Conveyor-belt scale program by PFREUNDT Save ... - Pfreundt GmbH

Conveyor-belt scale program by PFREUNDT Save ... - Pfreundt GmbH

Conveyor-belt scale program by PFREUNDT Save ... - Pfreundt GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

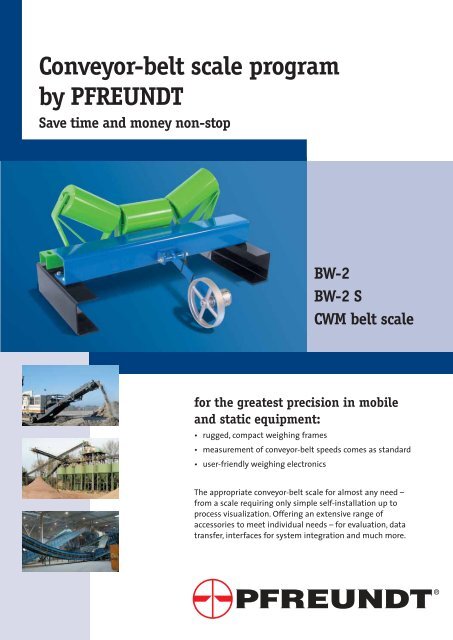

<strong>Conveyor</strong>-<strong>belt</strong> <strong>scale</strong> <strong>program</strong><br />

<strong>by</strong> <strong>PFREUNDT</strong><br />

<strong>Save</strong> time and money non-stop<br />

BW-2<br />

BW-2 S<br />

CWM <strong>belt</strong> <strong>scale</strong><br />

for the greatest precision in mobile<br />

and static equipment:<br />

• rugged, compact weighing frames<br />

• measurement of conveyor-<strong>belt</strong> speeds comes as standard<br />

• user-friendly weighing electronics<br />

The appropriate conveyor-<strong>belt</strong> <strong>scale</strong> for almost any need –<br />

from a <strong>scale</strong> requiring only simple self-installation up to<br />

process visualization. Offering an extensive range of<br />

accessories to meet individual needs – for evaluation, data<br />

transfer, interfaces for system integration and much more.

<strong>Conveyor</strong>-<strong>belt</strong> <strong>scale</strong>s<br />

<strong>by</strong> <strong>Pfreundt</strong>:<br />

Precise weighing on conveyor <strong>belt</strong>s<br />

Practical technology in use around the globe<br />

For more than 25 years, <strong>PFREUNDT</strong> has consistently pursued the ambitious goal of further<br />

developing trusted technologies to make them even more effective. The result: numerous<br />

practical innovations and patented solutions that are employed worldwide under the<br />

harshest conditions.<br />

Exact weight values under the harshest<br />

conditions<br />

Even under rough conditions such as in quarries, conveyor-<strong>belt</strong> <strong>scale</strong>s<br />

made <strong>by</strong> <strong>PFREUNDT</strong> guarantee the maximum degree of precision.<br />

They are rugged, exceptionally compact and can be installed or<br />

retrofitted on nearly any conveyor <strong>belt</strong>. The measurement of conveyor-<strong>belt</strong><br />

speed, a standard feature located directly on the <strong>belt</strong>, ensures precise<br />

data – even when there is <strong>belt</strong> slip on drive or return pulleys.<br />

<strong>PFREUNDT</strong> conveyor-<strong>belt</strong> <strong>scale</strong>s have proven themselves in both mobile<br />

and static applications. Whether in crushers, screening machines and<br />

conveyor <strong>belt</strong>s in the mining industry, mobile employment such as in<br />

road milling machines or surface miners, agricultural equipment such as<br />

beet loading machines or in the sorting and waste treatment facilities<br />

of the waste disposal sector – they have been working for years with<br />

precision and reliability.<br />

A <strong>scale</strong> custom-tailored to match your needs<br />

At <strong>PFREUNDT</strong>, customer service means an uncompromising focus on<br />

