Tailift Sales Manual - Worldwide Forklifts

Tailift Sales Manual - Worldwide Forklifts

Tailift Sales Manual - Worldwide Forklifts

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

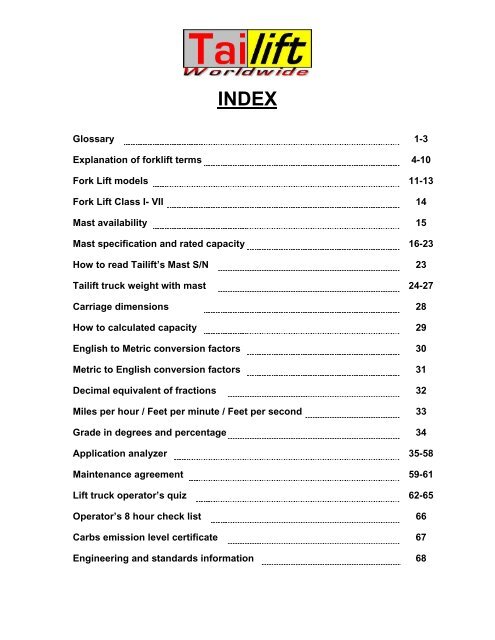

INDEX<br />

Glossary 1-3<br />

Explanation of forklift terms 4-10<br />

Fork Lift models 11-13<br />

Fork Lift Class I- VII 14<br />

Mast availability 15<br />

Mast specification and rated capacity 16-23<br />

How to read <strong>Tailift</strong>’s Mast S/N 23<br />

<strong>Tailift</strong> truck weight with mast 24-27<br />

Carriage dimensions 28<br />

How to calculated capacity 29<br />

English to Metric conversion factors 30<br />

Metric to English conversion factors 31<br />

Decimal equivalent of fractions 32<br />

Miles per hour / Feet per minute / Feet per second 33<br />

Grade in degrees and percentage 34<br />

Application analyzer 35-58<br />

Maintenance agreement 59-61<br />

Lift truck operator’s quiz 62-65<br />

Operator’s 8 hour check list 66<br />

Carbs emission level certificate 67<br />

Engineering and standards information 68

Glossary<br />

Counterweight: A dead or nonworking load (usually lead or cast iron) attached to or incorporated<br />

into the rear of a counterbalanced truck, used to balance the load carried on the forks.<br />

Cushion tire: A solid rubber tire molded to a rim and pressed on the wheel, also called a “solid”<br />

tire, most effective on smooth and/or paved surfaces. Size is shown as diameter x tread width x<br />

rim size.<br />

Drawbar pull: The pull a vehicle can exert on a load attached to is drawbar; depends on power,<br />

weight, and traction.<br />

Fork size: Dimensions of each fork expressed as thickness x width x length.<br />

Fork spread: The maximum distance the forks can be positioned; as measured from the outside<br />

edge of each fork.<br />

Free fork height: The distance from the floor to the carrying surface of the forks when the forks<br />

are at their highest position with the mast in the down position (before beginning to telescope).<br />

Can determine the ability to lift and carry loads within low overhead spaces such as containers<br />

and boxcars. This is computed by adding fork thickness to free lift.<br />

Free lift: The vertical distance the forks can be raised before the mast telescoping begins.<br />

Front overhang: The distance from the front axle to the front face of the forks.<br />

Gradeability: The slope up which a rolling machine can move at a uniform speed, stated in<br />

percentage or degrees. See table on page 21.<br />

Height to top of overhead guard: The distance from the floor to the highest point on the<br />

overhead guard.<br />

High visibility mast: Also known as see through masts or other names specific to a<br />

manufacturer. A mast designed for maximum operator visibility, usually accomplished by placing<br />

the lift cylinders to the sides.<br />

Horsepower: a unit of the rate of work; 33,000 pounds lifted one foot in one minute. Various<br />

measurements of horsepower include:<br />

Rated horsepower: The theoretical horsepower of an engine based on its<br />

dimensions and speed and determined in accordance to a particular standard.<br />

HP= Bore 2 x stroke x R.P.M. x No. of cylinders<br />

14,000<br />

(Note: SAE standard J816; 85 o F (29 o C) @ 500 ft (152m) altitude.)<br />

1 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

Indicated horsepower: The horse power developed in the cylinders, determined by the use of<br />

an indicator gauge. It does not include losses due to friction.<br />

Drawbar horsepower: The horsepower available to move a tractor and its load after deducting<br />

losses in the power train.<br />

Shaft, flywheel, brake horsepower: Actual horsepower produced by the engine after deducting<br />

the drag of accessories.<br />

Hydrostatic transmission: A transmission consisting of an engine driven variable displacement<br />

pump and motor providing infinitely variable speed control from zero to top speed without gears<br />

or clutches.<br />

Lifting speed: The upward speed of the forks either loaded or unloaded, expressed in feet per<br />

minute (fpm).<br />

Load capacity: The maximum load in pounds (or kilograms) that a truck can transport and/or<br />

stack to a specified height as rated by the manufacturer. Normally stated as a given load center,<br />

24 inches being the most common.<br />

Load center: The horizontal distance between the front vertical face of the forks and the<br />

longitudinal midpoint of an evenly distributed load. Note as the load center shifts forward<br />

(increases) the load capacity must be derated (decreased).<br />

Lowered overall height: The height of a mast in its most collapsed position; Either this<br />

dimension or possibly the height to the top of the overhead guard will determine through what<br />

passages, doorways, or under what obstructions a truck will pass.<br />

Lowering speed: The downward speed of the forks either loaded or unloaded, expressed in feet<br />

per minute (fpm).<br />

<strong>Manual</strong> transmission: A transmission employing gear trains and clutches engaged and shifted<br />

directly by an operator. It may employ up to five forward speeds.<br />

Maximum fork height: The ultimate surface height of the forks with the mast fully extended.<br />

Because of pallet or load overhang, stacking at precisely this height may not be possible.<br />

Maximum fork height, rated capacity: The ultimate height of a lift before the load must be<br />

derated. This list height is often accomplished with other than the standard mast.<br />

Minimum aisle, right angle stack: The smallest aisle width in which a truck can accomplish a<br />

right angle stacking procedure. Because some of a truck’s overall length (and the load itself) is<br />

ahead of the front wheels, the minimum aisle for a right angle stack need to be greater than the<br />

truck’s turning radius.<br />

Minimum aisle, right angle stack = turn radius + front overhang + load length + clearance.<br />

Outside turn radius: The radius of a circle with its center at the front wheel of the truck on the<br />

side of the truck towards which the truck is moving.<br />

2 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

Overall length (O.A.L.): The distance from the extreme rear of the truck to the front face of the<br />

forks.<br />

Overall width (O.A.W.): The distance between the widest parts of the truck.<br />

Pneumatic tires: An inflatable tire offering greater traction and cushioning (than cushion tires).<br />

Most appropriate for outdoor and rough surface areas. Size is typical shown as tread width x rim<br />

size – ply rating.<br />

Powershift transmission: A transmission that can be shifted while transmitting full engine<br />

power to the wheels, usually teamed with a torque converter to effectively absorb drive train<br />

shock. Available in single, two speed, three speed, and four speed versions.<br />

Torque: The twisting force exerted by or on a shaft without reference to the speed of the shaft.<br />

Torque = H.P. x 5252<br />

R.P.M.<br />

Torque converter: A hydraulic coupling that utilizes slippage to multiply torque.<br />

Travel Speed: The maximum speed a truck will achieve in high gear either loaded or unloaded.<br />

It’s expressed in miles per hour, can be converted to feet per minute by multiplying by 88. See<br />

table on page 20.<br />

Tread: The distance from the center line of one tire to the center line of its corresponding tire<br />

(i.e. front to front, rear to rear).<br />

Wheelbase: The distance from the front axle to the rear axle.<br />

3 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

Explanation of forklift terms<br />

Load capacity and load center<br />

The load capacity of a forklift truck varies depending<br />

on the horizontal distance between the vertical<br />

surface of the forks and the center of gravity of the<br />

load. A forklift truck is equipped with a load chart<br />

indicating this relationship between the distance and<br />

the load capacity. The X shown on this load chart is<br />

called the load center, and the Y which corresponds<br />

to the X is the maximum load capacity.<br />

Dimension<br />

4<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

Maximum fork height<br />

The maximum fork height denotes the height from the ground to the upper surfaces of the<br />

forks when the forks are raised to their highest position with the mast positioned vertically.<br />

Free lift<br />

The free lift is the maximum lifting height of the forks with the mast position remaining<br />

unchanged.<br />

Overall length<br />

With forks:<br />

Without forks:<br />

The length from the front end of the forks to the rear end of the truck body.<br />

The overall length minus the length of the forks, i.e., the length from the<br />

vertical surface of the forks to the rear of the truck body.<br />

Overall width<br />

The maximum width of a forklift truck with the steering wheel set in the straight ahead<br />

position.<br />

Overall height<br />

The height to the top of the forklift truck. The mast overall height is classified in two<br />

categories: mast extended overall height when the forks are fully raised and mast lowered<br />

height the forks are fully lowered. The mast lowered overall height must be compared to the<br />

height of the overhead guard. This dimension is essential when judging whether or not a<br />

forklift truck will be able to pass through and entrance to a building or some structure.<br />

Wheelbase<br />

The horizontal distance between the centers of the front and the rear axle.<br />

Front overhang<br />

Distance from the front axle center to the vertical surface of the forks.<br />

Rear overhang<br />

Distance from rear axle center to rear of the truck body.<br />

Tread<br />

Distance between the center of the left and right tires on the same axle, or in dual-tire models,<br />

the distance between the centers of the left and right dual tires.<br />

5<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

Turning radius<br />

The radius of the locus drawn by the extreme outward side of<br />

the truck body when the forklift turns either right or left at the<br />

minimum forward speed with the steering wheel turned<br />

completely is called the “outside minimum turning radius”.<br />

The radius of the locus drawn by the inner front tire is called<br />

the “inside minimum turning radius”.<br />

Right angle (90°) stacking aisle<br />

The right angle stacking aisle denotes the minimum width of<br />

an aisle in which a forklift truck is able to load and unload after<br />

completing a 90 degree turn.<br />

Right angle (90°) intersecting aisle<br />

The minimum turning radius indicates the sharpness of a turn,<br />

but it does not indicate how large a space is required to make<br />

a turn. The right angle intersecting aisle is defined as the<br />

minimum width of aisle which intersects at right angles<br />

through which the forklift truck is able to pass. The catalog<br />

data is for a non-loaded with the forks set at their widest<br />

position.<br />

Fork length<br />

The length from the vertical surfaces of the forks to the front end of the forks.<br />

