Chiksan® Swivel Joints - Topco Oilsite Products Ltd.

Chiksan® Swivel Joints - Topco Oilsite Products Ltd.

Chiksan® Swivel Joints - Topco Oilsite Products Ltd.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ContentsIntroductionWeco ® Plug ValvesWeco ® Check ValvesWeco ® Butterfly Valves and ActuatorsOriginal Chiksan ® <strong>Swivel</strong> <strong>Joints</strong>Original Weco ® Wing UnionsWeco ® Fittings and Pup <strong>Joints</strong>Integrated ServicesChiksan ® and Weco ® SpecificationsI1PV1CV1BV1SJ1WU1FP1IS1S1

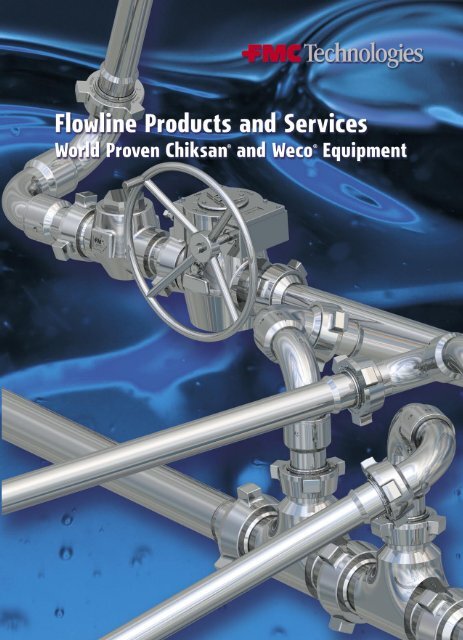

Flowline <strong>Products</strong> and ServicesFMC Technologies is the world’s leading supplier of flowlineproducts and services to the oilfield industry and is the standardagainst which all others are measured. From the original Chiksan ®and Weco ® products to the revolutionary equipment designs andintegrated services of today, FMC’s fluid control family ofproducts and services enables customers to achieve maximum lifeand value from their flowline systems throughout a completerange of applications.The success of FMC’s fluid control technology stems from astrong tradition of anticipating and responding to customer needsin every way possible. By focusing on the delivery of top productsand services, FMC Technologies is helping its customers facetomorrow’s technical and economic challenges today.I1

Flowline <strong>Products</strong> and ServicesHealth, Safety & EnvironmentAs a leading oilfield equipment and services provider,FMC Technologies stresses overall health, safety, andenvironment (HSE) in all of its operations and processes.With a proven record of outstanding HSE performance,FMC is a strong advocate of HSE training that goesbeyond the basic legal requirements. The goal is to ensurethat all field and office personnel are competent to carryout HSE critical duties, having received the appropriatetraining required by law, company policy, and clients.HSE policy covers all key elements of the business,including company safety policy statements, productsafety, risk assessment, monitoring, auditing, and review.Manufacturing LeaderFMC’s fluid control manufacturing facility is located inStephenville, Texas. The plant was constructed in 1980and expanded in 1984, 1987, and 1996. The facilityExperienced, Knowledgeable,Productive PeopleFMC’s global fluid control team is structured around topflowline professionals – individuals who understand yourbusiness and are dedicated to meeting your needs. Themanagement, engineering, and sales support staff areamong the most experienced in the oil and gas industry.Their knowledge and industry expertise show up in thequality of products and services delivered to you.occupies a 44-acre site and comprises 220,000 squarefeet of manufacturing capacity and 48,000 square feetof customer service, production support, and engineeringoffices. It utilizes the latest in computer numericalcontrolled (CNC) machining centers, productionplanning systems, computer aided design/computer aidedmanufacturing (CAD/CAM) systems, and the latesttechnology in order and distribution operating systems.The Stephenville facility produces a wide range of flowlineequipment for distribution worldwide.I2

Flowline <strong>Products</strong> and ServicesUnsurpassed QualityFMC’s fluid control quality system has been surveyed andapproved by DNV and meets ISO 9001 and EuropeanPressure Equipment Directive 97/23/CE. Most products aresupplied with the CE marking. Chiksan and Weco productsalso can be supplied with both type and case approval fromDNV, Lloyds, ABS, GGTN, and others. <strong>Products</strong> for sourgas service meet NACE MR-01-75 and API RP-14-E.Complete material certification and traceability are alsoavailable.Research and DevelopmentTo meet the evolving needs of its customers, FMCcontinually invests in flowline research and development.This industry-leading effort has resulted in a host of newproducts and refinements to existing products. All newproducts are subjected to exhaustive laboratory and fieldtests to ensure their reliability and integrity before they arereleased to the marketplace. Research and developmentcapabilities include exhaustive laboratory and field testing,destructive and nondestructive testing, three-dimensionalfinite element analysis, computational fluid dynamics, andthe flowline industry’s only high-velocity flow loop.Worldwide DistributionChiksan and Weco products are distributed from more than60 locations worldwide. FMC fluid control facilities stockmany flowline products in the specific sizes, pressures, andmaterials common in the various regions. From a replacementseal for a Chiksan swivel joint to a platform full ofwell servicing equipment, FMC Technologies delivers.Integrated ServicesTo satisfy the total flowline requirements of its customers,FMC Technologies has consolidated its industry-leadingafter-sales capabilities into a comprehensive IntegratedServices program. Integrated Services is helping customersworldwide realize the maximum value from their flowlineassets to guarantee that the right products are shipped tothe job site in top working condition. This total solutionsapproach includes the InteServ tracking and managementsystem, mobile inspection and repair, strategically locatedservice centers, and genuine Chiksan and Weco spare parts.I3

Weco ® Plug ValvesChoice of operators,actuatorsGear operators, pneumaticactuators, and hydraulicactuators are available.Body erosion virtuallyeliminatedFluid is forced between theplug/seal interface, limitingwear to replaceable parts.Ultimate sealability, noadjustments requiredFloating plug improves sealabilityand reduces plug wear.Low torque operationat all pressuresCylindrical plug fits between sealand side segments, reducing plugdrag on the valve body.Weco ULT and DR plug valves are premium, quarter-turn valves designed fora wide range of standard and sour gas drilling, production, and well-servicingapplications. These rugged valves are offered in single and dual-body designs inpressures to 20,000 psi. They range in size from 1 to 4-inches and come withthreaded, Weco wing union, flanged, and clamp hub ends. Consult factory forconfigurations. Like all pressure containing products, Weco plug valves requirespecial handling (see inside back cover for Warnings and Cautions).PV1

Weco ® Plug ValvesULT Plug ValvesThe benefits of FMC’s ULT plug valves are a direct resultof its unique design features. Combined, these features haveredefined the standards for plug valve operating principles andperformance.Ultimate SealabilityThe key to the ULT plug valve’s unprecedented seal integrityis its proprietary floating plug and dual-seal design. When thevalve is closed, the dual segment seal provides a redundant sealon the downstream side of the valve. In 3-inch and larger sizes,the ULT plug valve also employs a two-piece plug and stemdesign. When these valves are closed, line fluid pressure in thebody is equalized around the plug resulting in ultimate sealingand low operating torque.Ultimate Valve Body LifeIn addition to improved bi-directional seal performance, theULT plug valve dramatically extends service life. When atraditional plug valve is closed, high-pressure fluids are forcedbetween the upstream body and seal segment interface. Thisflow path can erode the valve body, potentially ruining thevalve. When a ULT plug valve is closed, the only available flowpath is between the seal segment and plug interface. This flowpath eliminates body erosion and limits any potential wear toreplaceable components.Ultimate Seal LifeIn addition to improved valve body life, two other frequentoperating problems associated with high-pressure plug valves –both of which cause premature damage to seals and increasedvalve operating torque – are solved by the ULT plug valve.Traditional plug valve designs can sometimes seal on theupstream side of the valve, resulting in extrusion damage to theupstream segment seal. Traditional plug valves can also trapbody pressure after line pressure is removed from the valve,resulting in extrusion damage to both upstream and downstreamsegment seals. The dual-seal design of the ULT plugvalve, by forcing flow between the plug and segment interface,eliminates both of these problems.Ultimate Life Cycle Cost SavingsSuperior sealability, increased life of valve body, and eliminationof premature seal damage result in significant savingsin life cycle costs of the ULT plug valve over traditional plugvalves. Qualification tests have proven that the ULT plug valveextends service life 3 to 5 times over other plug valves whilereducing maintenance costs. In smaller sizes, ULT parts kitsmay be used in existing DR plug valve bodies to extend the lifeof these valves.O P E R A T I N G P R I N C I P A LTop view — Valve openTop view — Valve closedLine fluidFloating plugProprietaryseal designFloating plugProprietaryseal designPV2

Weco ® Plug ValvesULT Plug Valves(3-inch and larger)Up to 20,000 psi cold working pressureHandles sand, proppant, and cementLinear wave springs prevent small particles fromentering metal-to-metal seal area, enabling usein a broad range of applications.Recommended serviceSlick water, sand, proppant/gel, and cementTwo-piece floating plug/stemProprietary floating plug and stemuniformly distribute load againstthe downstream seat to improvesealability and reduce plug wear.Fast, simple field repairBottom entry design provides accessto all valve internals without having toremove the operator or actuator.ULT Plug Valves(below 3-inch)Up to 20,000 psi cold working pressureRecommended serviceSlick water, sand, proppant/gel, and cementEliminates body washout, extends body lifeDual seals direct flow between the seal segment andplug to provide long, trouble-free service life.Eliminates body washout,extends body lifeDual seals direct flow between theseal segment and plug to providelong, trouble-free service life.Fast assemblyIntegral stem and plug provide fast,sure assembly without adjustments.Interchangeable designInternal components interchange withWeco DR valve components, potentiallyextending the life of those valve bodies.Eliminates corrosion in segment sealing areaDual segment seals greatly reduce erosive fluid flowbetween the seal segments and the plug valve body toimprove sealing capabilities and extend service life.See specifications tables (pages PV1A and PV2A) for sizes, dimensions, weights, materials, and part numbers.PV3

Weco ® Plug ValvesSpecialty ULT Plug ValvesThe ULT plug valve’s proven, proprietary design technology enablescustomers to take advantage of a wide range of configurations for ahost of specialty applications. Options include single and dual bodydesigns; drill pipe, Weco union, or flanged end connections; and sideoutlets. Consult factory for specific applications.ULT Dual Body Plug Valves(Weco Union x Flanged End Connections)ULT Dual BodyPlug Valves(Drill Pipe Connections)ULT Flanged Plug Valves(Flanged End Connections)See Specifications Tables (page PV1A) for sizes, dimensions, weights, materials, and part numbers.PV4

