primary tillage tools - Sunflower Manufacturing

primary tillage tools - Sunflower Manufacturing

primary tillage tools - Sunflower Manufacturing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

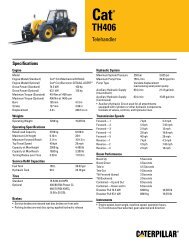

4213 Coulter chisel 4213 Coulter chisel4213 CoulterchiselWelcome To One-Pass SoilManagementWith coulters spaced every 7 1/2” andshanks on 15” centers, not much getspast the <strong>Sunflower</strong> Model 4213 CoulterChisel. Hydraulically adjusted coultergangs effectively size and cut residueto eliminate plugging and the need forshredding or discing before ripping. Therigid shearbolt or auto-reset shanks,meanwhile, completely fracture hardpansto a depth of 12” to 14”, breaking up soilcompaction that a wider-spaced shankarrangement would miss. Whether it’sused in the fall or the spring, the 4213is the perfect answer for removing soilcompaction, while opening up the surfacefor improved water intake and reducederosion.<strong>Sunflower</strong> - The Ultimate AnswerRigid ShearBoltA maximum point load of1,500 lbs. with a range ofpoints to control residue.4213 shank optionsAuto-ResetA maximumpoint load of 1,500 lbs.with a vertical trip heightof 13".3YEAR1. Optional Offset Shank Modules -These modules can be added to the rear bar ofthe machine, providing even more clearance fordemanding residue.2. Standard Walking Tandems - Standardwalking tandems minimize frame bounce anduneven penetration.3. Heavy-Duty Trash Bars - Heavy-duty 3” widechannel iron trash bars are mounted between eachcoulter blade to help keep the gangs clear of residueand dirt buildup.4. C-Flex Coulter Gang Hangers - Shockabsorbingmounts protect against field obstructions.Spring end collars help ensure the gang staysproperly torqued. Coulter gangs eliminate plugging orneed for shredding or discing before ripping.5. Single or Double Clevis AdjustableHitch - Either a single or double clevis adjustablehitch is available to allow front-to-rear leveling of themachine.4213 Coulter Chisel SpecsModelNumberCutting Width(m)Numberofshanksshankspacing(mm)transportwidth (m)6. Heavy-Duty Separating Spools - Each spoolweighs 50 lbs., enough weight to slice throughheavy residue. Gangs feature two rephasing lifthydraulic cylinders (protected by shock-absorbingmounts) to control the front gang depths withon-the-go adjustments.7. Heavy-Duty Frame - An all welded 4” x 6” x 3/8”frame with special formed gussets in all high stressareas. UHMW technology around the rock shaftsmeans no greasing needed and less parts wear.8. Well Braced Over the Top Hitch - All coulterchisels are fitted with overhead truss hitchesproviding down pressure to ensure no frame bounce.9. 20” Coulter Blades - Spaced on 7 1/2” centerswith long-life, trunnion-type bearings. Pre-fracturethe soil and size residue ahead of 15” spaced chiselshanks at 12”-14” maximum depth. Equipped with 13/4” gang shafts.Number ofcoultersEst. weight Rigidshanks (kg)Est. weight autoreset(kg)4213-7 8’-9” (2.7) 7 15” (381) 9’-8” (3) 14 6,068 lbs. (2752) 6,760 lbs. (3066)4213-9 11’-3” (3.4) 9 15” (381) 10’-11” (3.3) 18 6,632 lbs. (3008) 7,522 lbs. (3412)4213-11 13’-9” (4.2) 11 15” (381) 14’-3” (4.3) 22 7,602 lbs. (3448) 8,690 lbs. (3942)4213-13 16’-3” (5) 13 15” (381) 16’-2” (4.9) 26 8,162 lbs. (3702) 9,448 lbs. (4285)4213-15 18’-9” (5.7) 15 15” (381) 18’-9” (5.7) 30 9,202 lbs. (4174) 10,692 lbs. (4850)Note: Above specifications may vary slightly based on tires, hydraulic system, or other possible variances.We are continually striving to improve our machines; therefore, these specifications are subject to change without notice.1 2 34 56 78 9Learn more4 5on theWebwww.sunflowermfg.com