Floor height<br />

The height from the ground to the upper face of the floor board.<br />

Step height<br />

The height from the ground to the upper face of step.<br />

Seat height<br />

The height from the ground to the upper face of the seat when the operator [90 kg (199lbs)] is<br />

seated.<br />

6<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

Head clearance<br />

The head clearance from the under face of overhead guard to the upper face of seat when the<br />

operator [90 kg (199lbs)] is seated.<br />

Counterweight height<br />

The height from the ground to the top of the counterweight.<br />

Backrest height<br />

The height from upper of the forks to the top of backrest.<br />

Maximum fork spread<br />

The distance of outer forks when the forks are moved on the outsider notches of carriage.<br />

Minimum fork spread<br />

The distance of outer forks when the forks are move on the inside notches of carriage.<br />

Maximum ground clearance<br />

The height from the ground at the position<br />

where the clearance from the ground is<br />

considered minimum, except the elevating<br />

portion of the loading device and around the<br />

wheels.<br />

C 1 :<br />

C 2 :<br />

C 3 :<br />

under mast<br />

under power unit<br />

under frame<br />

Grade clearance<br />

The angle (α) between the plane contacting the front tires and passing the front lower end of<br />

the mast and ground is called the “Approach angle”.<br />

The angle (β) between the plane contacting the rear wheels and passing the rear lower end of<br />

the forklift truck and ground is called the “Departure angle”.<br />

The angle (γ) between the lane intersecting on the underside parts of the body where the first<br />

plane is tangent to the front tires and the second plane is tangent to the rear tires is called<br />

“Ramp brakeover angle”.<br />

7<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

These angles are essential for assessing the ability of a forklift truck to climb over an obstacle<br />

on the ground when traveling.<br />

Approach Angle Departure Angle Ramp break-over Angle<br />

Performance<br />

The performance of forklift truck is changed by road surface and oil temperature of the<br />

transmission or reduction gear etc.<br />

The value on this handbook shows on the concrete or asphalt road and oil temperature as<br />

below.<br />

Engine oil: more than 50 o C (122 o F)<br />

Transmission: more than 50 o C (122 o F)<br />

Torque converter: more than 80 o C (176 o F)<br />

Reduction gear: more than 50 o C (122 o F)<br />

Hydraulic tank: more than 40 o C (104 o F)<br />

Lifting/Lowering speed<br />

The speed of the forks as they move upwards and downwards is expressed both for their<br />

loaded state and unloaded state. The lowering speed has been limited (reduced) to prevent<br />

both vehicle instability and damage to the load which can result from sudden drops caused by<br />

the weight of the load.<br />

Travel speed<br />

The maximum truck speed when the accelerator pedal is fully opened.<br />

Drawbar pull<br />

The forklift truck is often used as a tractor for a<br />

trailer or other equipment. In such instances, the<br />

8<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

maximum traction varies according to the engine torque, reduction gear ratio, road surface<br />

and other factors. It also varies largely depending<br />

on whether or not the truck is loaded.<br />

Gradeability<br />

The “Gradeability” indicates the ability of the<br />

forklift to ascend a slope. This ability differs<br />

depending on whether it is loaded or not. The unit<br />

of measuring the Gradeability varies from<br />

manufacturer to manufacturer. The conversion<br />

table given below may be utilized for comparison<br />

purposes. The Gradeability of <strong>Tailift</strong> forklift trucks<br />

is normally expressed in tangent percent (tan 0%).<br />

Gradeability Conversion Table<br />

Degree Fraction tan 0% sin 0% Degree Fraction tan 0% sin 0%<br />

(0) (B/A) (B/A) (B/C) (0) (B/A) (B/A) (B/C)<br />

1 1/57.2 1.8 1.8 24 1/2.2 44.5 40.6<br />

2 1/28.6 3.5 3.5 25 1/2.1 46.6 42.2<br />

3 1/19.1 5.2 5.2 26 1/2.1 48.8 43.8<br />

4 1/14.3 7.0 7.0 27 1/2.0 51.0 45.4<br />

5 1/11.4 8.8 8.7 28 1/1.9 53.2 47.0<br />

6 1/9.5 10.5 10.5 29 1/1.8 55.4 48.5<br />

7 1/8.1 12.3 12.2 30 1/1.7 57.7 50.0<br />

8 1/7.1 14.0 13.9 31 1/1.7 60.0 51.5<br />

9 1/6.3 15.8 15.6 32 1/1.6 62.5 53.0<br />

10 1/5.7 17.6 17.4 33 1/1.5 64.9 54.5<br />

11 1/5.1 19.4 19.1 34 1/1.5 67.4 55.9<br />

12 1/4.7 21.3 20.8 35 1/1.4 70.0 57.4<br />

13 1/4.3 23.1 22.5 36 1/1.4 72.7 58.8<br />

14 1/4.0 24.9 24.1 37 1/1.3 75.4 60.2<br />

15 1/3.7 26.8 25.8 38 1/1.3 78.1 61.6<br />

16 1/3.5 28.7 27.5 39 1/1.2 81.0 62.9<br />

17 1/3.3 30.6 29.2 40 1/1.2 83.9 64.3<br />

18 1/3.1 32.5 30.9 41 1/1.2 86.9 65.6<br />

19 1/2.9 34.4 32.5 42 1/1.1 90.0 66.9<br />

20 1/2.7 36.4 34.2 43 1/1.1 93.3 68.2<br />

21 1/2.6 38.4 35.8 44 1/1.1 96.6 69.5<br />

22 1/2.5 40.4 37.4 45 1/1.0 100.0 70.7<br />

23 1/2.4 42.4 39.0<br />

9<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

Weight<br />

Truck weight: Total weight of a forklift truck without load.<br />

Gross truck weight: The truck weight plus the<br />

maximum load. In the <strong>Tailift</strong> forklift truck the<br />

gross truck weight also includes the weight<br />

of an operator.<br />

Weight distribution: The weight of a truck in<br />

both an unloaded and loaded state is<br />

distributed to the front wheels and rear<br />

wheels.<br />

10<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

11<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

12<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

13<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

Lift Truck Class I-VII<br />

Class I – Electric Motor Rider Trucks<br />

Lift Code 1- Counterbalance rider type, stand-up<br />

Lift Code 4- Three-wheel electric trucks, sit-down<br />

Lift Code 5- Counterbalanced rider type, pneumatic/cushion tire, sit-down (includes<br />

high and low platform)<br />

Class II – Electric Motor Narrow Aisle Trucks<br />

Lift Code 1- High lift straddle<br />

Lift Code 2- Order picker<br />

Lift Code 3- Reach type outrigger<br />

Lift Code 4- Side loaders, turret trucks, swing mast and convertible turret/stock pickers<br />

Lift Code 6- Low lift pallet and platform (rider)<br />

Class III – Electric Motor Hand Trucks<br />

Lift Code 1- Low lift platform<br />

Lift Code 2- Low lift walkie pallet<br />

Lift Code 3- Tractors<br />

Lift Code 4- Low lift walkie/center control<br />

Lift Code 5- Reach type outrigger<br />

Lift Code 6- High lift straddle<br />

Lift Code 7- High lift counterbalanced<br />

Lift Code 8- Low lift walkie/rider pallet<br />

Class IV – Internal Combustion Engine Trucks- Cushion Tires Only<br />

Lift Code 3- Fork, counterbalanced (cushion tire)<br />

Class V – Internal Combustion Engine Trucks- Pneumatic Tires Only<br />

Lift Code 4- Fork, counterbalanced (Pneumatic tire)<br />

Class VI– Electric and Internal Combustion Engine Tractors<br />

Lift Code 1- Sit-down rider<br />

Class VII – Rough Terrain Fork Lift Trucks<br />

Lift Code 1- All rough terrain fork lift trucks<br />

14 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

Mast Availability<br />

All of <strong>Tailift</strong> forklifts are equipped with wide view masts. The following four types are available.<br />

Among 2-stage wide view masts, the 2H type (High free lift mast) has more free lift than 2W type.<br />