Weco ® Check ValvesWeco check valves are used to isolate well-servicing equipment from highpressuretreating fluids during fracturing applications. Offered in three primarymodels, these rugged valves seal against a complete range of well-servicingfluids at pressures to 20,000 psi. Valves are available in 1-1/2 to 4-inch boresizes for standard and reverse flow. Sour gas models available. Consult factoryfor configurations. Like all pressure containing products, Weco check valvesrequire special handling (see inside back cover for Warnings and Cautions).Top-Entry Check ValvesRecommended serviceHigh-pressure well-servicing lines, fracturinglines, testing lines, cementing and circulatinglines, and other well service and stimulationapplicationsACME thread capCoarse, ACME thread capcan be easily removedwithout having to remove thevalve from the line.Fast, easy serviceTop-entry design andremovable flapper assemblymake repair fast and easy.Replaceable seatStainless steel seat isreplaceable, reducing theneed to scrap body.Open flow pathFlapper dynamics provideoptimum flow through the valveand low flow differential.Forged designForged body, unique flow dynamics,advanced erosion characteristics,and abrasion-resistant componentscombine for long service life.Abrasion resistant flapperCarboxylated nitrile flapper faceis abrasion resistant against acomplete range of well fluids.See specifications tables (pages CV1A and CV2A) for sizes, dimensions, weights, materials, and part numbers.CV1

Weco ® Check ValvesDart Check ValvesRecommended serviceExtreme nitrogen and carbondioxide services; wet or drynon-erosive flowEasy, low-cost serviceMain seal is located on seat,reducing exposure to flow.Enables seal to be replacedwithout replacing seat or dart.Low-inertia dart designHollow dart and fixed stemminimize pressure required tostart flow. Non-metallicbushing reduces friction,increasing dart and stem life.Minimizes explosivedecompressionExplosive decompressionresistant materials anddesign for long service life.N 2 and CO 2 capabilityStainless steel internalcomponents and specialelastomer seal handle gasvelocities in excess of250 feet/second.Flapper Check ValvesRecommended serviceSlick water, sand, proppant/gel, andcement servicesAbrasion resistant flapperCarboxylated nitrile flapper faceis abrasion resistant against acomplete range of well fluids.Open flow pathFlapper dynamics provideoptimum flow through the valveand low flow differential.Replaceable seatSeparate seat/body designensures the seat can bereplaced as needed.See specifications tables (pages CV1A and CV2A) for sizes, dimensions, weights, materials, and part numbers.CV2

Weco ® Butterfly Valves and ActuatorsChoice of operators, actuatorsAll Weco butterfly valve models canbe equipped with a wide range ofoperators and actuators.Outstanding flow efficiencyStreamlined disc design minimizesturbulence and pressure drop forgreater flow efficiency.Leak-proof installationRibbed seat face eliminates theneed for flange gaskets andensures leak-proof installation.Fast, simple field repairIf a valve should need repair, itcan be completely reconditionedin the field using interchangeablestock parts.Weco butterfly valves offer the ultimate in dependable, economical flow control.These field-proven valves are available from stock in 2 through 24-inch sizes andcan handle working pressures up to 175 psi. For pressure ratings from 176 psi upto 285 psi, consult factory. Wafer, notched, and lug-type body styles meetrequirements for new or existing flowline systems. Using a variety of materials,valve bodies, discs, stems, and seats can be individually matched to specificoperating conditions, including temperature range, type and concentration offluid, and various flow conditions. All materials meet ASTM and AISI standards.BV1

Weco ® Butterfly Valves and ActuatorsNo in-line pins, screws or boltsHex drive provides positive discmovement without in-line pins, screws,or bolts.Triple seal designAn O-ring, undersized stem holesin the seat, and correspondingflats on seat and disc hubs providethree completely independentseals. This unique feature isolatesboth the upper and lower stemsfrom line fluid, allowing use ofstandard stem material.Self-centering discDual stem with upper and lowertangential pins allows a selfcenteringdisc. This designprovides equal sealing pressure360° around the disc, ensuringpositive shut off and extendingservice life.Elastomer seatAn elastomer seat with two-piece,hard phenolic back-up eliminatesseat walking and allows the seatto expand under pressure, makingthe valve body the pressure containingcomponent.Standard Materials of ConstructionValve PartSeat & O-ringBodyStem (upper & lower)Standard MaterialNitrile (Buna N)(-20°F to 200°F)Ductile Iron410 Stainless SteelOptional MaterialsHypalon ® , Teflon ® , Viton ® ,EPDM, Red Natural RubberAluminum, Steel, Stainless Steel316 Stainless SteelDiscSpirol/Retainer PinsDuctile Iron302 Stainless SteelAluminum Bronze, 316 StainlessSteel, Ryton ® , Kynar ® , Halar, Teflon ®Coated, Nickel Plated, Hastelloy ®Other materials of construction available. Consult factory.BV2

Weco ® Butterfly Valves and ActuatorsModel 12Short neck, wafer body; 175 psi coldworking pressure, 2 to 12-inch sizes;150 psi cold working pressure, 14 and16-inch sizesRecommended serviceGeneral on/off and throttling servicesfrom 1mm Hg absolute vacuum to fullworking pressureFeatures• Valves are self-centering andmount between 125 or 150 lbANSI flangesModel 12NShort neck, notched body; 175 psi coldworking pressure, 2 to 6-inch sizesRecommended serviceGeneral on/off and throttling servicesfrom 1mm Hg absolute vacuum to fullworking pressureFeatures• Valves are notched to fit betweenlightweight flangesModel 22Long neck, wafer body; 175 psi cold workingpressure, 2 to 12-inch sizesRecommended serviceGeneral on/off and throttlingservices from 1mm Hg absolutevacuum to full working pressureFeatures• Valves are self-centering andmount between 125 or 150 lbANSI flanges• Long neck allows for pipe insulationModel 22LLong neck, lug body, 175 psi cold workingpressure, 2 to 24-inch sizesRecommended serviceGeneral on/off and throttling servicesfrom 1mm Hg absolute vacuum to fullworking pressureFeatures• Tapped lugs allow independentupstream or downstream bolting to125 or 150 lb ANSI flanges• Long neck allows for pipe insulationSee specifications tables (pages BV1A to BV3A) for sizes, dimensions, weights, materials, and part numbers.BV3

Weco ® Butterfly Valves and ActuatorsOperators & ActuatorsAll models and sizes of Weco butterfly valves can beequipped with Weco operators or actuators as wellas other brands of actuators. Typical options includestandard and throttling handles, gear operators,chain-wheel operators, vane actuators, pneumaticactuators, special controllers, and positioners.Pneumatic ActuatorsDouble-acting or fail-safe springreturn; 2 through 12-inch valve sizesRecommended servicePneumatic actuator foron/off valve operationFeatures• Mounts directly to Wecobutterfly valves withoutspecial adapters ormounting hardware• Full 90° operation with aminimum of 30 psi air, noadjustments requiredGear OperatorsWeatherproof, worm gear operator;2 through 24-inch valve sizesRecommended serviceManual on/off or throttling servicesFeatures• Operator has 90° travel arc withinternal travel stop screws for aplus or minus 20° adjustment ateither end of the travel• Mounts on the valve in anyquadrant• Chain wheel attachment available• Hand-wheel shaft extensionsavailableVane ActuatorQuarter-turn, double acting actuator;2 through 6-inch valve sizesRecommended serviceCompact, pneumatic actuator for on/offvalve operationFeatures• The only moving part, the vane, iscast integral to the shaft for sturdiness;does not require field lubrication• Fully repairable in-line• Mounts directly to valve in any quadrantStandard Handle2 through 12-inch valve sizesRecommended serviceRecommended for 8-inch valves and largerFeatures• Positive-stop gripper with integral locking lug ensuresfull open/full closed operation• Model 12 and 12N valves have a detent plate whichbolts on the valve body in each of four quadrants;Model 22 and 22L valve have a pre-notched topflange with on/off detent positionsThrottling Handle2 through 12-inch valve sizesRecommended serviceRecommended for 8-inch valves and largerFeatures• Notched detent plate and positive-stop gripper withintegral locking lug ensures positive locking in any of10 positions from full open or full closed operation• Detent plate bolts on the valve body in each of thefour quadrantsSee specifications tables (pages BV4A to BV10A) for sizes, dimensions, weights, materials, and part numbers.BV4

Original Chiksan ® <strong>Swivel</strong> <strong>Joints</strong>Streamlined bore minimizesflow restrictionsSmooth, round bore designminimizes turbulence andpressure drop. Longsweep ® andTripleStep swivel joints haveextra-long radius elbows thatoptimize flow characteristics andextend life in the ball race areaswhen handling abrasives atextremely high pressures.Proven packing designIndustry leading packing design integrates ananti-extrusion ring that serves as a retainer andbearing to reduce friction between the resilientpacking material and the packing chamberas the joint is rotated.Bearings key torotation, strengthTo assure long, dependableservice, Chiksan dual andtri-race ball bearing swivelsare designed to meet or exceedload capacities and serviceconditions. All ball races areeither flame hardened,carburized and hardened, orhave “snap-in” stainless steelball races.Field repairableIf packing, bearings, or ballplugs should need replacing,easy-to-use field repair kits areavailable.Chiksan swivel joints deliver significantly longer life, superior performance, andreduced maintenance. Designed for standard and sour gas services, these worldproven fittings come in 3/8 to 12-inch sizes and can handle pressures from vacuumto 20,000 psi. Many different Chiksan assembly configurations are available. Thesestyles can be combined in an unlimited variety of ways to suit practically anyinstallation. Available end connections are threaded, integral Weco ® wing union,beveled for welding, or flanged. Like all pressure containing products, Chiksanswivels require special handling (see inside back cover for Warnings and Cautions).SJ1

Original Chiksan ® <strong>Swivel</strong> <strong>Joints</strong>Chiksan ModelsColor CodingCold WorkingMaterialPressurepsi (bar)EndConnectionsNominal Sizes, in.3 1 3 ⁄8 ⁄2 ⁄4 1 11 ⁄4 11 ⁄2 2 21 ⁄2 3 4 6 8 10 12Dark Green175 (12) Ductile Iron Flanged✔ ✔Blue285 (20) Carbon Steel Flanged✔ ✔ ✔ ✔ ✔ ✔ ✔Low-Pressure<strong>Swivel</strong> <strong>Joints</strong>Dark Geen600 (41)Ductile IronNPT✔✔✔✔✔✔✔✔High-Pressure<strong>Swivel</strong> <strong>Joints</strong>Extra High-Pressure<strong>Swivel</strong> <strong>Joints</strong>Longsweep ®<strong>Swivel</strong> <strong>Joints</strong>TripleStep<strong>Swivel</strong> <strong>Joints</strong>BlueOlive Green (Sour Gas)SilverBlackBrownOlive Green (Sour Gas)Olive Green (Sour Gas)Black 10,000 (690) Alloy SteelOlive Green (Sour Gas)RedLight BlueBlackRed1,000 (69)6,000 (414)6,000 (414)10,000 (690)7,500 (517)7,500 (517)10,000 (690)15,000 (1034)15,000 (1034)20,000 (1379)10,000 (690)15,000 (1034)Carbon SteelCarbon SteelCarbon SteelCarbon SteelAlloy SteelAlloy SteelAlloy SteelAlloy SteelAlloy SteelAlloy SteelAlloy SteelAlloy SteelNPTBeveled forweldingWeco figure602 unionFemale linepipe threadsFemale linepipe threadsFemale linepipe threadsWeco figure1002 unionWeco figure1502 unionFemale linepipe threadsWeco figure1002 unionWeco figure2202 unionWeco figure1502 unionWeco figure2002 unionWeco figure1002 unionWeco figure1502 union✔ ✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔✔NotesAll body materials meet ASTM or AISI standards.Consult factory for special sizes, styles, end connections, or packing units.1. Flanged ends faced and drilled to Class 150 flange specifications, unless otherwise specified.2. Not available in Styles 80, 10, or other styles requiring more than two swivel connections.3. 3/8- to 4-inch sizes furnished with nitrile packing and brass or stainless steel anti-extrusion ring.4. 6- to 12-inch sizes furnished with nitrile packing and stainless steel anti-extrusion ring.5. Furnished with Fluoroelestomer or HNBR packing and stainless steel anti-extrusion ring. FMC Technologiesdoes not warrant the performance of any elastomer seal for sour gas service.6. Power make-up must be used for line pipe threaded connections to achieve rated cold working pressure.7. 3-inch size rated at 10,000 psi cold working pressure with integral Weco 1002 union ends only.8. 5-inch size available with threaded or beveled ends; limited to 3,000 psi cold working pressure.Sour Gas ServiceFMC Technologies manufactures Chiksan sour gas swivel joints in accordance with the National Associationof Corrosion Engineers (NACE) Standard MR-01-75 and the American Petroleum Institute’s (API) StandardRP-14-E. These swivel joints are specially heat-treated and inspected for controlled hardness. Becausethe specially heat treated steel required for sour gas service does not provide a strong enough bearingsurface, Chiksan sour gas swivel joints use patented snap-in ball races to assure extra strength and highload-bearing capacity. Fluoroelastomer or HNBR packing is used to isolate the races from the line fluid.Notes1,2,31,3,42,333,453,6,83,63,6553,6,7363333SJ2