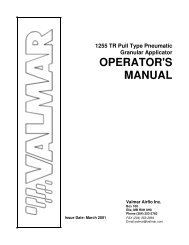

4233 Coulter chisel 4233 Coulter chisel4233 coulterchiselBig-Acreage Capacity AndPerformanceThe <strong>Sunflower</strong> Model 4233 Coulter Chiselis the obvious answer for large-acreagefarmers who need to take fall <strong>tillage</strong> to ahigher level of productivity. Designed tohandle higher horsepower tractors, the 4233features the same heavy-duty constructionas the 4213, but in three-section, 17 through23 shank configurations. Yet, its flexibleframe easily conforms to changing fieldcontours.Spring-cushioned coulter gangs feature7 1/2” blade spacing to effectively manageresidue levels, while ground-penetratingshanks open the field for maximummoisture absorption. Don’t take a chanceof not getting over fields after harvestor delaying planting of next year’s crop.Put the 4233 to work for acreage-eatingperformance.<strong>Sunflower</strong> - The Ultimate Answer3YEARRigid ShearBoltA maximum point load of1,500 lbs. with a range ofpoints to control residue.4233 shank optionsAuto-ResetA maximumpoint load of 1,500 lbs.with a vertical trip heightof 13".1. Optional Offset Shank Modules- These modules can be added to the rearbar of the machine, providing even moreclearance for demanding residue.2. Standard Walking Tandems -Standard walking tandems minimize framebounce and uneven penetration.3. Heavy-Duty Trash Bars -Heavy-duty 3” wide channel iron trash barsare mounted between each coulter bladekeeping the gangs clear of residue and dirtbuildup.4. C-Flex Coulter Gang Hangers- Shock-absorbing mounts protect againstfield obstructions. Spring end collars helpensure the gang stays properly torqued.Coulter gangs minimize plugging or needfor shredding or discing before ripping.5. Simple, Easy Adjustment - Singlepointdepth control for a simple, easyadjustment. Sets the depth for the entiremachine from one convenient location.1 2 3 4 5 66. Flexible Frames - Designed withflexible frames for all types of terrain andfolds to a narrow 14’6” transport width.7. Heavy-Duty Frame - An all-welded 4”x 6” x 3/8” frame with special formedgussets in all high stress areas. UHMWtechnology around the rock shafts meansno greasing needed and less parts wear.8. Single or Double ClevisAdjustable Hitch - Either a single ordouble clevis adjustable hitch is available toallow front-to-rear leveling of the machine.9. Heavy-Duty Separating Spools -Each spool weighs 50 lbs., enoughweight to slice through heavy residue.Gangs feature two rephasing lift hydrauliccylinders (protected by shock-absorbingmounts) to control the front gang depthswith on-the-go adjustments.4233 Coulter Chisel SpecsModelNumber4233-174233-194233-214233-23CuttingWidth(m)21’-3”(6.5)23’-9”(7.2)26’-3”(8)28’-9”(8.8)Numberof shanksshankspacing(mm)Operation:• Leave more residue by switching fromtwisted shovels to straight points.• Run the shanks 1-2” below thecompacted layer.7 8 9transportwidth (m)transportheight (m)Number ofcoulters17 15” (381) 14’-6” (4.4) 10’-3” (3.1) 3419 15” (381) 14’-6” (4.4) 11’-7” (3.5) 3821 15” (381) 14’-6” (4.4) 13’-1” (4) 4223 15” (381) 14’-6” (4.4) 14’ (4.3) 46Est. weightRigid shanks(kg)12,804 lbs.(5808)13,410 lbs.(6082)14,364 lbs.(6515)14,770 lbs.(6699)Est. weightauto reset(kg)14,487 lbs.(6571)15,291 lbs.(6936)16,443 lbs.(7458)17,047 lbs.(7732)Note: Above specifications may vary slightly based ontires, hydraulic system, or other possible variances.We are continually striving to improve our machines;therefore, these specifications are subject to changewithout notice.Learn more6 7on theWebwww.sunflowermfg.com