Not all masts are available on every model.<br />

15 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

TAILIFT IC CUSHION MAST SPECIFICATION AND RATED CAPACITY<br />

MODEL:FG15C<br />

OVERALL HEIGHT<br />

CAPACITY<br />

Basic Capacity at 24" Load Center<br />

Max Height Lower Extended Free lift<br />

Tilt<br />

degree<br />

Without<br />

Side Shifter<br />

With<br />

Side shifter<br />

mm(in) mm (in) mm (in) mm (in) F B kg (lb) kg (lb)<br />

MAST TYPE: Two stage Cushion Cushion<br />

3000(118) 1990(78.3) 4220(166) 150(6) 6 7 1350(3000) 1240(2730)<br />

3300(130) 2140(84.3) 4520(178) 150(6) 6 7 1350(3000) 1240(2730)<br />

3500(138) 2240(88.2) 4720(185.8) 150(6) 6 7 1350(3000) 1240(2730)<br />

4000(157.5) 2540(100) 5220(205.5) 150(6) 6 7 1350(3000) 1240(2730)<br />

MAST TYPE: Two stage full free<br />

3000(118) 1990(78.3) 4220(166) 1500(59) 6 7 1350(3000) 1240(2730)<br />

3300(130) 2140(84.3) 4520(178) 1650(65) 6 7 1350(3000) 1240(2730)<br />

3500(138) 2240(88.2) 4720(185.8) 1750(69) 6 7 1350(3000) 1240(2730)<br />

MAST TYPE: Three stage full free<br />

4000(157.5) 1924(75.7) 5220(205.5) 1333(52.5) 6 6 1260(2780) 1160(2550)<br />

4500(177) 2090(82.3) 5720(225) 1500(59) 6 6 1170(2580) 1070(2354)<br />

4870(192) 2140(84.3) 6090(240) 1623(64) 6 6 1150(2530) 1050(2310)<br />

5000(197) 2240(88) 6220(245) 1650(65) 6 6 1080(2380) 990(2180)<br />

5500(216.5) 2423(95.4) 6720(264.5) 1833(72) 6 6 810(1790) 740(1630)<br />

MODEL:FG18C<br />

OVERALL HEIGHT<br />

CAPACITY<br />

Basic Capacity at 24" Load Center<br />

Max Height Lower Extended Free lift<br />

Tilt<br />

degree<br />

Without<br />

Side Shifter<br />

With<br />

Side shifter<br />

mm(in) mm (in) mm (in) mm (in) F B kg (lb) kg (lb)<br />

MAST TYPE: Two stage Cushion Cushion<br />

3000(118) 2000(78.7) 4220(166) 150(6) 6 7 1590(3500) 1310(2880)<br />

3300(130) 2151(84.7) 4520(178) 150(6) 6 7 1590(3500) 1310(2880)<br />

3500(138) 2250(88.5) 4720(185.8) 150(6) 6 7 1590(3500) 1310(2880)<br />

4000(157.5) 2550(100.4) 5220(205.5) 150(6) 6 6 1590(3500) 1310(2880)<br />

MAST TYPE: Two stage full free<br />

3000(118) 2000(78.7) 4220(166) 1500(59) 6 7 1590(3500) 1310(2880)<br />

3300(130) 2150(84.7) 4520(178) 1650(65) 6 7 1590(3500) 1310(2880)<br />

3500(138) 2250(88.5) 4720(185.8) 1750(69) 6 7 1590(3500) 1310(2880)<br />

MAST TYPE: Three stage full free<br />

4000(157.5) 1933(78.7) 5220(205.5) 1333(52.5) 6 6 1530(3370) 1270(2790)<br />

4500(177) 2100(83) 5720(225.2) 1500(59) 6 6 1430(3150) 1180(2600)<br />

4870(192) 2140(84.3) 6220(245) 1623(64) 6 6 1400(3080) 1160(2550)<br />

5000(197) 2433(96) 6720(264.5) 1650(65) 6 6 1260(2770) 1030(2270)<br />

5500(216.5) 2650(104) 7220(284.3) 1833(72) 6 6 520(1140) 390(858)<br />

16 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

TAILIFT IC CUSHION MAST SPECIFICATION AND RATED CAPACITY<br />

MODEL:FG20C<br />

OVERALL HEIGHT<br />

CAPACITY<br />

Basic Capacity at 24" Load Center<br />

Max Height Lower Extended Free lift<br />

Tilt<br />

degree<br />

Without<br />

Side shifter<br />

With<br />

Side shifter<br />

mm(in) mm (in) mm (in) mm (in) F B kg(lb) kg(lb)<br />

MAST TYPE: Two stage Cushion Cushion<br />

3000(118) 1990(78.3) 4220(166) 150(6) 6 10 1818(4000) 1661(3655)<br />

3300(130) 2140(84.3) 4520(178) 150(6) 6 10 1818(4000) 1661(3655)<br />

3500(138) 2240(88.2) 4720(185.8) 150(6) 6 10 1818(4000) 1661(3655)<br />

4000(157.5) 2540(100) 5220(205.5) 150(6) 6 6 1818(4000) 1661(3655)<br />

MAST TYPE: Two stage full free<br />

3000(118) 1990(78.3) 4220(166) 1500(59) 6 10 1818(4000) 1661(3655)<br />

3300(130) 2140(84.3) 4520(178) 1650(65) 6 10 1818(4000) 1661(3655)<br />

3500(138) 2240(88.2) 4720(185.8) 1750(69) 6 10 1818(4000) 1661(3655)<br />

MAST TYPE: Three stage full free<br />

4000(157.5) 1924(75.7) 5220(205.5) 1333(52.5) 6 6 1818(4000) 1661(3655)<br />

4500(177) 2080(82.3) 5720(225.2) 1500(59) 6 6 1710(3762) 1553(3417)<br />

4870(192) 2140(84.3) 6090(240) 1623(64) 6 6 1650(3630) 1493(3285)<br />

5000(197) 2240(88) 6220(245) 1650(65) 6 6 1630(3586) 1473(3241)<br />

5500(216.5) 2423(95.4) 6720(264.5) 1833(72) 6 6 1500(3300) 1343(2955)<br />

MODEL: FG25C<br />

OVERALL HEIGHT<br />

CAPACITY<br />

Basic Capacity at 24" Load Center<br />

Max Height Lower Extended Free lift<br />

Tilt<br />

degree<br />

Without<br />

Side shifter<br />

With<br />

Side shifter<br />

mm(in) mm (in) mm (in) mm (in) F B kg(lb) kg(lb)<br />

MAST TYPE: Two stage Cushion Cushion<br />

3000(118) 1990(78.3) 4220(166) 150(6) 6 10 2270(5000) 2113(4655)<br />

3300(130) 2140(84.3) 4520(178) 150(6) 6 10 2270(5000) 2113(4655)<br />

3500(138) 2240(88.2) 4720(185.8) 150(6) 6 10 2270(5000) 2113(4655)<br />

4000(157.5) 2540(100) 5220(205.5) 150(6) 6 6 2270(5000) 2113(4655)<br />

MAST TYPE: Two stage full free<br />

3000(118) 1990(78.3) 4220(166) 1500(59) 6 6 2270(5000) 2113(4655)<br />

3300(130) 2140(84.3) 4520(178) 1650(65) 6 6 2270(5000) 2113(4655)<br />

3500(138) 2240(88.2) 4720(185.8) 1750(69) 6 6 2270(5000) 2113(4655)<br />

MAST TYPE: Three stage full free<br />

4000(157.5) 1924(75.7) 5220(205.5) 1333(52.5) 6 6 2270(5000) 2113(4655)<br />

4500(177) 2090(82.3) 5720(225.2) 1500(59) 6 6 2200(4840) 2043(4495)<br />

4870(192) 2140(84.3) 6090(240) 1623(64) 6 6 2150(4730) 1993(4385)<br />

5000(197) 2240(88) 6220(245) 1650(65) 6 6 2100(4620) 1943(4283)<br />

5500(216.5) 2423(95.4) 6720(264.5) 1833(72) 6 6 1910(4202) 1753(3857)<br />

17 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

TAILIFT IC CUSHION MAST SPECIFICATION AND RATED CAPACITY<br />

MODEL: FG30C<br />

OVERALL HEIGHT<br />

CAPACITY<br />

Basic Capacity at 24" Load Center<br />

Max Height Lower Extended Free lift<br />

Tilt<br />

degree<br />

Without<br />

Side shifter<br />

With<br />

Side shifter<br />

mm(in) mm (in) mm (in) mm (in) F B kg(lb) kg(lb)<br />

MAST TYPE: Two stage Cushion Cushion<br />

3000(118) 1990(78.3) 4220(166) 140(5.5) 6 10 2727(6000) 2527(5560)<br />

3300(130) 2140(84.3) 4520(178) 140(5.5) 6 10 2727(6000) 2527(5560)<br />

3500(138) 2240(88.2) 4720(185.8) 140(5.5) 6 10 2727(6000) 2527(5560)<br />

4000(157.5) 2540(100) 5220(205.5) 140(5.5) 6 6 2727(6000) 2527(5560)<br />

MAST TYPE: Two stage full free<br />

3000(118) 1990(78.3) 4220(166) 1500(59) 6 10 2727(6000) 2527(5560)<br />

3300(130) 2140(84.3) 4520(178) 1650(65) 6 10 2727(6000) 2527(5560)<br />

3500(138) 2240(88.2) 4720(185.8) 1750(69) 6 10 2727(6000) 2527(5560)<br />

MAST TYPE: Three stage full free<br />

4000(157.5) 1924(75.7) 5220(205.5) 1333(52.5) 6 6 2727(6000) 2527(5560)<br />

4500(177) 2090(82.3) 5720(225.2) 1500(59) 6 6 2650(5830) 2450(5390)<br />

4870(192) 2140(84.3) 6090(240) 1623(64) 6 6 2590(5698) 2390(5258)<br />

5000(197) 2240(88.2) 6220(245) 1650(65) 6 6 2500(5500) 2300(5060)<br />

5500(216.5) 2423(95.4) 6720(264.5) 1833(72) 6 6 2370(5210) 2170(4774)<br />

MODEL: FG35C<br />

OVERALL HEIGHT<br />

CAPACITY<br />

Basic Capacity at 24" Load Center<br />

Max Height Lower Extended Free lift<br />

Tilt<br />

degree<br />

Without<br />

Side shifter<br />

With<br />

Side shifter<br />

mm(in) mm (in) mm (in) mm (in) F B kg(lb) kg(lb)<br />

MAST TYPE: Two stage Cushion Cushion<br />

3000(118) 2065(81.3) 4220(166) 160(6.3) 6 6 3630(8000) 3340(7350)<br />

3300(130) 2215(87.2) 4520(178) 160(6.3) 6 6 3630(8000) 3340(7350)<br />

3500(138) 2315(91.1) 4720(185.8) 160(6.3) 6 6 3630(8000) 3340(7350)<br />

4000(157.5) 2545(100.2) 5220(205.5) 160(6.3) 6 6 3630(8000) 3340(7350)<br />

MAST TYPE: Two stage full free<br />

3000(118) 1900(78.3) 4220(166) 1500(59) 6 6 3630(8000) 3340(7350)<br />

3300(130) 2140(84.3) 4520(178) 1650(65) 6 6 3630(8000) 3340(7350)<br />

3500(138) 2240(88.2) 4720(185.8) 1750(69) 6 6 3630(8000) 3340(7350)<br />

MAST TYPE: Three stage full free<br />

4500(177) 2090(82.3) 5720(225) 1500(59) 6 6 3400(7480) 3120(6860)<br />

4870(192) 2160(85) 6090(240) 1623(64) 6 6 3200(7040) 2930(6450)<br />

5000(197) 2240(88) 6220(245) 1650(65) 6 6 3150(6930) 2880(6340)<br />

5500(216.5) 2423(95.4) 6720(264.5) 1833(72) 6 6 2950(6490) 2400(5370)<br />

18 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

TAILIFT IC PNEUMATIC MAST SPECIFICATION AND RATED CAPACITY<br />

MODEL: FD/FG15P<br />

OVERALL HEIGHT<br />

CAPACITY<br />

Basic Capacity at 24" Load Center<br />

Max Height Lower Extended Free lift<br />

Tilt<br />

degree<br />

Without Side<br />

shifter<br />

With<br />

Side shifter<br />

mm(in) mm (in) mm (in) mm (in) F B kg(lb) kg(lb)<br />

MAST TYPE: Two stage Pneumatic (std) Pneumatic (std)<br />

3000(118) 2000(78.7) 4220(166) 0(0) 6 12 1350(3000) 1250(2750)<br />

3300(130) 2150(84.7) 4520(178) 0(0) 6 12 1350(3000) 1250(2750)<br />

3500(138) 2250(88.5) 4720(185.8) 0(0) 6 12 1350(3000) 1250(2750)<br />

3700(145) 2400(94.5) 4920(193.7) 0(0) 6 12 1350(3000) 1250(2750)<br />

4000(157.5) 2500(100.4) 5220(205.5) 0(0) 6 6 1350(3000) 1250(2750)<br />

MAST TYPE: Two stage full free<br />

3000(118) 2000(78.7) 4220(166) 1500(59) 6 12 1350(3000) 1250(2750)<br />

3300(130) 2150(84.7) 4520(178) 1650(65) 6 12 1350(3000) 1250(2750)<br />

3500(138) 2250(88.5) 4720(185.8) 1750(69) 6 12 1350(3000) 1250(2750)<br />

MAST TYPE: Three stage full free<br />

4500(177) 2100(83) 5720(225) 1500(59) 6 6 1170(2580) 1080(2370)<br />

4870(192) 2150(84.7) 6090(240) 1623(64) 6 6 1150(2530) 1060(2330)<br />

5000(197) 2250(88.5) 6220(245) 1650(65) 6 6 900(2185) 820(1800)<br />

5500(216.5) 2433(96) 6720(264.5) 1833(72) 6 6 720(1590) 650(1430)<br />

6000(236) 2650(104) 7220(284) 2000(79) 6 6 540(1190) 480(1060)<br />

MODEL: FD/FG18P<br />

CAPACITY<br />

OVERALL HEIGHT<br />

Basic Capacity at 24" Load Center<br />

Without Without With With<br />

Max Overall Overall Free Tilt<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Height Lower Extended lift degree kg(lb) kg(lb) kg(lb) kg(lb)<br />

