ProLINFlasher - ProMik

ProLINFlasher - ProMik

ProLINFlasher - ProMik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Quality High speed programming Support www.promik.com<br />

2

WELCOME to the PRESENTATION of <strong>ProMik</strong><br />

The company <strong>ProMik</strong> was founded in 1995 and looks back on a long<br />

partnership with Freescale.<br />

<strong>ProMik</strong> has been on the forefront in developing efficient and reliable<br />

programming systems mainly for Freescale Microcontrollers.<br />

To the business fields of <strong>ProMik</strong> belongs:<br />

• developing and selling programming tools for a broad range of applications<br />

focused on the automotive industry<br />

• consultancy programming services and logistics<br />

• Engineering of professional high speed systems as well as automatic<br />

In-Line Programming stations<br />

Quality High speed programming Support www.promik.com<br />

24

DIFFERENT METHODS OF FLASH<br />

PROGRAMMING<br />

• OFF-LINE PROGRAMMING SERVICE<br />

• IN-LINE PROGRAMMING<br />

• FIELD (RE)PROGRAMMING<br />

Quality High speed programming Support www.promik.com<br />

2

OFF-LINE PROGRAMMING SERVICE<br />

• AUTOMATIC DEVICE HANDLING PA2012<br />

• CONTROLLED DEVICE POSITIONING<br />

• 2D/3D LEAD INSPECTION<br />

• PARALLEL PROGRAMMING<br />

• TAPE&REEL WITH LEAD INSPECTION<br />

• CUSTOMER SPECIFIC REQUIREMENTS<br />

e. g. SERIAL NUMBER, DEVICE TEST, etc.<br />

• LOG FILES FOR TRACEABILITY<br />

• LASERMARKING<br />

Quality High speed programming Support www.promik.com<br />

2

QUALITY ASPECTS<br />

• FREESCALE´S PROGRAMMING<br />

RECOMMENDATION<br />

• MARGIN VERIFY<br />

• TRACEABILITY / CHECKSUM<br />

• SELF ASSESSMENT OF PROGRAMMING<br />

ALGORITHMS<br />

• CERTIFICATION ISO/TS16949<br />

Quality High speed programming Support www.promik.com<br />

2

DIFFERENT METHODS OF FLASH<br />

PROGRAMMING<br />

• OFF-LINE PROGRAMMING SERVICE<br />

• IN-LINE PROGRAMMING<br />

• FIELD (RE)PROGRAMMING<br />

Quality High speed programming Support www.promik.com<br />

2

IN-LINE PROGRAMMING<br />

• SOFTWARE TOOLS<br />

WinStar<br />

MSP68Multi<br />

P-Online Win32<br />

P-Online Win-DLL<br />

• AUTOMATIC SYSTEMS and SEMI-AUTOMATIC SYSTEMS<br />

• MANUAL SYSTEM<br />

• INFLUENCE of APPLICATION<br />

e.g. WATCHDOG, POWER SUPPLY, OSCILLATOR, NOISE, etc.<br />

• INTEGRATION SUPPORT<br />

• QUALITY<br />

Quality High speed programming Support www.promik.com<br />

2

DIFFERENT METHODS OF FLASH<br />

PROGRAMMING<br />

• OFF-LINE PROGRAMMING SERVICE<br />

• IN-LINE PROGRAMMING<br />

• FIELD (RE)PROGRAMMING<br />

Quality High speed programming Support www.promik.com<br />

2

FIELD (RE)PROGRAMMING<br />

•CAN NETWORK<br />

•FLEX-RAY<br />

• LIN BOOTLOADER PROGRAMMING<br />

Quality High speed programming Support www.promik.com<br />

2

PROMIK CURRENTLY DEVELOPS A NEW PROGRAMMING SYSTEM<br />

Features of the new hardware<br />

NEWS<br />

• high performance PowerPC (up to 132 MHz)<br />

• high speed communication to the target MCU<br />

• support for multiple interfaces (BDM, JTAG, SPI, SCI, I2C, CAN, LIN, ...)<br />

• increased current sourcing capabilities to power the target<br />

• Fast Ethernet interface (100 MBit/s) for communication to the Host<br />

• USB interface for alternative communication to the Host<br />

• small dimensions (programmer can be placed close to the target )<br />

Quality High speed programming Support www.promik.com<br />

24

NEW Programming Hardware<br />

Base Module of the new Programmer<br />

Quality High speed programming Support www.promik.com<br />

24

Thanks for your attention!<br />

Quality High speed programming Support www.promik.com<br />

2

Margin Read Method of 9S12 and 9S12X<br />

used by <strong>ProMik</strong><br />

A: Margin Programmed, Special Test Mode (<strong>ProMik</strong>) , 9S12 and 9S12X<br />