the demand for precision, speed, ease of use and durability. <strong>PFREUNDT</strong>'s<br />

solutions are custom-made for each weighing task and bring immediate<br />

profits.<br />

With various models, electronics and an extensive range of accessories,<br />

each weighing system can be tailored exactly to meet your needs,<br />

offering optimal operational convenience, as well as far-reaching<br />

control over the weighings.<br />

The optional inclinometer automatically corrects the weighing system<br />

for changes in the angle of the conveyor-<strong>belt</strong> discharge – ensuring<br />

precise measurement in mobile applications, in particular.<br />

If needed, we can provide official calibration for static conveyor <strong>belt</strong>s,<br />

while also covering the remaining requirements of the Office of<br />

Weights and Measures.<br />

If you choose, you can evaluate several discharge conveyor <strong>belt</strong>s <strong>by</strong> using<br />

only one weighing electronics or represent the data visually <strong>by</strong> using the<br />

<strong>PFREUNDT</strong> software “CWM <strong>Conveyor</strong>-<strong>belt</strong> <strong>scale</strong>” on a PC. To do this, the<br />

weighing frames in the individual conveyor <strong>belt</strong>s are equipped with<br />

<strong>PFREUNDT</strong> CAN weighing modules and then networked with weighing<br />

electronics or with the PC.

NEW<br />

In the new BW-2 S for static<br />

applications, you have a low-priced<br />

weighing system that you can<br />

assemble yourself.<br />

For static conveyor <strong>belt</strong>s with a standard<br />

frame width of up to 1150 mm (45 in.) or<br />

1600 mm (63 in.).<br />

Easy self-assembly<br />

You can easily assemble the BW-2 S yourself.<br />

In this way you save on additional service personnel,<br />

doubling the value of your weighing system.<br />

Mechanic pre-assembled<br />

You can easily install the pre-assembled components <strong>by</strong><br />

following the clearly laid out instructions.<br />

Electronics pre-installed<br />

A prefabricated cable with plugs permits the straightforward<br />

connection of the sensor to the WK 50-S BW evaluation unit –<br />

the electronics need not even be opened.<br />

System pre-calibrated<br />

The weighing electronics are pre-set in our factory.<br />

All you need to do is set a few <strong>belt</strong> parameters and the <strong>scale</strong><br />

is independently precise and ready to be employed.<br />

When needed, you can further optimize the measured values<br />

in the installed <strong>scale</strong>s <strong>by</strong> running comparative weighings and<br />

<strong>by</strong> fine-tuning the electronics.<br />

Clear instructions are included in<br />

the scope of supply.<br />

You can however – as is the case for all <strong>PFREUNDT</strong> weighing<br />

systems – prefer to have one of our service technicians install<br />

and adjust the BW-2 S. The extensive service network of our<br />

own employees means that we are always within easy reach.<br />

• You will find options and accessories listed on page 5<br />

Standard scope of supply BW-2 S<br />

(Weighing frame 1150 or 1600 mm –<br />

depending on the conveyor <strong>belt</strong>)

