Revolution Installation Manual - RE Prescott Company

Revolution Installation Manual - RE Prescott Company

Revolution Installation Manual - RE Prescott Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

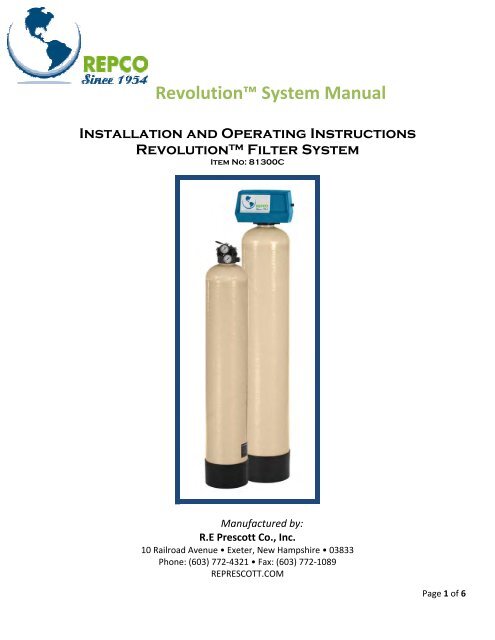

<strong>Revolution</strong> System <strong>Manual</strong><br />

<strong>Installation</strong> and Operating Instructions<br />

<strong>Revolution</strong> Filter System<br />

Item No: 81300C<br />

Manufactured by:<br />

R.E <strong>Prescott</strong> Co., Inc.<br />

10 Railroad Avenue • Exeter, New Hampshire • 03833<br />

Phone: (603) 772‐4321 • Fax: (603) 772‐1089<br />

<strong>RE</strong>P<strong>RE</strong>SCOTT.COM<br />

Page 1 of 6

<strong>Revolution</strong>® System<br />

The <strong>Revolution</strong> TM System includes a deluxe aeration tank along with a <strong>RE</strong>PCO Conditioner filter. The deluxe aeration<br />

tank it is built around a PVC head incorporating a built‐in micronizer (nozzle and venturi), internal air release float, and<br />

instrumentation, all in one package. The pressure gauges allow the installer to make adjustments to suit the best air<br />

draw, and a bypass allows for ease of service.<br />

<strong>Revolution</strong> System Application<br />

1. The <strong>Revolution</strong> TM is designed to work with submersible well pump installations operated by a pressure switch<br />

and pressure tank.<br />

2. The <strong>Revolution</strong> TM is not designed to work with jet pump systems or constant pressure systems<br />

3. The <strong>Revolution</strong> TM should be installed in accordance with applicable state and local plumbing codes.<br />

<strong>Revolution</strong> Aeration Tank Head<br />

<strong>Revolution</strong> Aeration Tank<br />

Figure 1 ‐ <strong>Revolution</strong> Aeration Tank<br />

Page 2 of 6

<strong>Revolution</strong>® System<br />

Assembly<br />

Assembling the <strong>Revolution</strong> Aeration Tank<br />

The <strong>Revolution</strong> Aeration Tank comes preassembled as seen in Figures 1 through 3.<br />

Figure 2 – <strong>Revolution</strong> Aeration Tank Head<br />

Figure 3 – <strong>Revolution</strong> Aeration Tank Head<br />

Page 3 of 6

<strong>Revolution</strong>® System<br />

Assembling the <strong>RE</strong>PCO Conditioner Filter<br />

The <strong>RE</strong>PCO Conditioner Filter should come preassembled. If not, filter media needs to be installed; follow instructions<br />

below.<br />

1. Remove Automatic Backwashing Valve from the top of empty mineral tank.<br />

2. Plug the top of the distributor tube so that no mineral falls down the tube during filling.<br />

3. Add specified amount of gravel to the bottom of the mineral tank so that the base of the distributor tube is<br />

sufficiently covered.<br />

4. Pour media into the tank until it reaches 18” from the top of the mineral tank.<br />

5. Remove the plug from distributor tube.<br />

6. Reinstall the Automatic Backwashing Valve to the top of the mineral tank. Be careful not to disturb the o‐ring<br />

that is located in the distributor tube opening and also on the flange that meets the top of the mineral tank.<br />

