2007 Issue 3 - Raytheon

2007 Issue 3 - Raytheon

2007 Issue 3 - Raytheon

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

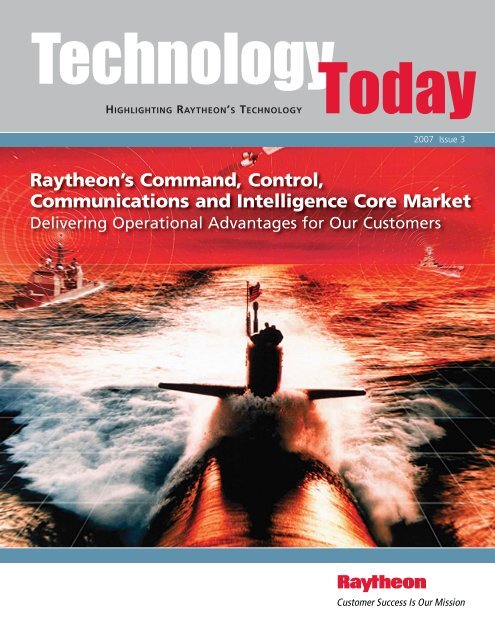

Technology<br />

Today<br />

HIGHLIGHTING RAYTHEON’S TECHNOLOGY<br />

<strong>2007</strong> <strong>Issue</strong> 3<br />

<strong>Raytheon</strong>’s Command, Control,<br />

Communications and Intelligence Core Market<br />

Delivering Operational Advantages for Our Customers

A Message From Dr. Taylor W. Lawrence<br />

Do you have an idea for an article?<br />

We are always looking for ways to connect<br />

with you — our engineering, technology and<br />

Mission Assurance professionals. If you have<br />

an article or an idea for an article regarding<br />

technical achievements, customer solutions,<br />

relationships, Mission Assurance, etc., send it<br />

along. If your topic aligns with a future issue<br />

of Technology Today or is appropriate for an<br />

online article, we will be happy to consider it<br />

and will contact you for more information.<br />

Send your article ideas to<br />

techtodayeditor@raytheon.com.<br />

2 <strong>2007</strong> ISSUE 3 RAYTHEON TECHNOLOGY TODAY<br />

Vice President of Engineering, Technology and Mission Assurance<br />

As one of <strong>Raytheon</strong>’s core markets, Command, Control, Communications and<br />

Intelligence (C3I) is central to our strategy of developing innovative technologies to<br />

drive growth and ensure Mission Assurance for our customers.<br />

We are on target. We are leveraging our C3I expertise in exciting ways and are<br />

developing a rich array of architectural constructs to look at command and control<br />

across the spectrum of requirements, from real-time fire control to large-scale logistics<br />

management of joint forces.<br />

We are increasing our footprint in the market with our Joint Fires (JFires)<br />

Demonstration program for multi-theater, multi-service Single Integrated Air<br />

Picture (SIAP) capability, and we are winning business with recent successes such as<br />

the Navy Multiband Terminal contract to provide the U.S. Navy with its next generation<br />

of satellite communications systems.<br />

This installment of Technology Today takes a closer look at C3I and highlights other<br />

ways we are increasing our C3I footprint, from the Perimeter Intrusion Detection<br />

System to protect New York City-area airports for the Port Authority of New York<br />

and New Jersey, to the Centaur automated handheld technical fire direction system.<br />

In this issue’s Leaders Corner, Peter Boland, vice president of corporate<br />

Engineering, discusses the role of Engineering at <strong>Raytheon</strong> and the challenges it<br />

faces in driving growth in C3I, MSI and all of our core market areas.<br />

While I’m on the subject of ET&MA leaders, I would once again like to extend my<br />

welcome to Greg Alston, our new vice president of Mission Assurance. Greg has hit<br />

the ground running since joining us in June, and has been busy developing an<br />

enterprisewide Mission Assurance vision, strategy and process, which we’ll begin<br />

introducing this winter.<br />

Finally, I would like to congratulate our Excellence in Operations and Quality<br />

Award winners. Ninety-five award recipients were recognized in June at the Mission<br />

