TAW & TPW Milling cutter - OSG

TAW & TPW Milling cutter - OSG

TAW & TPW Milling cutter - OSG

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

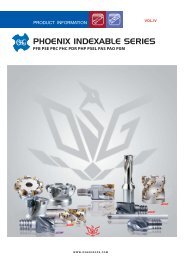

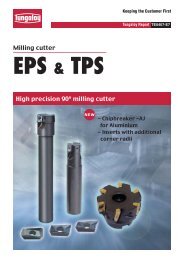

Keeping the Customer FirstTungaloy Report TE0407-E345° & 90° - <strong>Milling</strong> <strong>cutter</strong><strong>TAW</strong> & <strong>TPW</strong>NEW<strong>Milling</strong> made “easy”

<strong>TAW</strong> & <strong>TPW</strong> <strong>Milling</strong> <strong>cutter</strong><strong>Milling</strong> made “easy”NEWFeaturesWith the newly developed tool system forface and square shoulder milling Tungaloystrikes out in a new direction in precisionand design. This modern tool conceptconvinces in various application fields andenables productive and flexible utilisationon all different machining centres. Due totwo different versions (standard pitch andclose pitch type) this tool system offersoptimal adaptation to a great variety ofworking materials. All tools dispose of aninner coolant system directed precisely oneach insert. Thanks to the highly positiverake angle and the application orientedchipbreaker, lowest cutting forces can beachieved. Thus especially the machining ofunstable work pieces on low powermachining centres becomes totallyuncomplicated. The application of the HJhigh feed geometry in the 45° <strong>TAW</strong> milling<strong>cutter</strong> is revolutionary. Simply bychanging the insert the face milling <strong>cutter</strong>turns into a high feed milling <strong>cutter</strong>. Thispoints out the complete potential of ournew milling system as it realizes significantlyshorter machining times.BenefitsModern design in high precision light weightconstruction<strong>TAW</strong> milling <strong>cutter</strong> suited for high feed milling by simplychanging the insert<strong>Milling</strong> <strong>cutter</strong> in standard pitch and close pitch typeWide selection of chipbreaker geometries:MJ, ML, MS, AJ, HJ and withoutExtremely low cutting forces due to highly positive rakeangle and curved cutting edges*Excellent surface quality- Almost no chatter with repeated slotting*- Super flank accuracy- Wiper insert for <strong>TAW</strong> milling <strong>cutter</strong>1° 50 µmInner cooling deviceconventional<strong>TPW</strong>132

<strong>TAW</strong> & <strong>TPW</strong> <strong>Milling</strong> <strong>cutter</strong>NEWBenefits: Wiper0.12 mmFirst recommendation for excellentsurface qualities at high feed ratesfor the machining of steels, stainlesssteels, cast iron materials and aluminiumalloys. As a rule the applicationof one wiper insert is sufficient.SpecificationsWiper edge (Standard) W1 : 2.0 ~ 2.3 mmWiping flat (Wiper) W2 : 7.8 mmExcess length: 0.12 mmWiper: R500W2W1Our formula for high productivity:HJ = High feed millingVf = 4500 mm/minVf = 5500 mm/minVf = 6500 mm/minVf =3