Leaks could result.<br />

<strong>Installation</strong> / Start Up<br />

<strong>Installation</strong><br />

Set units into their final position and plumb in accordance with applicable state and local plumbing codes. Refer to<br />

appropriate control valve manual for inlet/outlet plumbing, drain line positioning, fitting assembly, power supply, and<br />

start up of control valve.<br />

<strong>Revolution</strong> Aeration Tank<br />

1. With a screw driver, manually unscrew the brass bypass screw counterclockwise to open the bypass port. Refer<br />

to figure 3. This will keep initial inlet pressure to a minimum. Do not exceed 100 PSI inlet pressure. The inlet<br />

pressure gauge is the bottom gauge. Refer to figure 2.<br />

2. Turn on power to well pump and manually adjust brass bypass screw to the desired air draw. Refer to air draw<br />

charts below.<br />

3. Shine a light behind mineral tank to confirm water level is consistently 14 to 18” below top of tank.<br />

Automatic Backwashing Valve<br />

Refer to Automatic Backwashing Valve <strong>Manual</strong> for <strong>Installation</strong>/Startup Instructions<br />

Page 4 of 6

<strong>Revolution</strong>® System<br />

<strong>RE</strong>PCO Conditioner Filter<br />

<strong>Revolution</strong> Aeration Tank<br />

Pressure Tank (Not Included)<br />

Figure 4 ‐ <strong>Revolution</strong> System<br />

Operation<br />

<strong>Revolution</strong> Aeration Tank<br />

1. When the well pump is filling the <strong>Revolution</strong> TM the nozzle and venturi draws air into the mineral tank as air draw<br />

charts indicate.<br />

2. As the air is drawn into the mineral tank, the water level drops to approximately 14” below top of mineral tank<br />

and the air release float assembly opens allowing excess air to be released through the air release connection.<br />

Refer to figure 2.<br />

3. As the air is released from the mineral tank the water level raises to approximately 10” below the top of the<br />

mineral tank and the air release float assembly closes.<br />

<strong>Revolution</strong> Aeration Tank Air Draw Charts<br />

5 GPM flow<br />

CFH air draw<br />

Inlet Pressure<br />

Gauge<br />

Outlet Pressure<br />

Gauge<br />

6.5 80 30<br />

4.5 80 40<br />

2.5 80 50<br />

Stops draw 80 52<br />

Figure 5 – 5 GPM Flow<br />

Page 5 of 6

<strong>Revolution</strong>® System<br />

7.5 GPM flow<br />

CFH air draw<br />

Inlet Pressure<br />

Gauge<br />

6.5 80 30<br />

4.0 80 40<br />

.75 80 50<br />

Stops draw 80 53<br />

Figure 6 – 7.5 GPM Flow<br />

10 GPM flow<br />

CFH air draw<br />

Outlet Pressure<br />

Gauge<br />

Inlet Pressure<br />

Gauge<br />

12.5 80 30<br />

11 80 40<br />

8 80 50<br />

Stops draw 80 52<br />

Figure 7 – 10 GPM Flow<br />

15 GPM flow<br />

CFH air draw<br />

Outlet Pressure<br />

Gauge<br />

Inlet Pressure<br />

Gauge<br />

9 80 30<br />

6 80 40<br />

1 80 50<br />

Stops draw 80 54<br />

Figure 8 – 15 GPM Flow<br />

Automatic Backwashing Valve<br />

Refer to Automatic Backwashing Valve <strong>Manual</strong> for Operation.<br />

Outlet Pressure<br />

Gauge<br />

Page 6 of 6