Assurance Forum with one of the company’s highest honors. The efforts of these<br />

award recipients have made significant contributions to the success of our company<br />

and our customers. They all deserve our thanks.<br />

Until next time …<br />

Dr. Taylor W. Lawrence

Technology Today is published<br />

quarterly by the Office of Engineering,<br />

Technology and Mission Assurance<br />

Vice President<br />

Dr. Taylor W. Lawrence<br />

Managing Editor<br />

Lee Ann Sousa<br />

Senior Editors<br />

John Cacciatore<br />

Kevin Wynn<br />

Art Director<br />

Debra Graham<br />

Photography<br />

Don Bernstein<br />

Rob Carlson<br />

Alain Ekmalain<br />

Dan Plumpton<br />

Charlie Riniker<br />

Bob Tures<br />

Jane Tucker<br />

Ken Ulbrich<br />

Publication Coordinator<br />

Carol Danner<br />

Contributors<br />

Len Brown<br />

Doc Daugherty<br />

Roberta Gotfried<br />

Jaclyn Gutmann<br />

Terry Hastings<br />

David Peter<br />

Barry Peterson<br />

Marcilene Pribonic<br />

Ralston Robertson<br />

Sharon Stein<br />

INSIDE THIS ISSUE<br />

C3I Systems: Critical Building Blocks to Delivering<br />

Net-Centric Solutions 4<br />

Perimeter Intrusion Detection System 6<br />

The Next Generation of Troposcatter Systems 9<br />

Leveraging Technology to Realize Service-Oriented Architectures 11<br />

Centaur Program Rapidly Calculates Weapon-Firing Data 14<br />

Leaders Corner: Q&A With Peter Boland 15<br />

Eye on Technology<br />

Processing 17<br />

Materials and Structures 18<br />

Rollout of Architecting Methods Course 20<br />

Getting to Know Your <strong>Raytheon</strong> Certified Architects 21<br />

CFM Profiles: Outstanding Achievements That Help Ensure<br />

Our Customers’ Mission Success 22<br />

2006 Excellence in Operations and Quality Awards 23<br />

<strong>Raytheon</strong>’s <strong>2007</strong> Mission Assurance Forum 24<br />

Spring Technology Network Symposia 25<br />

New MathMovesU Website 28<br />

<strong>Raytheon</strong> Homeland Security Radio Station 29<br />

U.S. and International Patents 30<br />

EDITOR’S NOTE<br />

Command, Control, Communications and Intelligence, or C3I — we all know what it<br />

stands for, but what does it really mean?<br />

Just think of your car. Commands are sent to the control portion of your car to increase<br />

temperature, send heated air to the windshield, add fuel to the engine, apply pressure<br />

to the brakes, or change the frequency band on your radio. These controls and numerous<br />

sensors are then communicated throughout the car. The dashboard becomes a situation<br />

awareness display to advise us of certain conditions (e.g., low oil pressure, washer<br />

fluid, gas, etc.). Similarly, communications provide navigation via your car’s GPS system.<br />

We also receive intelligence via our radios to advise us of inclement weather, road construction<br />

and rush hour conditions — all part of the C3I systems that we use every day.<br />

<strong>Raytheon</strong> uses these same principles to develop sophisticated C3I systems for our<br />

customers to provide safe, efficient air travel, to navigate ships and aircraft, to provide<br />

defensive capabilities to protect our military and civilians, and to provide homeland security.<br />

Essentially, by converting raw data into actionable information, these systems provide<br />

our customers on and off the battlefield with integrated multi-dimensional support.<br />

In this issue, you’ll read about some of these integrated systems, as well as what our<br />

Engineering leadership says about the vital role our engineers and technologists play in<br />

<strong>Raytheon</strong>’s success — and ultimately our customers’ success.<br />

Enjoy!<br />

Lee Ann Sousa<br />

RAYTHEON TECHNOLOGY TODAY <strong>2007</strong> ISSUE 3 3

Feature<br />

C3I Systems:<br />

Critical Building Blocks to Delivering<br />

Net-Centric Solutions<br />

4 <strong>2007</strong> ISSUE 3 RAYTHEON TECHNOLOGY TODAY<br />

Command, Control,<br />

Communications and<br />

Intelligence (C3I)<br />

capabilities are an<br />

essential ingredient to<br />

solving our customers’<br />

problems. <strong>Raytheon</strong> must<br />

be able to deliver these<br />

solutions in a context of<br />

systems-of-systems that<br />

are embedded in a netcentric<br />

operations (NCO)<br />

environment. This will<br />

demand seamless<br />

interaction and<br />

interoperability between<br />

communications systems,<br />

Command and Control<br />

(C2) systems and<br />

intelligence systems.<br />

In turn, this means that<br />

<strong>Raytheon</strong> will need to<br />

provide the associated<br />

systems engineering and<br />

architecture in order to<br />

deliver NCO-compatible<br />

solutions to our<br />

customers in the areas<br />

of homeland security,<br />

transportation<br />

management, urban<br />

warfare and defense.