mm(in) mm (in) mm (in) mm (in) F B Pneumatic Pneumatic Pneumatic Pneumatic<br />

MAST TYPE: Two stage (std) (dual) (std) (dual)<br />

3000(118) 2000(78.7) 4220(166) 0(0) 6 12 1590(3500) 1590(3500) 1520(3340) 1520(3340)<br />

3300(130) 2150(84.7) 4520(178) 0(0) 6 12 1590(3500) 1590(3500) 1520(3340) 1520(3340)<br />

3500(138) 2250(88.5) 4720(185.8) 0(0) 6 12 1550(3410) 1550(3410) 1440(3170) 1440(3170)<br />

3700(145) 2400(94.5) 4920(193.7) 0(0) 6 12 1500(3300) 1500(3300) 1390(3060) 1390(3060)<br />

4000(157.5) 2550(100.4) 5220(205.5) 0(0) 6 6 1450(3190) 1500(3300) 1350(2970) 1390(3060)<br />

MAST TYPE: Two stage full free<br />

3000(118) 2000(78.7) 4220(166) 1500(59) 6 12 1590(3500) 1590(3500) 1520(3340) 1520(3340)<br />

3300(130) 2150(84.7) 4520(178) 1650(65) 6 12 1590(3500) 1590(3500) 1520(3340) 1520(3340)<br />

3500(138) 2250(88.5) 4720(185.8) 1750(69) 6 12 1550(3410) 1550(3410) 1440(3170) 1440(3170)<br />

MAST TYPE: Three stage full free<br />

4500(177) 2100(83) 5720(225) 1500(59) 6 6 1350(2970) 1480(3260) 1250(2750) 1370(3010)<br />

4870(192) 2150(84.7) 6090(240) 1623(64) 6 6 1250(2750) 1380(3030) 1150(2530) 1270(2790)<br />

5000(197) 2250(88.5) 6220(245) 1650(65) 6 6 1150(2530) 1410(3100) 1060(2330) 1310(2880)<br />

5500(216.5) 2433(96) 6720(264.5) 1833(72) 6 6 950(2090) 1310(2880) 870(1910) 1210(2660)<br />

6000(236) 2650(104) 7220(284) 2000(79) 6 6 650(1430) 1100(2420) 590(1300) 1010(2220)<br />

19 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

TAILIFT IC PNEUMATIC MAST SPECIFICATION AND RATED CAPACITY<br />

MODEL: FD/FG20P<br />

CAPACITY<br />

OVERALL HEIGHT<br />

Basic Capacity at 24" Load Center<br />

Without Without With With<br />

Max Overall Overall Free Tilt<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Height Lower Extended lift degree kg(lb) kg(lb) kg(lb) kg(lb)<br />

mm(in) mm (in) mm (in) mm (in) F B Pneumatic Pneumatic Pneumatic Pneumatic<br />

MAST TYPE: Two stage (std) (dual) (std) (dual)<br />

3000(118) 2000(78.7) 4220(166) 0(0) 6 12 1818(4000) 1818(4000) 1690(3720) 1690(3720)<br />

3300(130) 2150(84.7) 4520(178) 0(0) 6 12 1818(4000) 1818(4000) 1690(3720) 1690(3720)<br />

3500(138) 2250(88.5) 4720(185.8) 0(0) 6 12 1818(4000) 1818(4000) 1690(3720) 1690(3720)<br />

3700(145) 2400(94.5) 4920(193.7) 0(0) 6 12 1818(4000) 1818(4000) 1690(3720) 1690(3720)<br />

4000(157.5) 2550(100.4) 5220(205.5) 0(0) 6 6 1818(4000) 1818(4000) 1690(3720) 1690(3720)<br />

MAST TYPE: Two stage full free<br />

3000(118) 2000(78.7) 4220(166) 1500(59) 6 12 1818(4000) 1818(4000) 1690(3720) 1690(3720)<br />

3300(130) 2150(84.7) 4520(178) 1650(65) 6 12 1818(4000) 1818(4000) 1690(3720) 1690(3720)<br />

3500(138) 2250(88.5) 4720(185.8) 1750(69) 6 12 1818(4000) 1818(4000) 1690(3720) 1690(3720)<br />

MAST TYPE: Three stage full free<br />

4500(177) 2100(83) 5720(225) 1500(59) 6 6 1700(3740) 1700(3740) 1580(3480) 1580(3480)<br />

4870(192) 2150(84.7) 6090(240) 1623(64) 6 6 1510(3320) 1510(3320) 1390(3060) 1500(3300)<br />

5000(197) 2250(88.5) 6220(245) 1650(65) 6 6 1310(2880) 1310(2880) 1210(2660) 1470(3240)<br />

5500(216.5) 2433(96) 6720(264.5) 1833(72) 6 6 1100(2420) 1100(2420) 1010(2220) 1390(3060)<br />

6000(236) 2650(104) 7220(284) 2000(79) 6 6 750(1650) 750(1650) 680(1500) 1300(2860)<br />

MODEL: FD/FG25P<br />

CAPACITY<br />

OVERALL HEIGHT<br />

Basic Capacity at 24" Load Center<br />

Without Without With With<br />

Max Overall Overall Free Tilt<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Height Lower Extended lift degree kg(lb) kg(lb) kg(lb) kg(lb)<br />

mm(in) mm (in) mm (in) mm (in) F B Pneumatic Pneumatic Pneumatic Pneumatic<br />

MAST TYPE: Two stage (std) (dual) (std) (dual)<br />

3000(118) 2000(78.7) 4220(166) 0(0) 6 12 2270(5000) 2270(5000) 2120(4660) 2120(4660)<br />

3300(130) 2150(84.7) 4520(178) 0(0) 6 12 2270(5000) 2270(5000) 2120(4660) 2120(4660)<br />

3500(138) 2250(88.5) 4720(185.8) 0(0) 6 12 2270(5000) 2270(5000) 2120(4660) 2120(4660)<br />

3700(145) 2400(94.5) 4920(193.7) 0(0) 6 12 2270(5000) 2270(5000) 2120(4660) 2120(4660)<br />

4000(157.5) 2550(100.4) 5220(205.5) 0(0) 6 6 2270(5000) 2270(5000) 2120(4660) 2120(4660)<br />

MAST TYPE: Two stage full free<br />

3000(118) 2000(78.7) 4220(166) 1500(59) 6 12 2270(5000) 2270(5000) 2120(4660) 2120(4660)<br />

3300(130) 2150(84.7) 4520(178) 1650(65) 6 12 2270(5000) 2270(5000) 2120(4660) 2120(4660)<br />

3500(138) 2250(88.5) 4720(185.8) 1750(69) 6 12 2270(5000) 2270(5000) 2120(4660) 2120(4660)<br />

MAST TYPE: Three stage full free<br />

4500(177) 2100(83) 5720(225) 1500(59) 6 6 1900(4180) 2140(4710) 1770(3890) 2000(4400)<br />

4870(192) 2150(84.7) 6090(240) 1623(64) 6 6 1550(3410) 2100(4620) 1450(3200) 1970(4330)<br />

5000(197) 2250(88.5) 6220(245) 1650(65) 6 6 1420(3120) 2090(4600) 1320(2900) 1950(4290)<br />

5500(216.5) 2433(96) 6720(264.5) 1833(72) 6 6 1150(2530) 1920(4220) 1060(2332) 1790(3938)<br />

6000(236) 2650(104) 7220(284) 2000(79) 6 6 800(1760) 1615(3550) 730(1610) 1500(3300)<br />

20 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

TAILIFT IC PNEUMATIC MAST SPECIFICATION AND RATED CAPACITY<br />

MODEL: FD/FG30P<br />

CAPACITY<br />

OVERALL HEIGHT<br />

Basic Capacity at 24" Load Center<br />

Without Without With With<br />

Max Overall Overall Free Tilt<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Height Lower Extended lift degree kg(lb) kg(lb) kg(lb) kg(lb)<br />

mm(in) mm (in) mm (in) mm (in) F B Pneumatic Pneumatic Pneumatic Pneumatic<br />

MAST TYPE: Two stage (std) (dual) (std) (dual)<br />

3000(118) 2000(78.7) 4220(166) 0(0) 6 12 2720(6000) 2720(6000) 2530(5560) 2530(5560)<br />

3300(130) 2150(84.7) 4520(178) 0(0) 6 12 2720(6000) 2720(6000) 2530(5560) 2530(5560)<br />

3500(138) 2250(88.5) 4720(185.8) 0(0) 6 12 2720(6000) 2720(6000) 2530(5560) 2530(5560)<br />

3700(145) 2400(94.5) 4920(193.7) 0(0) 6 12 2720(6000) 2720(6000) 2530(5560) 2530(5560)<br />

4000(157.5) 2550(100.4) 5220(205.5) 0(0) 6 6 2720(6000) 2720(6000) 2530(5560) 2530(5560)<br />

MAST TYPE: Two stage full free<br />

3000(118) 2000(78.7) 4220(166) 1500(59) 6 12 2720(6000) 2720(6000) 2530(5560) 2530(5560)<br />

3300(130) 2150(84.7) 4520(178) 1650(65) 6 12 2720(6000) 2720(6000) 2530(5560) 2530(5560)<br />