Original Chiksan ® <strong>Swivel</strong> <strong>Joints</strong>TripleStep <strong>Swivel</strong> <strong>Joints</strong>Exclusive design deliverslonger life, lower costTripleStep swivel joints deliverthe highest bending and axialload capacities in the industry.They also eliminate rejectionsfrom excessive wear in the ballrace area as well as swivelseizures due to corrosion andbrinnelling of the ball races.Advanced material selectionThe TripleStep swivel joint is manufactured from forged alloysteel with a closely controlled, proprietary chemicalcomposition and heat treatment to ensure superiortoughness, ductility, case depth, case hardness, and corestrength.Instream packing for longseal lifeWorld proven instream packingtechnology provides unsurpassedsealability and reliability in theharshest oilfield conditions. Anintegral anti-extrusion ring servesas a retainer and bearing to reducefriction between the resilientpacking material and the packingchamber as the joint is rotated.Unmatched erosion allowanceAn exclusive three step design coupledwith patented bearing race geometryadds significant wall thickness under themale races without increasing swivel jointsize or weight.Eliminates routine maintenanceAn improved environmental seal reduces thepotential for corrosion in the ball race area. Theintegrity of the seal and the use of a highperformancegrease during initial assemblyvirtually eliminates the need for periodic greasing.Competitive Hype VS. Proof PositiveDesigned especially for abrasive, high-pressure well servicing applications,TripleStep swivel joints have been proven against competitive swivels incustomer-witnessed flow loop tests and field applications. The uniquethree step ball race design provides significantly greater erosion allowancewithout increasing swivel joint size or weight. The result: TripleStepswivel joints deliver increased life, superior performance, and reducedmaintenance...lasting 2-1/2 to 5 times longer than competitive swivels.Thicker Where it CountsCompetitive swivels wear out first in the ball races, meaning they mustbe disassembled for inspection. TripleStep swivels wear in the elbows,meaning they can be inspected and returned to service withoutdisassembly. The TripleStep design places more material under the maleball race – a location that computational flow dynamics analysis and fieldtesting shows to be a high erosion area.SJ3Accelerated Wear Test(40ft/sec. with 6 ppa 20/40northern sand)Hours to Minimum Wear Allowance32.3165.459.0159.250.7247.592.5240.0Test 1 Test 2 Test 3 Test 4Competitive <strong>Swivel</strong>sFMC <strong>Swivel</strong>s

Original Chiksan ® <strong>Swivel</strong> <strong>Joints</strong>TSi (TripleStep)<strong>Swivel</strong> <strong>Joints</strong>10,000 psi cold working pressure;3 and 4-inch sizes15,000 psi cold working pressure; 3-inch sizeFor Longsweep swivels and sizes orpressures not shown, consult factory.Recommended serviceLong-radius elbows designed especially for high-pressure abrasiveapplications such as fracturing, choke-and-kill lines, cementing andcirculating hoses, acidizing, and test linesXHP (Extra High-Pressure) <strong>Swivel</strong><strong>Joints</strong>10,000 psi cold working pressure; 2-inch sizeRecommended serviceHydraulic control lines, mud lines, rotary line connections,BOP lines, test lines, water lines, offshore wellhead connections,cementing and circulating hoses, and choke-and-kill linesHP (High-Pressure)<strong>Swivel</strong> <strong>Joints</strong>6,000 psi cold working pressure; 3/8 to 4-inch sizesRecommended serviceHydraulic control lines, mud lines, rotary line connections, BOP lines,test lines, water lines, offshore wellhead connections, cementing andcirculating hoses, and choke-and-kill linesLow-Pressure<strong>Swivel</strong> <strong>Joints</strong>175 psi to 1,000 psi cold working pressure;3/4 to 12-inch sizesRecommended serviceTransfer lines, temporary flow lines, discharge lines, auxiliaryflow lines, water lines, and other general-service oilfieldapplicationsSee specifications tables (pages SJ1A to SJ8A) for sizes, dimensions, weights, materials, and part numbers.SJ4

Original Chiksan ® <strong>Swivel</strong> <strong>Joints</strong>Controlled hardness<strong>Swivel</strong> components are speciallyheat-treated and 100% tested forcontrolled hardness.Positive identificationChiksan swivels for sour gas service arestamped “Sour Gas” and painted withan olive green, zinc-chromate primer toensure quick, positive identification.Leak detectionA leak detection port betweenthe packing and O-ring sealsignals the need for packingreplacement.Snap-in ball racesSnap-in ball races providehard bearing surface to deliverextra strength and high loadbearingcapacity whenhandling sour gas.Chiksan Sour Gas <strong>Swivel</strong> JointProven packing designElastomeric packing with stainless steelanti-extrusion ring and secondary O-ringseal are used to isolate the races andbearings from line fluid.Sour Gas ServiceFMC Technologies manufactures Chiksan sour gas swivel jointsin accordance with the National Association of CorrosionEngineers (NACE) Standard MR-01-75 and the AmericanPetroleum Institute’s (API) Standard RP-14-E. These swiveljoints are specially heat-treated and inspected for controlledhardness. Because the specially heat-treated steel required forsour gas does not provide a hard enough bearing surface,Chiksan sour gas swivel joints use snap-in ball races for extrastrength and high load-bearing capacity. Sour gas swivel jointscome standard with integral Weco wing union end connections.They also have a leak-detection port between the packing and theO-ring seal. If leakage past the packing should occur, it is forcedthrough the port, signaling the need for packing replacement.For positive identification, all Chiksan sour gas swivel joints arestamped “Sour Gas” or “NACE MR-01-75” using low-stress dotstamping and painted with an olive green, zinc-chromate primerthat is unique to sour gas equipment.Chiksan <strong>Swivel</strong> <strong>Joints</strong> forSour Gas ServiceHigh-Pressure <strong>Swivel</strong> <strong>Joints</strong>6,000 psi cold working pressure, 2 and 3-inch sizes;Weco wing union end connectionsLongsweep <strong>Swivel</strong> <strong>Joints</strong>7,500 psi cold working pressure, 3-inch size;Weco wing union end connections10,000 psi cold working pressure, 1, 2, 3, and 4-inch sizes;Weco wing union end connections15,000 psi cold working pressure, 2 and 3-inch sizes;Weco wing union end connectionsSJ5

Original Chiksan ® <strong>Swivel</strong> <strong>Joints</strong>Chiksan <strong>Swivel</strong> Joint StylesChiksan swivel joints are available from stock in nine basic stylesor configurations. These styles permit 360-degree rotation andmovement in one, two, or three planes. They can be combined inan unlimited variety of ways to suit practically any installation.All Chiksan swivel joints are assembled using two or morestandard pieces.Although Chiksan swivel joints can be rotated while underfluid pressure, they are not recommended for services requiringcontinuous rotary motion. See inside back cover for additionalWarnings and Cautions.Style 20Style 30Style 40Style 50Style 60Style 70Style 80Style 10Style 100See specifications tables (pages SJ1A to SJ8A ) for sizes, dimensions, weights, materials, and part numbersSJ6

Chiksan ® <strong>Swivel</strong> <strong>Joints</strong>Chiksan Cementing andCirculating HosesChiksan cementing and circulating hoses can handle a completerange of standard and sour gas fluids at cold working pressures upto 15,000 psi. These rugged, all-steel hoses are available in 1 to3-inch sizes and configurations to meet virtually any need. Allmaterials meet ASTM or AISI standards.Recommended serviceHigh-pressure discharge lines, water lines, temporary flow lines, welltesting lines, cementing and circulating lines, and other high-pressureapplicationsFeatures• All designs feature Chiksan swivel joints which provide flexibility,absorb shock and vibration, and maximize flow characteristics• Weco wing union connections ensure fast, pressure-tight make-upand break-out without threading, welding, or special connections• Chiksan hoses fold up easily and quickly for transportation andstorage• Designs are available for sour gas services at cold working pressuresup to 15,000 psiSee specifications tables (page SJ5A) for sizes, dimensions, weights, materials, and part numbers.Chiksan Coiled Tubing Reel <strong>Swivel</strong>15,000 psi cold working pressure; 2 and 3-inch sizesRecommended serviceHigh-pressure coiled tubing applicationsReliable UV packingWith zero failures in thousands of high-pressuregate valve stem seal applications worldwide,proprietary UV packing provides greatersealability with lower torque than comparableseals.Converts for sour gas serviceBy changing out the Weco wing union subs,the assembly is converted to a sour gasswivel. This exclusive feature reducesinventory and lowers costs.Fast, easy field maintenanceThe swivel internal components can beserviced from the front without removingthe housing from the coiled tubing unit.Stepped bearing racesExclusive stepped bearing race geometryenables easy centering of the mandrelrelative to the packing. Stepped design alsoprovides low bearing stresses and torquefor longer bearing life.Consult factory for special coiled tubing applications.SJ7

Original Weco ® Wing UnionsSimple identificationNew, factory-shipped Wecowing unions are color codedfor quick identification.Choice of end connectionsWeco wing unions are available withline pipe or tubing threads, butt weld,or non-pressure seal end connections.Positive identificationFor positive identification in thefield, all Weco wing union nutsand subs include the Weco name,union figure number, size, andpressure rating. Additionally, Wecowing unions for sour gas serviceare stamped “Sour Gas.”Fast make-up, break-outThree lug nuts and self-lockingACME threads provide fastmake-up and break-outregardless of position or spacerestrictions.Interchangeable partsAll Weco wing union parts of the samefigure number, size, and pressure ratingare interchangeable. This feature makes iteasy to match male and female subs thatare frequently made-up and broken-out.Weco wing unions are the most complete line of standard and sour-gas servicepipe connectors in the world. Available in 1 to 12-inch nominal pipe sizes withcold working pressures up to 20,000 psi, Weco wing unions are manufacturedusing the finest raw materials, tooling procedures, and heat-treating techniquesavailable. Materials meet ASTM and AISI standards. Each union is carefullyinspected to ensure long, dependable service in the most extreme conditions.Like all pressure containing products, Weco wing unions require specialhandling (see inside back cover for Warnings and Cautions).WU1