B: Margin Programmed, Special Mode, 9S12X only<br />

C: Margin Programmed, User Mode, 9S12X only<br />

D: Margin Erased, User Mode, 9S12X only<br />

E: Margin Erased, Special Mode, 9S12X only<br />

F: Margin Erased, Special Test Mode (<strong>ProMik</strong>), 9S12 and 9S12X<br />

A BC D E F<br />

Quality High speed programming Support www.promik.com<br />

Margin<br />

Verify<br />

Reading<br />

Bit-cell Current<br />

2

Programming Conditions<br />

Hardware Considerations<br />

- Blocking capacitors<br />

-Noise<br />

- Voltage monitoring<br />

- Inductance<br />

-Verify<br />

- Oscillator consideration<br />

- RESET Pin of MCU<br />

Environmental Conditions<br />

- General environment conditions<br />

- Temperature<br />

- Relative Humidity<br />

- Dust Content<br />

- Mechanical Vibration<br />

- Electrostatic Discharge (ESD)<br />

- Shielding<br />

Quality High speed programming Support www.promik.com<br />

2

WinStar<br />

• windows based software for a single programmer system<br />

• menu driven<br />

• suitable for development lab<br />

Quality High speed programming Support www.promik.com<br />

24

Example for MCU Options<br />

WinStar - Options<br />

Quality High speed programming Support www.promik.com<br />

24

WinStar - Signatures<br />

Example for S12X family<br />

Quality High speed programming Support www.promik.com<br />

24

• windows based software for a multi programming system<br />

• graphical user interface<br />

MSP68Multi<br />

• suitable for factory programming (parallel programming)<br />

• standard or customized versions available<br />

Quality High speed programming Support www.promik.com<br />

24

Quality High speed programming Support www.promik.com 24

P-Online Win32<br />

• a collection of Win32 executables (*.exe) to perform certain tasks<br />

• suitable to be integrated in the customer software<br />

• can simply to be run from a batch job<br />

• standard or customized versions available<br />

Quality High speed programming Support www.promik.com<br />

24

P-Online Win32<br />

Examples of functions (e.g. for MC912DG128)<br />

• INIT_BAS.EXE initialize programmer<br />

• FILL_RAM.EXE transfer data to programmer's RAM<br />

• CONNECT.EXE switch on/off connections programmer MCU<br />

• UNSECURE.EXE erase and unsecure STAR12<br />

• ERAS_EEP.EXE erase EEPROM<br />

• ERASE_FL.EXE erase Flash areas<br />

• BLNK_CHK.EXE blank check<br />

• MODI_RAM.EXE modify programmer's RAM (Serial number, ...)<br />

• PRG_AREA.EXE program data specified by address area<br />

• PRG_SHDW.EXE program SHADOW WORD (HC12)<br />

• D_VERIFY.EXE verify data (data compare)<br />

• F_VERIFY.EXE verify data (checksum)<br />

• READ_DAT.EXE read MCU area<br />

• COPY_GO.EXE transfer data to MCU's RAM and start application<br />

Examples for customized EXE files<br />

• Initilaize.exe initialization (adapted to customer requirements)<br />

• Program.exe erase, program, verify ..<br />

Quality High speed programming Support www.promik.com<br />

24

P-Online Win-DLL<br />

• multi threaded windows dll<br />

• suitable to be used as a multi programming system<br />

(parallel programming)<br />

• Microsoft and Borland C/C++ Win32 libraries available<br />

• DLL with COM-interface<br />

(as typically used in Visual Basic applications)<br />

• standard or customized versions available<br />

Quality High speed programming Support www.promik.com<br />

24

Examples of DLL-API functions for MC9S12DG128:<br />

• DWERROR BlankCheck( BYTE bProgrammerNumber );<br />

• DWERROR ConfigureDll( BYTE bSerialPorts[ 12], // 0, 1... 20<br />

