Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PRODUCT INFORMATION<br />

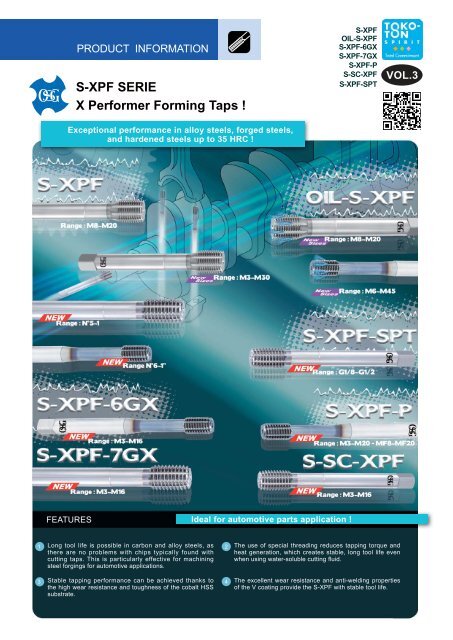

S-<strong>XPF</strong> SERIE<br />

X Performer Forming Taps !<br />

Exceptional performance in alloy steels, forged steels,<br />

and hardened steels up to 35 HRC !<br />

S-<strong>XPF</strong><br />

OIL-S-<strong>XPF</strong><br />

S-<strong>XPF</strong>-6GX<br />

S-<strong>XPF</strong>-7GX<br />

S-<strong>XPF</strong>-P<br />

S-SC-<strong>XPF</strong><br />

S-<strong>XPF</strong>-SPT<br />

VOL.3<br />

FEATURES<br />

Ideal for automotive parts application !<br />

1 Long tool life is possible in carbon and alloy steels, as<br />

there are no problems with chips typically found with<br />

cutting taps. This is particularly effective for machining<br />

steel forgings for automotive applications.<br />

2<br />

3 Stable tapping performance can be achieved thanks to 4<br />

the high wear resistance and toughness of the cobalt HSS<br />

substrate.<br />

The use of special threading reduces tapping torque and<br />

heat generation, which creates stable, long tool life even<br />

when using water-soluble cutting fl uid.<br />

The excellent wear resistance and anti-welding properties<br />

of the V coating provide the S-<strong>XPF</strong> with stable tool life.

INDEX<br />

TOOLS<br />

New Sizes<br />

New Sizes<br />

NEW<br />

NEW<br />

NEW<br />

NEW<br />

New Sizes<br />

NEW<br />

NEW<br />

NEW<br />

NEW<br />

NAME<br />

THREAD<br />

TYPE RANGE PAGE<br />

M<br />

S-<strong>XPF</strong> M 3 ~ M 30 4<br />

M<br />

OIL-S-<strong>XPF</strong> M 6 ~ M 45 5<br />

M<br />

S-<strong>XPF</strong>-6GX M 3 ~ M 16 6<br />

M<br />

S-<strong>XPF</strong>-7GX M 3 ~ M 16 7<br />

M<br />

S-<strong>XPF</strong>-P M 3 ~ M 20 8<br />

M<br />

S-SC-<strong>XPF</strong> M 3 ~ M 16 9<br />

MF<br />

S-<strong>XPF</strong> M 8 ~ M 20 10<br />

MF<br />

OIL-S-<strong>XPF</strong> M 8 ~ M 20 11<br />

MF<br />

S-<strong>XPF</strong>-P M 8 ~ M 20 12<br />

UNC<br />

S-<strong>XPF</strong> N° 5 ~ 1" 13<br />

UNF<br />

S-<strong>XPF</strong> N° 6 ~ 1" 14<br />

G<br />

S-<strong>XPF</strong>-SPT G 1/8 ~ G 1/2 15<br />

DIN 371<br />

1. Only M6 shanks have a male center.<br />

2. The proper drill hole size may change due to work material. Use the recommended drill hole<br />

size as a benchmark.<br />

3. As the hole diameter may vary by behavior of plasticity depending on the material, hardness<br />

and shapes of workpiece, the hole diameter should be determined through trial tapping prior to<br />

final machining.<br />

4. The drill hole size is for a 6H internal thread.<br />

5. TAP Limit does not guarantee thread limit for the internal thread after tapping.<br />

C0.%<br />

Cu<br />

0.5C0.4%<br />

BS<br />

ppcos weuge ppco ppcos ppo ppo pccoes <br />

0.45%<br />

BsC<br />

SCM<br />

PB<br />

55C<br />

Al<br />

545C<br />

AC,ADC<br />

DIN 374 DIN 376<br />

455C 1. The proper 5C drill hole size may SUSchange due SKD to work material. SC Use the recommended GG drill GGGhole<br />

size as a benchmark.<br />

2. As the hole diameter may vary by behavior of plasticity depending on the material, hardness<br />

and shapes of workpiece, the hole diameter should be determined through trial tapping prior<br />

to final machining.<br />

3. MC The drill hole ZDC size is for a 6H internal Ti thread. Ni<br />

Plast.<br />

Vinyl<br />

4. TAP Limit does not guarantee thread limit for the internal thread after tapping.<br />

2<br />

<strong>OSG</strong> Europe: www.osgeurope.com

Tapping torque has been reduced 30% compared to existing<br />

products!<br />

Tapping Torque<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

Characteritics and Instructions<br />

Torque Characteristics of S-<strong>XPF</strong> Taps<br />

S-<strong>XPF</strong><br />

Existing Product<br />

0<br />

0 1 2 3 4 5 6 7<br />

-10<br />

Instructions for use S-<strong>XPF</strong> & OIL-S-<strong>XPF</strong>.<br />

1. Check the forming condition in the same way as for<br />

conventional nu-roll taps.<br />

2. Highly lubricating water soluble or non-water soluble coolants<br />

are recommended.<br />

3. Use machines and toolholders with minimum runout.<br />

4. Cutting conditions may change depending on the strength of<br />

the work material, machines, and toolholders.<br />

5. The formed thread has a small slit at the crest.<br />

-20<br />

-30<br />

-40<br />

Time<br />

Applications for use S-<strong>XPF</strong> & OIL-S-<strong>XPF</strong>.<br />

*1 Please use a cutting fluid with high lubricity.<br />

Tool<br />

M12 × 1,5 DIN374<br />

Work Material Tapping Speed Ideal ◎ Good ○<br />

Work Material SCM440 (30HRC)<br />

Hole Size<br />

Dia. 11,3×25mm<br />

(Through)<br />

Tapping Length<br />

18mm (1,5D)<br />

(Blind)<br />

Tapping Speed 10m/min (265min -1 )<br />

Coolant Water Soluble (10%)<br />

Medium Carbon Steels<br />

C≤0.4% 15~30 ◎<br />

High Carbon Steels<br />

C≥0.45% 15~30 ◎<br />

Alloy Steels<br />

SCM 15~30 ◎<br />

Hardened Steels<br />

25~35HRC<br />

5~20 ◎<br />

Machine<br />

Vertical Machining Center<br />

Stainless Steels<br />

SUS 5~15 ○ *1<br />

Applications and Machining Examples for S-<strong>XPF</strong> Taps<br />

Applications and Machining Examples for OIL-S-<strong>XPF</strong> Taps<br />

■ Applications<br />

Tensile<br />

strength<br />

Hardness<br />

S-<strong>XPF</strong><br />

200 300 400 500 600 700 800 900 1,000 1,100 1,200 (N/mm2)<br />

0 10 15 20 25 30 35 40<br />

■ Machining Examples<br />

S-<strong>XPF</strong> Taps are able to achieve stable tapping even in alloy<br />