4412 Disc Ripper 4412 Disc Ripper4412 DiscripperDual Performance MeetsOne-Pass EfficiencySave time and fuel by tackling allyour fall <strong>tillage</strong> needs in a single passwith the <strong>Sunflower</strong> 4412 Disc Ripper.Designed to size and bury trash whileshattering hardpan at the same time,the 4412 also finishes the job withunmatched leveling ability. Key toits performance are the patentedC-Flex mounted disc blades, whichare mounted at a compound angle formore aggressive action and improvedclean-out ability in wet conditions.This patented compound-angled discarrangement also allows the unit torespond quickly and efficiently toobstacles found in the field.<strong>Sunflower</strong> - The Ultimate Answer12 3 43YEAR685791. Standard Walking Tandems - Standard walking tandemsminimize frame bounce and uneven penetration.2. Optional Shatter Wing - Increases horizontal fracturingability by lifting soil up and forward during operation.3. Self-leveling hitch - Front-to-rear leveling - once set the4412 will remain level both in and out of the ground.4. Adjustable Gangs - Height may be adjusted from 5” to 11”above ripper point for adjusting to different depths of surfacecompaction and residue amounts.5. Folding Rear Gangs - The folding rear gangs of 4412-7 foldfor transport.6. Multi Max-Depth Shanks - Adjustable 14”/18” maximumdepth settings.4412 shank optionsAuto-Reset Parabolic ShanksA maximum point load of 3,500 lbs. withoperating depths of up to 14”-18”. Parabolicshanks provide a wider shattering patternand require less draft than a straight shank.7. Patented C-Flex Shielding - Stops soil transfer from one disc tothe next. Reduces plugging of wet materials and trash.8. Parallel Linkage - Exclusive parallel links connect both the frontand rear disc gangs to the main frame. Links allow the disc gangs torun level no matter the height adjustment, as one might see in a planterstyle opener.9. Maintenance-Free UHMW Polymer Sleeves - MaintenancefreeUHMW polymer sleeves on the lift system require no greasing,eliminate wear points and improve overall performance of the machine.10. Individual C-Flex Mounted Cushioned Blades - Originallydeveloped for rock protection, the individual 12” spaced patented*C-Flex mounted discs blades not only react quickly and efficiently toobstacles found in fields, but also provide excellent clean-out in adversefield conditions. These attributes are in part due to the patented*unprecedented compound angle <strong>Sunflower</strong> designed into the front rowof individual discs.4412 disc ripper SpecsModelNumber4412-5cuttingwidth(m)12.5’(3.8)Numberofshanksshankspacing(mm)5 30” (762)4412-7 17.5’ (5.3) 7 30” (762)transportwidth(m)15’-5”(4.7)17’-4”(5.3)Number ofdiscs (f/R)14/1818/24Note: Above specifications may vary slightly based on tires, hydraulic system, or otherpossible variances.Est. weight(kg)13,615 lbs.(6176)16,200 lbs.(7348)We are continually striving to improve our machines; therefore, these specifications aresubject to change without notice.10Learn more8 9on theWebwww.sunflowermfg.com

