SCHNEEBERGER - CORVUS BBA 3000 6-Axis 3m tool - Asset-Trade

SCHNEEBERGER - CORVUS BBA 3000 6-Axis 3m tool - Asset-Trade

SCHNEEBERGER - CORVUS BBA 3000 6-Axis 3m tool - Asset-Trade

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Flexibility and Precision<br />

For broach grinding<br />

Programming technology<br />

QUINTO<br />

The <strong>SCHNEEBERGER</strong> grinding software<br />

With its sophisticated and streamlined design, <strong>CORVUS</strong> <strong>BBA</strong> has<br />

become the leading grinding machine for broaching <strong>tool</strong>s<br />

of all configurations. It is the result of many years of collaboration<br />

between renowned broach manufacturer K. HOFFMANN GmbH<br />

(Pforzheim Germany) and J. <strong>SCHNEEBERGER</strong> Maschinen AG.<br />

For flat, cylindrical or helical <strong>tool</strong>s, the machine kinematics and<br />

powerful software provides the end-user a highly efficient system<br />

for mastering a full range of grinding requirements.<br />

<strong>CORVUS</strong> <strong>BBA</strong> is available in three X-axis travel lengths:<br />

1100 mm (43.30”), 1700 mm (66.50”) und <strong>3000</strong> mm (118”).<br />

– diversified application range<br />

– continuous precision<br />

– rapid stock removal rate<br />

– speed and rigidity<br />

– long service life<br />

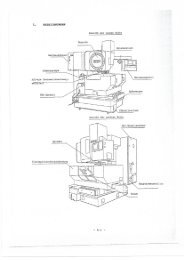

Optimum kinematics and superior machine<br />

construction are the fundamentals of enduringly<br />

accurate grinding results within the tightest tolerances.<br />

When it’s a question of high stock removal rates, the<br />

machine is uniquely suited to face the challenge with its<br />

water-cooled 9 kW (13 HP), direct-drive spindle motor.<br />

Our many years of experience in <strong>tool</strong> grinding provided<br />

the core values for the creation of QUINTO – a name<br />

widely recognized in the <strong>tool</strong> grinding industry for its easy<br />

to understand, user-friendly interface. One remarkable<br />

feature of QUINTO is its windows menu, guiding the user<br />

through the programming of the most complex <strong>tool</strong>s.<br />

New applications are easily integrated into the program.<br />

For grinding broaches, the geometry data is either readily<br />

available in the program library, or is quickly and accurately<br />

determined by the measuring probe, guaranteeing<br />

the ability to grind within minutes.<br />

© Copyright by <strong>SCHNEEBERGER</strong> Switzerland<br />

<strong>SCHNEEBERGER</strong>’s vast range of<br />

applications, such as milling cutters,<br />

high performance drills, reamers etc.,<br />

is also readily available on Corvus <strong>BBA</strong>.<br />

Options and accessories<br />

Flexible Fixturing<br />

Electronically controlled magnetic chucks<br />

are supplied in various sizes for clamping flat<br />

workpieces, and for cylindrical parts, there<br />

are dividing head, tailstock and steady rests<br />

available with a center height of 210 mm<br />

(8.26”).<br />

Smart grinding head<br />

With the programmable B and C axes, <strong>CORVUS</strong> <strong>BBA</strong> can<br />

meet the challenges of the most complex geometries – with the<br />

accuracy one has grown to expect from <strong>SCHNEEBERGER</strong>.<br />

In-process diamond roll truing.<br />

The functions of this option are<br />

controlled by the QUINTO<br />

grinding program and are fully<br />

integrated in the grinding<br />

process.<br />

All peripheral devices – from coolant filter systems<br />

to grinding wheels – are available through the<br />

<strong>SCHNEEBERGER</strong> Modular System.