<strong>TAW</strong> & <strong>TPW</strong> <strong>Milling</strong> <strong>cutter</strong>GradesNEWAH120 AH140 GH110 T3030- Coated fine grain carbide formilling of steels, alloy steelsand cast irons- The TiAlN-PVD coatingprovides for application inmedium to high cutting speedoperations.- High toughness for mediumfinishing and roughing ofstainless steels at low cuttingspeeds- PVD-coated grade suited formachining of cast ironmaterials.- Excellent wear resistance- New MT-CVD coated gradefor general milling operationsof carbon steels and alloysteels at medium cuttingspeeds- Superior balance betweenwear-resistance and toughness.T1015 NS740 KS05F DX140NEW- MT-CVD coated grade forgeneral milling operations ofcast irons at medium cuttingspeeds- High wear-resistance andtoughness- Uncoated Cermet withextreme wear-resistance andwell balanced toughness- For universal application inmilling operations of steel andcast iron materials atmedium cutting speeds- Best surface quality- Highly wear resistant,uncoated ultra-fine graincarbide for high cuttingspeeds- Extremely sharp cuttingedges for excellent surfacequalities- PCD grade suited for highspeed milling of non-ferrousmetals.- Excellent wear resistance45° high feed milling <strong>cutter</strong> withchipbreaker -HJ<strong>TAW</strong>ABTungaloyCompetitorCompetitor0.30 0.40 0.50 0.60 0.65Feed per tooth ft (mm/t)Machine:Vertical milling machine - 15 KWCutter: ø 100, t = 1Insert:SWMT13T3AFPR-HJWork material: 42CrMo4Cutting speed: Vc = 200 m/minFeed per tooth: ft = 0.30 ~ 0.65 mm/tAxial cutting depth: ap = 2.0 mmCutting width:ae = 50 mm90° Square shoulder (-MJ)Length of shoulder (mm)14<strong>TPW</strong>13 (MJ)12 Competitor ACompetitor B1086420-100 -50 0 50Profile accuracy (µm)Machine:Vertical milling machine - 15 KWCutter: ø 100, t = 5Insert:SWMT1304PDPR-MJWork material: C55Cutting speed: Vc = 100 m/minFeed per tooth: ft = 0.1 mm/tAxial cutting depth: ap = 3.0 mmCutting width:ae = 100 mmFeed1001002004

<strong>TAW</strong> & <strong>TPW</strong> <strong>Milling</strong> <strong>cutter</strong>ChipbreakerMJMLFirst choice for steel andcast iron machining- Stable cutting edges- Excellent chip flowRecommended for generalmachining of steel- Low cutting forceswithoutHJRecommended for generalmachining of steel and castiron- Highly stable cutting edgesRecommended for HPCmachining of stainless steel,steel and cast iron- High feed ratesMSAJFirst choice for machining ofstainless steel- Super soft cut- Low edge built-upFirst choice for machining ofaluminium alloys- Extremely sharp cuttingedgesWiperFirst choice for excellent surface quality at high feed rates- low cutting forcesNEWNEWWiper: surface roughness6 RaRy5Rz4Roughness (µm)321Machine:Vertical milling machine - 25 KWCutter: <strong>TAW</strong>13R125M40.0E12 (ø125, t = 12)Insert: SWMT13T3AFPR-MJ AH120 (t = 11)WWCW13T3AFER-WS NS740 (t = 1)Work material: Ck55Cutting speed: Vc = 200 m/minFeed per tooth: ft = 0.2 mm/tAxial cutting depth: ap = 1.0 mmCutting width: ae = 150 mmCoolant:without2000MJMJ + Wiper WS100with WiperRoughness (µm)20151050-5-10-15-200 2 4 6 8 10 12(mm)without WiperRoughness (µm)20151050-5-10-15-200 2 4 6 8 10 12(mm)5

<strong>TAW</strong> & <strong>TPW</strong> <strong>Milling</strong> <strong>cutter</strong>Specification: <strong>TPW</strong> milling <strong>cutter</strong> (90°)ødbaFSSP1102CSPB-3.5<strong>TPW</strong>13R050M22.0E04<strong>TPW</strong>13R063M22.0E05<strong>TPW</strong>13R080M27.0E06<strong>TPW</strong>13R100M32.0E07<strong>TPW</strong>13R125M40.0E08<strong>TPW</strong>13R050M22.0E05<strong>TPW</strong>13R063M22.0E06<strong>TPW</strong>13R080M27.0E08<strong>TPW</strong>13R100M32.0E10<strong>TPW</strong>13R125M40.0E12●●●●●●●●●●456785681012Dimensions (mm)øD ød F E a b5063801001255063801001252227324022273240405063405063202228.532202228.5326.37896.3789DTS5-3.5SS10.412.414.416.410.412.414.416.4P-3.5IP-15DFig. 1Fig. 2Centre boltItem code Fig.CM10X30H1CM12X30HTMBA-M16H2TMBA-M20HCM10X30H1CM12X30HTMBA-M16H2TMBA-M20HMJ13.555.0ML13.555.0MS13.565.0MJ (G)13.555.0AJ (G)13.5813.551.413.551.413.561.417°17°5.013.581.613.551.4EReplacement parts ShimDescriptionItem codeCentre boltF Clamping screw for insertClose StandardøDRake angle: A.R. 11.5°R.R. -13° ~ -10.5°Item codeStockNo. ofinserts Clamping screw for shimWrenchWrenchAirholewithwithwithwithwithwithwithwithSpecification: inserts for <strong>TPW</strong> milling <strong>cutter</strong> (90°)● Standard stock in Europe17°17°17°GradesItem codePVD coated CVD coated Cermet CarbideCornerAccuracy HoningWipingflat radiusAH120 AH140 T3030 T 1015 NS740 KS05FMax. apSWMT1304PDPR-MJ ● ● ● ● ●SWMT1304PDER-ML ● Mwith 1.4 0.8SWMT1304PDPR-MS ● 10.00SWGT1304PDPR-MJ ● ●GSWGT1304PDFR-AJ ● without 1.6 -7