steels (30HRC) with water soluble fluid.<br />

(HRC)<br />

■ Applications<br />

OIL-S-<strong>XPF</strong><br />

Tensile<br />

strength<br />

200 300 400 500 600 700 800 900 1,000 1,100 1,200<br />

(N/mm2)<br />

Hardness<br />

0 10 15 20 25 30 35 40<br />

(HRC)<br />

■ Machining Examples<br />

OIL-S-<strong>XPF</strong> Taps are able to achieve stable tapping even in alloy<br />

steels (30HRC) with water soluble fluid.<br />

Tool<br />

M14×1,5 DIN374<br />

Tool<br />

M8X1 6HX blind hole<br />

Work Material<br />

SCM440 (30HRC)<br />

Work Material<br />

42CrM04 (35HRC)<br />

Hole Size Dia. 13,3×25 (Through)<br />

Tapping Length 20mm (1,5D) (Blind)<br />

Hole Size 7,55 x 26<br />

Tapping Length 20,4mm (Blind)<br />

Tapping Speed 15m/min (341min -1 )<br />

Coolant Water Soluble (20)<br />

Tapping Speed<br />

Coolant<br />

12m/min<br />

Non water base lubricant<br />

Machine<br />

Vertical Machining Center<br />

Machine<br />

Vertical Machining Center<br />

S-<strong>XPF</strong><br />

1.354(Holes)<br />

GP-OUT<br />

OIL-S-<strong>XPF</strong><br />

6.100(Holes)<br />

ppcos weuge ppco ppcos ppo ppo pccoes <br />

Competitor A<br />

C0.%<br />

511(Holes)<br />

0.5C0.4% C0.45%<br />

SCM<br />

Rubbing noise<br />

55C 545C<br />

455C<br />

5C<br />

Competitor<br />

SUS<br />

1.800(Holes) SKD<br />

SC<br />

GG<br />

GGG<br />

Competitor B<br />

760(Holes)<br />

GP-OUT<br />

Cu<br />

BS<br />

BsC<br />

500<br />

PB<br />

Al<br />

1.000<br />

Tapping Holes<br />

AC,ADC<br />

MC<br />

1.500<br />

(Holes)<br />

ZDC<br />

Ti<br />

Ni<br />

2.000 4.000<br />

Tapping Holes<br />

Plast.<br />

6.000<br />

Vinyl<br />

8.000 10.000<br />

(Holes)<br />

<strong>OSG</strong> Europe: www.osgeurope.com<br />

3

S-<strong>XPF</strong><br />

METRIC<br />

METRISCH METRICO MÉTRIQUE<br />

M<br />

NEW<br />

sizes<br />

High performance forming<br />

tap<br />

Hochleistungsgewindeformer<br />

Maschio a rullare ad alta<br />

performance<br />

Taraud à refoulé à<br />

haute performance<br />

M<br />

METRISK METRISK<br />

METRICO <br />

High Performance rulletap<br />

High performance<br />

pressgängtapp<br />

Alta prestaciones,<br />

macho de laminación<br />

<br />

<br />

M<br />

HSS-Co<br />

V<br />

ISO 2<br />

6HX<br />

2<br />

d<br />

a<br />

DIN<br />

371<br />

l1<br />

L<br />

New Sizes<br />

New Sizes<br />

New Sizes<br />

EDP M P L l1 d a Drill Hole Size Z∆ Stock Price<br />

48030138 3 0,5 56 18 3,5 3,5 2,77 ~ 2,81 4 ●<br />

48030144 4 0,7 63 21 4,5 4,5 3,66 ~ 3,72 4 ●<br />

48030149 5 0,8 70 25 6,0 6,0 4,61 ~ 4,68 5 ●<br />

48030155 6 1 80 30 6,0 4,9 5,51 ~ 5,59 5 ●<br />

48030161 8 1,25 90 35 8,0 6,2 7,37 ~ 7,45 5 ●<br />

48030169 10 1,5 100 39 10,0 8,0 9,24 ~ 9,33 8 ●<br />

M<br />

HSS-Co<br />

V<br />

ISO 2<br />

6HX<br />

2<br />

d<br />

a<br />

DIN<br />

376<br />

l<br />

L<br />

<br />

<br />

New Sizes<br />

New Sizes<br />

New Sizes<br />

New Sizes<br />

New Sizes<br />

New<br />

EDP M P L l d a Drill Hole Size Z∆ Stock Price<br />

48030179 12 1,75 110 17 9 7 11,1 ~ 11,2 8 ●<br />

48030191 14 2 110 20 11 9 12,96 ~ 13,08 8 ●<br />

48030202 16 2 110 20 12 9 14,96 ~ 15,08 8 ●<br />

48069214 18 2,5 125 20 14 11 16,66 ~ 16,81 8 ●<br />

48069228 20 2,5 140 20 16 12 18,66 ~ 18,81 8 ●<br />

48069238 22 2,5 140 20 18 14,5 20,66 ~ 20,81 8 ●<br />

48069247 24 3 160 24 18 14,5 22,39 ~ 22,56 8 ●<br />

48069262 27 3 160 18 20 16 25,39 ~ 25,56 8 ●<br />

48069271 30 3,5 180 21 22 18 28,09 ~ 28,28 8 ●<br />

ppcos weuge ppco ppcos ppo ppo pccoes <br />

C0.%<br />

15~40<br />

m/min<br />

Sizes<br />

5~20<br />

Number of fl utes - Anzahl Schneiden - Numero di denti - Nombre de lèvres<br />

Z∆=<br />

Antal skær - Antal skär - Numero de ranuras - Число режущих кромок<br />

0.5C0.4%<br />

15~40<br />

m/min<br />

0.45%<br />

15~30<br />

m/min<br />

SCM<br />

15~30<br />

m/min<br />

55C<br />

m/min<br />

545C<br />

455C<br />

5C<br />

SUS<br />

8~20<br />

m/min<br />

SKD<br />

SC<br />

15~40<br />

m/min<br />

GG<br />

GGG<br />

Cu<br />

10~30<br />

m/min<br />

BS<br />

10~30<br />

m/min<br />

BsC<br />

10~30<br />

m/min<br />

PB<br />

Al<br />

20~50<br />

m/min<br />

AC,ADC<br />

20~40<br />

m/min<br />

MC<br />

ZDC<br />

10~30<br />

m/min<br />

Ti<br />

Ni<br />

Plast.<br />

Vinyl<br />

4<br />

<strong>OSG</strong> Europe: www.osgeurope.com<br />

● Delivery from stock<br />

○ Available on short notice

OIL-S-<strong>XPF</strong><br />

METRIC<br />

METRISCH METRICO MÉTRIQUE<br />

M<br />

NEW<br />

sizes<br />

High performance forming<br />

tap<br />

Hochleistungsgewindeformer<br />

Maschio a rullare ad alta<br />

performance<br />

Taraud à refoulé à<br />

haute performance<br />

