Concrete Crack Damage - Expanded Shale & Clay

Concrete Crack Damage - Expanded Shale & Clay

Concrete Crack Damage - Expanded Shale & Clay

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Expanded</strong> <strong>Shale</strong> & <strong>Clay</strong><br />

Minimize Compromises. Maximize Durability.<br />

txiesc.com |<br />

sales@txiesc.com<br />

<strong>Concrete</strong> <strong>Crack</strong> <strong>Damage</strong> –<br />

A Thing of the Past?<br />

General Facts:<br />

Early age concrete cracking and autogenous shrinkage can<br />

be minimized and in some cases completely eliminated and<br />

the service life greatly extended through the use of internal<br />

curing. By incorporating small quantities of prewetted<br />

lightweight aggregate throughout the concrete, the curing<br />

process is enhanced and extended.<br />

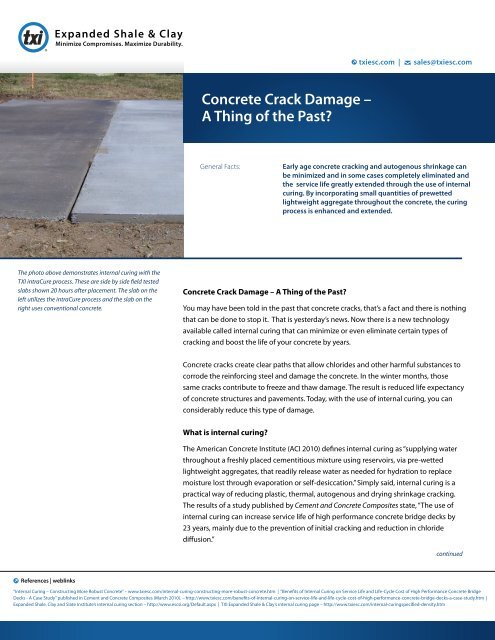

The photo above demonstrates internal curing with the<br />

TXI intraCure process. These are side by side field tested<br />

slabs shown 20 hours after placement. The slab on the<br />

left utilizes the intraCure process and the slab on the<br />

right uses conventional concrete.<br />

<strong>Concrete</strong> <strong>Crack</strong> <strong>Damage</strong> – A Thing of the Past?<br />

You may have been told in the past that concrete cracks, that’s a fact and there is nothing<br />

that can be done to stop it. That is yesterday’s news. Now there is a new technology<br />

available called internal curing that can minimize or even eliminate certain types of<br />

cracking and boost the life of your concrete by years.<br />

<strong>Concrete</strong> cracks create clear paths that allow chlorides and other harmful substances to<br />

corrode the reinforcing steel and damage the concrete. In the winter months, those<br />

same cracks contribute to freeze and thaw damage. The result is reduced life expectancy<br />

of concrete structures and pavements. Today, with the use of internal curing, you can<br />

considerably reduce this type of damage.<br />

What is internal curing?<br />

The American <strong>Concrete</strong> Institute (ACI 2010) defines internal curing as “supplying water<br />

throughout a freshly placed cementitious mixture using reservoirs, via pre-wetted<br />

lightweight aggregates, that readily release water as needed for hydration to replace<br />

moisture lost through evaporation or self-desiccation.” Simply said, internal curing is a<br />

practical way of reducing plastic, thermal, autogenous and drying shrinkage cracking.<br />

The results of a study published by Cement and <strong>Concrete</strong> Composites state, “The use of<br />

internal curing can increase service life of high performance concrete bridge decks by<br />

23 years, mainly due to the prevention of initial cracking and reduction in chloride<br />

diffusion.”<br />

continued<br />

References | weblinks<br />

“Internal Curing – Constructing More Robust <strong>Concrete</strong>” – www.txiesc.com/internal-curing-constructing-more-robust-concrete.htm | “Benefits of Internal Curing on Service Life and Life-Cycle Cost of High Performance <strong>Concrete</strong> Bridge<br />

Decks - A Case Study” published in Cement and <strong>Concrete</strong> Composites (March 2010). – http://www.txiesc.com/benefits-of-internal-curing-on-service-life-and-life-cycle-cost-of-high-performance-concrete-bridge-decks-a-case-study.htm |<br />

<strong>Expanded</strong> <strong>Shale</strong>, <strong>Clay</strong> and Slate Institute’s internal curing section – http://www.escsi.org/Default.aspx | TXI <strong>Expanded</strong> <strong>Shale</strong> & <strong>Clay</strong>’s internal curing page – http://www.txiesc.com/internal-curingspecified-density.htm

<strong>Expanded</strong> <strong>Shale</strong> & <strong>Clay</strong><br />

Minimize Compromises. Maximize Durability.<br />

txiesc.com |<br />

sales@txiesc.com<br />

continued<br />

<strong>Concrete</strong> <strong>Crack</strong> <strong>Damage</strong> –<br />

A Thing of the Past?<br />

Want to know more?<br />

The latest information will change your expectations about concrete and provide some<br />

valuable tools for translating those expectations into specifications for more sustainable,<br />

longer lasting concrete. If you are looking to improve the quality of your concrete, you can<br />

learn more about the details and benefits of internal curing by clicking on the following links:<br />

“Internal Curing – Constructing More Robust <strong>Concrete</strong>”<br />

(January 2012).<br />

published in Structure Magazine<br />

“Benefits of Internal Curing on Service Life and Life-Cycle Cost of High Performance <strong>Concrete</strong><br />

Bridge Decks - A Case Study” published in Cement and <strong>Concrete</strong> Composites (March 2010).<br />

You can also find many great resources at <strong>Expanded</strong> <strong>Shale</strong>, <strong>Clay</strong> and Slate Institute’s<br />

curing section and TXI <strong>Expanded</strong> <strong>Shale</strong> & <strong>Clay</strong>’s internal curing page.<br />

internal<br />

Give it a try on your next project, you will reap the benefits of increased durability and a<br />

significantly longer life for your concrete.<br />

TOP A photo of the cracking that occurred when<br />

using a ‘Conventional Bridge Deck Mixture” in<br />

Monroe County Indiana, after one year in service.<br />

ABOVE The currently ‘<strong>Crack</strong> Free’ Internally Cured<br />

<strong>Concrete</strong> Bridge Deck in Monroe County Indiana<br />

after one year in service