void (__stdcall *pfnInformation)( DWORD dwError, LPSTR szText ),<br />

BYTE bUseCallback ); // Using Callback<br />

• DWERROR EraseFlash( BYTE bEraseArea, // Erase areas<br />

BOOL iUnsecure, // Security flag<br />

BYTE bProgrammerNumber ); // Programmer<br />

• DWERROR InitBase( BYTE bVoltage, // Module voltage<br />

BYTE bResetIdent, // Identification value<br />

DWORD dwFrequency, // Oscillator frequency<br />

BYTE bPllSynr, // Multiplier PLL frequency<br />

BYTE bPllRefdv, // Divider PLL frequency<br />

DWORD dwBaudRate, // Baud rate serial port<br />

BYTE bProgrammerNumber ); // Programmer<br />

• DWERROR LoadFile( LPSTR szFileName, // File name<br />

WORD wEepromRemap ); // Start address EEPROM data<br />

• DWERROR ProgramArea( DWORD dwStartAddress, // Start address<br />

DWORD dwEndAddress, // End address<br />

BYTE bProgrammerNumber ); // Programmer<br />

• DWERROR VerifyCheckSum( DWORD dwStartAddress, // Start address<br />

DWORD dwEndAddress, // End address<br />

LPBYTE pbBuffer, // Source memory<br />

BYTE bProgrammerNumber ); // Programmer<br />

Quality High speed programming Support www.promik.com<br />

24

PROGRAMMING VIA LIN-BUS<br />

• BUS ACCESS<br />

• BOOTLOADER CONCEPT<br />

• TOOL EXAMPLE (PROLINFLASHER)<br />

• BENEFITS OF LIN BOOTLOADER<br />

Quality High speed programming Support www.promik.com<br />

2

Indirect Bus Access (Gateway)<br />

Backbone Bus (e.g. CAN )<br />

LIN Node<br />

LIN Node<br />

Gateway (Master)<br />

LIN Bus<br />

LIN Node<br />

LIN Node<br />

Programmer or<br />

Diagonistic tool<br />

Quality High speed programming Support www.promik.com<br />

2

Direct Bus Access<br />

LIN Node<br />

LIN Node<br />

Programmer<br />

LIN Bus<br />

LIN Node<br />

LIN Node<br />

Quality High speed programming Support www.promik.com<br />

2

Bootloader Concept<br />

• Memory Allocation (e.g. HC908EY16)<br />

PROTECTED<br />

AREA<br />

0x0000<br />

0xC000<br />

USER FLASH<br />

AREA<br />

0xFCFE..0xFCFF<br />

0xFD00<br />

0xFDFF<br />

0xFF7E<br />

0xFFDC<br />

0xFFFE<br />

0xFFFF<br />

Relocatable interrupt<br />

vectors<br />

User Application<br />

Reset Boot Flag<br />

Promik Trimm-Val<br />

Bootloader<br />

(256 Bytes)<br />

FLBPR Register<br />

Interrupt<br />

Vectors<br />

Reset Vector<br />

Start of user<br />

application<br />

Start of<br />

bootloader<br />

Interrupt<br />

relocation<br />

Quality High speed programming Support www.promik.com<br />

2

Bootloader Concept<br />

• Simplified Flow Diagram<br />

BOOTLOADER<br />

Timeout<br />

RESET<br />

RESET<br />

Boot Reset<br />

Flag set?<br />

Initialise<br />

Data Frame received ?<br />

CMD received?<br />

YES<br />

Load RAM<br />

and Execute<br />

YES<br />

USER APPL<br />

Application<br />

CMD<br />

received ?<br />

YES<br />

Quality High speed programming Support www.promik.com<br />

2

Bootloader Concept (Cont.)<br />

• Entering Bootloader from User Appl.<br />

Example: (LIN Data Dump Diagnostic Frame):<br />

Msg. Header Response Field<br />

Break SYC PID NAD PCI SID D1 D2 D3 D4 D5 CHK<br />

PID = 0x3C Protected Identifier 60 (0x3C, Master Request frame)<br />

NAD = 0x80 Data[0], Node address (to be defined)<br />

PCI = 0x06 Data[1], Protocol Control Information<br />

SID = 0xB4 Data[2], Service Identifier, Data Dump<br />

D1 = 0xAA Data[3], Data<br />

D2 = 0xBB Data[4], Data<br />

D3 = 0xCC Data[5], Data<br />

D4 = 0xDD Data[6], Data<br />

D5 = 0xEE Data[7], Data<br />

Since D1 … D5 can freely be chosen according to the LIN Specification, these bytes<br />