M<br />

METRISK METRISK<br />

METRICO <br />

High Performance rulletap<br />

High performance<br />

pressgängtapp<br />

Alta prestaciones,<br />

macho de laminación<br />

<br />

<br />

M<br />

HSS-Co<br />

V<br />

ISO 2<br />

6HX<br />

2<br />

d<br />

a<br />

DIN<br />

371<br />

l1<br />

L<br />

EDP M P L l1 d a Drill Hole Size Z∆ Stock Price<br />

48042155 6 1 80 30 6 4,9 5,51 ~ 5,59 5 ●<br />

48042161 8 1,25 90 35 8 6,2 7,37 ~ 7,45 5 ●<br />

48042169 10 1,5 100 39 10 8,0 9,24 ~ 9,33 8 ●<br />

M<br />

HSS-Co<br />

V<br />

ISO 2<br />

6HX<br />

2<br />

d<br />

a<br />

DIN<br />

376<br />

l<br />

L<br />

<br />

<br />

New Sizes<br />

New Sizes<br />

New Sizes<br />

New Sizes<br />

New Sizes<br />

New Sizes<br />

New Sizes<br />

New Sizes<br />

New Sizes<br />

New Sizes<br />

New Sizes<br />

EDP M P L l d a Drill Hole Size Z∆ Stock Price<br />

48042179 12 1,75 110 17 9 7 11,1 ~ 11,2 8 ●<br />

48042191 14 2 110 20 11 9 12,96 ~ 13,08 8 ●<br />

48042202 16 2 110 20 12 9 14,96 ~ 15,08 8 ●<br />

48071214 18 2,5 125 20 14 11 16,66 ~ 16,81 8 ●<br />

48071228 20 2,5 140 20 16 12 18,66 ~ 18,81 8 ●<br />

48071238 22 2,5 140 20 18 14,5 20,66 ~ 20,81 8 ●<br />

48071247 24 3 160 24 18 14,5 22,39 ~ 22,56 8 ●<br />

48071262 27 3 160 18 20 16 25,39 ~ 25,56 8 ●<br />

48071271 30 3,5 180 21 22 18 28,09 ~ 28,28 8 ●<br />

48071281 33 3,5 180 21 25 20 31,09 ~ 31,28 8 ○<br />

48071294 36 4 200 24 28 22 33,80 ~ 34,01 8 ○<br />

48071304 39 4 200 24 32 24 36,80 ~ 37,01 9 ○<br />

48071314 42 4,5 200 27 32 24 39,52 ~ 39,73 9 ○<br />

48071319 45 4,5 220 27 36 29 42,52 ~ 42,73 9 ○<br />

Number of fl utes - Anzahl Schneiden - Numero di denti - Nombre de lèvres<br />

Z∆=<br />

Antal skær - Antal skär - Numero de ranuras - Число режущих кромок<br />

ppcos weuge ppco ppcos ppo ppo pccoes <br />

C0.%<br />

0.5C0.4%<br />

C0.45%<br />

SCM<br />

55C<br />

545C<br />

455C<br />

5C<br />

SUS<br />

SKD<br />

SC<br />

GG<br />

GGG<br />

15~40<br />

m/min<br />

15~40<br />

m/min<br />

15~30<br />

m/min<br />

15~30<br />

m/min<br />

5~20<br />

m/min<br />

8~20<br />

m/min<br />

15~40<br />

m/min<br />

Cu<br />

BS<br />

BsC<br />

PB<br />

Al<br />

AC,ADC<br />

MC<br />

ZDC<br />

Ti<br />

Ni<br />

Plast.<br />

Vinyl<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

20~50<br />

m/min<br />

20~40<br />

m/min<br />

10~30<br />

m/min<br />

<strong>OSG</strong> Europe: www.osgeurope.com<br />

● Delivery from stock<br />

○ Available on short notice<br />

5

S-<strong>XPF</strong>-6GX<br />

METRIC<br />

METRISCH METRICO MÉTRIQUE<br />

High performance forming<br />

tap<br />

Hochleistungsgewindeformer<br />

Maschio a rullare ad alta<br />

performance<br />

Taraud à refoulé à<br />

haute performance<br />

M<br />

NEW<br />

M<br />

METRISK METRISK<br />

METRICO <br />

High Performance rulletap<br />

High performance<br />

pressgängtapp<br />

Alta prestaciones,<br />

macho de laminación<br />

сокороиоиеле<br />

ке меики<br />

M<br />

HSS-Co<br />

V<br />

ISO 2<br />

6GX<br />

2<br />

d<br />

a<br />

DIN<br />

371<br />

l1<br />

L<br />

EDP M P L l1 d a Drill Hole Size Z∆ Stock Price<br />

48086138 3 0,5 56 18 3,5 3,5 2,79 ~ 2,82 4 ●<br />

48086144 4 0,7 63 21 4,5 4,5 3,69 ~ 3,75 4 ●<br />

48086149 5 0,8 70 25 6 6 4,64 ~ 4,71 5 ●<br />

48086155 6 1 80 30 6 4,9 5,55 ~ 5,63 5 ●<br />

48086161 8 1,25 90 35 8 6,2 7,40 ~ 7,47 5 ●<br />

48086169 10 1,50 100 39 10 8 9,26 ~ 9,35 8 ●<br />

M<br />

HSS-Co<br />

V<br />

ISO 2<br />

6GX<br />

2<br />

d<br />

a<br />

DIN<br />

376<br />

l<br />

L<br />

<br />

<br />

EDP M P L l d a Drill Hole Size Z∆ Stock Price<br />

48086179 12 1,75 110 17 9 7 11,14 ~ 11,24 8 ●<br />

48086191 14 2 110 17 11 9 13,00 ~ 13,12 8 ●<br />

48086202 16 2 110 20 12 9 15,00 ~ 15,12 8 ●<br />

Number of fl utes - Anzahl Schneiden - Numero di denti - Nombre de lèvres<br />

Z∆=<br />

Antal skær - Antal skär - Numero de ranuras - Число режущих кромок<br />

ppcos weuge ppco ppcos ppo ppo pccoes <br />

C0.%<br />

0.5C0.4%<br />

C0.45%<br />

SCM<br />

55C<br />

545C<br />

455C<br />

5C<br />

SUS<br />

SKD<br />

SC<br />

GG<br />

GGG<br />

15~40<br />

m/min<br />

15~40<br />

m/min<br />

15~30<br />

m/min<br />

15~30<br />

m/min<br />

5~20<br />

m/min<br />

8~20<br />

m/min<br />

15~40<br />

m/min<br />

Cu<br />

BS<br />

BsC<br />

PB<br />

Al<br />

AC,ADC<br />

MC<br />

ZDC<br />

Ti<br />

Ni<br />

Plast.<br />

Vinyl<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

20~50<br />

m/min<br />

20~40<br />

m/min<br />

10~30<br />

m/min<br />

6<br />

<strong>OSG</strong> Europe: www.osgeurope.com<br />

● Delivery from stock<br />

○ Available on short notice

S-<strong>XPF</strong>-7GX<br />

