Hardness Tester TH130 - Test and Measurement Instruments CC

Hardness Tester TH130 - Test and Measurement Instruments CC

Hardness Tester TH130 - Test and Measurement Instruments CC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

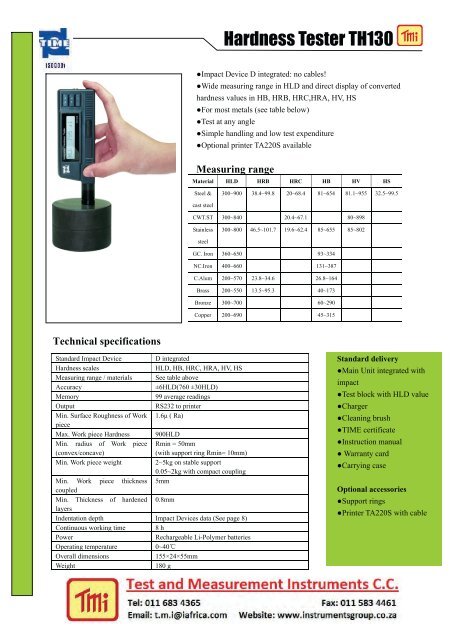

<strong>Hardness</strong> <strong><strong>Test</strong>er</strong> <strong>TH130</strong>Impact Device D integrated: no cables!Wide measuring range in HLD <strong>and</strong> direct display of convertedhardness values in HB, HRB, HRC,HRA, HV, HSFor most metals (see table below)<strong>Test</strong> at any angleSimple h<strong>and</strong>ling <strong>and</strong> low test expenditureOptional printer TA220S availableMeasuring rangeMaterial HLD HRB HRC HB HV HSSteel &300~900 38.4~99.8 20~68.4 81~654 81.1~955 32.5~99.5cast steelCWT.ST 300~840 20.4~67.1 80~898Stainless300~800 46.5~101.7 19.6~62.4 85~655 85~802steelGC. Iron 360~650 93~334NC.Iron 400~660 131~387C.Alum 200~570 23.8~34.6 26.8~164Brass 200~550 13.5~95.3 40~173Bronze 300~700 60~290Copper 200~690 45~315Technical specificationsSt<strong>and</strong>ard Impact Device D integrated<strong>Hardness</strong> scalesHLD, HB, HRC, HRA, HV, HSMeasuring range / materials See table aboveAccuracy±6HLD(760 ±30HLD)Memory99 average readingsOutputRS232 to printerMin. Surface Roughness of Work 1.6µ ( Ra)pieceMax. Work piece <strong>Hardness</strong> 900HLDMin. radius of Work piece(convex/concave)Rmin = 50mm(with support ring Rmin= 10mm)Min. Work piece weight 2~5kg on stable support0.05~2kg with compact couplingMin. Work piece thickness 5mmcoupledMin. Thickness of hardened 0.8mmlayersIndentation depth Impact Devices data (See page 8)Continuous working time 8 hPowerRechargeable Li-Polymer batteriesOperating temperature 0~40Overall dimensions155×24×55mmWeight180 gSt<strong>and</strong>ard deliveryMain Unit integrated withimpact<strong>Test</strong> block with HLD valueChargerCleaning brushTIME certificateInstruction manual Warranty cardCarrying caseOptional accessoriesSupport ringsPrinter TA220S with cable

Optional Support RingsSupport RingsNo. Type Sketch of non-conventionalRemarkssupporting ring1 Z10-15 For testing cylindrical outsidesurface R10R152 Z14.5-30 For testing cylindrical outsidesurface R14.5R303 Z25-50 For testing cylindrical outsidesurface R25R504 HZ11-13 For testing cylindrical insidesurface R11R135 HZ12.5-17 For testing cylindrical insidesurface R12.5R176 HZ16.5-30 For testing cylindrical insidesurface R16.5R307 K10-15 For testing spherical outsidesurface SR10SR158 K14.5-30 For testing spherical outsidesurface SR14.5SR309 HK11-13 For testing spherical insidesurface SR11SR1310 HK12.5-17 For testing spherical insidesurface SR12.5SR1711 HK16.5-30 For testing spherical insidesurface SR16.5SR3012 UN For testing cylindrical outsidesurface, radius adjustable R10