can be used for security and authentification purposes.<br />

*If thers’s no valid user application, the Bootloader Mode is<br />

automatically entered after power-on reset.<br />

Quality High speed programming Support www.promik.com<br />

2

TOOL EXAMPLE (PROLINFLASHER)<br />

• HARDWARE SETUP<br />

AC Adapter<br />

IN OUT<br />

Volt. Control<br />

RS232<br />

Host<br />

PC <strong>ProMik</strong> Flasher<br />

DT<br />

+12V<br />

LIN-Bus<br />

GND<br />

Target ECU<br />

ON ON ON OFF<br />

1. LIN Target ECU not Self-Powered<br />

RS232<br />

OFF ON<br />

IN OUT<br />

Volt. Control<br />

Host<br />

PC <strong>ProMik</strong> Flasher<br />

DT<br />

automatic<br />

controlled<br />

automatic<br />

controlled<br />

+12V<br />

LIN-Bus<br />

GND<br />

2. <strong>ProMik</strong> Flasher not Self-Powered<br />

Target ECU<br />

Quality High speed programming Support www.promik.com<br />

2<br />

ON<br />

ON<br />

KL30<br />

KL30

TOOL EXAMPLE (Cont.)<br />

Power Supply Configuration and Serial Ports Configuring Bootloader Entry Messages<br />

Quality High speed programming Support www.promik.com<br />

2

TOOL EXAMPLE (Cont.)<br />

Quality High speed programming Support www.promik.com<br />

2

FEATURES OF PROMIK LIN BOOTLOADER<br />

SUMMARISED<br />

• fail safe, i.e. can be started even if (re-)programming is interrupted by watchdog,<br />

resets, power failure.<br />

• consumes little user flash resources ( appr. 300 bytes for HC908EY16, MM908E62x<br />

MCUs )<br />

• fast start-up time (appr. 24 CPU Bus Cycles for HC08 EY16, MM908E62x MCUs)<br />

• communication even if master and slave relative clock freq. differ by up-to ±14%<br />

• special timeout and reset features to deal with unintentional user SW run-away into<br />

bootloader<br />

• Flash driver routines not in bootloader to rule out dangers of unintentional flash<br />

programming<br />

• provision for special user application software test before final user appl. validation<br />

• security and authentification features to access the bootloader<br />

• easy to integrate into customer user application<br />

Quality High speed programming Support www.promik.com<br />

2

BENEFITS OF A LIN BOOTLOADER<br />

• End-Of-Line Programming<br />

- Logistics<br />

- time-to-market shortened<br />

• Field-Updates<br />

- Save repair costs and time<br />

Quality High speed programming Support www.promik.com<br />

2

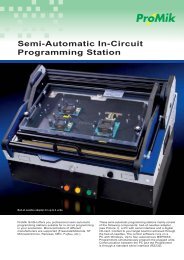

Semi-Automatic In-Circuit<br />

Programming Station<br />

Bed-of-needles adapter for up to 4 units<br />

<strong>ProMik</strong> GmbH offers you professional semi-automatic<br />

programming stations suitable for in-circuit programming<br />

in your production. Microcontrollers of different<br />

manufacturers are supported (Freescale/Motorola, ST<br />

Microelectronics, Renesas, NEC, Fujitsu, etc.).<br />

These semi-automatic programming stations mainly consist<br />

of the following components: bed-of-needles adapter<br />

(see Picture 1), a PC with serial interface and a digital<br />

I/O-card. Contact to your target board is achieved through<br />

the bed-of-needles. The control software runs on a<br />

PC with Windows. Up to four autonomous MSP68XX<br />

Programmers simultaneously program the plugged units.<br />

Communication between the PC and the Programmer<br />

is through a standard serial interface (RS232).

Semi-Automatic In-Circuit<br />

Programming Station<br />

Adapter with an additional stamping unit Interface connectors on the adapter rear side<br />