METRIC<br />

METRISCH METRICO MÉTRIQUE<br />

High performance forming<br />

tap<br />

Hochleistungsgewindeformer<br />

Maschio a rullare ad alta<br />

performance<br />

Taraud à refoulé à<br />

haute performance<br />

M<br />

NEW<br />

M<br />

METRISK METRISK<br />

METRICO <br />

High Performance rulletap<br />

High performance<br />

pressgängtapp<br />

Alta prestaciones,<br />

macho de laminación<br />

сокороиоиеле<br />

ке меики<br />

M<br />

HSS-Co<br />

V<br />

ISO 2<br />

7GX<br />

2<br />

d<br />

a<br />

DIN<br />

371<br />

l1<br />

L<br />

EDP M P L l1 d a Drill Hole Size Z∆ Stock Price<br />

48087138 3 0,5 56 18 3,5 3,5 2,81 ~ 2,85 4 ●<br />

48087144 4 0,7 63 21 4,5 4,5 3,71 ~ 3,77 4 ●<br />

48087149 5 0,8 70 25 6 6 4,66 ~ 4,73 5 ●<br />

48087155 6 1 80 30 6 4,9 5,56 ~ 5,64 5 ●<br />

48087161 8 1,25 90 35 8 6,2 7,42 ~ 7,50 5 ●<br />

48087169 10 1,50 100 39 10 8 9,30 ~ 9,39 8 ●<br />

M<br />

HSS-Co<br />

V<br />

ISO 2<br />

7GX 2<br />

d<br />

a<br />

DIN<br />

376<br />

l<br />

L<br />

<br />

<br />

EDP M P L l d a Drill Hole Size Z∆ Stock Price<br />

48087179 12 1,75 110 17 9 7 11,17 ~ 11,28 8 ●<br />

48087191 14 2 110 20 11 9 13,04 ~ 13,16 8 ●<br />

48087202 16 2 110 20 12 9 15,04 ~ 15,16 8 ●<br />

Number of fl utes - Anzahl Schneiden - Numero di denti - Nombre de lèvres<br />

Z∆=<br />

Antal skær - Antal skär - Numero de ranuras - Число режущих кромок<br />

ppcos weuge ppco ppcos ppo ppo pccoes <br />

C0.%<br />

0.5C0.4%<br />

C0.45%<br />

SCM<br />

55C<br />

545C<br />

455C<br />

5C<br />

SUS<br />

SKD<br />

SC<br />

GG<br />

GGG<br />

15~40<br />

m/min<br />

15~40<br />

m/min<br />

15~30<br />

m/min<br />

15~30<br />

m/min<br />

5~20<br />

m/min<br />

8~20<br />

m/min<br />

15~40<br />

m/min<br />

Cu<br />

BS<br />

BsC<br />

PB<br />

Al<br />

AC,ADC<br />

MC<br />

ZDC<br />

Ti<br />

Ni<br />

Plast.<br />

Vinyl<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

20~50<br />

m/min<br />

20~40<br />

m/min<br />

10~30<br />

m/min<br />

<strong>OSG</strong> Europe: www.osgeurope.com<br />

● Delivery from stock<br />

○ Available on short notice<br />

7

S-<strong>XPF</strong>-P<br />

METRIC<br />

METRISCH METRICO MÉTRIQUE<br />

High performance forming<br />

tap<br />

Hochleistungsgewindeformer<br />

Maschio a rullare ad alta<br />

performance<br />

Taraud à refoulé à<br />

haute performance<br />

M<br />

NEW<br />

4P chamfer<br />

4 Gang. Anschnittlänge<br />

4 filleti<br />

4 entrée gun<br />

M<br />

METRISK METRISK<br />

METRICO ETPECK<br />

High Performance rulletap<br />

High performance<br />

pressgängtapp<br />

Alta prestaciones,<br />

macho de laminación<br />

сокороиоиеле<br />

кемеики<br />

4 x stigning på opløb<br />

4 x stigning<br />

4 pasos<br />

4 <br />

M<br />

HSS-Co<br />

V<br />

ISO 2<br />

6HX<br />

4<br />

d<br />

a<br />

DIN<br />

371<br />

l1<br />

L<br />

EDP M P L l1 d a Drill Hole Size Z∆ Stock Price<br />

48088138 3 0,5 56 18 3,5 3,5 2,77~2,81 4 ●<br />

48088144 4 0,7 63 21 4,5 4,5 3,66~3,72 4 ●<br />

48088149 5 0,8 70 25 6 6 4,61~4,68 5 ●<br />

48088155 6 1 80 30 6 4,9 5,51~5,59 5 ●<br />

48088161 8 1,25 90 35 8 6,2 7,37~7,45 5 ●<br />

48088169 10 1,50 100 39 10 8 9,24~9,33 8 ●<br />

M<br />

HSS-Co<br />

V<br />

ISO 2<br />

6HX 4<br />

d<br />

a<br />

DIN<br />

376<br />

l<br />

L<br />

<br />

<br />

EDP M P L l d a Drill Hole Size Z∆ Stock Price<br />

48088179 12 1,75 110 17 9 7 11,1~11,2 8 ●<br />

48088191 14 2 110 20 11 9 12,96~13,08 8 ●<br />

48088202 16 2 110 20 12 9 14,96~15,08 8 ●<br />

Number of fl utes - Anzahl Schneiden - Numero di denti - Nombre de lèvres<br />

Z∆=<br />

Antal skær - Antal skär - Numero de ranuras - Число режущих кромок<br />

ppcos weuge ppco ppcos ppo ppo pccoes <br />

C0.%<br />

0.5C0.4%<br />

C0.45%<br />

SCM<br />

55C<br />

545C<br />

455C<br />

5C<br />

SUS<br />

SKD<br />

SC<br />

GG<br />

GGG<br />

15~40<br />

m/min<br />

15~40<br />

m/min<br />

15~30<br />

m/min<br />

15~30<br />

m/min<br />

5~20<br />

m/min<br />

8~20<br />

m/min<br />

15~40<br />

m/min<br />

Cu<br />

BS<br />

BsC<br />

PB<br />

Al<br />

AC,ADC<br />

MC<br />

ZDC<br />

Ti<br />

Ni<br />

Plast.<br />

Vinyl<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

20~50<br />

m/min<br />

20~40<br />

m/min<br />

10~30<br />

m/min<br />

8<br />

<strong>OSG</strong> Europe: www.osgeurope.com<br />

● Delivery from stock<br />

○ Available on short notice

S-SC-<strong>XPF</strong><br />

METRIC<br />

METRISCH METRICO MÉTRIQUE<br />

High performance forming<br />

tap<br />

Hochleistungsgewindeformer<br />

Maschio a rullare ad alta<br />

performance<br />

Taraud à refoulé à<br />

haute performance<br />