Original Weco ® Wing UnionsFigureNumberAssemblyColor KeyStandardServiceColdWorkingPressure Rating, psi, bar Nominal Pipe Sizes, inchesNotesStandardSour Gas (see note 8)TestColdWorkingTest1251 1 ⁄4321 1 ⁄2402502 1 ⁄265380410051256150820010250123001001,000691,500103NANA✔✔✔✔✔✔2002,0001383,000207NANA✔✔✔✔✔✔✔12062,0001383,000207NANA✔✔✔✔✔✔✔✔✔✔12072,0001383,000207NANA✔✔✔✔✔12112,0001383,000207NANA✔✔✔✔✔✔✔4002,5001723,7502592,5001723,750259✔✔✔✔ ✔1,5,64004,0002766,0004144,0002766,000414✔✔✔✔1,46006,0004149,000621NANA✔✔✔✔✔✔16026,0004149,0006216,0004149,000621✔✔✔✔✔✔✔1,2100210,00069015,00010347,50051711,250776✔✔✔✔✔✔✔✔1,2,3,9100310,00069015,00010347,50051711,250776✔✔✔✔✔1,3,10150215,000103422,500155110,00069015,0001034✔✔✔✔✔1,2,3200220,000137930,0002068NANA✔✔✔72202NA NA15,000103422,5001551✔✔7Notes• NA- Not Available• All end connections with line pipe threads unless otherwise noted.1. Butt-weld available. Consult factory for wall thickness.2. Non pressure seal configurations available.3. Power make-up must be used for line pipe threaded connections to achieve rated cold working pressure.4. Line pipe threads are not offered for sour gas service in this figure number.5. Line pipe threads are not recommended for sour gas service above 4-inch nominal pipe size.6. Figure 400 available in 5 1/2- and 7-inch OD with casing threads.7. Available in butt-weld ends only.8. All unions for sour gas service are painted olive green, stamped “SOUR GAS” or “NACEMR-01-75” and have specially modified material properties.9. 5 and 6-inch sizes rated at 7,500 psi CWP and 11,250 test; 5 and 6-inch unions forsour gas service rated at 5,000 psi CWP and 7,500 psi test.10. 4 and 5-inch sizes rated at 7,500 psi CWP and 11,250 test; 4 and 5-inch unions forsour gas service rated at 5,000 psi CWP and 7,500 psi test.Sour gas serviceFMC manufactures Weco sour gas unions in accordance with the National Association ofCorrosion Engineers (NACE) Standard MR-01-75 and American Petroleum Institute’s (API)Standard RP-I4-E.WU2

Original Weco ® Wing UnionsProven Seal DesignsMetal-tometalsealMalesubFemalesubLow-Pressure Services (1,000 to 2,000 psi)Weco wing unions for low-pressure services feature a primarymetal-to-metal seal. The spherical surface of the male suband the conical surface of the female sub provide a large,ball-and-cone sealing surface. This metal-to-metal seal remainsleak-proof even when one surface is slightly pitted ormisaligned.Metal-tometalsealSealringMalesubFemalesubMedium-Pressure Services (2,000 to 4,000 psi)Many Weco wing union designs supplement the metal-to-metalseal with a resilient O-ring in the male sub. The replaceableO-ring extends union life and protects the metal-to-metal sealagainst corrosion.Metal-tometalsealSealringMalesubFemalesubHigh-Pressure Services (6,000 to 20,000 psi)Weco wing unions for high-pressure services feature areplaceable, lip-type seal ring in the female sub. This primaryseal protects the secondary metal-to-metal seal from abrasionand corrosion while minimizing flow turbulence.Tubingor pipeSealringMalesubFemalesubNPS (Non-Pressure Seal) OptionFigures 602, 1002, and 1502The Weco non-pressure seal option is especially designed forabrasive, high-pressure wing union services where weldedconnections are undesirable. This design provides strong,permanent end connections without butt welding. The unionends are shop assembled to pipe or tubing. An epoxy threadcompound is used to secure the connection.Interchangeable partsWeco wing union parts of the same figure number, size, and pressure rating areinterchangeable, making it easy to match male and female subs that are frequentlymade-up and broken-out. For positive identification in the field, all Weco wing unionnuts and subs include the Weco name, figure number, size, and pressure rating. It isvital that the user positively identify union connections and components to avoidmismatch conditions and potential union failure. See inside back cover for details.WU3

Original Weco ® Wing UnionsFigure 1001,000 psi cold working pressureRecommended serviceManifold and line connectionsFeatures• Pressure-tight make-up with hammer• Economical low-pressure unionFigure 2002,000 psi cold working pressureRecommended serviceGeneral service manifolds and linesFeatures• Economical, general-purpose union• 1 to 4-inch sizesFigure 2062,000 psi cold working pressureRecommended serviceManifold line connections, suction service,and corrosion serviceFeatures• O-ring in male sub improves sealing and protectsmetal-to-metal seal against corrosion• Replaceable O-ring extends union service life• 1 to 10-inch sizesFigure 2072,000 psi cold working pressureRecommended serviceSeals manifold connections and protects unionthreadsFeatures• Parts interchangeable with Figures 200 and 206• O-ring on blanking cap ensures a leak-free seal• Cap can be tapped for pressure gauge• Available in butt-weldFigure 2112,000 psi cold working pressureRecommended serviceProduction systems with electrolytic corrosionproblemsFeatures• Laminated insulating rings provide 35 millionohms resistance across the union• O-ring in male sub provides a positive primary seal• Seal ring in female sub delvers a positivesecondary sealFigure 4004,000 psi cold working pressure through 4-inchsizes; 2,500 psi cold working pressure, 5 through12-inch sizesRecommended serviceManifold line connections, pump suction,and mud servicesFeatures• 2-1/2 through 12-inch sizes have O-rings forprimary seal• Butt-weld available• Available for sour gas serviceSee specifications tables (pages WU1A to WU6A) for sizes, dimensions, weights, materials, and part numbers.WU4

Original Weco ® Wing UnionsFigure 6006,000 psi cold working pressureRecommended serviceSteam service, boiler connections, and manifoldline connections for production, drilling, and wellservicingFeatures• Bronze seat provides primary seal; will not rustin water servicesFigure 6026,000 psi cold working pressureRecommended serviceManifold line connections and mud serviceFeatures• Replaceable, lip-type seal provides primary seal,protects secondary metal-to-metal seal, andminimizes flow turbulence• Butt-weld available• Available for sour gas service at 6,000 psicold working pressureFigure 100210,000 psi cold working pressure through 4-inchsizes; 7,500 psi cold working pressure, 5 and6-inch sizesRecommended serviceCementing, fracturing, acidizing, testing, andchoke-and-kill linesFeatures• Replaceable, lip-type seal• 5 and 6-inch sizes have O-rings for primary seals• Available for sour gas service: 7,500 psi coldworking pressure• Butt-weld availableFigure 1003Misaligning union10,000 psi cold working pressure, 2 and 3-inchsizes; 7,500 psi cold working pressure, 4 and5-inch sizesRecommended serviceFor high-pressure connections where lines cannotbe alignedFeatures• Ball seat provides positive seal with up to 7-1/2°misalignment; 2-inch model up to 4°• Replaceable O-ring on male sub provides primaryseal• Available with threaded or butt-weld endsFigure 150215,000 psi cold working pressureRecommended serviceCementing, fracturing, acidizing, testing, andchoke-and-kill linesFeatures• Replaceable, lip-type seal• Available for sour gas service: 10,000 psi coldworking pressure; butt-weld or non-pressureseal configurations only• Butt-weld availableFigure 200220,000 psi cold working pressureRecommended serviceCementing, fracturing, acidizing, testing, andchoke-and-kill linesFeatures• Replaceable, lip-type seal• 2 and 3-inch line sizes• Butt-weld configurations onlySee specifications tables (pages WU1A to WU6A) for sizes, dimensions, weights, materials, and part numbers.WU5

Original Weco ® Wing UnionsQuick, positive identificationWeco unions for sour gas service arestamped “Sour Gas” and painted withan olive green zinc-chromate primer toensure quick, positive identification.Meets industry standardsAll Weco wing unions for sour gasservice meet both the NationalAssociation of Corrosion EngineersStandard MR-01-75 and APIStandard RP-14-E.Controlled hardnessWeco union subs and nuts arespecially heat-treated and 100%tested for controlled hardness.Positive sealingPrimary fluoroelastomer seal andmetal-to-metal seal combine todeliver positive sealing throughout thestated pressure range.Figure 2202Sour Gas ServiceFMC Technologies manufactures Weco sour gas wing unions inaccordance with the National Association of Corrosion Engineers(NACE) Standard MR-01-75 and American Petroleum Institute(API) Standard RP-14-E. These outstanding, field-proven unionsare specially heat treated for controlled hardness. For fast, sureidentification, each Weco sour gas union is stamped “Sour Gas”or “NACE MR-01-75” using low stress dot stamping and paintedwith an olive green zinc-chromate primer that is unique to sourgas equipment. FMC Fluid Control uses fluoroelastomer seals orO-rings in all sour gas unions, but does not warrant theperformance of any elastomer for sour gas service.Caution: It is possible to interchange sour gas parts with standardservice products. Users must adopt safe practices for identification,installation, use, maintenance, and storage of sour gas equipment.(See inside back cover for additional Warnings and Cautions.)Weco Wing Unions forSour Gas ServiceFigure 4004,000 psi cold working pressure, 1 through 4-inch sizes; 2,500 psicold working pressure, 5 through 12-inch sizes; butt-weld onlyabove 4-inch sizesFigure 6026,000 psi cold working pressure, 1 through 4-inch sizesFigure 10027,500 psi cold working pressure, 1 through 4-inch sizes;5,000 psi cold working pressure, 5 and 6-inch sizesFigure 10037,500 psi cold working pressure, 2 and 3-inch sizes;5,000 psi cold working pressure, 4 and 5-inch sizesFigure 150210,000 psi cold working pressure, 1 through 4-inch sizes;butt-weld or non-pressure seal configurations onlyFigure 220215,000 psi cold working pressure, 2, 2-1/2, and 3-inch sizes;butt-weld onlySee specifications tables (page WU5A) for sizes, dimensions, weights, materials, and part numbers.WU6

