Colibri Compact drives Intelligent positioning systems - GUNDA ...

Colibri Compact drives Intelligent positioning systems - GUNDA ...

Colibri Compact drives Intelligent positioning systems - GUNDA ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Intelligent</strong> <strong>positioning</strong> <strong>systems</strong><br />

<strong>Colibri</strong><br />

<strong>Compact</strong> <strong>drives</strong><br />

precise – flexible – efficient

<strong>Compact</strong> format – innovative solutions – future-proof technology<br />

These have been the driving factors for <strong>GUNDA</strong> Electronic GmbH since its<br />

foundation in 1995 – the year in which the company brought the first compact<br />

drive to the global market. Since then <strong>GUNDA</strong> Electronic has been working<br />

in the field of automation solutions with stepper motor technology to develop<br />

compact components with simple operation, which facilitate economical<br />

and energy-efficient solutions for diverse and individual applications.<br />

All products are developed at <strong>GUNDA</strong> Electronic by a qualified and experienced<br />

team and are produced in Germany in accordance with high quality benchmarks.<br />

Economical alternative to solutions with air<br />

<strong>GUNDA</strong> drive <strong>systems</strong> are the alternative to pneumatic axes.<br />

The advantages: Better drive behaviour, more precise <strong>positioning</strong>, greater<br />

flexibility, easy and individual configuration, lower operating costs.<br />

Our products<br />

<strong>Colibri</strong>: The compact drive<br />

Faster, more precise change of position with optimised energy consumption<br />

The <strong>Colibri</strong> drive constitutes the basis of our products - controller and motor in a compact<br />

unit: Position control with program memory, power output stage, diverse inputs and outputs,<br />

various bus connections and an integrated encoder.<br />

<strong>Colibri</strong>-C: The controllers<br />

The heart of the system by itself<br />

For use in a switch cabinet or directly adjacent to the motor with varying scopes of functionality,<br />

from simple basic control right through to bus variants.<br />

<strong>Colibri</strong>-L: The electrical linear units<br />

The <strong>Colibri</strong> drive paired with linear movement<br />

The linear units are available as electrical spindle axes, toothed belt axes, lifting cylinders,<br />

lifting cylinders with guide unit or as short lifting units, each complete with attached motor<br />

and controller.<br />

<strong>Colibri</strong>-G: The gripper<br />

Small, intelligent and all the requisite functions aboard<br />

The electrical gripper with extremely simple operation and infinitely adjustable gripping<br />

force.<br />

We keep a comprehensive range of accessories in stock for project planning, assembly and commissioning.

<strong>Colibri</strong> – the optimum solution for decentralised drive tasks<br />

compact and safe<br />

Low installation volumes and minimal wiring requirements enable installation<br />

even where spatial conditions are tight; the robust EMC-protected housing<br />

is fully potted and ensures safe operation even under harsh ambient conditions.<br />

• precise<br />

• flexible<br />

• efficient<br />

quiet and low-resonance<br />

The dynamic switching of the step resolution ensures quiet, low-resonance<br />

running, particularly at low speeds.<br />

reliable and precise<br />

The compact format of <strong>Colibri</strong> <strong>drives</strong> guarantees low-maintenance operation<br />

over a lengthy service life; the perfect interplay between electronics<br />

and mechanics as well as the integrated position monitoring ensure precise<br />

<strong>positioning</strong> and controlled operation of the stepper motor.<br />

simple and economical<br />

Straightforward commissioning ensures an effective and economical drive<br />

solution.<br />

The <strong>Colibri</strong> compact devices<br />

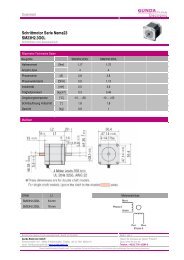

<strong>Colibri</strong> 34<br />

· Stepper motor size NEMA34<br />

· Suitable for use up to a torque of 9 Nm<br />

· Max. phase current adjustable up to 10 A<br />

· Available with different control options<br />

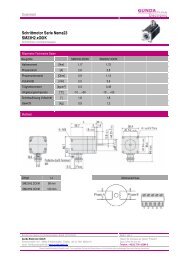

<strong>Colibri</strong> 23<br />

· Stepper motor size NEMA23<br />

· Suitable for use up to a torque of 2 Nm<br />

· Max. phase current adjustable up to 3 A<br />

· Available with different control options<br />

<strong>Colibri</strong> Basic: The basic variants<br />

The equally high-performance basic variants<br />

<strong>Colibri</strong> 34 Basic, <strong>Colibri</strong> 23 Basic Mini and<br />