M<br />

NEW<br />

Short chamfer<br />

kurzer Anschnitt<br />

Imbocco corto<br />

Entrée courte<br />

M<br />

METRISK METRISK<br />

METRICO ETECK<br />

High Performance rulletap<br />

High performance<br />

pressgängtapp<br />

Alta prestaciones,<br />

macho de laminación<br />

сокороиоиеле<br />

кемеики<br />

Kort indløb<br />

Kort faslängd<br />

Chaflán corto<br />

<br />

M<br />

HSS-Co<br />

V<br />

ISO 2<br />

6HX<br />

1,5<br />

d<br />

a<br />

DIN<br />

371<br />

l1<br />

L<br />

EDP M P L l1 d a Drill Hole Size Z∆ Stock Price<br />

48089138 3 0,5 56 18 3,5 3,5 2,77~2,81 4 ●<br />

48089144 4 0,7 63 21 4,5 4,5 3,66~3,72 4 ●<br />

48089149 5 0,8 70 25 6 6 4,61~4,68 5 ●<br />

48089155 6 1 80 30 6 4,9 5,51~5,59 5 ●<br />

48089161 8 1,25 90 35 8 6,2 7,37~7,45 5 ●<br />

48089169 10 1,50 100 39 10 8 9,24~9,33 8 ●<br />

M<br />

HSS-Co<br />

V<br />

ISO 2<br />

6HX 1,5<br />

d<br />

a<br />

DIN<br />

376<br />

l<br />

L<br />

<br />

<br />

EDP M P L l d a Drill Hole Size Z∆ Stock Price<br />

48089179 12 1,75 110 17 9 7 11,1~11,2 8 ●<br />

48089191 14 2 110 20 11 9 12,96~13,08 8 ●<br />

48089202 16 2 110 20 12 9 14,96~15,08 8 ●<br />

Number of fl utes - Anzahl Schneiden - Numero di denti - Nombre de lèvres<br />

Z∆=<br />

Antal skær - Antal skär - Numero de ranuras - Число режущих кромок<br />

ppcos weuge ppco ppcos ppo ppo pccoes <br />

C0.%<br />

0.5C0.4%<br />

C0.45%<br />

SCM<br />

55C<br />

545C<br />

455C<br />

5C<br />

SUS<br />

SKD<br />

SC<br />

GG<br />

GGG<br />

15~40<br />

m/min<br />

15~40<br />

m/min<br />

15~30<br />

m/min<br />

15~30<br />

m/min<br />

5~20<br />

m/min<br />

8~20<br />

m/min<br />

15~40<br />

m/min<br />

Cu<br />

BS<br />

BsC<br />

PB<br />

Al<br />

AC,ADC<br />

MC<br />

ZDC<br />

Ti<br />

Ni<br />

Plast.<br />

Vinyl<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

20~50<br />

m/min<br />

20~40<br />

m/min<br />

10~30<br />

m/min<br />

<strong>OSG</strong> Europe: www.osgeurope.com<br />

● Delivery from stock<br />

○ Available on short notice<br />

9

S-<strong>XPF</strong><br />

METRIC FINE<br />

METRISC FEIN METRICO FINE MÉTRIQUE FIN<br />

High performance forming<br />

tap<br />

Hochleistungsgewindeformer<br />

Maschio a rullare ad alta<br />

performance<br />

Taraud à refoulé à<br />

haute performance<br />

MF<br />

MF<br />

METRISK FINGEVIND METRISK FIN<br />

METRICO FINO COK<br />

High Performance rulletap<br />

High performance<br />

pressgängtapp<br />

Alta prestaciones,<br />

macho de laminación<br />

OOTEOCT<br />

<br />

<br />

MF<br />

HSS-Co<br />

V<br />

ISO 2<br />

6HX<br />

DIN<br />

374<br />

2<br />

l<br />

L<br />

d<br />

a<br />

EDP MF P L l d a Drill Hole Size Z∆ Stock Price<br />

48030162 8 1 90 10 6 4,9 7,51 ~ 7,59 5 ●<br />

48030171 10 1 90 12 7 5,5 9,51 ~ 9,59 8 ●<br />

48030170 10 1,25 100 12 7 5,5 9,37 ~ 9,45 8 ●<br />

48030182 12 1 100 15 9 7,0 11,52 ~ 11,6 8 ●<br />

48030181 12 1,25 100 15 9 7,0 11,39 ~ 11,46 8 ●<br />

48030180 12 1,5 100 15 9 7,0 11,25 ~ 11,34 8 ●<br />

48030192 14 1,5 100 15 11 9,0 13,25 ~ 13,34 8 ●<br />

48030203 16 1,5 100 15 12 9,0 15,25 ~ 15,34 8 ●<br />

48030216 18 1,5 110 15 14 11 17,25 ~ 17,34 8 ●<br />

48030230 20 1,5 125 15 16 12 19,25 ~ 19,34 8 ●<br />

Number of fl utes - Anzahl Schneiden - Numero di denti - Nombre de lèvres<br />

Z∆=<br />

Antal skær - Antal skär - Numero de ranuras - Число режущих кромок<br />

ppcos weuge ppco ppcos ppo ppo pccoes <br />

C0.%<br />

15~40<br />

m/min<br />

0.5C0.4%<br />

15~40<br />

m/min<br />

C0.45%<br />

15~30<br />

m/min<br />

SCM<br />

15~30<br />

m/min<br />

55C<br />

5~20<br />

m/min<br />

545C<br />

455C<br />

5C<br />

SUS<br />

8~20<br />

m/min<br />

SKD<br />

SC<br />

15~40<br />

m/min<br />

GG<br />

GGG<br />

Cu<br />

BS<br />

BsC<br />

PB<br />

Al<br />

AC,ADC<br />

MC<br />

ZDC<br />

Ti<br />

Ni<br />

Plast.<br />

Vinyl<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

20~50<br />

m/min<br />

20~40<br />

m/min<br />

10~30<br />

m/min<br />

10<br />

<strong>OSG</strong> Europe: www.osgeurope.com<br />

● Delivery from stock<br />

○ Available on short notice

OIL-S-<strong>XPF</strong><br />

METRIC FINE<br />

METRISC FEIN METRICO FINE MÉTRIQUE FIN<br />

MF<br />

NEW<br />

sizes<br />

High performance forming<br />

tap<br />

Hochleistungsgewindeformer<br />

Maschio a rullare ad alta<br />

performance<br />

Taraud à refoulé à<br />

haute performance<br />

MF<br />

METRISK FINGEVIND METRISK FIN<br />

METRICO FINO COK<br />

High Performance rulletap<br />

High performance<br />

pressgängtapp<br />

Alta prestaciones,<br />

macho de laminación<br />

OOTEOCT<br />

<br />

<br />

MF<br />

HSS-Co<br />