PC Control Software for a System with 3 Programmers<br />

Technical data<br />

• mechanical changeable adapter<br />

with parallel closing pressure mechanic<br />

• robust and durable mechanic,<br />

cover with damper<br />

• the housing can be opened<br />

for debugging purposes<br />

• ease of use due to the slanted housing<br />

• suitable for up to 4 MSP68XX<br />

Programmers<br />

• expandable to a tandem system<br />

(2 adapters can work in parallel<br />

controlled through only one control<br />

software, thus up to 8 programmers<br />

can do their tasks simultaneously)<br />

• handling and visualization is done<br />

through 3 push-buttons/status lamps<br />

red/yellow/green (in conjunction<br />

with the control software running<br />

on the host system<br />

e.g. green lamp = programming OK,<br />

red lamp = programming failed,<br />

green push-button = start the<br />

programming task,<br />

red push-button = confirm failed<br />

programming attempt)<br />

• cover interlock while the programming<br />

task is running, to prevent accidental<br />

opening<br />

• quick and easy changeover for different<br />

units (3 knurled screws for the<br />

bed-of-needles and 2 knurled screws<br />

for the cover with holding down<br />

elements)<br />

• interfaced through a 96-pole<br />

VG-connector, standard 192 test points,<br />

expandable for up to 384 test points<br />

• customized interface<br />

• mech. dimensions:<br />

530 x 450 x 330 mm (B x T x H)<br />

• max. usable area:<br />

350 x 230 mm (B x T)<br />

<strong>ProMik</strong> Programmiersysteme<br />

für die Mikroelektronik GmbH<br />

Südwestpark 100<br />

90449 Nürnberg, Germany<br />

Telefon +49 911-252665-0<br />

Telefax +49 911-252665-66<br />

info@promik.com<br />

www.promik.com

In-Line<br />

Programming System<br />

Automatic Loading Unit Automatic In-Line Programming Station Automatic Unloading Unit

<strong>ProMik</strong> Programmiersysteme<br />

für die Mikroelektronik GmbH<br />

Südwestpark 100<br />

90449 Nürnberg, Germany<br />

Telefon +49 911-252665-0<br />

Telefax +49 911-252665-66<br />

info@promik.com<br />

www.promik.com

Lead inspection<br />

PA2012<br />

Software<br />

Based on Windows XP workstation<br />

for programming and optical inspection<br />

• Network capability<br />

• Statistics<br />

• Log files for traceability according<br />

to ISO/TS16949<br />

• Handling system controlled by Simatic S7<br />

Hardware<br />

Industrial PC<br />

• Strong Pentium IV Processor<br />

• Flat screen 17” TFT-Monitor<br />

• Local operating buttons<br />

• Image processing system<br />

Programming system<br />

Based on Muliprogrammer MSP68XX<br />

• programming time not an issue<br />

• Programming capacity: 1200 pcs/hour<br />

• smart programming algorithem<br />

• spec. libraries for: various MCU´s<br />

(freescale, RENESAS, NEC, Microchip,<br />

ST-Micro, etc.)<br />

• production management (order document)<br />

• open top sockets for various packages:<br />

QFP, TQFP, TSSOP, SOIC, PLCC, BGA, etc.<br />

• File Format: Motorola (S-Record),<br />

Intel (HEX), ELF-format.<br />

Image processing for LEAD inspection<br />

Every machine cycle controlled by optical inspection<br />

• 2D Colinearity for LEAD inspection<br />

• 3D Coplanarity for LEAD inspection<br />

• system consists of 4 CCD-Cameras<br />

Tray stacker Taping<br />

Tray stacker<br />

Tray stacker for input and output<br />

• JEDEC Standard Trays<br />

• Stacker for up to 200 mm height<br />

• Capacity for 20 trays<br />

• Tray teaching via camera<br />

Stick feeder (Option)<br />

Stick feeder for input<br />

• Output Tape&Reel<br />

• Capacity for 15 sticks<br />

Taping<br />

The taping capability is integrated<br />

• 8 mm to 56 mm Tape Width<br />

• Heat adhesive sealing<br />

• Optical detection after part insert<br />

• Reject handling<br />

Handling System<br />

• Ultra speed multiple axis<br />

• Handles all device packages<br />

• 0 to 360 degree rotation<br />

• 3 sec handling time e.g. Tray to Tape<br />

• Vacuum pump<br />

Technical data<br />

power: 3 x 400 V / 16 A<br />

pneumatic: 6 bar<br />

air consumption: approx. 10 l/min.<br />

vacuum: - 0.9 bar<br />

weight: approx. 200 kg<br />

dimensions(HxWxD) : 1700x1500x1300 mm<br />

<strong>ProMik</strong> Programmiersysteme<br />

für die Mikroelektronik GmbH<br />

Südwestpark 100<br />

90449 Nürnberg, Germany<br />

Telefon +49 911-252665-0<br />

Telefax +49 911-252665-66<br />

info@promik.com<br />

www.promik.com

Professional Programming System PA2012<br />

- Programming time no longer an issue<br />

- Programming time reduced<br />

to the component handling time

file:///K|/FTF_Munich/Präsentation/<strong>ProMik</strong>_FTF_Presentation/Traceability/908E624_traceability_sample.txt<br />

2005.08.15 09:03:02:984: -------- Auftrag Laden: d:\Auftrag\Testkunde\ABC_954_051<br />

\ABC_954_051_15-08-05.auf<br />

2005.08.15 09:03:07:734: -------- Programmierungsmodul wird initialisiert --------<br />