Options – exclusive to BW-2:<br />

The inclinometer for mobile<br />

applications and the CAN weighing<br />

module for connecting several<br />

weighing frames to one weighing<br />

electronics are placed securely in a<br />

stable aluminum wiring box. If<br />

needed a robust plug connection<br />

can be mounted here.<br />

Weighing and master data can be<br />

exchanged between the weighing<br />

electronics and the PC <strong>by</strong> a GSM<br />

modem or <strong>by</strong> radio.<br />

Rather than using GSM or radio,<br />

data transfer can also be<br />

accomplished using the memo box.<br />

For data transfers it is hooked up<br />

alternately to the serial interfaces<br />

(RS232) of the weighing electronics<br />

and the PC.<br />

• Additional options and accessories<br />

are listed on page 5<br />

The BW-2 is a robust weighing system for static and<br />

mobile applications for standard frame widths from<br />

800 mm (31.5 in.) to 1600 mm (63 in.) . Master and<br />

weighing data memories as well as an extensive range<br />

of options, allow for many different kinds of evaluation<br />

as well as for data transfer and processing.<br />

Also for mobile application<br />

The BW-2 with optional inclinometer is the ideal<br />

weighing system for use in mobile devices such as crushers<br />

and screening machines. Even in road milling<br />

machines, surface miners and agricultural machinery<br />

such as beet loading machines, the BW-2 consistently<br />

delivers exact weight values.<br />

Full control through WK 50<br />

The weighing electronics WK50 included in the scope of<br />

supply offers extensive master and weighing data<br />

memory as well as interfaces, e.g. for data exchange<br />

with the control room. This may be done <strong>by</strong> GSM, radio<br />

or memo box for example, automatically at night, which<br />

makes the WK 50 the ideal solution for rapid processing<br />

of weighing data in your EDP. Furthermore with an<br />

optional statistical <strong>program</strong> you can also evaluate<br />

performance data.<br />

Approval for static conveyor <strong>belt</strong>s<br />

When needed, we are able to offer the BW-2 to you as<br />

an officially calibrated weighing system for static<br />

conveyor <strong>belt</strong>s, which meet the requirements of the<br />

Office of Weights and Measures.<br />

Weighing electronics for several conveyor<br />

<strong>belt</strong>s<br />

By using <strong>PFREUNDT</strong> CAN weighing modules, several<br />

conveyor-<strong>belt</strong>s equipped with weighing frames can<br />

be evaluated while using only one WK 50 weighing<br />

electronics.<br />

We provide the <strong>PFREUNDT</strong> Office Software P.O.S. in <strong>program</strong> modules for the P.C.<br />

– adapted to your needs. The software can be used as a pure communications<br />

interface for client-side user <strong>program</strong>s, for full master and journal data<br />

evaluation or to create invoices.<br />

P.O.S. is a high-performance sector-specific software developed especially <strong>by</strong><br />

<strong>PFREUNDT</strong> for Windows®. With P.O.S. your weighing data which you use to<br />

control your weighing enterprise and to manage your company will be<br />

processed immediately.<br />

POS Mobil plus<br />

Master and journal data<br />

evaluation<br />

Data transfer<br />

Memo box<br />

Cable<br />

GSM<br />

Accounting<br />

Radio

<strong>PFREUNDT</strong> BW-2 S and<br />

BW-2 conveyor-<strong>belt</strong> <strong>scale</strong>s<br />

compared.<br />

The BW-2 S is the cost-effective weighing system for static<br />

conveyor <strong>belt</strong>s. Because of its many options, the BW-2 offers<br />

the appropriate solution to various weighing tasks: Ranging<br />

from mobile applications, to the evaluation of several conveyor<br />

<strong>belt</strong>s to an officially calibrated version. Furthermore it provides<br />