V<br />

ISO 2<br />

6HX<br />

2<br />

DIN<br />

374<br />

l<br />

L<br />

d<br />

a<br />

New Sizes<br />

EDP MF P L l d a Drill Hole Size Z∆ Stock Price<br />

48042162 8 1 90 10 6 4,9 7,51 ~ 7,59 5 ●<br />

48042171 10 1 90 12 7 5,5 9,51 ~ 9,59 8 ●<br />

48042170 10 1,25 100 12 7 5,5 9,37 ~ 9,45 8 ●<br />

48042181 12 1,25 100 15 9 7,0 11,39 ~ 11,46 8 ●<br />

48042180 12 1,5 100 15 9 7,0 11,25 ~ 11,34 8 ●<br />

48042192 14 1,5 100 15 11 9,0 13,25 ~ 13,34 8 ●<br />

48042203 16 1,5 100 15 12 9,0 15,25 ~ 15,34 8 ●<br />

48042216 18 1,5 110 15 14 11,0 17,25 ~ 17,34 8 ●<br />

48071230 20 1,5 125 15 16 12,0 19,25 ~ 19,34 8 ●<br />

Number of fl utes - Anzahl Schneiden - Numero di denti - Nombre de lèvres<br />

Z∆=<br />

Antal skær - Antal skär - Numero de ranuras - Число режущих кромок<br />

ppcos weuge ppco ppcos ppo ppo pccoes <br />

C0.%<br />

0.5C0.4%<br />

C0.45%<br />

SCM<br />

55C<br />

545C<br />

455C<br />

5C<br />

SUS<br />

SKD<br />

SC<br />

GG<br />

GGG<br />

15~40<br />

m/min<br />

15~40<br />

m/min<br />

15~30<br />

m/min<br />

15~30<br />

m/min<br />

5~20<br />

m/min<br />

8~20<br />

m/min<br />

15~40<br />

m/min<br />

Cu<br />

BS<br />

BsC<br />

PB<br />

Al<br />

AC,ADC<br />

MC<br />

ZDC<br />

Ti<br />

Ni<br />

Plast.<br />

Vinyl<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

20~50<br />

m/min<br />

20~40<br />

m/min<br />

10~30<br />

m/min<br />

<strong>OSG</strong> Europe: www.osgeurope.com<br />

● Delivery from stock<br />

○ Available on short notice<br />

11

S-<strong>XPF</strong>-P<br />

METRIC<br />

METRISCH METRICO MÉTRIQUE<br />

High performance forming<br />

tap<br />

Hochleistungsgewindeformer<br />

Maschio a rullare ad alta<br />

performance<br />

Taraud à refoulé à<br />

haute performance<br />

MF<br />

NEW<br />

4P chamfer<br />

4 Gang. Anschnittlänge<br />

4 filleti<br />

4 entrée gun<br />

MF<br />

METRISK METRISK<br />

METRICO ETPECK<br />

High Performance rulletap<br />

High performance<br />

pressgängtapp<br />

Alta prestaciones,<br />

macho de laminación<br />

<br />

<br />

4 x stigning på opløb<br />

4 x stigning<br />

4 pasos<br />

4 <br />

MF<br />

HSS-Co<br />

V<br />

ISO 2<br />

6HX<br />

4<br />

d<br />

DIN<br />

374<br />

l<br />

L<br />

a<br />

EDP MF P L l d a Drill Hole Size Z∆ Stock Price<br />

48088162 8 1 90 10 6 4,9 7,51 ~ 7,59 5 ●<br />

48088171 10 1 90 12 7 5,5 9,51 ~ 9,59 8 ●<br />

48088170 10 1,25 100 12 7 5,5 9,37 ~ 9,45 8 ●<br />

48088182 12 1 100 15 9 7,0 11,52 ~ 11,6 8 ●<br />

48088181 12 1,25 100 15 9 7,0 11,39 ~ 11,46 8 ●<br />

48088180 12 1,5 100 15 9 7,0 11,25 ~ 11,34 8 ●<br />

48088192 14 1,5 100 15 11 9,0 13,25 ~ 13,34 8 ●<br />

48088203 16 1,5 100 15 12 9,0 15,25 ~ 15,34 8 ●<br />

48088216 18 1,5 110 15 14 11 17,25 ~ 17,34 8 ●<br />

48088230 20 1,5 125 15 16 12 19,25 ~ 19,34 8 ●<br />

Number of fl utes - Anzahl Schneiden - Numero di denti - Nombre de lèvres<br />

Z∆=<br />

Antal skær - Antal skär - Numero de ranuras - Число режущих кромок<br />

ppcos weuge ppco ppcos ppo ppo pccoes <br />

C0.%<br />

0.5C0.4%<br />

C0.45%<br />

SCM<br />

55C<br />

545C<br />

455C<br />

5C<br />

SUS<br />

SKD<br />

SC<br />

GG<br />

GGG<br />

15~40<br />

m/min<br />

15~40<br />

m/min<br />

15~30<br />

m/min<br />

15~30<br />

m/min<br />

5~20<br />

m/min<br />

8~20<br />

m/min<br />

15~40<br />

m/min<br />

Cu<br />

BS<br />

BsC<br />

PB<br />

Al<br />

AC,ADC<br />

MC<br />

ZDC<br />

Ti<br />

Ni<br />

Plast.<br />

Vinyl<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

20~50<br />

m/min<br />

20~40<br />

m/min<br />

10~30<br />

m/min<br />

12<br />

<strong>OSG</strong> Europe: www.osgeurope.com<br />

● Delivery from stock<br />

○ Available on short notice

S-<strong>XPF</strong><br />

UNC<br />

UNC UNC UNC<br />

High performance forming<br />

tap<br />

Hochleistungsgewindeformer<br />

Maschio a rullare ad alta<br />

performance<br />

Taraud à refoulé à<br />

haute performance<br />

UNC<br />

NEW<br />

UNC<br />

UNC UNC<br />

UNC UNC<br />

High Performance rulletap<br />

High performance<br />

pressgängtapp<br />

Alta prestaciones,<br />

macho de laminación<br />

сокороиоиеле<br />

ке меики<br />

UNC<br />

HSS-Co<br />

V<br />

ANSI<br />

2BX<br />

2<br />

d<br />

a<br />

DIN<br />

2182<br />

l1<br />

L<br />

EDP UNC P L l1 d a Drill Hole Size Z∆ Stock Price<br />

48091459 5 40 56 18 3,5 2,7 2,86 ~ 2,93 4 ●<br />

48091461 6 32 56 20 4 3 3,09 ~ 3,17 4 ●<br />

48091464 8 32 63 21 4,5 3,4 3,76 ~ 3,84 4 ●<br />

48091466 10 24 70 25 6 4,9 4,26 ~ 4,35 5 ●<br />

48091471 1/4 20 80 30 7 5,5 5,66 ~ 5,76 5 ●<br />

48091474 5/16 18 90 35 8 6,2 7,18 ~ 7,29 5 ●<br />

48091479 3/8 16 90 35 9 7 8,66 ~ 8,78 8 ●<br />