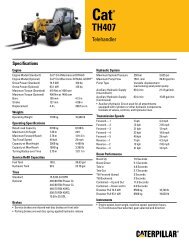

4511 / 4530 Disc chisel 4511 / 4530 Disc chisel4511/4530Disc chiselThe Answer To Today’sCropping Challenges12 3 4 5 6 78Higher plant populations, genetically modifiedhybrids and larger combines have certainly donetheir share to increase yields and speed harvest.But they all come with trade-offs, like a growingresidue problem and greater compaction.Fortunately, the <strong>Sunflower</strong> 4500 Series discchisel is aggressive enough to handle even thetoughest residue and compaction.Hydraulically adjustable front and rear disc gangscan be independently adjusted, enabling you tofine-tune the machine from field to field to obtainthe desired effects. While the front disc gangsizes and mixes the residue in the top few inchesof soil for faster decomposition, discs on the reargangs level and finish the swath for spring <strong>tillage</strong>or planting. In the meantime, chisel shanks,spaced on 15”centers for optimum residue flow,provide maximum soil fracturing to depths of12” to 14” for future root growth.<strong>Sunflower</strong> - The Ultimate Answer3YEARRigid ShearBoltFor light and rock-freesoils, with a range ofpoints to control residue.4511 / 4530 shank optionsAuto-ResetA maximumpoint load of 1,500 lbs.with a vertical trip heightof 13".1. Hydraulic Front and Rear Gangs - Vary the amount of residue that can beburied and fine-tune the machine from field to field. Depth gauge on front and reargangs can be seen from the tractor seat for added convenience to the operator.2. C-Flex Mounted Disc Blades - Patented* individual C-Flex mounteddisc blades provide additional rock protection, and allow you to work in wetterconditions, when compared to a solid front gang.3. Self-Leveling Hitch - Self-leveling hitch and front-to-rear leveling - once set the4511/4530 will remain level both in and out of the ground.4. Depth Gauges - Disc depth gauges both front and rear are visible from tractorseat.4511 / 4530 Disc Chisel SpecsModelNumberCuttingWidth (m)transportwidth (m)transportHeight (m)Numberof shanksshank spacing(mm)Number ofblades (f/R)5. Patented* C-Flex Shielding - Stops soil transfer from one disc to the next. Reducesplugging of wet materials and trash.6. Exclusive Parallel Links - Parallel links connect both the front and rear disc gangs tothe main frame. Links allow the disc gangs to run level no matter the height adjustment.7. Single Point Depth Control - Front mounted single point depth control sets thedepth for the entire machine.8. UHMW Polymer Sleeves - Spend more time in the field and less time with dailymaintenance. Maintenance-free UHMW polymer sleeves on the lift system require nogreasing, and improve overall performance of the machine.bladespacing (f/R)Tires & size4511-9 11’-3” (3.4) 13’-9” (4.2) 6’-8” (2) 9 15” (381) 12/16 12/10.5 (4) 12.5Lx15(318x381)4511-11 13’-9” (4.2) 17’-2” (5.2) 6’-8” (2) 11 15” (381) 14/20 12/10.5 (4) 12.5Lx15(318x381)4511-13 16’-3” (5) 16’-9” (5.1) 8’-9” (2.7) 13 15” (381) 18/22 12/10.5 (4) 12.5Lx15(318x381)4511-15 18’-9” (5.7) 18’-8” (5.7) 10’-3” (3.1) 15 15” (381) 20/28 12/10.5 (4) 12.5Lx15(318x381)4530-19 23’-9” (7.2) 18’-1” (5.5) 11’-7” (3.5) 19 15” (381) 24/32 12/10.5(4) 12.5Lx15(318x381)Est. Weight(kg)13,160 lbs.(5969)14,385 lbs.(6525)16,680 lbs.(7566)17,900 lbs.(8119)24,360 lbs.(11049)Note: Specifications may vary slightly based on tires,hydraulic system, or other possible variances.We are continually striving to improve our machines;therefore, these specifications are subject to changewithout notice.Learn more10 11on theWebwww.sunflowermfg.com

2433 chisel plow 2433 chisel plow2433 chisel plowShatter The Toughest YieldBarrierTough conditions and compacted fields call fora tough machine. That’s why the <strong>Sunflower</strong>Model 2433 is the heaviest chisel plow webuild. The rugged 4 X 6-inch tubular steeltongue, for example, extends from front to rearbeneath the framework and is bolted to eachbar to distribute stress across the entire frame.121. Adjustable Hitch - Ratchet-jack adjustablehitch allows precise leveling of the chisel framefrom front to rear. No bolts to remove or linkagesto unhook, simply ratchet the handle of the jackto decrease the draft load and smooth out thesoil finish.2. Walking Tandems - Walking tandems areavailable on all sections, allowing the machineto follow the ground contour, maintaining amore consistent shank depth. The tandembeam pivots on a set of greasable taperedroller bearings for smooth, long-lasting service.Grease-fitting-equipped six-bolt hubs and heavyduty2” slip-in spindles feature triple-lip seals.3. Single-Point Depth Control - Frontmounteddepth control allows the operator toset the depth of the entire chisel from a single,convenient location. No need to move fromframe to frame setting each section as you go;just turn the handle and dial in your depth.4. Hydraulic Lift System - Rephasinghydraulic lift system features two 4” x 8”cylinders with hydraulic stroke control andmatching 3 3/4” x 8” slave cylinders. Shankdepth control is precise and the traditionalrockshaft linkage wear-points are minimized.2433 shank optionsrigid shearboltShanksAdded protection againstshank breakage without theadditional cost of springs. Abeefy 1 1/2”x 2” and 30” ofunderframe clearance. Shankmounts provide shear-boltprotection and retain theshank in the event of a shearboltbreakage.Take your choice of rigid, rigid shear bolt orspring cushion shanks spaced on 12” centers,for shattering compaction while attaining goodsoil mix and residue flow across the full cuttingwidth. There’s no better way to improve waterand nutrient infiltration over the winter than tobreak up hardpan and rough up the soil surfacein the fall during your post harvest <strong>tillage</strong>operation. And with sizes to match even thelargest high-horsepower tractors, you can covera large number of acres before the snow flies.32433 Chisel Plow SpecsModelNumberworkingwidths(m)Number ofextensionsNumber ofshanks-Center frameNumber ofshankswingframetransportheight (m)transportwidth (m)est. weight (kg)2433-25 25’ (7.6) 0 13 6 9’-10” (3) 18’-7” (5.7) 9,135 lbs. (4143)2433-27 27’ (8.2) 1 13 7 10’-6” (3.2) 18’-7” (5.7) 9,369 lbs. (4250)2433-31 31’ (9.4) 0 13 9 12’-8” (3.9) 18’-7” (5.7) 9,917 lbs. (4498)2433-33 33’ (10.1) 1 13 10 13’-4” (4.1) 18’-7” (5.7) 10,151 lbs. (4604)2433-35 35’ (10.7) 2 13 11 14’-4” (4.4) 18’-7” (5.7) 10,465 lbs. (4747)2433-37 37’ (11.3) 0 13 12 15’-7” (4.7) 18’-7” (5.7) 11,039 lbs. (5007)2433-39 39’ (11.9) 1 13 13 16’-3” (5) 18’-7” (5.7) 11,273 lbs. (5113)Spring Cushion ShanksHusky 1 1/4” x 2” with 30”clearance. Shank-to-framestress is controlled by arugged ductile shank mount.Reversible 5/8” x 2” pointsare standard equipment.<strong>Sunflower</strong> - The Ultimate Answer3YEAR2433-41 41’ (12.5) 2 13 14 17’-3” (5.3) 18’-7” (5.7) 11,587 lbs. (5256)Note: Above specifications may vary slightly based on tires, hydraulic system, or other possible variances.We are continually striving to improve our machines; therefore, these specifications are subject to change without notice.4Learn more12 13on theWebwww.sunflowermfg.com