3500(138) 2250(88.5) 4720(185.8) 1750(69) 6 12 2720(6000) 2720(6000) 2530(5560) 2530(5560)<br />

MAST TYPE: Three stage full free<br />

4500(177) 2100(83) 5720(225) 1500(59) 6 6 2600(5720) 2690(5920) 2420(5320) 2500(5500)<br />

4870(192) 2150(84.7) 6090(240) 1623(64) 6 6 2240(4930) 2600(5720) 2080(4580) 2440(5370)<br />

5000(197) 2250(88.5) 6220(245) 1650(65) 6 6 2100(4620) 2580(5680) 1940(4270) 2400(5280)<br />

5500(216.5) 2433(96) 6720(264.5) 1833(72) 6 6 1650(3630) 2440(5370) 1520(3340) 2270(4990)<br />

6000(236) 2650(104) 7220(284) 2000(79) 6 6 1100(2420) 2050(4510) 990(2180) 1990(4180)<br />

MODEL: FD/FG35P<br />

CAPACITY<br />

OVERALL HEIGHT<br />

Basic Capacity at 24" Load Center<br />

Without Without With With<br />

Max Overall Overall Free Tilt<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Height Lower Extended lift degree kg(lb) kg(lb) kg(lb) kg(lb)<br />

mm(in) mm (in) mm (in) mm (in) F B Pneumatic Pneumatic Pneumatic Pneumatic<br />

MAST TYPE: Two stage (std) (dual) (std) (dual)<br />

3300(130) 2150(84.7) 4520(178) 0(0) 6 12 3500(8000) 3500(8000) 3330(7680) 3330(7680)<br />

3500(138) 2250(88.5) 4720(185.8) 0(0) 6 12 3500(8000) 3500(8000) 3330(7680) 3330(7680)<br />

3700(145) 2400(94.5) 4920(193.7) 0(0) 6 12 3500(8000) 3500(8000) 3330(7680) 3330(7680)<br />

4000(157.5) 2550(100.4) 5220(205.5) 0(0) 6 6 3250(7150) 3500(8000) 3330(7680) 3330(7680)<br />

MAST TYPE: Two stage full free<br />

3000(118) 2000(78.7) 4220(166) 1500(59) 6 12 3500(8000) 3500(8000) 3330(7680) 3330(7680)<br />

3300(130) 2150(84.7) 4520(178) 1650(65) 6 12 3500(8000) 3500(8000) 3330(7680) 3330(7680)<br />

3500(138) 2250(88.5) 4720(185.8) 1750(69) 6 12 3500(8000) 3500(8000) 3330(7680) 3330(7680)<br />

MAST TYPE: Three stage full free<br />

4500(177) 2100(83) 5720(225) 1500(59) 6 6 3000(6600) 3400(7480) 2850(6270) 3240(7060)<br />

4870(192) 2150(84.7) 6090(240) 1623(64) 6 6 2450(5390) 3300(7260) 2300(5060) 3140(6910)<br />

5000(197) 2250(88.5) 6220(245) 1650(65) 6 6 2400(5280) 3300(7260) 2270(4950) 3140(6910)<br />

5500(216.5) 2433(96) 6720(264.5) 1833(72) 6 6 1700(3740) 3200(7040) 1590(3500) 3050(6710)<br />

6000(236) 2650(104) 7220(284) 2000(79) 6 6 1600(3520) 3000(6600) 1490(3280) 2850(6270)<br />

21 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

TAILIFT IC PNEUMATIC MAST SPECIFICATION AND RATED CAPACITY<br />

MODEL: FD/FG40P<br />

CAPACITY<br />

OVERALL HEIGHT<br />

Basic Capacity at 24" Load Center<br />

Without Without With With<br />

Max Overall Overall Free Tilt<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Height Lower Extended lift degree kg(lb) kg(lb) kg(lb) kg(lb)<br />

mm(in) mm (in) mm (in) mm (in) F B Pneumatic Pneumatic Pneumatic Pneumatic<br />

MAST TYPE: Two stage (std) (dual) (std) (dual)<br />

3000(118) 2190(86) 4220(166) 0(0) 6 12 4000(8800) 4000(8800) 3573(7860) 3573(7860)<br />

3300(130) 2340(92) 4520(178) 0(0) 6 12 4000(8800) 4000(8800) 3573(7860) 3573(7860)<br />

3500(138) 2490(98) 4720(185.8) 0(0) 6 12 4000(8800) 4000(8800) 3573(7860) 3573(7860)<br />

3700(145) 2590(102) 4920(193.7) 0(0) 6 12 4000(8800) 4000(8800) 3573(7860) 3573(7860)<br />

4000(157.5) 2790(110) 5220(205.5) 0(0) 6 6 4000(8800) 4000(8800) 3573(7860) 3573(7860)<br />

MAST TYPE: Two stage full free<br />

3000(118) 2190(86) 4220(166) 1490(59) 6 12 4000(8800) 4000(8800) 3573(7860) 3573(7860)<br />

3300(130) 2340(92) 4520(178) 1650(65) 6 12 4000(8800) 4000(8800) 3573(7860) 3573(7860)<br />

3500(138) 2490(98) 4720(185.8) 1750(69) 6 12 4000(8800) 4000(8800) 3573(7860) 3573(7860)<br />

MAST TYPE: Three stage full free<br />

4500(177) 2200(87) 5720(225) 1490(59) 6 6 4000(8800) 4000(8800) 3573(7860) 3573(7860)<br />

4800(189) 2380(94) 6020(237) 1600(63) 6 6 3800(8360) 3900(8580) 3385(7450) 3480(7660)<br />

5000(197) 2380(94) 6220(245) 1650(65) 6 6 3500(7700) 3700(8140) 3100(6842) 3290(7238)<br />

5500(216.5) 2590(102) 6720(264.5) 1850(73) 6 6 2700(5940) 3400(7480) 2350(5168) 3008(6617)<br />

6000(236) 2790(110) 7220(284) 2000(79) 6 6 2200(4840) 3000(6600) 1878(4133) 2631(5788)<br />

MODEL: FD/FG45P<br />

CAPACITY<br />

OVERALL HEIGHT<br />

Basic Capacity at 24" Load Center<br />

Without Without With With<br />

Max Overall Overall Free Tilt<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Side<br />

shifter Side shifter<br />

Height Lower Extended lift degree kg(lb) kg(lb) kg(lb) kg(lb)<br />

mm(in) mm (in) mm (in) mm (in) F B Pneumatic Pneumatic Pneumatic Pneumatic<br />

MAST TYPE: Two stage (std) (dual) (std) (dual)<br />

3000(118) 2190(86) 4220(166) 0(0) 6 12 4500(9900) 4500(9900) 4043(8894) 4043(8894)<br />

3300(130) 2340(92) 4520(178) 0(0) 6 12 4500(9900) 4500(9900) 4043(8894) 4043(8894)<br />

3500(138) 2490(98) 4720(185.8) 0(0) 6 12 4500(9900) 4500(9900) 4043(8894) 4043(8894)<br />

3700(145) 2590(102) 4920(193.7) 0(0) 6 12 4500(9900) 4500(9900) 4043(8894) 4043(8894)<br />

4000(157.5) 2790(110) 5220(205.5) 0(0) 6 6 4500(9900) 4500(9900) 4043(8894) 4043(8894)<br />

MAST TYPE: Two stage full free<br />

3000(118) 2190(86) 4220(166) 1490(59) 6 12 4500(9900) 4500(9900) 4043(8894) 4043(8894)<br />

3300(130) 2340(92) 4520(178) 1650(65) 6 12 4500(9900) 4500(9900) 4043(8894) 4043(8894)<br />

3500(138) 2490(98) 4720(185.8) 1750(69) 6 12 4500(9900) 4500(9900) 4043(8894) 4043(8894)<br />

MAST TYPE: Three stage full free<br />

4500(177) 2200(87) 5720(225) 1490(59) 6 6 4150(9130) 4150(9130) 3714(8170) 3714(8170)<br />

4800(189) 2380(94) 6020(237) 1600(63) 6 6 4100(9020) 4100(9020) 3667(8068) 3667(8068)<br />

5000(197) 2380(94) 6220(245) 1650(65) 6 6 4000(8800) 4100(9020) 3573(7860) 3667(8068)<br />

5500(216.5) 2590(102) 6720(264.5) 1850(73) 6 6 2900(6380) 3900(8580) 2537(5583) 3479(7653)<br />

6000(236) 2790(110) 7220(284) 2000(79) 6 6 2300(5060) 3600(6380) 1972(4340) 3196(7032)<br />

22 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

TAILIFT IC PNEUMATIC MAST SPECIFICATION AND RATED CAPACITY<br />

MODEL: FD/FG50P<br />

CAPACITY<br />

OVERALL HEIGHT<br />

Basic Capacity at 24" Load Center<br />

Without Without With With<br />

Max Overall Overall Free Tilt Side shifter Side shifter<br />

Side<br />

shifter<br />

Side<br />

shifter<br />

Height Lower Extended lift degree kg(lb) kg(lb) kg(lb) kg(lb)<br />

mm(in) mm (in) mm (in) mm (in) F B Pneumatic Pneumatic Pneumatic Pneumatic<br />

MAST TYPE: Two stage (std) (dual) (std) (dual)<br />

3000(118) 2190(86) 4220(166) 0(0) 6 12 5000(11000) 5000(11000) 4514(9930) 4514(9930)<br />

3300(130) 2340(92) 4520(178) 0(0) 6 12 5000(11000) 5000(11000) 4514(9930) 4514(9930)<br />

3500(138) 2490(98) 4720(185.8) 0(0) 6 12 5000(11000) 5000(11000) 4514(9930) 4514(9930)<br />

3700(145) 2590(102) 4920(193.7) 0(0) 6 12 5000(11000) 5000(11000) 4514(9930) 4514(9930)<br />

4000(157.5) 2790(110) 5220(205.5) 0(0) 6 6 5000(11000) 5000(11000) 4514(9930) 4514(9930)<br />

MAST TYPE: Two stage full free<br />

3000(118) 2190(86) 4220(166) 1490(59) 6 12 5000(11000) 5000(11000) 4514(9930) 4514(9930)<br />

3300(130) 2340(92) 4520(178) 1650(65) 6 12 5000(11000) 5000(11000) 4514(9930) 4514(9930)<br />

3500(138) 2490(98) 4720(185.8) 1750(69) 6 12 5000(11000) 5000(11000) 4514(9930) 4514(9930)<br />

MAST TYPE: Three stage full free<br />

4500(177) 2200(87) 5720(225) 1490(59) 6 6 4300(9460) 4500(9900) 3855(8481) 4043(8895)<br />