UNC<br />

HSS-Co<br />

V<br />

ANSI<br />

2BX<br />

2<br />

d<br />

a<br />

DIN<br />

2183<br />

l<br />

L<br />

<br />

<br />

EDP UNC P L l d a Drill Hole Size Z∆ Stock Price<br />

48091484 7/16 14 100 18,1 8 6,2 10,12 ~ 10,27 8 ●<br />

48091489 1/2 13 110 19,5 9 7 11,62 ~ 11,78 8 ●<br />

48091494 9/16 12 110 21,1 11 9 13,14 ~ 13,28 8 ●<br />

48091501 5/8 11 110 23,1 12 9 14,61 ~ 14,76 8 ●<br />

48091515 3/4 10 125 20,3 14 11 17,65 ~ 17,80 8 ●<br />

48091526 7/8 9 140 22,6 18 14,5 20,66 ~ 20,84 8 ●<br />

48091538 1 8 160 25,4 18 14,5 23,63 ~ 23,84 8 ●<br />

Number of fl utes - Anzahl Schneiden - Numero di denti - Nombre de lèvres<br />

Z∆=<br />

Antal skær - Antal skär - Numero de ranuras - Число режущих кромок<br />

ppcos weuge ppco ppcos ppo ppo pccoes <br />

C0.%<br />

0.5C0.4%<br />

C0.45%<br />

SCM<br />

55C<br />

545C<br />

455C<br />

5C<br />

SUS<br />

SKD<br />

SC<br />

GG<br />

GGG<br />

15~40<br />

m/min<br />

15~40<br />

m/min<br />

15~30<br />

m/min<br />

15~30<br />

m/min<br />

5~20<br />

m/min<br />

8~20<br />

m/min<br />

15~40<br />

m/min<br />

Cu<br />

BS<br />

BsC<br />

PB<br />

Al<br />

AC,ADC<br />

MC<br />

ZDC<br />

Ti<br />

Ni<br />

Plast.<br />

Vinyl<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

20~50<br />

m/min<br />

20~40<br />

m/min<br />

10~30<br />

m/min<br />

<strong>OSG</strong> Europe: www.osgeurope.com<br />

● Delivery from stock<br />

○ Available on short notice<br />

13

S-<strong>XPF</strong><br />

UNF<br />

UNF UNF UNF<br />

UNF<br />

NEW<br />

High performance forming<br />

tap<br />

Hochleistungsgewindeformer<br />

Maschio a rullare ad alta<br />

performance<br />

Taraud à refoulé à<br />

haute performance<br />

UNF<br />

UNF UNF<br />

UNF UNF<br />

High Performance rulletap<br />

High performance<br />

pressgängtapp<br />

Alta prestaciones,<br />

macho de laminación<br />

сокороиоиеле<br />

ке меики<br />

UNF<br />

HSS-Co<br />

V<br />

ANSI<br />

2BX<br />

2<br />

d<br />

a<br />

DIN<br />

2182<br />

l1<br />

L<br />

EDP UNF P L l1 d a Drill Hole size Z∆ Stock Price<br />

48091462 6 40 56 20 4 3 3,19 ~ 3,26 4 ●<br />

48091467 10 32 70 25 6 4,9 4,41 ~ 4,47 5 ●<br />

48091472 1/4 28 80 30 7 5,5 5,87 ~ 5,94 5 ●<br />

48091476 5/16 24 90 35 8 6,2 7,39 ~ 7,47 5 ●<br />

48091481 3/8 24 90 35 9 7 8,98 ~ 9,06 8 ●<br />

V ANSI<br />

UNF 2BX 2<br />

HSS-Co<br />

d<br />

a<br />

DIN<br />

2183<br />

l<br />

L<br />

<br />

<br />

EDP UNF P L l d a Drill Hole size Z∆ Stock Price<br />

48091486 7/16 20 100 12,7 9 7 10,45 ~ 10,55 8 ●<br />

48091491 1/2 20 100 12,7 9 7 12,04 ~ 12,14 8 ●<br />

48091496 9/16 18 100 14,1 11 9 13,56 ~ 13,64 8 ●<br />

48091504 5/8 18 100 14,1 12 9 15,15 ~ 15,23 8 ●<br />

48091517 3/4 16 110 12,7 14 12 18,22 ~ 18,30 8 ●<br />

48091528 7/8 14 125 14,5 18 14,5 21,27 ~ 21,38 8 ●<br />

48091539 1 12 125 16,9 18 14,5 24,26 ~ 24,37 8 ●<br />

Number of fl utes - Anzahl Schneiden - Numero di denti - Nombre de lèvres<br />

Z∆=<br />

Antal skær - Antal skär - Numero de ranuras - Число режущих кромок<br />

ppcos weuge ppco ppcos ppo ppo pccoes <br />

C0.%<br />

0.5C0.4%<br />

C0.45%<br />

SCM<br />

55C<br />

545C<br />

455C<br />

5C<br />

SUS<br />

SKD<br />

SC<br />

GG<br />

GGG<br />

15~40<br />

m/min<br />

15~40<br />

m/min<br />

15~30<br />

m/min<br />

15~30<br />

m/min<br />

5~20<br />

m/min<br />

8~20<br />

m/min<br />

15~40<br />

m/min<br />

Cu<br />

BS<br />

BsC<br />

PB<br />

Al<br />

AC,ADC<br />

MC<br />

ZDC<br />

Ti<br />

Ni<br />

Plast.<br />

Vinyl<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

20~50<br />

m/min<br />

20~40<br />

m/min<br />

10~30<br />

m/min<br />

14<br />

<strong>OSG</strong> Europe: www.osgeurope.com<br />

● Delivery from stock<br />

○ Available on short notice

S-<strong>XPF</strong>-SPT<br />

G (BSP)<br />

G (BSP) G (BSP) G (BSP)<br />

G<br />

NEW<br />

High performance<br />

forming tap<br />

Hochleistungsgewindeformer<br />

Maschio a rullare ad alta<br />

performance<br />

Taraud à refoulé à<br />

haute performance<br />

G<br />

G (BSP) G (BSP)<br />

G (BSP) G (BSP)<br />

High Performance rulletap<br />

High performance<br />

pressgängtapp<br />

Alta prestaciones,<br />

macho de laminación<br />

<br />

<br />

G<br />

HSS-Co<br />

V<br />

2<br />

d<br />

a<br />

DIN<br />

2189<br />

l<br />

L<br />

<br />

<br />

EDP G P L l d a Drill Hole size Z∆ Stock Price<br />

48064838 1/8 28 90 9 7 5,5 9,24 ~ 9,35 8 ●<br />

48064839 1/4 19 100 13 11 9 12,41 ~ 12,62 8 ●<br />

48064840 3/8 19 100 13 12 9 15,92 ~ 16,12 8 ●<br />

48064841 1/2 14 125 18 16 12 19,93 ~ 20,15 8 ●<br />

Number of fl utes - Anzahl Schneiden - Numero di denti - Nombre de lèvres<br />