Other Weco ® UnionsTank Unions500 psi maximum line pressure, 6, 8, 10, and 12-inch sizesRecommended serviceMud tanks, mud tank connecting lines, and pump suction flangesFeatures• Molded nitrile seal provides a compression seal• Makes up with hammer• Elongated cross-section of seal ring ensures greater sealingsurface when in contact with the pipe• Accepts up to 7° pipe misalignment• 6, 8, and 10-inch sizes may be socket welded to pipe or buttwelded to tubing; 12-inch sizes require butt-weldAir-O-Unions150 psi maximum line pressure, 4, 6, 8, 10, 13-3/8, and 16-inch sizesRecommended serviceMud suction and return lines and low-pressure fluid linesFeatures• Shot of rig air inflates tube to seal around pipe• Fast, easy make-up without close alignment• Allows pipe expansion or misalignment without breaking the seal• No nuts, bolts, or wrenches requiredSocket weldSuction-Hose Unions500 psi maximum line pressure, 4, 5, and 6-inch sizesRecommended serviceMud system suction linesFeatures• Replaceable O-ring seal• Choice of end fittings• Secondary metal-to-metal seal• Socket welded, threaded, or hose nippleLine pipe threadsHose nippleSocket weld with female plug assemblySee specifications tables (pages WU5A and WU6A) for sizes, dimensions, weights, materials, and part numbers.WU7

Weco ® Fittings and Pup <strong>Joints</strong>Weco FittingsUp to 20,000 psi cold working pressure;1 to 4-inch bore sizesRecommended serviceHigh-pressure well servicing lines, fracturinglines, testing lines, cementing and circulatinglines, and other well service and stimulationapplicationsOptimized, lightweight designsSave valuable weight and space.Complete range of configurationsTees, elbows, crosses, wyes, and lateralscan be combined to suit virtually anyapplication.Integral Weco wingunion end connectionsHigh-strength, high integrityconnections every time.Forged constructionwith full traceabilityWeco fittings and pup joints have been optimized for minimum weight and size.These rugged products are ideal for handling a complete range of standard andsour gas well servicing fluids at pressures up to 20,000 psi. Available in 1 to 4-inchsizes, both fittings and pups feature forged construction with integral Weco wingunion ends (see page WU2 for high-pressure and NPS seal designs) for a highstrength,high-integrity connection every time. Weco pups and fittings come withfull material traceability and can be supplied with Charpy impact values. Like allpressure containing products, Weco pups and fittings require special handling(see inside back cover for Warnings and Cautions).FP1

Weco ® Fittings and Pup <strong>Joints</strong>Weco Pup <strong>Joints</strong>Up to 20,000 psi cold working pressure;2, 3, and 4-inch bore sizes, lengths to 20 feetRecommended ServiceHigh-pressure well servicing lines, fracturinglines, testing lines, cementing and circulatinglines, and other well service and stimulationapplicationsIntegral and NPS designsAvailable in integral and non pressureseal designs to suit virtually all oilfieldapplications.Recessed area for name tagProvides protected area for pup jointidentification.Specially machined shoulderprevents nut from slidingdown pupDesign decreases risk of injury topersonnel.Weco wing union nutdetaches for field repairPermits fast, easy service atthe job site.O P T I M I Z E D F O R G E D F I T T I N G SFMC Technologies offers the smallest, lightest integral forged fittings onthe market. To minimize the size and weight of each fitting, engineersperformed a finite element stress analysis on each fitting bodydesign. From these results, the geometry wasoptimized for weight, and forgings were developedfor each size and type of fitting. The fittingswere then subjected to laboratory and fieldtesting. The result: You save weight and spacewithout sacrificing service life or safety.FP2

Integrated ServicesChiksan ® and Weco ® flowline products have set global industry standardsfor quality, reliability, and service life for almost 75 years. However, superiorproducts alone are not enough to meet the diverse challenges that operatorsand well-servicing companies face today. FMC’s Integrated Services businesspledges to meet or exceed customer expectations by providing value throughservices, technology, and competencies, and by safely following establishedstandards without compromise. This total solutions approach to managingfluid control equipment is helping flowline customers worldwide realize themaximum value and service life from their fluid control assets.IS1

Integrated ServicesWorld’s Leading FlowlineService SolutionInteServ DatabaseFMC’s proprietary web-based database delivers unmatchedstandards for flowline data collection, documentation, andcertifications. Built-in planning and tracking tools identifyequipment usage patterns, inspection, and repair intervals toensure the right products are shipped to the right job in topworking condition. The bottom line: Customers improve safety,maximize equipment utilization, and minimize equipmentmaintenance costs.4 Fully integrated global database4 Internet-based asset tracking and reporting system4 Flexible data extraction tools for detailed asset analysisIS2

Integrated ServicesAsset ManagementTracking and maintaining the volume of flowline equipmentused in high-pressure pumping services is a major undertaking.Asset management is a cooperative program where speciallytrained FMC personnel inventory, track, and maintain acustomer’s flowline assets at their facility or in a designatedFMC facility. Asset management is helping customers worldwidesignificantly increase equipment utilization rates andservice life while reducing total costs and safety concerns.Mobile Inspection and RepairFMC introduced its mobile inspection and repair service in1996. Today, the industry’s largest fleet of mobile units performscomplete inspection and repair services at customer locationsthroughout the world. The mobile package includes inspection,testing, repair, documentation, and certification with the goalof extending product life and reducing operator costs.IS3

Integrated ServicesService CentersTo keep Chiksan and Weco products in top working condition,FMC offers factory rebuild services from strategic locationsworldwide. FMC is aggressively working to expand its in-houserefurbishment services to meet growing demand, includingbutterfly valve and cement head inspection and repair.Spare Parts ManagementChiksan and Weco products are manufactured to precisedimensional tolerances using specialized materials of construction,unique machining processes, and strict quality controlmeasures. The service life of these products can be extendedwith routine maintenance and periodic repair using genuineFMC spare parts.IS4

Chiksan ® and Weco ® SpecificationsContentsWeco Plug Valve SpecificationsWeco Check Valve SpecificationsWeco Butterfly Valve and Actuator SpecificationsChiksan <strong>Swivel</strong> Joint SpecificationsWeco Wing Union SpecificationsWeco Fitting SpecificationsWeco Pup Joint SpecificationsRecommended Temperature RangesWarnings and CautionsPV1ACV1ABV1ASJ1AWU1AF1APJ1ATR1AIBCS1

Weco ® Plug Valve SpecificationsPlug ValvesModelULT 150DR 150DR 200ULT 150 (Manual)ULT 100 (Manual)ULT 150 (Hydraulic)ULT 100 (Hydraulic)ULT 150 (Handwheel)ULT 100 (Handwheel)ULT 200 (Hydraulic)ULT 200 (Handwheel)ULT 200 (Handwheel)ULT 100 (Hydraulic)ULT 100 (Handwheel)ULT 150 (Hydraulic)ULT 150 (Handwheel)NominalSize, in.111x21x2 (.38 bore)1x222223333333334444Part No.P516114P524578P516108P516146P51620832475273248705322300832341833265904P5010103265123326742732651223265257P519087P519453P522233P518352P518356P516015P519749Weco EndConnection*1502100215021502100215021002200222021502100215021002150210022002200222021002100215021502ServiceStandardSourStandardStandardSourStandardSourStandardSourStandardSourStandardSourStandardSourStandardStandardSourStandardStandardStandardStandardNote: 1”, 1x2” ULT 150, DR150 and DR200 plug valves can be furnished with hydraulic actuators.* Other end connections are available. Consult factory.CWPpsi (bar)15,000 (1034)10,000 (690)15,000 (1034)15,000 (1034)10,000 (690)15,000 (1034)10,000 (690)20,000 (1380)15,000 (1034)15,000 (1034)10,000 (690)15,000 (1034)10,000 (690)15,000 (1034)10,000 (690)20,000 (1380)20,000 (1380)15,000 (1034)10,000 (690)10,000 (690)15,000 (1034)15,000 (1034)Weightlb (kg)37 (16.8)37 (16.8)43 (19.5)58 (26.3)37 (16.8)93 (42.2)93 (42.2)83 (37.6)83 (37.6)238 (108)241 (109)337 (153)340 (154)288 (131)288 (131)754 (342)634 (288)640 (290)738 (335)660 (299)774 (351)660 (299)ABFCCDEDEGDR 150 with Manual OperatorULT 150 with Handwheel OperatorPV1A

Weco ® Plug Valve SpecificationsModelNominalSize, in.Ain. (mm)Bin. (mm)Cin. (mm)Din. (mm)Ein. (mm)Fin. (mm)Gin. (mm)14.69 (119)5.88 (149)6.59 (167)1.75 (45)2.88 (73)——14.69 (119)5.88 (149)6.59 (167)1.75 (45)2.88 (73)——ULT 1501x24.69 (119)5.88 (149)6.59 (167)1.75 (45)3.93 (100)——1x2 (.38 bore)4.69 (119)5.88 (149)6.59 (167)1.75 (45)3.93 (100)——1x24.69 (119)5.88 (149)6.59 (167)1.75 (45)3.93 (100)——DR 15026 (152)7.88 (200)8.05 (205)2.62 (67)3.93 (100)——26 (152)7.88 (200)8.05 (205)2.62 (67)3.93 (100)——DR 20026.06 (154)9.19 (233)8.05 (205)2.62 (67)3.76 (96)——26.06 (154)9.19 (233)8.05 (205)2.62 (67)3.76 (96)——ULT 150 (Manual)3——14.27 (363)5 (127)4.55 (116)—15.69 (399)ULT 100 (Manual)3——14.27 (363)5 (127)4.55 (116)—15.69 (399)ULT 150 (Hydraulic)3——21.81 (554)5 (127)4.55 (116)—15.69 (399)ULT 100 (Hydraulic)3——21.81 (554)5 (127)4.55 (116)—15.69 (399)ULT 150 (Handwheel)3——14.47 (368)5 (127)4.55 (116)22.12 (562)15.69 (399)ULT 100 (Handwheel)3——14.47 (368)5 (127)4.55 (116)22.12 (562)15.69 (399)ULT 200 (Hydraulic)3——29.63 (753)6.26 (159)6 (152)—22.08 (561)ULT 200 (Handwheel)3——17.62 (448)6.26 (159)6 (152)36.88 (937)22.08 (561)ULT 200 (Handwheel)3——17.62 (448)6.26 (159)6 (152)36.88 (937)22.08 (561)ULT 100 (Hydraulic)4——28.49 (724)7.00 (118)4.94 (126)—22.85 (580)ULT 100 (Handwheel)4——19.1 (485)7.00 (118)4.94 (126)38.36 (974)22.85 (580)ULT 150 (Hydraulic)4——28.49 (724)7.00 (118)6.14 (156)—22.85 (580)ULT 150 (Handwheel)4——19.1 (485)7.00 (118)6.14 (156)38.29 (973)22.85 (580)CCDEDEGGULT 150 with Manual OperatorULT 150 with Hydraulic ActuatorPV2A