<strong>TAW</strong> & <strong>TPW</strong> <strong>Milling</strong> <strong>cutter</strong>Cutting conditions <strong>TAW</strong> (45°)Roughing (Cutting depth: ap > 1.0 mm)Work materalsMild steelLow alloyed steelSt37, etc.(< 180HB)Carbon steelAlloy steelCk45, 42CrMo4, etc.(< 300HB)Die & Prehardened steelX96CrMoV12, etc.(< 30HRC)Stainless steel(< 250HB)Grey cast ironDuctile cast ironAluminium alloys(Si: < 12 %)Aluminium alloys(Si: > 13 %)Copper alloysGradeAH120T3030AH140NS740AH120T3030AH140NS740AH120T3030AH140AH120T1015AH120KS05FKS05FKS05F* ChoiceIIIIIIIVIIIIIIIVIIIIIIIIIIIIICuttingFeed per tooth ft (mm/t)speedVc (m/min) MJ ML without HJ MS AJ100 ~ 270 0.05 ~ 0.3 0.05 ~ 0.25 0.05 ~ 0.3 0.2 ~ 0.6 - -150 ~ 300 0.05 ~ 0.3 - 0.05 ~ 0.3 0.2 ~ 0.6 - -80 ~ 180 0.05 ~ 0.3 - - - 0.1 ~ 0.25 -100 ~ 300 0.05 ~ 0.23 - 0.05 ~ 0.23 - - -100 ~ 230 0.05 ~ 0.25 0.05 ~ 0.2 0.05 ~ 0.25 0.2 ~ 0.5 - -150 ~ 280 0.05 ~ 0.25 - 0.05 ~ 0.25 0.2 ~ 0.5 - -80 ~ 150 0.05 ~ 0.25 - - 0.2 ~ 0.5 - -100 ~ 230 0.05 ~ 0.2 - 0.05 ~ 0.2 - - -100 ~ 180 0.05 ~ 0.2 0.05 ~ 0.15 0.05 ~ 0.2 0.2 ~ 0.4 - -100 ~ 180 0.05 ~ 0.2 - 0.05 ~ 0.2 0.2 ~ 0.4 - -80 ~ 200 0.1 ~ 0.25 - - 0.2 ~ 0.5 0.1 ~ 0.2 -150 ~ 250 0.1 ~ 0.25 0.1 ~ 0.2 0.1 ~ 0.25 0.2 ~ 0.5 - -100 ~ 250 0.05 ~ 0.25 - 0.05 ~ 0.25 0.2 ~ 0.6 - -100 ~ 250 0.05 ~ 0.25 0.05 ~ 0.2 0.05 ~ 0.25 0.2 ~ 0.6 - -300 ~ 1000 - - - - - 0.05 ~ 0.280 ~ 300 - - - - - 0.05 ~ 0.2200 ~ 500 - - - - - 0.05 ~ 0.2Finishing (Cutting depth: ap < 1.0 mm)Work materals GradeCutting*Feed per tooth ft (mm/t)Choice speedVc (m/min) MJ ML without HJ MS AJMild steel AH120 I 100 ~ 270 0.05 ~ 0.25 0.05 ~ 0.2 0.05 ~ 0.25 0.2 ~ 0.6 - -Low alloyed steel T3030 II 150 ~ 300 0.05 ~ 0.25 - 0.05 ~ 0.25 0.2 ~ 0.6 - -St37, etc. AH140 III 80 ~ 180 0.05 ~ 0.25 - - - 0.05 ~ 0.2 -(< 180HB) NS740 IV 100 ~ 300 0.05 ~ 0.2 - 0.05 ~ 0.2 - - -Carbon steel AH120 I 100 ~ 230 0.05 ~ 0.2 0.05 ~ 0.15 0.05 ~ 0.2 0.2 ~ 0.5 - -Alloy steel T3030 II 150 ~ 280 0.05 ~ 0.2 - 0.05 ~ 0.2 0.2 ~ 0.5 - -Ck45, 42CrMo4, etc. AH140 III 80 ~ 150 0.05 ~ 0.2 - - 0.2 ~ 0.5 - -(< 300HB) NS740 IV 100 ~ 230 0.05 ~ 0.18 - 0.05 ~ 0.18 - - -Die & Prehardened steel AH120 I 100 ~ 180 0.05 ~ 0.18 0.05 ~ 0.12 0.05 ~ 0.18 0.2 ~ 0.4 - -X96CrMoV12, etc. T3030 II 100 ~ 180 0.05 ~ 0.18 - 0.05 ~ 0.18 0.2 ~ 0.4 - -(< 30HRC)Stainless steel AH140 I 80 ~ 200 0.1 ~ 0.2 - - 0.2 ~ 0.5 0.1 ~ 0.18 -(< 250HB) AH120 II 150 ~ 250 0.1 ~ 0.2 0.1 ~ 0.18 0.1 ~ 0.2 0.2 ~ 0.5 - -Grey cast iron T1015 I 100 ~ 250 0.1 ~ 0.2 - 0.1 ~ 0.2 0.2 ~ 0.6 - -Ductile cast iron AH120 III 100 ~ 250 0.1 ~ 0.2 0.05 ~ 0.18 0.1 ~ 0.2 0.2 ~ 0.6 - -Aluminium alloys KS05F I 300 ~ 1000 - - - - - 0.05 ~ 0.2(Si: 13 %)Copper alloys KS05F I 200 ~ 500 - - - - - 0.05 ~ 0.2Choice*I FirstII Wear-resistanceIII ToughnessIV Surface quality8

