Download Reverse Engineering & Rapid Prototyping Brochure

Download Reverse Engineering & Rapid Prototyping Brochure

Download Reverse Engineering & Rapid Prototyping Brochure

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Shaping the Technology of Tomorrow<br />

www.udri.udayton.edu<br />

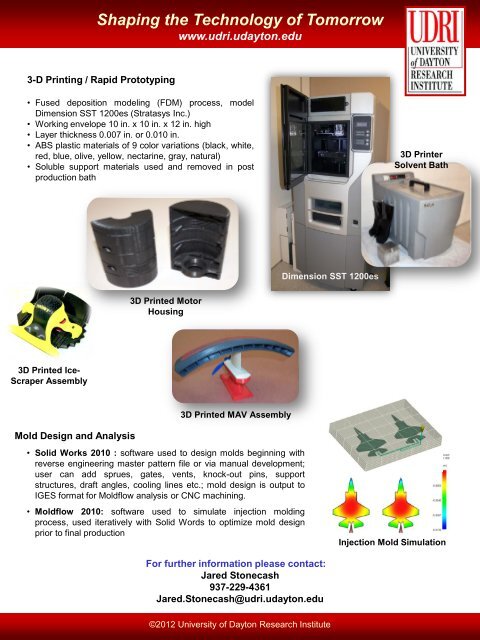

3-D Printing / <strong>Rapid</strong> <strong>Prototyping</strong><br />

• Fused deposition modeling (FDM) process, model<br />

Dimension SST 1200es (Stratasys Inc.)<br />

• Working envelope 10 in. x 10 in. x 12 in. high<br />

• Layer thickness 0.007 in. or 0.010 in.<br />

• ABS plastic materials of 9 color variations (black, white,<br />

red, blue, olive, yellow, nectarine, gray, natural)<br />

• Soluble support materials used and removed in post<br />

production bath<br />

3D Printer<br />

Solvent Bath<br />

Dimension SST 1200es<br />

3D Printed Motor<br />

Housing<br />

3D Printed Ice-<br />

Scraper Assembly<br />

3D Printed MAV Assembly<br />

Mold Design and Analysis<br />

• Solid Works 2010 : software used to design molds beginning with<br />

reverse engineering master pattern file or via manual development;<br />

user can add sprues, gates, vents, knock-out pins, support<br />

structures, draft angles, cooling lines etc.; mold design is output to<br />

IGES format for Moldflow analysis or CNC machining.<br />

• Moldflow 2010: software used to simulate injection molding<br />

process, used iteratively with Solid Words to optimize mold design<br />

prior to final production<br />

Injection Mold Simulation<br />

For further information please contact:<br />

Jared Stonecash<br />

937-229-4361<br />

Jared.Stonecash@udri.udayton.edu<br />

©2012 University of Dayton Research Institute