statistical information, data processing and data transfer.<br />

Options for BW-2 S and BW-2<br />

With the <strong>PFREUNDT</strong> printer –<br />

designed for harsh conditions –<br />

weighing tickets can now be printed<br />

immediately on site – even<br />

using copies.<br />

Weighing tickets – both in the<br />

standard format and custom formatted<br />

to meet your needs– can<br />

be printed with carbon copies on<br />

robust WK 50 printers.<br />

The robust control cabinet<br />

protects the weighing electronics<br />

during outdoor service or against<br />

unauthorized access.<br />

Additional options and accessories:<br />

Mounting bracket* and metal cover for the weighing<br />

frame, target weight relays*, current outlet (analog 0/4 -<br />

20 mA), weighing ticket box, control cabinet heating,<br />

power supply unit, calibration weight**. (compare table).<br />

* included as standard within the BW-2 scope of supply<br />

** BW-2<br />

Equipment<br />

and options<br />

BW-2 S<br />

BW-2<br />

Officially calibrated /<br />

legal for trade<br />

left: WK 50-S BW with printer<br />

right: WK 50 with printer<br />

Features:<br />

static weighing<br />

mobile weighing/correction calculation of changing<br />

<strong>belt</strong> angle <strong>by</strong> using an inclinometer<br />

officially calibrated*/approved<br />

speed measurement on the conveyor <strong>belt</strong><br />

pre-mounted weighing frames<br />

mounting bracket for weighing frame<br />

rugged, demountable plug connection<br />

prefabricated cable with plugs<br />

cable extension<br />

cover plate for weighing frames<br />

control cabinet, power supply unit, control cabinet heating<br />

printer, weighing tickets, weighing ticket box<br />

target weight input<br />

target weight relay<br />

current outlet, analog (0/4-20 mA)<br />

interfaces, e.g. for DP options to transfer data <strong>by</strong> GSM<br />

or memo box and POS software<br />

evaluation of several weighing frames <strong>by</strong> means of CAN<br />

weighing modules<br />

self-assembly/installation<br />

assembly/installation <strong>by</strong> <strong>PFREUNDT</strong> service<br />

calibration weight<br />

*if the requirements of the Office of Weights and Measures are<br />

fulfilled <strong>by</strong> the customers<br />

standard equipment/scope of supply<br />

optional

Process visualization with <strong>PFREUNDT</strong><br />

CWM <strong>Conveyor</strong>-<strong>belt</strong> <strong>scale</strong><br />

Using the CWM conveyor-<strong>belt</strong> <strong>scale</strong> PC <strong>program</strong>, you can hold up to<br />

8 static <strong>belt</strong> <strong>scale</strong>s in view on your computer monitor. At the same<br />

time, the weighing frames that have been equipped with CAN<br />

weighing modules are directly connected to the PCs, which have<br />

likewise been equipped with CAN interfaces. Operation, visualization,<br />

and evaluation – e.g. shift reports – can be carried out straight away<br />

on the computer without any additional display electronics.<br />

Your advantages:<br />

• Access to the most important data at one glance<br />

• Precise observation of each individual <strong>belt</strong> <strong>scale</strong><br />

• Administration of daily total,<br />

shift total and current total<br />

• Record of idle running and down times<br />

• Zeroing of all <strong>belt</strong> <strong>scale</strong>s with<br />

one press of the button.<br />

• Administration of shifts and shift models<br />

• Daily and shift evaluations<br />

• Administration of “virtual conveyor <strong>belt</strong>s”

You will receive the CWM <strong>belt</strong> <strong>scale</strong> as a total system solution:<br />

We provide you with the <strong>program</strong> already installed on a compact<br />

and robust industrial PC for installation in the control cabinet or<br />

if requested, in the control box. In this way, the system operates<br />

independently and securely without being affected <strong>by</strong> other<br />

software, which means that errors or <strong>program</strong> crashes can be<br />

avoided.<br />

The computer itself, with its robust components, is particularly<br />

suitable to harsh user conditions. It offers a large color display<br />

with a touch-screen user interface. The CAN interface for linking<br />

the separate <strong>belt</strong> <strong>scale</strong>s with CAN weighing modules and other<br />

interfaces such as USB and WLAN are also part of the system<br />

configuration.

Visit us on the internet or give<br />

us a call, we will be happy to<br />

advise you.<br />

<strong>PFREUNDT</strong> <strong>GmbH</strong><br />

Ramsdorfer Straße 10<br />

D-46354 Südlohn<br />

+49 (0) 28 62 / 98 07-0<br />

Fax +49 (0) 28 62 / 98 07-99<br />

E-mail: info@pfreundt.de<br />

Internet:www.pfreundt.de<br />

Presented <strong>by</strong>:<br />

Our challenge:<br />

We weigh<br />

the world<br />

204 -8S-ADE 2-06-06 Oi Rights reserved for changes and further developments.