4800(189) 2380(94) 6020(237) 1600(63) 6 6 4200(9240) 4400(9700) 3750(8250) 3902(8585)<br />

5000(197) 2380(94) 6220(245) 1650(65) 6 6 4100(9020) 4400(9700) 3573(7860) 3902(8585)<br />

5500(216.5) 2590(102) 6720(264.5) 1850(73) 6 6 3000(6600) 4000(8800) 2631(5786) 3573(7860)<br />

6000(236) 2790(110) 7220(284) 2000(79) 6 6 2400(5280) 3800(8360) 2066(4545) 3385(7447)<br />

HOW TO READ TAILIFT ‘S MAST SERIAL NUMBER<br />

Mast serial numbers are usually located on the left hand side of the upright, just about eye level<br />

Examples of mast serial number:<br />

S/N: 2 - 2 33- 5066 S/N : 3 -3 5 - 1111<br />

Ton<br />

Stage<br />

3.3 meter Actual S/N<br />

4.8 meter<br />

Full free<br />

Ton Stage 5 meter Actual S/N<br />

4.5 meter<br />

S/N: 2 - 3 48 F -1111 S/N: 3 -3 45 - 1111<br />

23 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

TAILIFT LPG AND DIESEL TRUCK WEIGHT<br />

MAST FG 18C FG 20C<br />

TYPE Meter Inches kg lb kg lb<br />

W.V. 3 118 2870 6310 3300 7260<br />

W.V. 3.3 130 2890 6360 3380 7440<br />

W.V. 3.5 138<br />

W.V. 4 158<br />

W.V. 4.5 177<br />

FFL 3 118<br />

FFL 3.3 130 2920 6420 3400 7480<br />

FFL 3.5 138<br />

FFL 4 158<br />

TSU 4 158 3600 7920<br />

TSU 4.87 192 3010 6620 3620 7960<br />

TSU 5 197<br />

TSU 5.5 217<br />

Side Shifter net weight 50 110 70 154<br />

MAST FG 25C FG 30C FG 35C<br />

TYPE Meter Inches kg lb kg lb kg lb<br />

W.V. 3 118 3730 8210 4270 9240 4900 10780<br />

W.V. 3.3 130 3750 8250 4300 9460 4932 10850<br />

W.V. 3.5 138<br />

W.V. 4 158<br />

W.V. 4.5 177<br />

FFL 3 118<br />

FFL 3.3 130 3780 8320 4320 9500<br />

FFL 3.5 138<br />

FFL 4 158<br />

TSU 4 158 3920 8620<br />

TSU 4.87 192 3970 8730 4450 9790 5110 11240<br />

TSU 5 197 4050 8910<br />

TSU 5.5 217<br />

Side shifter net weight 70 154 70 154 70 154<br />

24<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

TAILIFT LPG AND DIESEL TRUCK WEIGHT<br />

Mast FG 15P FD 15P FG 18P FD 18P<br />

Type Meter Inches kg lb kg lb kg lb kg lb<br />

W.V. 3 118 2920 6420 3000 6600 3970 6530 3050 6710<br />

W.V. 3.3 130 2970 6530 3050 6710 3010 6620 3090 6800<br />

W.V. 3.5 138 2990 6580 3070 6750 3030 6670 3110 6840<br />

W.V. 4 157.5 3050 6710 3130 6890 3090 6800 3170 6970<br />

W.V. 4.5 177 3130 6890 3210 7060 3170 6970 3250 7150<br />

FFL 3 118 2960 6510 3040 6690 3000 6600 3080 6780<br />

FFL 3.3 130 2990 6580 3070 6750 3030 6670 3110 6840<br />

FFL 3.5 138 3020 6640 3100 6820 3060 6730 3140 6910<br />

FFL 4 157.5 3060 6730 3150 6930 3090 6800 3170 6970<br />

TSU 4 157.5 3140 6910 3220 6910 3180 6700 3260 7170<br />

TSU 4.87 192 3160 6950 3240 7130 3200 7040 3280 7220<br />

TSU 5 197 3180 7000 3260 7170 3220 7090 3300 7260<br />

TSU 5.5 197 3220 7080 3300 7260 3250 7150 3330 7330<br />

Side shifter net weight 50 110 50 110 50 110 50 110<br />

Mast FG 20P FD 20P FG 25P FD 25P<br />

Type Meter Inches kg lb kg lb kg lb kg lb<br />

W.V. 3 118 3500 7700 3580 7880 3720 8180 3800 8360<br />

W.V. 3.3 130 3560 7830 3640 8010 3780 8320 3860 8490<br />

W.V. 3.5 138 3570 7850 3650 8030 3790 8340 3870 8520<br />

W.V. 4 157.5 3630 7980 3710 8160 3890 8560 3970 8730<br />

W.V. 4.5 177 3670 8070 3750 8250<br />

FFL 3 118 3530 7770 3610 7940 3750 8250 3830 8430<br />

FFL 3.3 130 3560 7830 3640 8010 3780 8320 3860 8490<br />

FFL 3.5 138 3590 7900 3670 8070 3810 8380 3890 8560<br />

FFL 4 157.5 3610 7940 3690 8120 3830 8430 3970 8730<br />

TSU 4 157.5 3720 8180 3800 8360 3940 8670 4020 8840<br />

TSU 4.87 192 3750 8250 3830 8430 3970 8730 4080 8980<br />

TSU 5 197 3770 8290 3850 8470 4000 8800 4100 9020<br />

TSU 5.5 197 3790 8340 3870 8510 4010 8820 4130 9090<br />

Side shifter net weight 70 154 70 154 70 154 70 154<br />

25<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

TAILIFT LPG AND DIESEL TRUCK WEIGHT<br />

Mast FG 30P FD 30P FG 35P FD 35P<br />

Type Meter inches kg lb kg lb kg lb kg lb<br />

W.V. 3 118 4420 9720 4500 9900 4620 10160 4700 10340<br />

W.V. 3.3 130 4450 9790 4530 9970 4640 10230 4720 10380<br />

W.V. 3.5 138 4470 9830 4550 10010 4650 10230 4750 10450<br />

W.V. 4 157.5 4510 9920 4590 10100 4680 10300 4770 10490<br />

W.V. 4.5 177 4560 10030 4640 10210 4710 10360 4810 10580<br />

W.V. 5 197 4650 10230 4690 10318<br />

FFL 3 118 4450 9790 4530 9970 4630 9460 4710 10360<br />

FFL 3.3 130 4480 9860 4560 10030 4660 10250 4740 10430<br />

FFL 3.5 138 4510 9920 4590 10100 4690 10320 4770 10490<br />

FFL 4 157.5 4540 9990 4630 10190 4720 10380 4800 10560<br />

TSU 4 157.5 4660 10250 4750 10450 4800 10560 4880 10740<br />

TSU 4.87 192 4680 10300 4770 10500 4810 10580 4890 10760<br />

TSU 5 197 4700 10340 4790 10540 4840 10650 4980 11154<br />

TSU 5.5 197 4740 10430 4830 10630 4890 10760 4970 10930<br />

TSU 6 216.5 4830 10620 4910 10800 4950 10890 5010 11022<br />

TSU 6.5 216.5 4990 10978<br />

Side shifter net weight 90 198 90 198 90 198 90 198<br />

Mast FG 40P FD 40P FG 45P FD 45P<br />

Type Meter Inches kg lb kg lb kg lb kg lb<br />

W.V. 3 118 6470 14260 6420 14120 6600 14520 6550 14410<br />

W.V. 3.3 130 6460 14210 6610 14540 6570 14450<br />

W.V. 3.5 138 6500 14300 6630 14590 6590 14500<br />

W.V. 4 157.5 6550 14410 6670 14680 6630 14590<br />

W.V. 4.5 177<br />

W.V. 3.7 145.7 6525 14355<br />

FFL 3 118 6470 14230 6620 14560 6600 14520<br />

FFL 3.3 130 6510 14320 6660 14650 6640 14610<br />

FFL 3.5 138 6560 14430 6670 14670 6650 14630<br />

FFL 4 157.5 6610 14540 6690 14720 6670 14670<br />

TSU 4 157.5 6600 14520 6730 14800 6680 14700<br />

TSU 4.8 189 6700 14740 6750 14850 6700 14740<br />

TSU 5 197 6780 14920 6780 14920 6730 14810<br />

TSU 5.5 197 6850 15100<br />

Side shifter net weight 110 242 110 242 110 242 110 242<br />

26<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

TAILIFT LPG AND DIESEL TRUCK WEIGHT<br />

Mast FG 50P FD 50P<br />

Type Meter Inches kg lb kg lb<br />

W.V. 3 118 6750 14850 6700 14740<br />

W.V. 3.3 130 6780 14916<br />

W.V. 3.5 138 6850 15070<br />

W.V. 4 157.5 6950 15290<br />

W.V. 4.5 177 7100 15620<br />

FFL 3 118 6730 14810<br />

FFL 3.3 130<br />

FFL 3.5 138<br />

FFL 4 157.5<br />

TSU 4 157.5<br />

TSU 4.8 189<br />

TSU 5 197 6860 15090<br />

TSU 5.5 197<br />

Side shifter net weight 230 506 230 506<br />

W.V. = Wide view mast<br />

FFL= Two stage full free<br />

TSU= Triple stage full free<br />

27<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

DUAL PNEUMATIC TIRES<br />

MODEL SIZE P.R. RIM (inch)<br />

S.W.<br />

Load<br />

O.D. (inch) PSI<br />

(inch)<br />

(lbs)<br />

20T - 25T 7.00-12 12 5.00 7.4 26.7 125 5995<br />

30T - 35T 7.00-15 12 5.50 7.7 29.3 100 4590<br />

40T – 50T 7.50-16 12 6.00 7.0 31.1 100 7995<br />

Total Width (dual tires)<br />

MODEL<br />

DIMENSIONS (in)<br />

20T – 25T 60.32<br />

30T - 35T 65.16<br />

40T – 50T 66.14<br />

CARRIAGE DIMENSIONS<br />

20T – 25T (in) 30T - 35T (in) 40T – 45T (in) 50T (in)<br />

A 8.74 12.13 12.13 16.93<br />

B 13.47 17.64 17.64 22.44<br />

C 15.91 20 20 24.80<br />

D 17.91 17.21 18.43 18.43<br />

E 40.32 45.28 51.58 51.58<br />

F 64.96 64.96 68.11 68.11<br />

28 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

How to calculate the approximate capacity of your<br />

truck with an attachment<br />

A=<br />

B=<br />

C=<br />

Truck’s basic capacity-pounds.<br />

Distance from center line of front wheel to<br />

fork face-inches.<br />

Distance from fork face to rated load<br />

center- inches.<br />

D=<br />

E=<br />

F=<br />

G=<br />

H=<br />

Weight of the attachment-pounds.<br />

Distance form center line of front wheel<br />

to carriage face-inches.<br />

Distance from carriage face to<br />

attachment’s center of gravity-inches.<br />

Distance from carriage face to rear face<br />

of load-inches.<br />

Distance from rear face of load to center<br />

of load-inches.<br />

Net Capacity A (B + C) - D (E + F)<br />

With attachment<br />

E + G + H<br />

Example: Assume A=4,000 lbs B=12” C=24” D=1,000 lbs<br />

E=10” F= 9” G= 6” H=24”<br />