2005.08.15 09:03:17:984: [ 0] Beginn 15.08.2005 09:03:07<br />

2005.08.15 09:03:17:984: [ 0] Kunde: Testkunde<br />

2005.08.15 09:03:17:984: [ 0] Auftragsnr.: 815456<br />

2005.08.15 09:03:17:984: [ 0] Aufgabe: Programmieren<br />

2005.08.15 09:03:17:984: [ 0] Sachnummer: ABC.954.051<br />

2005.08.15 09:03:18:000: [ 0] Materialcode: ABC.954.010<br />

2005.08.15 09:03:18:000: [ 0] Benutzer: wh<br />

2005.08.15 09:03:18:000: [ 0] Appl.-Version: 1.25.6.0<br />

2005.08.15 09:03:18:000: [ 0] DLL-Version: 1.10.1.0<br />

2005.08.15 09:03:18:000: [ 0] System: PA2012-01<br />

2005.08.15 09:03:18:843: [ 0] Programmer 1 SA-Nr.: 0601<br />

2005.08.15 09:03:19:953: [ 0] Programmer 2 SA-Nr.: 0602<br />

2005.08.15 09:03:21:140: [ 0] Programmer 3 SA-Nr.: 0603<br />

2005.08.15 09:03:22:250: [ 0] Programmer 4 SA-Nr.: 0604<br />

2005.08.15 09:03:23:484: [ 0] Programmer 5 SA-Nr.: 0605<br />

2005.08.15 09:03:24:625: [ 0] Programmer 6 SA-Nr.: 0606<br />

2005.08.15 09:03:25:703: [ 0] Programmer 7 SA-Nr.: 0607<br />

2005.08.15 09:03:26:906: [ 0] Programmer 8 SA-Nr.: 0608<br />

2005.08.15 09:03:28:000: [ 0] Programmer 9 SA-Nr.: 0609<br />

2005.08.15 09:03:29:125: [ 0] Programmer 10 SA-Nr.: 0610<br />

2005.08.15 09:03:30:234: [ 0] Programmer 11 SA-Nr.: 0611<br />

2005.08.15 09:03:31:328: [ 0] Programmer 12 SA-Nr.: 0612<br />

2005.08.15 09:03:31:625: [ 0] MCU-Typ: MM908E624<br />

2005.08.15 09:03:31:625: [ 0] Zugelassene Spannungswerte: 830 - 890<br />

2005.08.15 09:03:31:625: [ 0] Programmierung:<br />

2005.08.15 09:03:31:625: [ 0] Leerbereiche füllen: nein<br />

2005.08.15 09:03:31:625: [ 0] Verifizierung:<br />

2005.08.15 09:03:31:625: [ 0] Verifizierung durch Prüfsummenvergleich<br />

2005.08.15 09:03:31:625: [ 0] Verifizierungsspannung: 5,0 V<br />

2005.08.15 09:03:31:640: [ 0] Verifizierungsspannung: 5,4 V<br />

2005.08.15 09:03:31:640: [ 0] Verifizierungsspannung: 4,5 V<br />

2005.08.15 09:03:31:640: [ 0] Datei: D:\pattern\Test\ABC_954_051\v13_fill_8E.s19<br />

2005.08.15 09:03:31:640: [ 0] Prüfsumme: $08A7<br />

2005.08.15 09:03:31:640: [ 0] Security-Code: C2 78 C2 84 CF 22 C2 8A<br />

2005.08.15 09:03:31:640: [ 0] 1. Datenblock: $C000 - $FDFE<br />

2005.08.15 09:03:31:656: [ 0] 2. Datenblock: $FF7E - $FF7E<br />

2005.08.15 09:03:31:656: [ 0] 3. Datenblock: $FFDC - $FFFF<br />

2005.08.15 09:03:31:656: [ 0] <strong>ProMik</strong> 6<br />

2005.08.15 09:03:31:687: -------- InitializeProgrammerInterface: ok --------<br />

2005.08.15 09:03:31:984: System: <strong>ProMik</strong>-6<br />

2005.08.15 09:03:31:984: Appl.-Version: 1, 2, 121, 293<br />

2005.08.15 09:32:25:734: LOT-Nummer 1: 1TMEA00NER0<br />

file:///K|/FTF_Munich/Präsentation/<strong>ProMik</strong>_FTF_Presentation/Traceability/908E624_traceability_sample.txt (1 von 3)24.10.2005 11:54:31

file:///K|/FTF_Munich/Präsentation/<strong>ProMik</strong>_FTF_Presentation/Traceability/908E624_traceability_sample.txt<br />