Z∆=<br />

Antal skær - Antal skär - Numero de ranuras - Число режущих кромок<br />

ppcos weuge ppco ppcos ppo ppo pccoes <br />

C0.%<br />

0.5C0.4%<br />

C0.45%<br />

SCM<br />

55C<br />

545C<br />

455C<br />

5C<br />

SUS<br />

SKD<br />

SC<br />

GG<br />

GGG<br />

15~40<br />

m/min<br />

15~40<br />

m/min<br />

15~30<br />

m/min<br />

15~30<br />

m/min<br />

5~20<br />

m/min<br />

8~20<br />

m/min<br />

15~40<br />

m/min<br />

Cu<br />

BS<br />

BsC<br />

PB<br />

Al<br />

AC,ADC<br />

MC<br />

ZDC<br />

Ti<br />

Ni<br />

Plast.<br />

Vinyl<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

10~30<br />

m/min<br />

20~50<br />

m/min<br />

20~40<br />

m/min<br />

10~30<br />

m/min<br />

<strong>OSG</strong> Europe: www.osgeurope.com<br />

● Delivery from stock<br />

○ Available on short notice<br />

15

S-<strong>XPF</strong> Taps are able to achieve stable tapping even in medium carbon steels (with Vanadium) using water soluble fluid.<br />

Tool<br />

M10×1.5 DIN371<br />

S-<strong>XPF</strong><br />

1.770 (Holes)<br />

Rubbing noise<br />

Work Material S45VC (21HRC)<br />

Hole Size φ9.3×25 (Through)<br />

Competitor A TiN coating<br />

1.226 (Holes)<br />

GP-OUT<br />

Tapping Length 25mm (2.5D) (Through)<br />

Competitor A TiCN coating<br />

939 (Holes)<br />

Rubbing noise<br />

Tapping Speed 15m/min(477min -1 )<br />

Competitor B TiN coating<br />

894 (Holes)<br />

Rubbing noise<br />

Coolant Water Soluble (20%)<br />

Machine<br />

Vertical Machining Center<br />

500<br />

1.000 1.500 2.000<br />

Tapping Holes<br />

(Holes)<br />

Even for applications that are difficult for cutting taps, such as deep threading of three times the nominal diameter, the fluteless S-<strong>XPF</strong> taps<br />

perform stable machining using water soluble coolant.<br />

Tool<br />

Work Material<br />

M6×1 DIN371<br />

S45C(90HRB)<br />

S-<strong>XPF</strong><br />

6.020 (Holes)<br />

GP-OUT<br />

Hole Size φ5.55×25 (Through)<br />

Tapping Length 18mm(3D) (Blind)<br />

Competitor A<br />

4.816 (Holes) GP-OUT<br />

Tapping Speed 20m/min(1,061min -1 )<br />

Coolant Water Soluble (10%)<br />

Competitor B<br />

4.212 (Holes)<br />

GP-OUT<br />

Machine<br />

Horizontal Machining Center<br />

2.000<br />

4.000 6.000 8.000<br />

Tapping Holes<br />

(Holes)<br />

Even for applications that are difficult for cutting taps, such as deep threading of three times the nominal diameter, the fluteless OIL-S-<strong>XPF</strong><br />

taps perform stable machining using water soluble coolant.<br />

Tool<br />

M10 x 1,25 4 HX blind hole<br />

Work Material<br />

Hole Size<br />

C70<br />

φ9,3 x 3D<br />

OIL-S-<strong>XPF</strong><br />

1.800 (Holes)<br />

Tapping Length 25mm (Blind)<br />

Tapping Speed<br />

20m/min<br />

Competitor<br />

800 (Holes)<br />

Coolant<br />

Machine<br />

Non water base lubricant<br />

Horizontal Machining Center<br />

500 1.000 1.500 2.000 2.500<br />

Tapping Holes<br />

(Holes)<br />

Even for applications that are difficult for cutting taps, such as deep threading of three times the nominal diameter, the fluteless OIL-S-<strong>XPF</strong><br />

taps perform stable machining using water soluble coolant.<br />

Tool<br />

M8 x 1,25 6 HX blind hole<br />

Work Material GGG70<br />

Hole Size φ7,4 x 19<br />

Tapping Length 14,5mm (Blind)<br />

Tapping Speed 10m/min<br />

OIL-S-<strong>XPF</strong><br />

Competitor<br />

6.000 (Holes)<br />

7.500 (Holes)<br />

Coolant<br />

Machine<br />

Non water base lubricant<br />

Horizontal Machining Center<br />

2. 000 4.000 6.000 8.000 10.000<br />

Tapping Holes<br />

(Holes)<br />

<strong>OSG</strong> EUROPE s.a.<br />

Av. Lavoisier 1<br />

B-1300 Wavre Nord<br />

Belgium<br />

Tel. + 32.10.230508<br />

Fax + 32.10.230531<br />

E-mail: info@osgeurope.com<br />

www.osgeurope.com<br />

TOOL COMMUNICATION<br />

Tool specifications subject to change without notice<br />

All rights reserved. ©<strong>OSG</strong> Europe 2009.<br />

EURS-<strong>XPF</strong> SERIE VOL308R11a<br />

<strong>OSG</strong> Europe: www.osgeurope.com<br />

The contents of this catalogue are provided to you for viewing only. They are not intended for reproduction either in part or in whole in this or other medium.<br />

They cannot be copied, used to create derivation work or used for any reason, by means without the express, written permission of the copyright owner.<br />

If prices are stated, they are netto unit-prices and any eventual tax(es) have to be added. The company is not responsable for any printing error in technical, price and/or any other data.

![HXL&VXL oil industry [Europe].indd - OSG](https://img.yumpu.com/30736963/1/184x260/hxlvxl-oil-industry-europeindd-osg.jpg?quality=85)