a world leader in valve technology - Federal International (2000) Ltd

a world leader in valve technology - Federal International (2000) Ltd

a world leader in valve technology - Federal International (2000) Ltd

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2373_Oliver Valves_Inners 12/5/2004 1:21 PM Page 17<br />

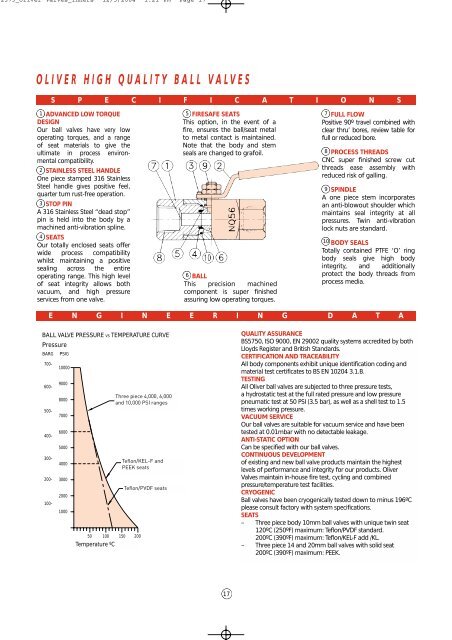

OLIVER HIGH QUALITY BALL VALVES<br />

S P E C I F I C A T I O N S<br />

1 ADVANCED LOW TORQUE<br />

DESIGN<br />

Our ball <strong>valve</strong>s have very low<br />

operat<strong>in</strong>g torques, and a range<br />

of seat materials to give the<br />

ultimate <strong>in</strong> process environmental<br />

compatibility.<br />

2 STAINLESS STEEL HANDLE<br />

One piece stamped 316 Sta<strong>in</strong>less<br />

Steel handle gives positive feel,<br />

quarter turn rust-free operation.<br />

3 STOP PIN<br />

A 316 Sta<strong>in</strong>less Steel “dead stop”<br />

p<strong>in</strong> is held <strong>in</strong>to the body by a<br />

mach<strong>in</strong>ed anti-vibration spl<strong>in</strong>e.<br />

4 SEATS<br />

Our totally enclosed seats offer<br />

wide process compatibility<br />

whilst ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g a positive<br />

seal<strong>in</strong>g across the entire<br />

operat<strong>in</strong>g range. This high level<br />

of seat <strong>in</strong>tegrity allows both<br />

vacuum, and high pressure<br />

services from one <strong>valve</strong>.<br />

5 FIRESAFE SEATS<br />

This option, <strong>in</strong> the event of a<br />

fire, ensures the ball/seat metal<br />

to metal contact is ma<strong>in</strong>ta<strong>in</strong>ed.<br />

Note that the body and stem<br />

seals are changed to grafoil.<br />

6 BALL<br />

This precision mach<strong>in</strong>ed<br />

component is super f<strong>in</strong>ished<br />

assur<strong>in</strong>g low operat<strong>in</strong>g torques.<br />

7 FULL FLOW<br />

Positive 90º travel comb<strong>in</strong>ed with<br />

clear thru’ bores, review table for<br />

full or reduced bore.<br />

8 PROCESS THREADS<br />

CNC super f<strong>in</strong>ished screw cut<br />

threads ease assembly with<br />

reduced risk of gall<strong>in</strong>g.<br />

9 SPINDLE<br />

A one piece stem <strong>in</strong>corporates<br />

an anti-blowout shoulder which<br />

ma<strong>in</strong>ta<strong>in</strong>s seal <strong>in</strong>tegrity at all<br />

pressures. Tw<strong>in</strong> anti-vibration<br />

lock nuts are standard.<br />

10 BODY SEALS<br />

Totally conta<strong>in</strong>ed PTFE ‘O’ r<strong>in</strong>g<br />

body seals give high body<br />

<strong>in</strong>tegrity, and additionally<br />

protect the body threads from<br />

process media.<br />

E N G I N E E R I N G D A T A<br />

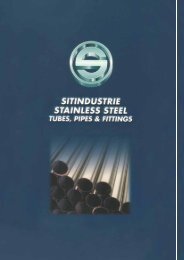

BALL VALVE PRESSURE VS TEMPERATURE CURVE<br />

Pressure<br />

100-<br />

300-<br />

BARG<br />

700-<br />

600-<br />

500-<br />

400-<br />

200-<br />

PSIG<br />

10000<br />

9000<br />

8000<br />

7000<br />

6000<br />

5000<br />

4000<br />

3000<br />

<strong>2000</strong><br />

1000<br />

50<br />

100<br />

Temperature ºC<br />

Three piece 4,000, 6,000<br />

and 10,000 PSI ranges<br />

Teflon/KEL-F and<br />

PEEK seats<br />

Teflon/PVDF seats<br />

150 200<br />

QUALITY ASSURANCE<br />

BS5750, ISO 9000, EN 29002 quality systems accredited by both<br />

Lloyds Register and British Standards.<br />

CERTIFICATION AND TRACEABILITY<br />

All body components exhibit unique identification cod<strong>in</strong>g and<br />

material test certificates to BS EN 10204 3.1.B.<br />

TESTING<br />

All Oliver ball <strong>valve</strong>s are subjected to three pressure tests,<br />

a hydrostatic test at the full rated pressure and low pressure<br />

pneumatic test at 50 PSI (3.5 bar), as well as a shell test to 1.5<br />

times work<strong>in</strong>g pressure.<br />

VACUUM SERVICE<br />

Our ball <strong>valve</strong>s are suitable for vacuum service and have been<br />

tested at 0.01mbar with no detectable leakage.<br />

ANTI-STATIC OPTION<br />

Can be specified with our ball <strong>valve</strong>s.<br />

CONTINUOUS DEVELOPMENT<br />

of exist<strong>in</strong>g and new ball <strong>valve</strong> products ma<strong>in</strong>ta<strong>in</strong> the highest<br />

levels of performance and <strong>in</strong>tegrity for our products. Oliver<br />

Valves ma<strong>in</strong>ta<strong>in</strong> <strong>in</strong>-house fire test, cycl<strong>in</strong>g and comb<strong>in</strong>ed<br />

pressure/temperature test facilities.<br />

CRYOGENIC<br />

Ball <strong>valve</strong>s have been cryogenically tested down to m<strong>in</strong>us 196ºC<br />

please consult factory with system specifications.<br />

SEATS<br />

– Three piece body 10mm ball <strong>valve</strong>s with unique tw<strong>in</strong> seat<br />

120ºC (250ºF) maximum: Teflon/PVDF standard.<br />

200ºC (390ºF) maximum: Teflon/KEL-F add /KL.<br />

– Three piece 14 and 20mm ball <strong>valve</strong>s with solid seat<br />

200ºC (390ºF) maximum: PEEK.<br />

17