1,1 1,5<br />

1,8 2,5<br />

2,2<br />

3<br />

1,1 1,5<br />

Total Head <strong>in</strong> m<br />

7,5 7,2 6,7<br />

7,5<br />

7,2<br />

6,7<br />

11 10,5 9,8<br />

11<br />

15 14,3<br />

9,8<br />

8,3 7,8 7,4<br />

8,3<br />

12,3<br />

15<br />

4,7<br />

6,9<br />

6,9 6,3<br />

10,4<br />

13<br />

CAPACITY<br />

3 5 7,5 9 10,5 12 13,5 15 16,5 18 19,5 21 22,5 24 27 30 33 26 39<br />

5,8 5,2 4,7 4,3 4<br />

3,2 2,8 2,5 2<br />

5,8 5,5 5,2<br />

6,3 6 5,8 5,8 5,4 5,3 5,1 4,9 4,7 4,5 4,3 4<br />

4,3<br />

5,3<br />

4<br />

3,8 3,2<br />

3,8 3,5<br />

2,8 2,5 2<br />

4,8<br />

4,9<br />

4,3<br />

4,3<br />

3,9 3<br />

3<br />

2<br />

2<br />

8,8 8,3 6,7 5,5 4,5 3,3 2,3<br />

11<br />

7 5,6 4,1 2,7<br />

3,3<br />

RW2000<br />

RW1500<br />

10<br />

0<br />

Q<br />

2 3 4 5 10 20 30 40 50 100 200 300 600 m 3 /h<br />

1 2 3 4 5 10 15 20 30 40 50 100 I/s<br />

MODEL<br />

CAPACITY<br />

kW cv<br />

m3/h 0 6 12 18 24 30 36 39 42 45 48 54 60 66 72 78 84 90 96 102<br />

RWI 3030.2T<br />

2,2 3,0 12 10,7 9,5 8,3 7 6 5 4,5 4 3,6 3,2 2,5 1,8 1<br />

RWI <strong>304</strong>0.2T<br />

3,0 4,0<br />

9,3 8 7,3 6,8 6<br />

3<br />

RWI 3050.2T<br />

3,7 5,0 18,7 18,2 17,5 15,3 14 12,6 11,8 11 10,2 9,4 7,9 6,2 5 4<br />

RWI 3060.2T<br />

4,4 6,0 22,3 21,2 20,4 17,9 16,6 15,2 14,6 14 13,4 12,8 11,3 10 8,8 7,5 6,3 5 3,8 2,5<br />

RWI 3075.2T<br />

RWI 3020.4T<br />

RWI 3030.4T<br />

RWI <strong>304</strong>0.4T<br />

RWI 3050.4T<br />

5,5<br />

1,5<br />

2,2<br />

3,0<br />

3,7<br />

7,5<br />

2,0<br />

3,0<br />

4,0<br />

5,0<br />

Total Head <strong>in</strong> m<br />

25<br />

5<br />

5<br />

8<br />

4,9<br />

21<br />

4,8 3,6 4,3 4<br />

3,7 3,5 3,4 3,2 2,9<br />

16,5 15,3 14 12,5 10,8 9<br />

2,5 2 1,5<br />

5,8 5,6 5,4 5,1 4,8 4,4 4,2 4,1 4 3,8 3,5 3,1 2,8 2,4 2,1<br />

7,8 7,4<br />

6,5 6,2 6 5,9 5,8 4,9 4,5<br />

3,3<br />

19<br />

2,8 2,3<br />

9,5 9,2 8,9 8,5 8,1 7,8 7,4 7,2 6,9 6,7 6,5 6 5,6 5 4,6 4,1 3,5 3 2,4 1,8<br />

53