MANmagazine Turbo 1/2015

With the MANmagazine by MAN Diesel & Turbo, we invite you to explore our universe of versatile technology. Join us on a world tour to Ecuador, Saudi Arabia, China and Switzerland to discover the fascinating and awe-inspiring details of cutting-edge power, marine and turbo applications.

With the MANmagazine by MAN Diesel & Turbo, we invite you to explore our universe of versatile technology. Join us on a world tour to Ecuador, Saudi Arabia, China and Switzerland to discover the fascinating and awe-inspiring details of cutting-edge power, marine and turbo applications.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

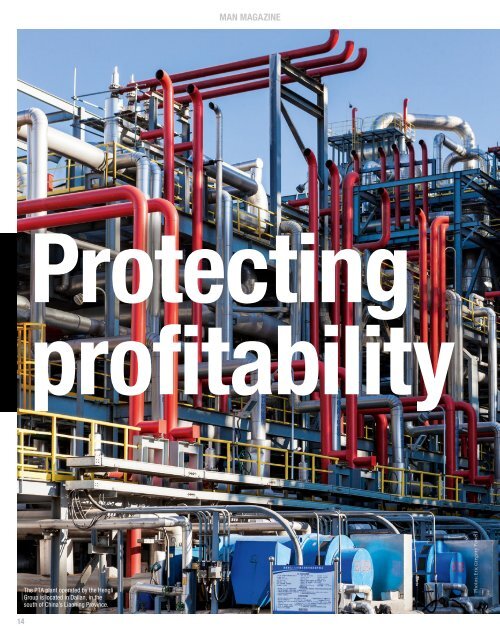

man magazine<br />

1/<strong>2015</strong><br />

Teamwork and trust is essential<br />

for a project of this magnitude.<br />

The rising cost of raw materials<br />

exerts pressure on<br />

manufacturing margins. By<br />

increasing production efficiency,<br />

MAN Diesel & <strong>Turbo</strong><br />

production trains facilitate<br />

even expanding competitiveness<br />

for a leading PTA<br />

manufacturer in China.<br />

Protecting<br />

profitability<br />

The PTA plant operated by the Hengli<br />

Group is located in Dalian, in the<br />

south of China’s Liaoning Province.<br />

Foto: Photos: Eric Gregory Powell<br />

“With this<br />

partner, we<br />

have entered<br />

the league of<br />

mega PTA<br />

plants.”<br />

Dr. Lothar Wallscheid, VP Basic Industry<br />

segment, MAN Diesel & <strong>Turbo</strong><br />

This radial gear stage compressor<br />

RG160 reflects the rapid turbine<br />

development of recent years.<br />

B<br />

ased in Dalian, China, the Hengli<br />

Group is one of the world’s major<br />

manufacturers of terephthalic<br />

acid (PTA), one of the key chemicals used in<br />

making plastics and textiles. Recently, the rising<br />

costs of raw materials have squeezed margins<br />

to the point that some of the company’s<br />

competitors have struggled to stay profitable.<br />

The Hengli Group, however, has managed to<br />

buck that trend. One of the key reasons for this<br />

business resilience is its decision to use MAN<br />

Diesel & <strong>Turbo</strong> production trains to upgrade<br />

the efficiency of its manufacturing facilities in<br />

Dalian. “With the Hengli Group as one of our<br />

major partners, we’ve entered the league of<br />

mega PTA plants,” says Dr. Lothar Wallscheid,<br />

VP Basic Industry segment at MAN Diesel &<br />

<strong>Turbo</strong>. “For the Dalian facility, we initially developed<br />

four machinery trains that became<br />

operational in 2013. As requirements grew,<br />

Hengli ordered another two identical trains –<br />

so far the world’s largest of their kind.”<br />

“Our trains are the beating heart of PTA<br />

production for Hengli,” adds Marc Groß from<br />

MAN Diesel & <strong>Turbo</strong>’s onsite team. “The train<br />

consists of a compressor that powers the production<br />

reactor, an axial expander used to recover<br />

energy from the production process, as<br />

well as a steam turbine and engine generator<br />

to produce electricity powering the plant.”<br />

Hengli’s PTA production facilities are of<br />

particular strategic importance to the company,<br />

because around 50% of the manufactured<br />

14 15