<strong>Colibri</strong> 17 Basic Mini are actuated via digital<br />

I/O or clock/direction signals.<br />

<strong>Colibri</strong> 17<br />

· Stepper motor size NEMA17<br />

· Suitable for use up to a torque of 0.5 Nm<br />

· Max. phase current adjustable up to 3 A<br />

· Available with different control options

Low volume – high performance<br />

Powerful<br />

stepper motor<br />

Encoder<br />

Encoder<br />

electronics<br />

Power unit<br />

Microprocessor<br />

controller<br />

Program memory<br />

I/O interface<br />

Bus connections<br />

Motor output<br />

stage<br />

1 2 3 4 5 6 7 8 9 10<br />

Perfect <strong>positioning</strong><br />

• quiet, low-resonance running<br />

• operation constantly controlled<br />

• autonomous system monitoring<br />

• voltage monitoring of the output stage<br />

• without step loss<br />

Top quality<br />

precise<br />

• all devices are individually tested<br />

• automated full testing<br />

prior to delivery<br />

• manufactured in Germany<br />

flexible<br />

Simple integration<br />

• different control options<br />

• bus connections<br />

> Profibus DP<br />

> CANopen<br />

> RS485<br />

• various performance classes<br />

• variable hardware configuration<br />

Suitability for diverse applications<br />

• high protection class up to IP67<br />

• up to 50°C ambient temperature<br />

without external ventilation<br />

• reliable operation in all fitting positions<br />

• suitable for robust use<br />

Economical use<br />

efficient<br />

• fully integrated controller<br />

• download functions<br />

• low-maintenance operation<br />

• highly efficient<br />

• low costs in both operation<br />

and procurement<br />

Ease of use<br />

• simple installation<br />

• straightforward commissioning<br />

• safe integration into existing<br />

<strong>systems</strong><br />

• comprehensive range of accessories

The control options<br />

• Clock & direction<br />

Superordinate<br />

position control<br />

• Clock/direction input optionally for 24 V or RS422 signals<br />

• Adjustable up to 1/8 step<br />

• Up to max. 30 kHz with an impulse ratio of 50%<br />

• Controllable via digital/<br />

analogue inputs<br />

PLC or<br />

switches, sensors<br />

Start/stop 24 V digital input<br />

Select position 24 V digital inputs<br />

Analog speed and position specification<br />

• Positions are stored internally and recalled via I/O inputs<br />

from the PLC<br />

• Via an analogue input it is possible to stipulate the speed or position<br />

• Various operating modes can be set<br />

(e.g. print mark control, set selection, set sequence)<br />

• actuation via field bus<br />

PLC or PC<br />

RS485, CANopen or Profibus<br />

Our software is available<br />

free of charge for<br />

the straightforward<br />

configuration of all<br />

components via PC.<br />

• RS485 via open protocol<br />

• CANopen DSP402<br />

• Profibus DP

Sophisticated precision – the <strong>Colibri</strong> drive<br />

Our "intelligent axes" – the <strong>Colibri</strong> <strong>drives</strong> – are used for a wide range of applications, where cost or space savings<br />

demand decentralised drive solutions. A dynamic switching of the step solution ensures quiet and low-resonance running<br />

behaviour.<br />

The compact devices comprise a stepper motor and an electronic unit – compact within a single housing.<br />

The controller is fully potted and therefore offers:<br />

A high protection class, IP67 (without motor), optimum temperature control and comprehensive safeguarding<br />

against vibrations<br />

<strong>Colibri</strong> <strong>Compact</strong><br />

for Profibus DP, CANopen, RS485 or digital I/0<br />

Basic version<br />

for digital I/O, clock / direction signal<br />

<strong>Colibri</strong> 34 <strong>Colibri</strong> 23 <strong>Colibri</strong> 17 <strong>Colibri</strong> 34 Basic <strong>Colibri</strong> 23 Basic <strong>Colibri</strong> 17 Basic<br />