<strong>Raytheon</strong> is developing enterprise<br />

architectures, reference architectures<br />

and systems engineering<br />

approaches that will provide a jump start<br />

for the rapid development and deployment<br />

of these C3I solutions. For example, in the<br />

last two years, <strong>Raytheon</strong> has been investing<br />

in developing reference architectures for<br />

communications, C2, netted sensors and<br />

homeland security. These tools will allow<br />

us to design and develop near-term solutions<br />

for our customers in the context of<br />

a long-term C3I vision.<br />

Dr. David Alberts, director of Research for<br />

the Department of Defense Networks and<br />

Information Integration, points out in a<br />

recent article 1 that C3I demands agility,<br />

focus and convergence. Agility requires that<br />

we address complexity and uncertainty.<br />

Focus provides the necessary concept and<br />

purpose, and convergence provides the<br />

goal-seeking process that guides actions<br />

and effects. These three fundamental<br />

principles are driving the solutions presented<br />

in this C3I issue of Technology Today.<br />

The first article is an example of how<br />

<strong>Raytheon</strong> is combining communications<br />

with C2 and intelligence, to address a<br />

homeland security problem for the Port<br />

Authority of New York and New Jersey,<br />

which serves almost 90 million annual<br />

passengers. Perimeter Intrusion Detection<br />

System (PIDS) uses C2 to detect, assess and<br />

track intrusions, and provides the necessary<br />

communications for the wireless mobile<br />

users and sensors to operate effectively in a<br />

cluttered, complex environment and in all<br />

weather conditions. The PIDS system also<br />

provides intelligence on activities in areas<br />

surrounding the airport boundaries. Longrange<br />

surveillance sensors are used to<br />

detect and track suspicious targets, and<br />

long-range cameras are used to monitor<br />

suspicious activities. Repeated activities can<br />

be noted and analyzed using PIDS recording<br />

and playback functions to look for behavioral<br />

patterns. This project is extendable for<br />

homeland security and defense applications,<br />

such as the defeat of improvised<br />

explosive devices (IED).<br />

The second article discusses how to leverage<br />

Service Oriented Architecture (SOA) in<br />

NCO system solutions. It describes how a<br />

C2 system, Advanced Field Artillery Tactical<br />

Data System (AFATDS), uses C3I technology<br />

tools and our <strong>Raytheon</strong> C2 reference architecture<br />

to update an existing capability and<br />

expand it to a more generic, longer term<br />

solution. It allows the user to use the<br />

Global Information Grid (GIG) to achieve<br />

information superiority. The warfighter can<br />

discover, view and act on information that<br />

was previously hidden from the user.<br />

Intelligence information is provided by the<br />

Distributed Common Ground System<br />

(DCGS) Integration Backbone (DIB). The DIB<br />

is also used to integrate AFATDS and the<br />

Joint Target Manager (JTM). This results in<br />

the integration of Fires with ISR (Intelligence,<br />

Surveillance and Reconnaissance). The use<br />

of SOA has allowed <strong>Raytheon</strong> to spiral-in<br />

new technology capabilities to achieve an<br />

effects-based solution within a long-term<br />

NCO vision.<br />

The third article addresses a communications<br />

systems approach to C3I. The next<br />

generation of troposcatter systems will provide<br />

over-the-horizon high-capacity military<br />

communications as an alternative to satellite<br />

communications. <strong>Raytheon</strong> has developed<br />

a next-generation troposcatter terminal<br />

that is no larger than a satellite terminal,<br />

is quickly set up, requires no special<br />

operator skills and provides data rates in<br />

excess of 20 Mbps. This capability will<br />

support the interconnectivity of present<br />

and future C3I systems.<br />

The last article describes the use of a<br />

commercial-off-the-shelf (COTS) personal<br />

digital assistant (PDA) as a key component<br />

to provide decision support solutions to<br />

C3I systems. This system, Centaur, is a<br />

modern lightweight solution that can<br />

provide accurate firing solutions for rapid<br />

deployment units.<br />

These articles provide a quick overview of<br />

how <strong>Raytheon</strong> is using architecture and systems<br />

engineering solutions in a NCO environment.<br />

We are also paying special attention<br />

to ensure that these C3I solutions are<br />

agile, focused and convergent — and<br />