Net Capacity 4000lbs (12” + 24”) – 1000 lbs. (10”+ 9”)<br />

10” + 6” + 24”<br />

Net Capacity<br />

Net Capacity<br />

144,000 in-lbs.-19,000 in-lbs<br />

40 in<br />

3125 lbs.<br />

29 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

English to Metric Conversion Factors<br />

Multiply English unit by Length To obtain metric unit<br />

Inch 25.4 Millimeter<br />

Inch 2.54 Centimeter<br />

Foot 30.48 Centimeter<br />

Foot 0.3048 Meter<br />

Yard 0.9144 Meter<br />

Mile 1.609 Kilometer<br />

Area<br />

Sq. Inch 6.452 Sq. Centimeter<br />

Sq. Foot 0.0929 Sq. Meter<br />

Sq. Yard 0.8361 Sq. Meter<br />

Acre 0.4047 Hectare<br />

Sq. mile 2.59 Sq. Kilometer<br />

Capacity/Volume<br />

Cu. Inch 0.0164 Liter<br />

Cu. Foot 0.0283 Cu. Meter<br />

Cu. Yard 0.765 Cu. Meter<br />

U.S. Gallon 3.785 Liter<br />

U.S. Gallon 0.833 Imp. Gallon<br />

Weight<br />

Ounce 28.35 Gram<br />

Pound 0.4536 Kilogram<br />

Pound 453.6 Gram<br />

Short Ton 907.18 Kilogram<br />

Long Ton 1016.05 Kilogram<br />

Short Ton 0.907 Metric Ton<br />

Long Ton 1.016 Metric Ton<br />

Power<br />

Horsepower 1.0138 Metric Horsepower<br />

Horsepower 0.7457 Kilowatt<br />

Pressure<br />

Lbs per sq. Inch 0.0703 kg. per sq cm<br />

lbs per sq. foot 4.8824 kg. per sq m<br />

Normal atmosphere 1.0332 kg. per sq cm<br />

30 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

Metric to English Conversion Factors<br />

Multiply Metric unit by To obtain English unit<br />

Length<br />

Millimeter .03937 Inch<br />

Centimeter .3937 Inch<br />

Centimeter .0328 Foot<br />

Meter 3.28 Foot<br />

Meter 1.0936 Yard<br />

Kilometer .6214 Mile<br />

Area<br />

Sq. Centimeter .1550 Sq. Inch<br />

Sq. Meter 10.76 Sq. Foot<br />

Sq. Meter 1.196 Sq. Yard<br />

Hectare 2.471 Acre<br />

Sq. Kilometer .3861 Sq. mile<br />

Capacity/Volume<br />

Liter 61.02 Cu. Inch<br />

Cu. Meter 35.316 Cu. Foot<br />

Cu. Meter 1.308 Cu. Yard<br />

Liter .2642 U.S. Gallon<br />

Imp. Gallon 1.20 U.S. Gallon<br />

Weight<br />

Gram .0353 Ounce<br />

Kilogram 2.2046 Pound<br />

Gram .0022 Pound<br />

Kilogram .0011 Short Ton<br />

Kilogram .00098 Long Ton<br />

Metric Ton 1.1023 Short Ton<br />

Metric Ton .98 Long Ton<br />

Power<br />

Metric Horsepower .9863 Horsepower<br />

Kilowatt 1.341 Horsepower<br />

Pressure<br />

kg. per sq cm 14.223 Lbs per sq. Inch<br />

kg. per sq m .2048 lbs per sq. foot<br />

kg. per sq cm .9678 Normal atmosphere<br />

31 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

DECIMAL EQUIVALENTS OF FRACTIONS<br />

1/64 0.015625 33/64 0.515625<br />

1/32 0.031250 17/32 0.531250<br />

3/64 0.046875 35/64 0.546875<br />

1/16 0.062500 9/16 0.562500<br />

5/64 0.078125 37/64 0.578125<br />

3/32 0.093750 19/32 0.593750<br />

7/64 0.109375 39/64 0.609375<br />

1/8 0.125000 5/8 0.625000<br />

9/64 0.140625 41/64 0.640625<br />

5/32 0.156250 21/32 0.656250<br />

11/64 0.171875 43/64 0.671875<br />

3/16 0.187500 11/16 0.687500<br />

13/64 0.203125 45/64 0.703125<br />

7/32 0.218750 23/32 0.718750<br />

15/64 0.234375 47/64 0.734375<br />

1/4 0.250000 3/4 0.750000<br />

17/64 0.265625 49/64 0.765625<br />

9/32 0.281250 25/32 0.781250<br />

19/64 0.296875 51/64 0.796875<br />

5/16 0.312500 13/16 0.812500<br />

21/64 0.328125 53/64 0.828125<br />

11/32 0.343750 27/32 0.843750<br />

23/64 0.359375 55/64 0.859375<br />

3/8 0.375000 7/8 0.875000<br />

25/64 0.390625 57/64 0.890625<br />

13/32 0.406250 29/32 0.906250<br />

27/64 0.421875 59/64 0.921875<br />

7/16 0.437500 15/16 0.937500<br />

29/64 0.453125 61/64 0.953125<br />

15/32 0.468750 31/32 0.968750<br />

31/64 0.484375 63/64 0.984375<br />

1/2 0.500000 1/1 1.000000<br />

32 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

Miles per hour in feet per minute and feet per second<br />

Miles per hour Feet per minute Feet per second<br />

1 88 1.47<br />

2 176 2.93<br />

3 264 4.40<br />

4 352 5.87<br />

5 440 7.33<br />

6 528 8.80<br />

7 616 10.27<br />

8 704 11.73<br />

9 792 13.20<br />

10 880 14.67<br />

11 968 16.13<br />

12 1,056 17.60<br />

13 1,144 19.07<br />

14 1,232 20.53<br />

15 1,320 22.00<br />

16 1,408 23.47<br />

17 1,496 24.93<br />

18 1,584 26.40<br />

19 1,672 27.87<br />

20 1,760 29.33<br />

21 1,848 30.80<br />

22 1,936 32.27<br />

23 2,024 33.73<br />

24 2,112 35.20<br />

25 2,200 36.67<br />

33 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

Grade in degrees and percent<br />

Degree Percent (Tan) Degree Percent (Tan)<br />

1 1.80 23 42.40<br />

2 3.50 24 44.50<br />

3 5.20 25 46.60<br />

4 7.00 26 48.80<br />

5 8.80 27 51.00<br />

6 10.50 28 53.20<br />

7 12.30 29 55.40<br />

8 14.00 30 57.70<br />

9 15.80 31 60.00<br />

10 17.60 32 62.50<br />

11 19.40 33 64.90<br />

12 21.30 34 67.40<br />

13 23.10 35 70.00<br />

14 24.90 36 72.70<br />

15 26.80 37 75.40<br />

16 28.70 38 78.10<br />

17 30.60 39 81.00<br />

18 32.50 40 83.90<br />

19 34.40 41 86.90<br />

20 36.40 42 90.00<br />

21 38.40 43 93.30<br />

22 40.40 44 96.60<br />

34 <strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

Application Analyzer<br />

Contents:<br />

Part 1<br />

1. Maximum weight lifted<br />

2. Height load is lifted<br />

3. Pallet Dimensions<br />

4. Product data<br />

5. Towing considerations<br />

6. Forks<br />

7. Attachments<br />

8. Ventilation conditions<br />

9. Floor and surface conditions<br />

10. Future Changes<br />

11. Boxcar loading/unloading<br />

12. Truck loading/unloading<br />

13. Overhead obstruction<br />

14. Future changes<br />

15. Dock plate data<br />

16. Ramp data<br />

17. Future changes<br />

18. Other pertinent facts<br />

Part 2<br />

‣ Bulk storage calculations<br />

‣ Bulk storage aisle illustration<br />

‣ Right angle stack calculations (normal load)<br />

‣ Right angle illustration (normal load)<br />

‣ Right angle stack calculations (wide load)<br />

‣ Right angle illustration (wide load)<br />

‣ Intersecting aisle width calculations<br />

‣ Intersecting aisle illustration<br />

‣ Survey sheet<br />

35<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

Part 1<br />

1. Maximum weight lifted kg<br />

lbs<br />

2. Height load is lifted<br />

2a. Height to which maximum weight is lifted:*<br />

Lift height<br />

Fork deflection<br />

Tire wear and<br />

crush<br />

lift-off<br />

clearance<br />

Pallet thickness where<br />

applicable<br />

(see items 3d, pg 24)<br />

Minimum required<br />

MFH<br />

mm + 25mm + 25 mm + 50 mm + mm = mm<br />

in + 1” + 1” + 2” + in = in<br />

Suggest customer stock his heaviest load at the lowest elevation and his lightest loads at the highest elevation. If<br />

customer agrees to this procedure, record in this section.<br />

2b. Weight to be lifted to maximum height* kg<br />

2c. Maximum height ever required (2b):<br />

lbs<br />

Lift height<br />

Fork deflection<br />

Tire wear and<br />

crush<br />

lift-off<br />

clearance<br />

Pallet thickness where<br />

applicable<br />

(see items 3d, pg 24)<br />

Minimum required<br />

MFH<br />

mm + 25mm + 25 mm + 50 mm + mm = mm<br />

in + 1” + 1” + 2” + in = in<br />

2d.<br />

Alternate Ratings: There may be some loads (not necessarily the maximum or minimum weight) to be lifted (not<br />

necessarily to the maximum or minimum height) which will be needed to calculate the correct truck for your<br />

customer.<br />

Weight kg Height mm<br />

lbs<br />

in<br />

36<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

* Note: Be sure to include pallet weight when figuring maximum weight.<br />

3. Pallet Dimension<br />

3a. Stringer length(Dimension A) mm<br />

in<br />

3b. Width (Dimension B) mm<br />

in<br />

3c. Height (Dimension C) mm<br />

in<br />

3d. Thickness (detail D) mm<br />

in<br />

3e. Weight kg<br />

lbs<br />

Sketch of typical tub container<br />

Note: If pallets are not going to be used. Determine needs and enter information here. Or make sketch in this<br />