2005.08.15 09:32:25:734: LOT-Nummer 2: NA<br />

2005.08.15 09:32:25:734: DTE-Nummer 1: 9D05110512<br />

2005.08.15 09:32:25:734: DTE-Nummer 2: NA<br />

2005.08.15 09:34:02:125: [ 1] Programmierung OK Trim=$7B Original($FDC2)=$80, Spg.=859<br />

2005.08.15 09:34:06:859: [ 2] Programmierung OK Trim=$90 Original($FDC2)=$96, Spg.=871<br />

2005.08.15 09:34:10:640: [ 3] Programmierung OK Trim=$B0 Original($FDC2)=$B7, Spg.=871<br />

2005.08.15 09:34:15:531: [ 4] Programmierung OK Trim=$80 Original($FDC2)=$8A, Spg.=872<br />

2005.08.15 09:34:19:296: [ 5] Programmierung OK Trim=$BA Original($FDC2)=$C2, Spg.=882<br />

2005.08.15 09:34:19:546: Chip ablegen; Socket: 1; ChipId: 22490<br />

2005.08.15 09:34:19:640: Chip OK; Socket: 1; ChipId: 22490<br />

2005.08.15 09:34:23:078: [ 6] Programmierung OK Trim=$91 Original($FDC2)=$9A, Spg.=862<br />

2005.08.15 09:34:23:765: Chip ablegen; Socket: 2; ChipId: 22491<br />

2005.08.15 09:34:23:796: Reel Start<br />

2005.08.15 09:34:23:890: Chip OK; Socket: 2; ChipId: 22491<br />

2005.08.15 09:34:23:890: [ 1] Programmierung OK Trim=$AB Original($FDC2)=$AD, Spg.=865<br />

2005.08.15 09:34:27:937: Chip ablegen; Socket: 3; ChipId: 22492<br />

2005.08.15 09:34:27:968: Reel Start<br />

2005.08.15 09:34:28:031: Chip OK; Socket: 3; ChipId: 22492<br />

2005.08.15 09:34:32:218: [ 7] Programmierung OK Trim=$AB Original($FDC2)=$B4, Spg.=869<br />

2005.08.15 09:34:32:281: Chip ablegen; Socket: 4; ChipId: 22493<br />

2005.08.15 09:34:32:312: Reel Start<br />

2005.08.15 09:34:32:375: Chip OK; Socket: 4; ChipId: 22493<br />

2005.08.15 09:34:36:578: Chip ablegen; Socket: 5; ChipId: 22494<br />

2005.08.15 09:34:36:640: Reel Start<br />

2005.08.15 09:34:36:703: Chip OK; Socket: 5; ChipId: 22494<br />

2005.08.15 09:34:40:890: Chip ablegen; Socket: 6; ChipId: 22495<br />

2005.08.15 09:34:40:937: Reel Start<br />

2005.08.15 09:34:41:000: Chip OK; Socket: 6; ChipId: 22495<br />

2005.08.15 09:34:41:500: [ 2] Programmierung OK Trim=$CC Original($FDC2)=$D2, Spg.=860<br />

2005.08.15 09:34:45:453: Chip ablegen; Socket: 7; ChipId: 22497<br />

2005.08.15 09:34:45:484: Reel Start<br />

2005.08.15 09:34:45:546: Chip OK; Socket: 7; ChipId: 22497<br />

2005.08.15 09:34:45:781: [ 3] Programmierung OK Trim=$84 Original($FDC2)=$8D, Spg.=871<br />

2005.08.15 09:34:49:765: Chip ablegen; Socket: 1; ChipId: 22496<br />

2005.08.15 09:34:49:796: Reel Start<br />

2005.08.15 09:34:49:859: Chip OK; Socket: 1; ChipId: 22496<br />

2005.08.15 09:34:50:140: [ 4] Programmierung OK Trim=$9D Original($FDC2)=$A6, Spg.=863<br />

2005.08.15 09:34:53:968: Chip ablegen; Socket: 2; ChipId: 22498<br />

2005.08.15 09:34:54:000: Reel Start<br />

2005.08.15 09:34:54:093: Chip OK; Socket: 2; ChipId: 22498<br />

2005.08.15 09:34:54:343: [ 5] Programmierung OK Trim=$96 Original($FDC2)=$A0, Spg.=874<br />

2005.08.15 09:34:58:312: Chip ablegen; Socket: 3; ChipId: 22499<br />

2005.08.15 09:34:58:359: Reel Start<br />

2005.08.15 09:34:58:421: Chip OK; Socket: 3; ChipId: 22499<br />

2005.08.15 09:34:58:640: [ 6] Programmierung OK Trim=$8F Original($FDC2)=$98, Spg.=873<br />