Max. torque 9Nm 2 Nm 0.5 Nm 9Nm 2 Nm 0.5 Nm<br />

Motor voltage +24V to +60V DC +24V to +48V DC +24V to +60V DC +24V to +48V DC<br />

Max. phase current adjustable up to 10A adjustable up to 3A adjustable up to 10A adjustable up to 3A<br />

Temperature range<br />

0 to +50°C without external ventilation<br />

Control voltage<br />

+24V to +36V DC<br />

Current reduction<br />

adjustable<br />

Inputs +24V DC, 2 mA +24V DC, 10 mA<br />

Outputs +24V DC, 150 mA +24V DC, 10 mA<br />

Step resolution 1/8, 1/4, 1/2, 1/1<br />

Options<br />

(on request)<br />

Multi turn encoder (absolute), single turn encoder, motor with IP65, brake, gearing or a combination of these options.<br />

Customer-specific<br />

applications:<br />

These are easily realised due to the operating system's integrated "download function".<br />

Dimensions:<br />

The dimensions of the compact devices are dependent on the motors used (refer to datasheets).<br />

Operating modes<br />

Variants<br />

Operating mode<br />

Set selection: Sets stored in the controller (max. 31) can be preselected and started via 5 binary encoded inputs in any order.<br />

Set sequence: A program sequence stored in the controller is processed on a set-by-set basis with the input "Start".<br />

Digital I/O<br />

Print mark control: In drive mode the <strong>positioning</strong> is determined by means of a print mark. The drive runs until the "Print<br />

mark" input comes and then ramps down.<br />

Flank selection: A modification for the versions set selection and set sequence is possible in that the <strong>positioning</strong> can<br />

be triggered with either the positive or the negative starting flank.<br />

Clock/direction<br />

Profibus DP<br />

CANopen<br />

RS485<br />

The compact unit is able to process clock and direction signals directly from a superordinate control. The following<br />

operating modes can be set: Full step operation, half step operation, quarter step operation, eighth step operation.<br />

Interface operation<br />

Interface operation<br />

Interface operation<br />

Analog speed<br />

Analog position<br />

The speed can be stipulated by means of an external analog signal.<br />

The position can be stipulated by means of an external analog signal.<br />

Only with the basic versions<br />

For detailed information please refer to our datasheets or go to www.gunda-gmbh.de.

<strong>Intelligent</strong> <strong>positioning</strong> <strong>systems</strong><br />

Accessories for the <strong>Colibri</strong> drive<br />

for maximum precision<br />

For project planning, assembly and commissioning<br />

Our accessories are precisely tailored to our products and simplify<br />

the programming, installation and commissioning of our <strong>drives</strong>.<br />

Designation<br />

Description<br />

Connection cable suitable for drag chain use Delivery lengths of up to 20m<br />

from 24 V to 60 V,<br />

Power unit<br />

with transformer, 3-phase<br />

2.5 A to 18 A<br />

Profibus<br />

Interface converter<br />

incl. Windows software for configuration<br />

CANopen<br />

TTL / RS485<br />

Hand-held control unit with teach-in-function for RS485/ASCII and TTL protocol CRC300, CRC50<br />

Planetary gearing<br />

PD040 for NEMA 17/ 23<br />

1- 3 stage<br />

Gearing<br />

PD065 for NEMA 23/ 34<br />

3 : 1 to 1000 : 1<br />

PD085 for NEMA 34<br />

For further information and technical datasheets please go to www.gunda-gmbh.de/downloads

www.petakon.de<br />

Siemensstraße 16/1<br />

88048 Friedrichshafen<br />

Germany<br />

Telephone: +49 (0) 7541 952840<br />

Fax: +49 (0) 7541 9528419<br />

Email: info@gunda-gmbh.de<br />

Internet: www.gunda-gmbh.de<br />

Explore our full product range at:<br />

www.gunda-gmbh.de<br />

Please call us with any questions on: +49 (0) 7541 952840<br />

Or contact our competent specialist dealer.<br />

Your specialist dealer: