Tungaloy-Hard_Turnin.. - OSG

Tungaloy-Hard_Turnin.. - OSG

Tungaloy-Hard_Turnin.. - OSG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

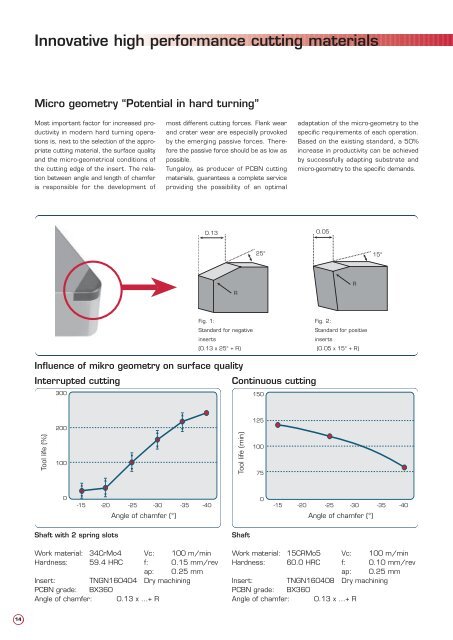

Innovative high performance cutting materialsMicro geometry “Potential in hard turning”Most important factor for increased productivityin modern hard turning operationsis, next to the selection of the appropriatecutting material, the surface qualityand the micro-geometrical conditions ofthe cutting edge of the insert. The relationbetween angle and length of chamferis responsible for the development ofmost different cutting forces. Flank wearand crater wear are especially provokedby the emerging passive forces. Thereforethe passive force should be as low aspossible.<strong>Tungaloy</strong>, as producer of PCBN cuttingmaterials, guarantees a complete serviceproviding the possibility of an optimaladaptation of the micro-geometry to thespecific requirements of each operation.Based on the existing standard, a 50%increase in productivity can be achievedby successfully adapting substrate andmicro-geometry to the specific demands.0.130.0525°15°RRFig. 1:Standard for negativeinserts(0.13 x 25° + R)Fig. 2:Standard for positiveinserts(0.05 x 15° + R)Influence of mikro geometry on surface qualityInterrupted cuttingContinuous cutting300150200125Tool life (%)100Tool life (min)1007500-15 -20 -25 -30 -35 -40 -15 -20 -25 -30 -35 -40Angle of chamfer (°) Angle of chamfer (°)Shaft with 2 spring slotsWork material: 34CrMo4 Vc: 100 m/min<strong>Hard</strong>ness: 59.4 HRC f: 0.15 mm/revap: 0.25 mmInsert: TNGN160404 Dry machiningPCBN grade: BX360Angle of chamfer: 0.13 x …+ RShaftWork material: 15CRMo5 Vc: 100 m/min<strong>Hard</strong>ness: 60.0 HRC f: 0.10 mm/revap: 0.25 mmInsert: TNGN160408 Dry machiningPCBN grade: BX360Angle of chamfer: 0.13 x …+ R14

![HXL&VXL oil industry [Europe].indd - OSG](https://img.yumpu.com/30736963/1/184x260/hxlvxl-oil-industry-europeindd-osg.jpg?quality=85)