Cutting conditions <strong>TPW</strong> (90°)Roughing (Cutting depth: ap > 1.0 mm)Work materalsMild steelLow alloyed steelSt37, etc.(< 180HB)Carbon steelAlloy steelCk45, 42CrMo4, etc.(< 300HB)Die & Prehardened steelX96CrMoV12, etc.(< 30HRC)Stainless steel(< 250HB)Grey cast ironDuctile cast ironAluminium alloys(Si: < 12 %)Aluminium alloys(Si:>13%)Copper alloysGradeAH120T3030AH140NS740AH120T3030AH140NS740AH120T3030AH140AH120T1015AH120KS05FKS05FKS05FAH120T3030AH140NS740AH120T3030AH140NS740AH120T3030AH140AH120T1015AH120KS05FKS05FKS05F* ChoiceIIIIIIIVIIIIIIIVIIIIIIIIIIIFinishing (Cutting depth: ap < 1.0 mm)Work materalsMild steelLow alloyed steelSt37, etc.(< 180HB)Carbon steelAlloy steelCk45, 42CrMo4, etc.(< 300HB)Die & Prehardened steelX96CrMoV12, etc.(< 30HRC)Stainless steel(< 250HB)Grey cast ironDuctile cast ironAluminium alloys(Si: < 12 %)Aluminium alloys(Si: > 13 %)Copper alloysChoice*I FirstII Wear-resistanceIII ToughnessIV Surface qualityGradeII* ChoiceIIIIIIIVIIIIIIIVIIIIIIIIIIIIICuttingFeed per tooth ft (mm/t)speedVc (m/min) MJ ML MS AJ100 ~ 270 0.05 ~ 0.25 0.05 ~ 0.2 - -150 ~ 300 0.05 ~ 0.25 - - -80 ~ 180 0.05 ~ 0.25 - 0.05 ~ 0.2 -100 ~ 300 0.05 ~ 0.15 - - -100 ~ 230 0.05 ~ 0.2 0.05 ~ 0.15 - -150 ~ 280 0.05 ~ 0.2 - - -80 ~ 150 0.05 ~ 0.2 - - -100 ~ 230 0.05 ~ 0.15 - - -100 ~ 180 0.05 ~ 0.15 0.05 ~ 0.12 - -100 ~ 180 0.05 ~ 0.15 - - -80 ~ 200 0.05 ~ 0.2 - 0.05 ~ 0.18 -150 ~ 250 0.05 ~ 0.2 0.05 ~ 0.15 - -100 ~ 250 0.05 ~ 0.2 - - -100 ~ 250 0.05 ~ 0.2 0.05 ~ 0.15 - -300 ~ 1000 - - - 0.05 ~ 0.280 ~ 300 - - - 0.05 ~ 0.2200 ~ 500 - - - 0.05 ~ 0.2Cuttingspeed<strong>TAW</strong> & <strong>TPW</strong> <strong>Milling</strong> <strong>cutter</strong>Feed per tooth ft (mm/t)Vc (m/min) MJ ML MS AJ100 ~ 270 0.05 ~ 0.2 0.05 ~ 0.18 - -150 ~ 300 0.05 ~ 0.2 - - -80 ~ 180 0.05 ~ 0.2 - 0.05 ~ 0.18 -100 ~ 300 0.05 ~ 0.12 - - -100 ~ 230 0.05 ~ 0.18 0.05 ~ 0.12 - -150 ~ 280 0.05 ~ 0.18 - - -80 ~ 150 0.05 ~ 0.18 - - -100 ~ 230 0.05 ~ 0.12 - - -100 ~ 180 0.05 ~ 0.12 0.05 ~ 0.1 - -100 ~ 180 0.05 ~ 0.12 - - -80 ~ 200 0.05 ~ 0.18 - 0.05 ~ 0.15 -150 ~ 250 0.05 ~ 0.18 0.05 ~ 0.12 - -100 ~ 250 0.05 ~ 0.18 - - -100 ~ 250 0.05 ~ 0.18 0.05 ~ 0.12 - -300 ~ 1000 - - - 0.05 ~ 0.280 ~ 300 - - - 0.05 ~ 0.2200 ~ 500 - - - 0.05 ~ 0.29

