Technical Data Sheet PercoTop ® Putty 3508 - Movac Group Limited

Technical Data Sheet PercoTop ® Putty 3508 - Movac Group Limited

Technical Data Sheet PercoTop ® Putty 3508 - Movac Group Limited

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

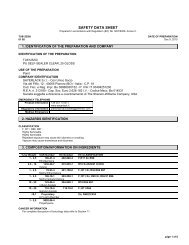

<strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong><br />

<strong>PercoTop</strong> <strong>®</strong> <strong>Putty</strong> <strong>3508</strong><br />

CS161<br />

Sprayable <strong>Putty</strong><br />

Application<br />

Gravity feed<br />

Suction feed<br />

(High pressure spraying)<br />

Remarks<br />

Application Thinner Spray Pressure Number of coats<br />

viscosity<br />

nozzle<br />

DIN 4 at 20°C<br />

(s) (%) (mm) (bar)<br />

As mixed - 2.0-2.5 2.0-3.0 5 coats will give 500-600 µ.<br />

(Film thickness up to 1000<br />

µ is possible.)<br />

On bare steel sheet a film thickness of at least 150 µ (after sanding) is required.<br />

Drying<br />

Air drying at 20°C<br />

2 hours<br />

Forced drying<br />

Drying time<br />

Drying temperature<br />

Flash time: 10-15 minutes.<br />

Depending on film thickness.<br />

30 minutes<br />

60°C object temperature<br />

IR drying<br />

Medium wave: 15-20 minutes.<br />

Short wave: 10-12 minutes (for 50 % performance).<br />

Recoatability<br />

Sandability<br />

With reference to above mentioned drying times.<br />

As filling putty<br />

Pre sanding: mechanical with sandpaper of coarseness P100-P120.<br />

Post sanding: mechanical with sandpaper of coarseness P240-P280.<br />

Recoatable<br />

With itself.<br />

Treat bare and putty spots with <strong>PercoTop</strong> primers.<br />

Fill with <strong>PercoTop</strong> fillers.<br />

Effective June 2009<br />

CS161 - 2 - EN<br />

3/4