Weco ® Check Valve SpecificationsTop Entry Check ValvesNominalSize, in.Cold WorkingPressure, psi (bar)EndConnectionsFlowOrientationPartNumberAin. (mm)Bin. (mm)Weightlb (kg)315,000 (1034)15,000 (1034)1502 FxM1502 MxFStandardReverseP521623P52444015.67 (398)15.67 (398)9.54 (242)9.54 (242)116 (53)116 (53)410,000 (690)15,000 (1034)1002 FxM1502 FxMStandardStandardP525809P52476019.75 (502)19.75 (502)11.88 (302)11.88 (302)239 (109)276 (126)In-Line Flapper Check ValvesNominalSize, in.Cold WorkingPressure, psi (bar)EndConnectionsFlowOrientationPartNumberAin. (mm)Bin. (mm)Weightlb (kg)1.515,000 (1034)1502 MxFReverseP51973414.04 (357)7 (178)81 (37)15,000 (1034)1502 FxMStandard326917314.04 (357)7 (178)84 (38)215,000 (1034)1502 MxFReverse326947214.04 (357)7 (178)84 (38)20,000 (1379)2002 FxMStandard326915816.91 (430)8 (203)123 (56)6,000 (414)602 FxMStandardP50195915.67 (398)8.12 (206)121 (55)6,000 (414)602 MxFReverseP51997815.67 (398)8.12 (206)124 (56)36,000 (414)602 FxFStandardP50203512.27 (312)8.12 (206)100 (45)15,000 (1034)1502 FxMStandard326905215.67 (398)8.12 (206)122 (55)15,000 (1034)1502 MxFReverseP51843215.67 (398)8.12 (206)126 (57)20,000 (1379)2002 FxMStandardP52009922.79 (579)13 (330)442 (201)6,000 (414)602 FxMStandardP51320422.79 (579)12.25 (311)378 (171)410,000 (690)15,000 (1034)1002 FxM1502 FxMStandardStandardP517718P51789421.13 (537)22.79 (579)11.25 (286)12.25 (311)280 (127)385 (175)15,000 (1034)1502 MxFReverseP51846822.79 (579)12.25 (311)385 (38)Dart Check ValvesNominalSize, in.Cold WorkingPressure, psi (bar)EndConnectionsFlowOrientationPartNumberAin. (mm)Bin. (mm)Weightlb (kg)1.515,000 (1034)15,000 (1034)1502 FxM1502 MxFStandardReverseP525269P52381114.04 (357)14.04 (357)10.31 (262)10.31 (262)86 (39)86 (39)215,000 (1034)1502 FxMStandardP51077114.04 (357)10.31 (262)87 (40)315,000 (1034)1502 FxMStandardP51077315.67 (398)11.43 (290)130 (59)Note: Some sizes and models are available with a vent cap connection for relief of trapped pressure on downstreamside which can occur in flowlines when valve is checked closed. Consult factory for more information.Consult factory for configurations available for models not shown above as wellas installation instructions.CV1A

Weco ® Check Valve SpecificationsTop Entry Check ValvesABIn-Line Flapper Check ValvesABDart Check ValvesABCV2A

Weco ® Butterfly Valve SpecificationsModel 12Sizes, in. 2 2 1/2 3 4Part No. 3227485 3227486 3227487 32458196 8 10 12 143227493 3232417 3227495 3227496 3255865163255869A4 31 ⁄321265 5 ⁄81505 29 ⁄321507 9 ⁄321857 25 ⁄321989 13 ⁄3223910 21 ⁄3227112 5 ⁄3230914 31 ⁄3238017 7 ⁄16443B376.23 11 ⁄3284.93 5 ⁄892.14 1 ⁄41085 5 ⁄1613571788 1 ⁄42109 3 ⁄424810 3 ⁄826411 15 ⁄16303C4 1 ⁄81054 7 ⁄81245 3 ⁄81376 7 ⁄81758 3 ⁄42221127913 3 ⁄834016 1 ⁄841017 11 ⁄1644920 1 ⁄8511Dimensions, in., mmDEFG2 1 ⁄1652.45 ⁄8 Sq.15.941021 1 ⁄3226.22 1 ⁄263.55 ⁄8 Sq.15.941021 1 ⁄3226.23 1 ⁄1677.85 ⁄8 Sq.15.941021 1 ⁄3226.24 1 ⁄161035 ⁄8 Sq.15.941021 9 ⁄3232.56 1 ⁄161545 ⁄8 Sq.15.941021 9 ⁄3232.58 1 ⁄162057 ⁄8 Sq.22.261521 9 ⁄3232.5102547 ⁄8 Sq.22.261521 9 ⁄3232.5123051 1 ⁄8 Sq.28.661521 9 ⁄3232.513 1 ⁄43371 1 ⁄8 Sq.28.661521 9 ⁄3232.515 1 ⁄43872*50.882033 3 ⁄1681H1 5 ⁄8411 3 ⁄4451 3 ⁄4452512 1 ⁄8542 1 ⁄2642 1 ⁄2643763764102IJ7 ⁄1611.13 1 ⁄482.67 ⁄1611.13 1 ⁄482.67 ⁄1611.13 1 ⁄482.67 ⁄1611.13 1 ⁄482.67 ⁄1611.13 1 ⁄482.6Body: Ductile Iron Disc: Ductile Iron Stems: 416 Stainless Steel Seat: Nitrile* 2 inch diameter with 1/2 inch keywayModel 12N (For use with lightweight industrial flanges.)Sizes, in.Part No.AB2 3 4 5 63229885 3230052 32298864 31 ⁄32126376.25 29 ⁄321503 5 ⁄892.17 9 ⁄321854 1 ⁄41083229887 32298887 9 ⁄321854 13 ⁄161227 25 ⁄321985 5 ⁄161359 ⁄1614.351279 ⁄1614.351279 ⁄1614.351279 ⁄1614.3512717 ⁄3213.56 1 ⁄2165I Dia., 4 holes thru;on J dia. bolt circleLNo. of notchesequally spacedM Radius ofnotchC4 1 ⁄81055 3 ⁄81376 7 ⁄81757 3 ⁄41978 3 ⁄4222FK Dia.D2 1 ⁄1652.43 1 ⁄1677.84 1 ⁄161035 1 ⁄161296 1 ⁄16154Model 12N onlyDimensions, in., mmEFGHIJ5 ⁄8 Sq.15.94101.61 1 ⁄3226.21 5 ⁄841.37 ⁄1611.13 1 ⁄482.65 ⁄8 Sq.15.94101.61 1 ⁄3226.21 3 ⁄444.57 ⁄1611.13 1 ⁄482.65 ⁄8 Sq.15.94101.61 9 ⁄3232.5250.87 ⁄1611.13 1 ⁄482.65 ⁄8 Sq.15.94101.61 9 ⁄3232.52 1 ⁄8547 ⁄1611.13 1 ⁄482.65 ⁄8 Sq.15.94101.61 9 ⁄3232.52 1 ⁄8547 ⁄1611.13 1 ⁄482.6DGAEK3 3 ⁄482.64 3 ⁄81116 3 ⁄81626 29 ⁄321758 1 ⁄2216L41026152615261528203BM5 ⁄167.95 ⁄167.93 ⁄89.53 ⁄89.53 ⁄89.5Body: Ductile IronStems: 416 Stainless SteelDisc: Ductile IronSeat: NitrileCHBV1A

Weco ® Butterfly Valve SpecificationsModel 22LSizes, in.Part No.2 2 1/2 3 4 5 6 8 10 12 14 16 18 20 243225748 3225749 3225750 32257513225752 3225753 3225754 3225755 3225756 3255867 3255870 3255871 3255872 3255873A7 9 ⁄321857 25 ⁄321988 1 ⁄162059 5 ⁄322339 21 ⁄3224510 5 ⁄3225811 19 ⁄3229512 27 ⁄3232614 11 ⁄3236414 31 ⁄3238017 7 ⁄1644318 7 ⁄1646819 7 ⁄1649423 3 ⁄4603B376.23 11 ⁄3284.93 5 ⁄892.14 1 ⁄41084 13 ⁄161225 5 ⁄1613571788 1 ⁄42109 3 ⁄424810 3 ⁄826411 15 ⁄1630312 15 ⁄1632913 15 ⁄1635417 1 ⁄8435C615271787 1 ⁄21919229102541127913 1 ⁄2343164061948320 3 ⁄452723 1 ⁄45912563527 1 ⁄469232813D2 1 ⁄1652.42 1 ⁄263.53 1 ⁄1677.84 1 ⁄161035 1 ⁄161296 1 ⁄161548 1 ⁄16205102541230513 1 ⁄433715 9 ⁄3238817 9 ⁄3243919 1 ⁄448923584E5 ⁄8 Sq.15.95 ⁄8 Sq.15.95 ⁄8 Sq.15.95 ⁄8 Sq.15.95 ⁄8 Sq.15.95 ⁄8 Sq.15.97 ⁄8 Sq.22.27 ⁄8 Sq.22.21 1 ⁄8 Sq.28.61 1 ⁄8 Sq.28.62*50.82*50.82*50.82.5 **63.5Dimensions, in., mmFGHI4101.61 1 ⁄3226.21 5 ⁄841.37 ⁄1611.14101.61 1 ⁄3226.21 3 ⁄444.57 ⁄1611.14101.61 1 ⁄3226.21 3 ⁄444.57 ⁄1611.14101.61 9 ⁄3232.5250.87 ⁄1611.14101.61 9 ⁄3232.52 1 ⁄8547 ⁄1611.14101.61 9 ⁄3232.52 1 ⁄8547 ⁄1611.16152.41 9 ⁄3232.52 1 ⁄263.59 ⁄1614.36152.41 9 ⁄3232.52 1 ⁄263.59 ⁄1614.36152.41 9 ⁄3232.5376.29 ⁄1614.36152.41 9 ⁄3232.5376.29 ⁄1614.38203.23 3 ⁄16814101.617 ⁄3213.58203.23 3 ⁄16814 1 ⁄2114.317 ⁄3213.58203.23 3 ⁄1681512717 ⁄3213.58203.24 3 ⁄81116 1 ⁄1615421 ⁄3216.7J3 1 ⁄482.63 1 ⁄482.63 1 ⁄482.63 1 ⁄482.63 1 ⁄482.63 1 ⁄482.651275127512751276 1 ⁄2165.16 1 ⁄2165.16 1 ⁄2165.16 1 ⁄2165.1K5 ⁄8 -115 ⁄8 -115 ⁄8 -115 ⁄8 -113 ⁄4 -103 ⁄4 -103 ⁄4 -107 ⁄8 -97 ⁄8 -91-81-81 1 ⁄8-71 1 ⁄8-71 1 ⁄4 -7L410241024102820482048204820412305123051230516406164062050820508M4 3 ⁄41215 1 ⁄214061527 1 ⁄21918 1 ⁄22169 1 ⁄224111 3 ⁄429914 1 ⁄43621743218 3 ⁄447621 1 ⁄454022 3 ⁄45782563529 1 ⁄2750Body: Ductile Iron Disc: Ductile Iron Stems: 416 Stainless Steel Seat: Nitrile* 2 inch diameter with 1/2 inch keyway** 2.5 inch diameter with 5/8 inch keywayGE2”-12” sizeI dia., 4 holes thru;on J dia. bolt circleFAD Dia.F90°45°B14”-24” sizeI dia., 4 holes thru;on J dia. bolt circleCHK UNC tapped hole thruL places onM diameter bolt centerF Dia.BV3A