Common components and featurescommon components & features1231. PATENTED C-FLEX MOUNTSWhether they’re used to support a full disc gang ona 4213/4233 Coulter Chisel or individually mountedgangs on a <strong>Sunflower</strong> disc chisel, our patentedC-Flex bearing standards absorb disc shockcreated by rocks, field obstructions and normaldiscing. Additional C-Flex benefits include theability to clear residue better than conventional rigidstandards; extended bearing, spool and disc bladelife, and easy maintenance.2. HEAVY-DUTY FRAMEAll <strong>Sunflower</strong> <strong>primary</strong> <strong>tillage</strong> <strong>tools</strong> feature anall-welded, box-beam frame with specially formedgussets in all high-stress areas for maximumreliability and a long service life. All models alsofeature a maintenance-free lift system, whichutilizes space-age UHMW plastic sleeves on liftpivots, to eliminate the need for greasing, whiledecreasing parts wear and maintenance.3. STANDARD WALKING TANDEMSWalking tandem axles, which offset each setof support wheels, minimize frame bounce anduneven penetration, while providing the necessarysupport and flotation in the field and on the road.4. MAINTENANCE-FREE HINGESHeavy-duty wing hinges incorporate maintenancefreeUHMW plastic sleeves that eliminate greasingand increase service life.O p t i o n a lFinishing AttachmentsTHREE-ROW, HEAVY-DUTY COIL TINE HARROWUniform germination depends on a smooth,level seedbed that warms evenly. Designed towork in heavy crop residue, the Heavy-DutyCoil Tine Harrow features three rows of 1/2”x 22” coil tines with 12” spacing on each barto produce a 4” overall tine spacing for evensoil and residue distribution. Spring-loadedparallel mounting arms maintain the necessarydown-pressure, while keeping the tine angleconsistent. Yet, tine pitch angle on eachsection can be easily adjusted without the useof <strong>tools</strong>. Each section also features back-upprotection and maximum flexibility that helpsensure against skips and gouges. Available for:4213/4233, 4500/4530 and 4400 Series.ROLLING TREADERSDesigned to work in dryer conditions and stonefreeapplications the <strong>Sunflower</strong> Rolling Treaderis the perfect answer for maximum weedcontrol and greater soil pulverization. Eight rowsof 7/16” x 1 1/2” curved and twisted carbonsteel teeth per row help bring weeds to thesoil surface, while mixing residue and levelingand firming the soil surface. In the meantime,the 18” in diameter treader reels ride on1 1/2” shafts and triple-sealed bearings toensure maximum reliability. Available for: 2400,4213/4233 Series.FIVE-ROW SPIKE DRAG HARROWFor the ultimate in seedbed preparation orchemical incorporation, add the five-row spikedrag harrow to any 4213 or 4233 model.Indexed tines on five individual bars createa smooth level surface by breaking up clodsand evenly distributing both soil and cropresidue. Reversible bar connector links allowfor both flexible and rigid harrow postures toattain the desired action. Equally important,the harrow’s 11” x 3/4” spikes are spacedon 1 3/4” centers to handle heavy residuewithout bunching. Available for: 4213/4233Series. The 3‐row version of the spike dragharrow is available for the 2433 Series.CHOPPER REELSThe <strong>Sunflower</strong> Chopper Reel attachmentprovides just the right amount of aggressiveaction needed to size residue, break upclods, and level and condition the soil forone-pass seedbed preparation. Rugged 16”reels with 15” offset blades provide reliableperformance in a wide variety of residueconditions, while 1 3/4” reel shafts with twotriple-sealed, trunnion-mounted bearingsper reel provide the reliability you demand.Available for: 4213/4233 Series.4Learn more14 15on theWebwww.sunflowermfg.com

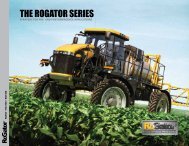

4610 / 4630 Disc Ripper 4610 / 4630 Disc Ripper4610/4630Disc RipperThe Size And Strength ToHandle Today’s NeedsThe new <strong>Sunflower</strong> 4600 Series Disc Ripperdoes more than just fulfill the demand for amachine that is large enough to maximizethe power ratings of today’s high horsepowertractors. It’s also tough enough to handlethe <strong>tillage</strong> demands of corn-on-corn rotationprograms.Available in working widths from 14’ to 26’,the 4600 Series disc ripper combines <strong>primary</strong>surface <strong>tillage</strong> via two ranks of individuallymounted disc blades with fracturing of subsoilcompaction for maximum crop potential.Fact is, the Model 4630-13, equipped with 13parabolic spring-reset shanks, is the largestflexible frame disc ripper in the industry.Add your choice of three different finishingharrow options — a heavy-duty coil tineharrow, two-bar coil tine harrow or five-barspike tooth harrow — and the 4600 can betailored to handle virtually any soil type andcropping condition in North America.3YEAR1. Heavy-Duty Frame - The 4600 disc chisel is one ofthe strongest and heaviest units of its kind, thanks in partto an all-welded mainframe constructed of 4” X 8” X 3/8”steel tube. The frame is also cross-braced and gusseted fortrouble-free service and the strength to withstand the highstress of aggressive <strong>tillage</strong>.2. Standard Walking Tandems - Walking tandemaxles, which offset each set of support wheels, equippedwith 385/66R 22.50 tires and 8-bolt hubs, provide thenecessary support and flotation in the field and on theroad.4600 Disc ripper SpecsModelNumberSF4610-07SF4610-09SF4630-11SF4630-13DESCRIPTIONDisc RipperIndividually Mounted BladesParabolic Auto-Reset ShanksDisc RipperIndividually Mounted BladesParabolic Auto-Reset ShanksDisc RipperIndividually Mounted BladesParabolic Auto-Reset ShanksDisc RipperIndividually Mounted BladesParabolic Auto-Reset ShanksCutting Width(m)14’(4.3)18’(5.5)22’(6.7)26’(7.9)Shank Spacing(mm)24”(610)24”(610)24”(610)24”(610)3. Individually Mounted Disc Blades - Two ranks ofindividually mounted 28” x 5/16” disc blades — the largestin the industry — provide an effective cut of 7 1/2” tosize and bury heavy residue. The operating range of 0 to 8inches deep is adjusted remotely from the tractor cab.4. Parabolic Spring-Reset Shanks - The parabolicspring-reset shanks have a 3,500-pound maximum trippressure and set at 24” shank spacing. Each shank isconstructed of 1 1/4” high-strength, abrasion-resistant steelwith a chromium carbide shin guard to protect the shankfrom excessive wear.Blade Sizes(mm)28”(711)28”(711)28”(711)28”(711)Number OfBladesNote: Above specifications may vary slightly based on tires, hydraulic system, or other possible variances.We are continually striving to improve our machines; therefore, these specifications are subject to change without notice.20283640TransportDimensionsWidth x Height (m)14’ 5” x 7’ 0”(4.4 X 2.1)19’ 7” x 7’ 0”(6 x 2.1)19’ 3” x 13’ 6”(5.9 x 4.1)19’ 3” x 13’ 6”(5.9 x 4.1)Est. Weight(kg)14,906 lbs.(6761)17,565 lbs.(7967)28,376 lbs.(12,871)29,689 lbs.(13,467)123<strong>Sunflower</strong> - The Ultimate Answer4Learn more16 17on theWebwww.sunflowermfg.com

“<strong>Sunflower</strong> equipment helps open the residue-management window.”The weather around Redwood Falls,Minnesota, can get pretty cold duringthe winter. That’s part of the reasonKen Felleson, who farms around1,000 acres of corn and soybeans inpartnership with his brother, Bob, likesto use a <strong>Sunflower</strong> 4511 disc chisel toget his <strong>primary</strong> <strong>tillage</strong> done in the fallbefore the snow flies. Not only doesthe 4511 size and bury much of thegrowing amount of residue, but thechisel helps break up soil compaction,allowing moisture to penetrate the soilprofile. Most important, it helps get thedecomposition process started alittle earlier.“We’re seeing a lot more trash in thefields than we used to,” Ken admits,noting that a lot of their corn consists ofRoundup Ready triple stacked varieties.“I don’t know that the stalks are anythicker or heavier, but there seem to bea lot more leaves and husks with thenew varieties. I’ve found, too, that itdepends on the brand more than it doesthe particular hybrid. If we can get overthe fields in the fall with the disc chisel,we can get a better handle on residuemanagement and start preparing thefield for spring.”Felleson realizes that the microbes thatbreak down residue are always mostaggressive right below the soil surfacewhere there’s a good mix of soil, air andmoisture. Unfortunately, those microbesgo dormant when the soil temperaturedrops to 40 degrees, which meansthe window closes pretty quickly inMinnesota.Felleson says their residue managementprogram starts with the use of apull-type stalk chopper shortly afterharvest. Weather permitting, they followwith the disc chisel at approximately sixmiles per hour a few days later.“It leaves a nice mix,” he says. “Whenyou look down from the tractor cab,you can see about 60 to 65 percentblack dirt. Once the buried residuedeteriorates over the winter and we hitit with the field cultivator and a crumblerattachment in the spring, it leaves anideal seedbed, which ultimately leads toa better stand and higher yields.“On the other hand, I think the<strong>Sunflower</strong> disc chisel leaves the surfacea lot more level to begin with,” he adds.“I’ve seen the job other brands do inthe fall, and it seems the fields are alot more uneven. I know, too, that the<strong>Sunflower</strong> does a better job when we’reworking in heavy soil or wet ground. Itmay pull harder, but it still does the job.”Ken says the key is to set the frontdiscs just deep enough to throw a littledirt, since the main function of theindividually mounted discs is to cut thestalks.“If you can get the front discs to throwenough dirt to hold the leaves andtrash in place, it seems the twist onthe shovels can do an even better jobof burying it,” Felleson says, noting thathe particularly likes the easily visibledepth gauges and the hydraulic frontand rear gangs, which allow him to varythe amount of residue that is buried.“And since there aren’t any spindles onthe front gangs, there’s nothing to stopresidue from moving through when it’sdesired,” he concludes. “I’m certainlyhappy with its performance.”GrowerKen FellesonLocationRedwood Falls, MinnesotaSituationResidue management inhigh-population stackedgeneticscornSoil ConditionBetter aeration and agood mix of black soiland residueTillage Tool Used<strong>Sunflower</strong> 4511 DiscChiselLearn more18 19on theWebwww.sunflowermfg.com

Primary Tillage Tools4213 | 4233 | 4412 | 4511 | 4530 | 4610 | 4630 | 2433<strong>Sunflower</strong>. The Ultimate Answer.AGCO Corporation4205 River Green ParkwayDuluth, GA 30096PRINTED IN U.S.A.SF11B002BAC (08) 7 SG©2011 AGCO Corporation. All rights reserved. This document and all of itscontents are owned exclusively by AGCO and are protected by copyrightlaw. AGCO has a corporate policy of continuous product improvement anddevelopment; therefore, specifications are subject to change without any advancenotice. AGCO is not responsible for differences between the specifications orillustrations contained in this publication and the actual equipment. Equipmentproduced by other manufacturers is shown in photographs in this brochure forthe purpose of illustration only and is not intended as an endorsement of thatparticular equipment or its suitability. AGCO, 4205 River Green Parkway, Duluth,GA 30096.We proudly support:For more information:www.sunflowermfg.com