<strong>TAW</strong> & <strong>TPW</strong> <strong>Milling</strong> <strong>cutter</strong>Nomenclature for TAC milling <strong>cutter</strong>NEWCode DescriptionT Shell typeE EndmillH TMS typeCodePEDARBXLVFCZGDescription0° (90°) ~ 10°10° ~ 20°30° ~ 40°40° ~ 50°for round insertBall endmillfor high feedLong cutting edgefor difficult-to-cut materialsfor finishingfor chamferingfor Z-feedfor counterboreCodeCPDEFN(W)Description7°11°15°20°25°90°SpecialRLDescriptionRightLeft <strong>Milling</strong> <strong>cutter</strong> type Relief angle / Applications Relief angleCutting edgeof insertlength (mm) Cutting directionCode T P W 13 R 050 M 22.0 E 04for exampleCode050063080100125160 Effective <strong>cutter</strong> ø System of unit Mounting hole Mounting type No. of insertsDescriptionø50 mmø63 mmø80 mmø100 mmø125 mmø160 mmCode Description Code Description Code Description Code DescriptionMUmminch22.027.032.040.0ø22 mmø27 mmø32 mmø40 mm-EA-WCJISDINANSIShank (cylinder)Shank (weldon)Shank (combination)04050607081012164567810121610