Weco ® Butterfly Valve AccessoriesStandard and Throttle HandlesStandard for Models 12, 12NStandard for Models 22, 22LThrottling for all ModelsAValve Size, in.2 - 3 4 & 6 8 & 10 123234078 3231336 3227946 32279473234092 3231337 3216208 32162243235577 3235578 3228018 32280192 3 ⁄860.32 1 ⁄263.5376.22 3 ⁄469.9ECStandard On-Off HandleDimensions, in., mmBCD9 1 ⁄22412 3 ⁄469.91 7 ⁄1636.510 7 ⁄82762 3 ⁄469.91 11 ⁄1642.91538141021 11 ⁄1642.91948341021 11 ⁄1642.9DBAE4102410261526152Note: Butterfly valve assemblies include a standard detent plate for on-off operations.Handle assemblies for throttling service include a throttling detent plate to replacethe standard detent plate on the valve.CGear OperatorsStandardHandwheelChain-wheelAttachmentABCD2 - 6321783832236892 1 ⁄8541 1 ⁄16276 1 ⁄21655127Valve Size, in.8 & 10 12 14 16 - 20 243217839 3217840 3256506 3256507 32565083223690 3223691 3256839 3256840 CF2 1 ⁄263.51 1 ⁄431.8102547 1 ⁄21912 1 ⁄263.51 1 ⁄431.8102547 1 ⁄2191376.21 1 ⁄238.114356153813 5 ⁄892.12 3 ⁄860.3143561538151272 1 ⁄263.51435615381CIEGThrottling HandleJHFEDimensionsin., mmEF4 3 ⁄41211 5 ⁄841.371782 9 ⁄1665.171782 9 ⁄1665.17 3 ⁄41973 1 ⁄879.49 5 ⁄82454 1 ⁄211411 5 ⁄82954 5 ⁄8118D = number of turns to openG6 5 ⁄161609 1 ⁄823211 5 ⁄829515 1 ⁄438715 1 ⁄438717 1 ⁄4438HIJ3 1 ⁄288.9376.241024 3 ⁄41213 1 ⁄288.96 1 ⁄41594 3 ⁄41213 1 ⁄288.96 1 ⁄41595 5 ⁄81433 1 ⁄288.96 1 ⁄21655 3 ⁄41463 1 ⁄288.992299 1 ⁄22413 1 ⁄288.910 1 ⁄4260BABV4A

Weco ® Pneumatic Actuator SpecificationsPneumatic Actuators - Double ActingModel 330 350 550 550A 590 590ASizes, in. 2 - 6 5 - 6 8 - 10 12 10 12Part # 3235438 3237369 3236771 3237183 3237886 3237887WeightABCDEFGHJKLlbkgin.mmin.mmin.mmin.mmin.mmin.mmin.mmin.mmin.mmin.mmin.8 1 ⁄23.912 9 ⁄163198 3 ⁄42223 5 ⁄1684.17 13 ⁄161981 15 ⁄1649.22 1 ⁄1652.4250.83 7 ⁄898.44 5 ⁄161101 7 ⁄1636.53 ⁄8 -16 UNC188.216 1 ⁄851112 5 ⁄163133 5 ⁄1684.17 13 ⁄161981 15 ⁄1649.22 1 ⁄1652.43 5 ⁄1684.16 1 ⁄2165.14 5 ⁄161101 7 ⁄1636.53 ⁄8 -16 UNC3515.919 3 ⁄849213 11 ⁄163485 3 ⁄1613312 1 ⁄163083 3 ⁄1690.53 1 ⁄1677.83 5 ⁄1684.16 1 ⁄21655 5 ⁄161351 7 ⁄847.61 ⁄2 -13 UNC3515.919 3 ⁄849213 11 ⁄163485 3 ⁄1613212 1 ⁄163083 3 ⁄1690.53 1 ⁄1677.83 5 ⁄1684.16 1 ⁄21655 5 ⁄161351 7 ⁄847.61 ⁄2 -13 UNC55252255915 7 ⁄84035 3 ⁄1613212 1 ⁄163083 3 ⁄16813 1 ⁄1677.85 5 ⁄1613510 9 ⁄162685 5 ⁄161351 7 ⁄847.61 ⁄2 -13 UNC55252255915 7 ⁄84035 3 ⁄1613912 1 ⁄163083 3 ⁄16813 1 ⁄1677.85 5 ⁄1613510 9 ⁄162685 5 ⁄161351 7 ⁄847.61 ⁄2 -13 UNCMin.mm3 1 ⁄482.63 1 ⁄482.65127512751275127Nin.mm5 ⁄815.95 ⁄815.97 ⁄822.21 1 ⁄828.67 ⁄822.21 1 ⁄828.64 mounting holesL on M bolt circleboth sidesFN squareN square broachinternal to acceptvalve stemHGED1/4 NPTinlet1/4 NPT inletdoubleactingbreather-springreturnBCKAJBV5A

Weco ® Pneumatic Actuator SpecificationsPneumatic Actuators - Spring ActingModelSizes, in.Part #WeightABCDEFGHJKLlbkgin.mmin.mmin.mmin.mmin.mmin.mmin.mmin.mmin.mmin.mmin.3322 - 2 1/23237525135.919 9 ⁄1649715 3 ⁄44003 5 ⁄1684.18 5 ⁄82191 15 ⁄1649.22 1 ⁄1652.4250.83 7 ⁄898.44 5 ⁄161101 7 ⁄1636.53 ⁄8 -16 UNC3333 - 43237368156.819 9 ⁄1649715 3 ⁄44003 5 ⁄1684.18 5 ⁄82191 15 ⁄1649.22 1 ⁄1652.4250.83 7 ⁄898.44 5 ⁄161101 7 ⁄1636.53 ⁄8 -16 UNC3543 - 432373732511.320 1 ⁄451416 7 ⁄164183 5 ⁄1684.18 5 ⁄82191 15 ⁄1649.22 1 ⁄1652.43 5 ⁄1684.16 1 ⁄21654 5 ⁄161101 7 ⁄1636.53 ⁄8 -16 UNC3555 - 632375153114.120 1 ⁄451416 7 ⁄164183 5 ⁄1684.18 5 ⁄82191 15 ⁄1649.22 1 ⁄1652.43 5 ⁄1684.16 1 ⁄21654 5 ⁄161101 7 ⁄1636.53 ⁄8 -16 UNC5968 - 1032378659342.230 1 ⁄8765246105 1 ⁄1612913 1 ⁄83333 3 ⁄16813 1 ⁄1677.85 5 ⁄1613510 9 ⁄162685 5 ⁄161351 7 ⁄847.61 ⁄2 -13 UNC597A12323786610648.130 1 ⁄8765.2246105 3 ⁄1613213 1 ⁄83333 3 ⁄16813 1 ⁄1677.85 5 ⁄1613510 9 ⁄162685 5 ⁄161351 7 ⁄847.61 ⁄2 -13 UNCMin.mm3 1 ⁄482.63 1 ⁄482.63 1 ⁄482.63 1 ⁄482.651275127Nin.mm5 ⁄815.95 ⁄815.95 ⁄815.95 ⁄815.97 ⁄822.21 1 ⁄828.64 mounting holesL on M bolt circleboth sidesFN squareN square broachinternal to acceptvalve stemHGED1/4 NPTinlet1/4 NPT inletdoubleactingbreather-springreturnBCKAJBV6A

Weco ® Pneumatic Actuator SpecificationsPneumatic Vane ActuatorFits 2” - 6” size butterfly valvesModel200Part #WeightAlbkgin.mm3258068104.548.66220FABEDBin.mm5.56141CDEin.mmin.mmin.mm7.001784.621172.3158.71/4 NPTInletGCFGin.mmin.mm3.4186.62.0050.83/8-16 tapped hole x.56 deep3 places on 3.25 dia. bolt circleboth sidesBV7A

Weco ® Actuator Sizing InformationActuator Sizing InformationRequired Operating Torques:There are three torques to be considered when selectingthe proper actuator for a butterfly valve:(1) Seating Torque - The torque required todisplace a resilient seat and effect shutoff(2) Bearing Torque - The torque required toovercome friction forces on the valve shaftbearing surfaces(3) Dynamic Torque - Torque due to fluid forceswhich tend to close the valve.The torques for resilient seated valves tabulated in thissection are the sum of (1) and (2) above for various shutoffpressures. These tabulated values include a safetyfactor large enough to insure proper valve operation inmost general butterfly valve applications. Where unusualservice conditions exist (such as likelihood of seat swelling,or low and high temperature seat hardening), anadditional safety factor may be applicable.Dynamic TorqueDynamic torque is torque on the valve shaft due to thefluid forces on the valve disc. This torque is a function ofvalve diameter, pressure drop, and a torque coefficient(Ct) which varies with angle opening. Torque is calculatedby the equation:T = C tD 3 ∆PWhere: T = Dynamic torque (in-lb)D = Valve Dia. (in.)C t= Dynamic torque coefficient(see table below)C t vs. Angle OpenAngle Open 0 10 20 30 40 50 60 70 80 90C t 0 .007 .014 .022 .033 .050 .087 .143 .215 0BV8A

Weco ® Actuator Sizing InformationDynamic torque is not usually of major concern inresilient seated butterfly valves unless the line velocityexceeds 20 fps. If line velocity exceeds this, a checkshould be made to insure that actuator output exceedsthe calculated dynamic torque. Dynamic torque shouldbe checked at 80° open for on-off applications.Dynamic torque is of prime consideration in situationswhere line velocity is not recovered downstream of thevalve. This situation exists on installations where’ thereis an unlimited source and less than 6 diameters of pipedownstream of the valve. If a valve discharges to theatmosphere, the pressure drop across the valve will beequal to the height of water above the valve for all anglesof valve opening. This pressure drop must not exceedthe pressure drop tabulated in Maximum ∆P vs. AngleOpening Tables for any angle. If it does, provisions mustbe made for velocity recovery by adding downstreampiping.Actuator Sizing For Tee LinkagesFor standard tee linkage applications where oneactuator operates two butterfly valves of the same sizewith one valve opening as the other valve closes, theactuator sizing will be the same as for a single butterflyvalve application. For the actuator sizing for othertandem linkage applications, consult the factory.Low-Torque ValvesUndercut discs are available for butterfly valve applicationsthat require lower seating torques. For completeinformation, consult factory.Actuators Sizing Torque for Weco Butterfly ValvesValveSize,in.0 psi0 kPa50 psi345 kPaSeating Torque In Inch-lb (N*m), @ Various Line Pressures75 psi517 kPa100 psi690 kPa125 psi862 kPa150 psi1034 kPa175 psi1207 kPa2901090109210941196119811100112 1/2130151301513415138161421614617150173200232002320623212242182522425230264350403504036641382433984541447430495535605356056664597676287165974690786770877708782393876999291059821111,03511781,3501531,3501531,4751671,6001811,7251951,8502091,975223102,1002372,1002372,3402642,5802922,8203193,0603463,300373123,0003393,0003393,4003843,8004294,2004754,6005205,000565143,6804164,2404794,7905415,3506055,9006676,480732164,8805515,7306476,5807447,4308408,2809369,1401030186,2307047,4608438,6909829,920112111,150126012,3901400207,7708789,380106011,000124312,610142514,230161015,84017902411,100125014,010158016,920191019,830224022,740257025,6502900NOTE: For valves using Teflon seats, use torque value at highest standard value rating even for lower pressure applications.Above figures are for values used in wet service, for dry service valves contact factory.BV9A