2005.08.15 09:35:02:625: Chip ablegen; Socket: 4; ChipId: 22500<br />

file:///K|/FTF_Munich/Präsentation/<strong>ProMik</strong>_FTF_Presentation/Traceability/908E624_traceability_sample.txt (2 von 3)24.10.2005 11:54:31

file:///K|/FTF_Munich/Präsentation/<strong>ProMik</strong>_FTF_Presentation/Traceability/908E624_traceability_sample.txt<br />

2005.08.15 09:35:02:656: Reel Start<br />

2005.08.15 09:35:02:718: Chip OK; Socket: 4; ChipId: 22500<br />

2005.08.15 09:35:03:390: [ 7] Programmierung OK Trim=$86 Original($FDC2)=$8E, Spg.=880<br />

2005.08.15 09:35:07:187: Chip ablegen; Socket: 5; ChipId: 22501<br />

2005.08.15 09:35:07:218: Reel Start<br />

2005.08.15 09:35:07:281: Chip OK; Socket: 5; ChipId: 22501<br />

2005.08.15 09:35:07:281: [ 1] Programmierung OK Trim=$81 Original($FDC2)=$8B, Spg.=871<br />

2005.08.15 09:35:11:265: Chip ablegen; Socket: 6; ChipId: 22502<br />

2005.08.15 09:35:11:312: Reel Start<br />

2005.08.15 09:35:11:375: Chip OK; Socket: 6; ChipId: 22502<br />

2005.08.15 09:35:11:656: [ 2] Programmierung OK Trim=$AF Original($FDC2)=$B7, Spg.=864<br />

2005.08.15 09:35:15:593: Chip ablegen; Socket: 7; ChipId: 22503<br />

2005.08.15 09:35:15:656: Reel Start<br />

2005.08.15 09:35:15:718: Chip OK; Socket: 7; ChipId: 22503<br />

2005.08.15 09:35:16:453: [ 3] Programmierung OK Trim=$6E Original($FDC2)=$72, Spg.=883<br />

2005.08.15 09:35:19:968: Chip ablegen; Socket: 1; ChipId: 22504<br />

2005.08.15 09:35:20:000: Reel Start<br />

2005.08.15 09:35:20:062: Chip OK; Socket: 1; ChipId: 22504<br />

2005.08.15 09:35:20:531: [ 4] Programmierung OK Trim=$8F Original($FDC2)=$98, Spg.=866<br />

2005.08.15 09:35:24:265: Chip ablegen; Socket: 2; ChipId: 22505<br />

2005.08.15 09:35:24:328: Reel Start<br />

2005.08.15 09:35:24:390: Chip OK; Socket: 2; ChipId: 22505<br />

2005.08.15 09:35:25:000: [ 5] Programmierung OK Trim=$A9 Original($FDC2)=$B2, Spg.=882<br />

2005.08.15 09:35:28:562: Chip ablegen; Socket: 3; ChipId: 22506<br />

2005.08.15 09:35:28:593: Reel Start<br />

[Barcode Label Nr. ]<br />

Manuf=Freescale<br />

MPN=1PMM908E624ACDWB<br />

Lot1=1TMEA00NER0<br />

Date1=9D05110512<br />

Lot2=1TMEA017570<br />

Date2=9D0519<br />

CusProdID=ABC.954.051<br />

Software=V13-FILL-8E.S19<br />

Qty=Q1716<br />

MSLvIn=3<br />

MSLvInHrs=168 Hours<br />

TofDry=3 Hours<br />

MSLvOut=3<br />

MSLvOutHrs=-3,0 Hours<br />

Seq/Reel/Set No=<br />

Tray/Set=<br />

Zusatz=Pb-free=N, RoHS=N<br />

Theta=245<br />

TotalQ=0<br />

file:///K|/FTF_Munich/Präsentation/<strong>ProMik</strong>_FTF_Presentation/Traceability/908E624_traceability_sample.txt (3 von 3)24.10.2005 11:54:31

<strong>ProLINFlasher</strong>

<strong>ProLINFlasher</strong><br />

PC Control Software for a System with 3 Programmers<br />

<strong>ProMik</strong> Programmiersysteme<br />

für die Mikroelektronik GmbH<br />

Südwestpark 100<br />

90449 Nürnberg, Germany<br />

Telefon +49 911-252665-0<br />

Telefax +49 911-252665-66<br />

info@promik.com<br />

www.promik.com