<strong>TAW</strong> & <strong>TPW</strong> <strong>Milling</strong> <strong>cutter</strong>Practical examplesFace milling<strong>Milling</strong> <strong>cutter</strong>:Insert:Grade:<strong>TAW</strong>13R100M32.0E10(ø 100, t = 10)SWMT13T3AFPR-HJAH120Work material: C45 (1.0503)Machine:<strong>Milling</strong> machineCutting speed: Vc = 250 m/minNo. of revolutions: n = 800 rpmFeed:Vf = 4000 mm/minFeed per tooth: ft = 0.5 mm/tCutting depth: ap = 2.0 mmCutting width: ae = 80 mmResult:Compared to machining with conventionaltools, machining time has beenreduced to only 22 %. Thus extremelyproductive tool life has been achieved.Face milling<strong>Milling</strong> <strong>cutter</strong>:Insert:Grade:Work material:Machine:Cutting speed:No. of revolutions:Feed:Feed per tooth:Cutting depth:Cutting width:<strong>TAW</strong>13R080M27.0E08(ø 80, t = 8)SWMT13T3AFPR-HJAH140X2CrNiMo17-13-2(1.4404)<strong>Milling</strong> machineVc = 180 m/minn = 716 rpmVf = 2577 mm/minft = 0.45 mm/tap = 1.5 mmae=52mmResult:Compared to conventional machiningwith HSS-<strong>cutter</strong> + further finishing operation,the complete machining processis very economically handled withjust one tool.Face milling of case flanges<strong>Milling</strong> <strong>cutter</strong>: <strong>TAW</strong>13R100M32.0E07(ø 100, t = 7)Insert:SWMT13T3AFPR-HJGrade:T3030Work material: St50 (1.0531)Machine:<strong>Milling</strong> machineCutting speed: Vc = 242 m/minNo. of revolutions: n = 770 rpmFeed:Vf = 3000 mm/minFeed per tooth: ft = 0.55 mm/tCutting depth: ap = 1.8 ~ 2.0 mmCutting width: ae = 82 mmCoolant:EmulsionResult:With the use of HJ chipbreaker, feedrate could be increased by 54 %, inspite of unstable working part conditions.Competitor also applies coatedcarbide inserts for this kind of machiningprocess.Face milling of pump case flanges<strong>Milling</strong> <strong>cutter</strong>: <strong>TAW</strong>13R063M22.0E06(ø 63, t = 6)Insert:SWMT13T3AFPR-HJGrade:AH120Work material: GG25Machine:<strong>Milling</strong> machineCutting speed: Vc = 250 m/minNo. of revolutions: n = 1260 rpmFeed:Vf = 3150 mm/minFeed per tooth: ft = 0.5 mm/tCutting depth: ap = 1.5 ~ 2.0 mmCutting width: ae=45mmCoolant:EmulsionResult:With the application of the HJ chipbreakerfor face milling operation ofpump case flanges, the machiningtime was reduced by 30 minutes. Feedrate was eight times that of our competitors.11

<strong>TAW</strong> & <strong>TPW</strong> <strong>Milling</strong> <strong>cutter</strong>Tungaloy Europe GmbHElisabeth-Selbert-Str. 3D - 40764 LangenfeldTel. +49 (0 21 73) 9 04 20 -0Fax +49 (0 21 73) 9 04 20 -18e-mail: info@tungaloy.dewww.tungaloy-eu.comTungaloy Italia S.p.A.Via E. Andolfato, 10I - 20126 MILANOTel. +39 (02) 25 20 12-1Fax +39 (02) 25 20 12-65e-mail: info@tungaloy.itwww.tungaloy-eu.comTungaloy France S.a.r.l.6, Avenue des AndesF - 91952 COURTABOEUF CEDEXTel. +33 (01) 64 86 43 00Fax +33 (01) 69 07 78 17e-mail: info@tungaloy.frwww.tungaloy-eu.comDistributed by:ISO 9001 certified ISO 14001 certifiedQC00J0056 EC97J112318/10/1996 26/11/1997Tungaloy Corporation Production Division,Tungaloy CorporationTE0407-E3

![HXL&VXL oil industry [Europe].indd - OSG](https://img.yumpu.com/30736963/1/184x260/hxlvxl-oil-industry-europeindd-osg.jpg?quality=85)