Weco ® Actuator Sizing InformationMinimum Air Pressure for Weco Pneumatic Actuators OperatingWeco Valves at 175 psi Rated PressureDoubleActingModels330350550550A590590A302072" - 4"2" - 6"8"-8" - 10"12"Actuator air pressure: psi, kPa50345Valve Sizes2" - 5"2" - 6"8" - 10"-8" - 10"12"755172" - 6"2" - 6"8" - 10"NOTES1. Pressures above line for air to open, spring to close. Below line for air to close, spring to open.2. All of the above ratings are conservative for normal installations. Abnormally high torque conditions may necessitate increased actuator capability.3. Maximum actuator air pressure 120 psi, except 80 psi maximum pressure on Models 350, 590 and 590A.12"8" - 10"12"SpringReturnModels332333354355596597AActuator air pressure: psi (kPa) (Note 1)30 (207)40 (276)2" - 2 1/2"-2" - 4"---40 (276)50 (345)2" - 2 1/2"-2" - 4"-8" - 10"-Valve Sizes60 (414)70 (483)2" - 2 1/2"-2"- 4"2" - 6"8" - 10"12"70 (483)80 (552)2" - 2 1/2"2" - 4"2" - 4"2" - 6"8" - 10"12"Weco Pneumatic Actuator Torque Ratings (note air pressure)DoubleActingModels330350550550A590590ADisplacementcu. in.cu. cm254107211801201970120197035558203555820Rated torquein. lbN*m1,1501301,1501305,5006225,5006225,5006225,500622Pressureto achieverated torquepsikPa805523020780552805523020730207SpringReturnModels332333354355596597ADisplacementcu. in.cu. cm25410254072118072118035558203555820Springclosingtorquein. lbN*m1501742548425481,0501193,3003735,000565Springopeningtorquein. lbN*m3003485096850962,1002376,60074610,0001130Air openingtorque @80 psiin. lbN*m1,000113725822,6412982,01622811,36612809,6661100Air closingtorque @80 psiin. lbN*m85096300342,2162509661098,0669114,666527NOTE: All of the above ratings are for normal installations. Abnormally high torque conditions may necessitate increased actuator air pressure.Weco Model 200Vane-Type Pneumatic ActuatorOperating ConditionsMaximum Operating Pressure 120 psi (8.27 bar)Maximum Housing Pressure 180 psi (12.41 bar)Displacement 41 cu. in. (672 cu. cm.)/90°StrokeTorque DataPressurepsikPaTorque Output in. lbmm kg4027680090604141,200136805521,6001811006902,0002261208272,400271Minimum Actuator Pressure for Weco Valvesat 175 psi line pressureValve Size 2”- 4” 5” 6”PressurepsikPa302074531060414NOTE: All of the above ratings are for normal installations. Abnormally high torqueconditions may necessitate increased actuator air pressure.BV10A

Chiksan ® <strong>Swivel</strong> Joint SpecificationsTripleStep and Longsweep ® <strong>Swivel</strong> <strong>Joints</strong>ABBAABACABAABABABCBASize/ModelBore in. (mm)CWPpsi(bar)EndConnectionsStyle 20Part No. AWtlbkgStyle 30 Style 40Style 50Part No. A BWtlbkgWtPart No. A B lb Part No. A B CkgWtlbkgStyle 60Part No. A BWtlbkg1” LS10.88 (22)10,000(690)ThreadedCF61015374.381117.1418183.6N/A31395464.381117.281857.02178167.2CF1” LS15.88 (22)15,000(1034)1502 (MxF)1502 (MxM)CFCF3259291N/A4.061038.4213125.5N/AN/A3139547N/A4.061037.351878.42132210.2CFCF1.5” LS101.3 (33)10,000(690)ThreadedP5060476.5316683.6CFN/A31397797.962029.372387.962022611.8CF1.5” LS151.3 (33)15,000(1034)1502 (MxF)1502 (MxM)P510860CF10.872762612CFN/AN/AN/A3139778N/A51279.423910.12573415.5CFCF2” LS101.88 (48)10,000(690)ThreadedP5235257.2183146.231398886.381629.01229219.531398906.3616210.732733013.631399046.416310.7427392293716.83144545922992292913.21502 (MxF)P51410011.152833716.831441265.514010.912773616.3N/A31394755.514010.7427310.922775625.53144630112791127948222” LS151.88 (48)15,000(1034)1502 (MxM)CFN/AN/A32672037.2818510.7427310.922776027.2610155911279112796228.11502 (FxF)CF9.03229209.1N/AN/A31440005.514010.742738.792234218.9P5049528.792238.792233716.92” LS201.88 (48)20,000(1379)2002 (MxF)2002 (MxM)CFCFCFN/AN/AN/A3144569N/A5.1213010.927712.423156228.3CFP51232512.5131812.513186630.23” TSi72.75 (70)7,500(517)ThreadedCFN/AN/AN/ACF3” TSi152.75 (70)15,000(1034)1502 (MxF)1502 (MxM)P505417CF12.63205223.8P505416N/A7.920114.43666831N/AN/AP505327N/A7.920116.441714.436610748.4P505420CF14.536814.53689141.33” TSi203 (76)20,000(1379)2002 (MxF)CFCFN/A31451339.6924621.253820.4518299136CF4” TSi103.88 (98)10,000(690)1002 (MxF)1002 (MxM)P516092CF14.153597433.6P517487N/A8.321116.24119945N/AN/AP516091N/A8.321118.146016.241116173.3CFCF4” XHTL3.5 (89)10,000(690)1502 (MxF)P517048N/AN/A31305029.6924621.253820.4518275125P50065620.3851820.38518234106SJ1A

Chiksan ® <strong>Swivel</strong> Joint SpecificationsTripleStep and Longsweep <strong>Swivel</strong> <strong>Joints</strong>BBBACACACBDBBDACBACACBACACDDDStyle 70Style 80Style 10Style 100Size/ModelBore in. (mm)PSI(bar)EndConnectionsPart No. A B C DWtlbkgPart No. A B C DWtlbkgPart No. A B CWtlbkgPart No. A B C DWtlbkg1” LS10.88 (22)10,000(690)ThreadedN/ACF31414547.141817.461897.141812410.9N/A1” LS15.88 (22)15,000(1034)1502 (MxF)1502 (MxM)N/AN/AP516135N/A8.41817.471907.471904.061032812.9313955031458868.42138.42137.41887.41888.42138.42132712.12712.1CFCF1.5” LS101.3 (33)10,000(690)ThreadedN/ACFP5015427.962029.372387.962022611.8N/A1.5” LS151.3 (33)15,000(1034)1502 (MxF)1502 (MxM)N/AN/AP502504N/A10.122579.372389.3723851274721.13139781313978010.1225710.122579.372389.3723810.1225710.1225744205223.5CFCF2” LS101.88 (48)10,000(690)Threaded31398916.3816210.7327310.732736.381624721.231398928.9122610.7327310.732736.381625625.63139476922910.727292294520.5N/A1502 (MxF)P5054825.514010.7327310.732735.51406027.2313990110.927710.7325610.732565.51408036.5313990510.927710.727210.92776127.7314409410.9727910.7327310.7327310.912778237.52” LS151.88 (48)15,000(1034)1502 (MxM)N/AN/A313947710.927710.727210.92777031.8313990310.9727910.7327310.7327310.912779040.71502 (FxF)N/AN/AP5189608.822410.727210.92775022.7CF2” LS201.88 (48)20,000(1379)2002 (MxF)2002 (MxM)N/AN/ACFN/A3144570314457110.927712.5131810.8127510.9127712.4231512.523187835.28739.5CF314457212.531810.927710.927712.531810849.13” TSi72.75 (70)7,500(517)ThreadedN/AN/AP52421812.8832716.4241712.8832710246.4CF3” TSi152.75 (70)15,000(1034)1502 (MxF)1502 (MxM)N/AN/AP505409N/A14.436616.441716.44177.920114565.9P505325P50532614.536814.436616.441716.441714.436614.436612958.714364.8P505410P50541114.436614.436616.441716.441716.441716.441714.637114.637116876.118182.23” TSi203 (76)20,000(1379)2002 (MxF)N/ACF314513420.451821.253820.4518360164CF4” TSi103.88 (98)10,000(690)1002 (MxF)1002 (MxM)N/AN/ACFN/AP516094P51609316.140915.940418.146018.146016.241116.241119889.820995CFCF4” XHTL3.5 (89)10,000(690)1502 (MxF)N/ACF313050120.451821.253820.4518338154CFSJ2A

High-Pressure <strong>Swivel</strong> <strong>Joints</strong>Chiksan ® <strong>Swivel</strong> Joint SpecificationsSJ3AA3.31843.31845.311355.311355.471395.471396.661698.252109.122329.62244lbkg1.50.71.50.72.81.32.81.341.841.8125.5188.22511.43817.3A1.94491.94492.72692.72693.19813.19814.031024.881244.621175.56141B2.81712.81714.621174.621174.721204.721205.841487.121819.4424010.81275lbkg1.80.81.80.83.81.73.61.652.352.3156.822103716.85123.2ThreadedThreadedThreadedThreadedThreadedThreadedThreadedThreadedThreadedThreadedWtCWPpsi(bar)WtWtStyle 20 Style 40Style 30 Style 50Wt3111290311131432209463207727320773432077413207749CF3207756320776431112913111315322094732077283207735320774332077503220167320775732077653111292311131632209483207729320773632077443207751322106832077583207766PartNumberPartNumberPartNumberPartNumberNom.Sizein..38.5.7511.251.522.534C2.81712.81714.621174.621174.721204.721204.031024.881248.622199.88251A1.94491.94492.62672.62673.19813.19814.031024.881244.621175.56141B2.13542.13544.221074.221074.281094.281095.881497.681958.7522210.56268lbkg2.51.12.51.14.524.526.32.86.32.819.58.92913.23817.36429.13111293311131732208833205399320773732054003205637321995932077593207767A1.94491.94492.72692.72693.19813.19815.841487.121814.621175.56141B2.88732.88734.221074.221074.281094.281095.881497.681957.942029.83250lbkg3.31.53.31.56.83.16.83.183.6104.52712.33716.85324.18639.1EndConnections6,000(414)6,000(414)6,000(414)6,000(414)6,000(414)6,000(414)6,000(414)6,000(414)6,000(414)6,000(414)ABABABACExtra High-Pressure <strong>Swivel</strong> <strong>Joints</strong>ThreadedWtNom.Sizesin.2WtWtStyle 20 Style 40Style 30 Style 50Wt3213066 3213067 3213068 3222842PartNumberPartNumberPartNumberPartNumberA6.97177lbkg146.4A4.12105B6.48165lbkg219.5lbkg2812.7A4.12105B6.45164C7.52191lbkg3616.4A4.12105B6.38162CWPpsi(bar)10,000(690)EndConnectionsABABABAC