Space. Be certain to identify dimension “A” with respect to the direction the lift truck will approach the load as<br />

shown in the sketch above.<br />

37<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

4. Product Data<br />

4a. Type of Product(s)<br />

4b. Load length from vertical face of forks( see detail “A”) mm<br />

(measured in direction of stringer)<br />

in<br />

mm<br />

4c. Load width (see detail “B”) in<br />

4d. Load height (see detail “C”) * mm<br />

in<br />

in<br />

Note:<br />

* Be sure to ask if loads will be double stacked. Yes No<br />

* If single or combined loads exceed 600mm/24” vertical load center, refer to your spec sheets, or contact the<br />

factory for proper derating specifications.<br />

* The diameter of the Ram must be smaller than the inner diameter of the rug<br />

* Load backrest extension height must be equal to or greater than 50% of the top layer of the load.<br />

38<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

4e. Load Center (LC) for symmetrical loads ( see Note below)<br />

Load center is equal to ½ of dimension “A” from step 4b<br />

Load Center<br />

_____________ mm<br />

______________in<br />

4f. Load Center (LC) for Non-Symmetrical loads *<br />

For Non-Symmetrical loads: To find the LC set load on round pipe until load is balanced. Always measure Load<br />

Center from face of forks. Once LC has been identified by this technique, enter data in appropriate place (4f).<br />

Always recommend lifting a load up from the heaviest side and from the shortest LC distance.<br />

Load Center<br />

_____________ mm<br />

______________in<br />

* Note: If horizontal load center exceeds 600 mm or 24”, consult spec sheets or contact the factory for proper derate<br />

information and capacity cutoff.<br />

39<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

5. Towing consideration (if applicable)<br />

Total weight<br />

Maximum weight towed…. = kg<br />

load weight + trailer weight<br />

= lbs<br />

* Note: The major problem in using a lift truck to tow a load is in stopping the total weight. For accurate selection of a<br />

truck that may be used to tow loads, you must contact the factory.<br />

6. Forks<br />

6a. Length* mm in<br />

Thickness mm in<br />

Width mm in<br />

Detail:<br />

Note: Forks should not extend beyond pallet or product load. Minimum fork length should engage at least ¾ of<br />

the load or product damage or spearing can occur.<br />

40<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

7. Attachments<br />

7a. Type of attachments used*<br />

Side Shifter<br />

Carton Clamp<br />

Appliance clamp<br />

Paper roll clamp<br />

Rotator<br />

7b. Identification<br />

Attachment manufacturer and type<br />

Model<br />

Serial Numbers<br />

Attachment capacity rating<br />

Weight of attachment<br />

Lost load center (see attachment specifications)<br />

Horizontal center of gravity (see attachment specifications)<br />

Pul-Pac<br />

Rug ram<br />

Fork positioner<br />

Lateral clamp<br />

Other<br />

Specify<br />

ARM/PAD- Description<br />

ARM/PAD- Size<br />

7c. Customer satisfaction<br />

Is current attachment satisfactory:<br />

Yes<br />

No (describe problems, leaks, hoses, etc.)<br />

Notes: All attachments will reduce the trucks capacity. Some attachments will reduce effective height.<br />

41<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

8. Ventilation conditions<br />

Consider both summer and winter conditions. Use worst case. Draw line from the point on the scale that best<br />

describes customer’s ventilation conditions. All power systems intersected by the line in clear area may be<br />

used, subject to OSHA requirements which are the responsibility of the user. Those power systems<br />

intersected by the line in shaded area can also be considered<br />

All or almost all of<br />

duty cycle outdoors<br />

Some indoor use<br />

under very good<br />

ventilation<br />

Majority of duty<br />

cycle indoors with<br />

good-very good<br />

ventilation<br />

Majority of duty<br />

cycle indoors with<br />

Fair ventilation<br />

Almost all of duty<br />

cycle indoors with<br />

fair ventilation<br />

Used in enclosed<br />

area or in<br />

restricted<br />

ventilation<br />

Diesel<br />

Gasoline<br />

Gasoline with catalytic converter<br />

Liquid petroleum gas (LPG)<br />

LPG with catalytic converter<br />

Electric<br />

9. Floor and surface conditions<br />

Consider both summer and winter conditions in evaluating surfaces:<br />

9a. Tire type<br />

Line up on appropriate horizontal and vertical scales. (Area containing intersection of points indicates<br />

appropriate choice.) If line fall into grey areas, consider most appropriate tire for application conditions.<br />

Note: Brushed concrete. Asphalt, etc. are considered good friction surface. Polished concrete, metal plate, etc. are<br />

considered poor friction surfaces.<br />

9a. Tire experience<br />

Satisfied Frequent flat poor traction experience<br />

Details:<br />

tire chunking excessive wear unsatisfactory battery life- electric truck only<br />

Caution: Where customer anticipates using lift truck in areas where the wheel load limits, steer and drive/loaded<br />

and unloaded, exceeds his floor loading limits, record his limits and advise customer.<br />

42<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

10. Future changes<br />

Possible or anticipated customer changes in future to items 1-9<br />

none<br />

Maximum load<br />

Product dimension<br />

Duty cycle indicate(n umber of work shift per day)<br />

Maximum height Building changes (items 8 & 9)<br />

Describe dates and nature of anticipate d changes:<br />

43<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

11. Boxcar loading or unloading (if not applicable, go to item 12)<br />

11a. Minimum width________________ of loading doors.<br />

11b. Clearance between height of door and top of dockplate (always check down height of upright in travel<br />

position to insure clearance.)<br />

Height<br />

= ____________ mm<br />

=_____________in<br />

11c. If the product will double stacked in the boxcar, complete the following:<br />

If product is double<br />

stacked. Enter<br />

height of surface on<br />

which highest load<br />

rests<br />

Fork deflection<br />

Tire wear and<br />

crush<br />

lift-off<br />

clearance<br />

Pallet thickness where<br />

applicable<br />

(see items 3d, pg 24)<br />

+ 25mm + 25 mm + 50 mm + mm = mm<br />

+ 1” + 1” + 2” + in = in<br />

= ____________ mm<br />

Clearance<br />

=_____________in<br />

Note: * Once you determine double stack clearance data, make sure upright and load backrest extension<br />

selection does not make contact with boxcar roof or door in loading and unloading situation.<br />

*Check overhead guard height.<br />

11d. Describe surface of dockplate:<br />

44<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

12. Truck loading or unloading (if not applicable, go to item 13)<br />

12a. Trailer inside width _____________________.<br />

12b. Clearance between height of door and top of dockplate (only if dockplate is inside of entryway).<br />

= ____________ mm<br />

=_____________in<br />

12c. If the product will double stacked in the trailer, complete the following:<br />

If product is double<br />

stacked. Enter<br />

height of surface on<br />

which highest load<br />

rests<br />

Fork deflection<br />

Tire wear and<br />

crush<br />

lift-off<br />

clearance<br />

Pallet thickness where<br />

applicable<br />

(see items 3d, pg 24)<br />

mm + 25mm + 25 mm + 50 mm + mm = mm<br />

in + 1” + 1” + 2” + in = in<br />

= ____________ mm<br />

=_____________in<br />

Notes: *Make sure you are considering the smallest trailer in which loading occurs. Once you determine double<br />

stack clearance data, make sure upright and load backrest extension selection does not make contact<br />

with trailer roof or door in loading and unloading situations.<br />

*Always check trailer floor loading.<br />

*Check overhead guard<br />

12d. Describe surface of dockplate:<br />

45<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

13. Overhead Obstructions<br />

Maximum overall<br />

height lowered<br />

13a. Height of lowest mezzanine, conveyor, overhead pipe, sprinkler, doorway, etc.<br />

mm<br />

in truck travel path.<br />

in<br />

13b. Height of lowest obstruction between girders or support beams in product lifting and storage area.<br />

Clearance height<br />

Maximum overall<br />

height raised<br />

mm<br />

minus<br />

150mm/6” mm<br />

in<br />

Clearance<br />

in<br />

14. Future changes<br />

None<br />

Date and nature of anticipated changes<br />

46<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

15. Dock plate data (if not applicable, go to item 16)<br />

15a. Describe surface dockplate:<br />

15b. Length mm<br />

in<br />

Height<br />

mm<br />

in<br />

15c. Percent of incline (see sketch) (H x 100)=<br />

L<br />

% of incline<br />

15d. Warped dockplate*<br />

yes - no<br />

*Note: Check for the steepest section of a warped dockplate. This situation could affect the percent of incline. Use a<br />

level type protractor to determine the angle of the warped dockplate (degrees x 2.22 =% incline slope) or consult with<br />

factory representative for details on how to compute for warped dockplate. You should consider recommending a new<br />

dockplate.<br />

47<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

16. Ramp data (if not applicable, go to item 17)<br />

Note: Describe steepest grade only.<br />

16a. Length mm<br />

in<br />

Height<br />

mm<br />

in<br />

16b. Percent of incline<br />

(H x 100)=<br />

L<br />

% of incline<br />

16c. Surface type (see item 9, page 8)<br />

Detail:<br />

17. Future changes<br />

Customer comments or anticipated changes to items 15-16.<br />

none<br />

date and nature of anticipated changes<br />

18. Other pertinent facts Yes No<br />

18a. Truck used at night, outdoors or with poor lighting<br />

18b. Truck may need to back up in areas where other personnel might be present<br />

18c. Trucks used outdoors in all weather conditions<br />

18d. Corrosive chemicals and flammable substance are present in working area<br />

48<br />

<strong>Tailift</strong> <strong>Sales</strong> <strong>Manual</strong> 2005

Determine insurance classification *<br />

UL Classification (check one)<br />

Type G Type LPS Type EE<br />

Type GS Type E Type D<br />

Type LP Type ES Type DS<br />

*Note: UL classification are determined by either insurance carrier, OSHA, or by the local fire marshall.<br />

18e.<br />

Abnormal operating conditions: (ditches, chunked out floors, railroad tracks, high<br />

heat operations, extreme dirt, magnetic fields, etc.)<br />

Yes<br />

No<br />

Explain:<br />

18f. Abnormal operating environment (pulp, chemicals, sawdust, fiber, etc.)<br />

Explain:<br />

Yes<br />

No<br />

Signature<br />

Representative<br />

Date<br />

49<br />