consistent with the direction of Dr. Alberts.<br />

This will allow us to address future customer<br />

needs by adding new technology-<br />

Jude Franklin, Ph.D.<br />

Director, <strong>Raytheon</strong> IED Defeat<br />

Enterprise Campaign<br />

Feature<br />

related, operational capabilities within a<br />

future context of NCO.<br />

In the last four years, I have been the technical<br />

director for NCS C2 systems, a member<br />

of the <strong>Raytheon</strong> Architecture Review<br />

Board and the technical leader on the Net<br />

Centric Operations Enterprise Campaign.<br />

I will bring this experience, coupled with<br />

<strong>Raytheon</strong> C3I systems capabilities, to my<br />

next <strong>Raytheon</strong> assignment. To that end, I<br />

have recently been appointed director of<br />

the <strong>Raytheon</strong> IED Defeat Enterprise<br />

Campaign. I look forward to working with<br />

all of you in <strong>Raytheon</strong> as we address this<br />

critical problem and provide solutions to<br />

our military personnel and civilians.<br />

Please check out our IED Defeat URL on<br />

the <strong>Raytheon</strong> home page and send us your<br />

proposed solutions.<br />

Jude E. Franklin, Ph. D.<br />

jude_e_franklin@raytheon.com<br />

1 David S. Alberts, “Agility, Focus, and Convergence:<br />

The Future of Command and Control” International C2<br />

Journal, Volume 1, Number 1, <strong>2007</strong>, Command and<br />

Control Research Program, OASD, NII.<br />

RAYTHEON TECHNOLOGY TODAY <strong>2007</strong> ISSUE 3 5

Feature<br />

The Perimeter Intrusion Detection System ...<br />

6 <strong>2007</strong> ISSUE 3 RAYTHEON TECHNOLOGY TODAY<br />

assisting the Port Authority of<br />

New York and New Jersey<br />

Intrusion detection,<br />

tracking and assessment

<strong>Raytheon</strong> was awarded a $100<br />

million contract in January 2006<br />

to develop the Perimeter Intrusion<br />

Detection System (PIDS) for the Port<br />

Authority of New York and New Jersey<br />

(PANYNJ). PANYNJ operates the world’s premier<br />

airport system serving almost 90 million<br />

passengers annually. These airports —<br />

John F. Kennedy International (JFK), Newark<br />

Liberty International, LaGuardia (LGA), and<br />

Teterboro — employ close to 70,000 people<br />

and represent a combined annual economic<br />

contribution to the region of $48 billion.<br />

The PIDS mission is to detect, assess and<br />

track intruders attempting to gain access<br />

into exterior secure areas, and to aid<br />

PANYNJ in determining and dispatching the<br />

appropriate response forces to counter<br />

intrusions. Threats include landside intrusions<br />

at all four airports and waterside<br />

intrusions at JFK and LGA.<br />

PIDS provides a layered, multi-sensor<br />

defense against intrusions by employing<br />

intrusion detection, tracking and assessment<br />

throughout all required secure areas<br />

in good and adverse weather. Various sensors<br />

— ground surveillance radars (GSR),<br />

video motion detection-equipped cameras<br />

and smart fencing — combined with overlapping<br />

coverage provide a minimum 95<br />

percent probability of detection (P d ), a low<br />

probability of false alarm (P fa ), a low nuisance<br />

alarm rate (NAR), and a 99.9 percent<br />

operational availability (A o ). Target locations<br />

are displayed in real-time on an airport<br />

facility map at the operator’s control and<br />

display workstation (CDW).<br />

Upon detection of an intrusion event, PIDS<br />

provides an assessment capability based on<br />

infrared (IR), low light level, and daylight<br />

video cameras in good and adverse weather.<br />

Assessment cameras are automatically<br />

slaved to the intruder location, and surveillance<br />

sensor feedback maintains the camera(s)<br />

on the target track. Users may also<br />

manually control any assessment camera.<br />

Video is displayed to the PIDS users on the<br />

CDW and on large screen (46”diagonal)<br />

ceiling- or wall-mounted monitors at selected<br />

facility locations.<br />

There are several components to the user<br />

interface presented on the CDW: (1) the<br />

facility map with intruder and police vehicle<br />

locations; (2) multiple video windows displaying<br />

live or recorded video; (3) an event<br />

queue, with standard operating procedures<br />

automatically displayed based on the<br />

selected event’s type; and (4) system<br />

administration tools. The PIDS operator is<br />

able to control all aspects of the system<br />

from this single user interface.<br />

Wireless mobile communications with Port<br />

Authority Police Department officers in the<br />

field is also provided. Target locations are<br />

displayed on vehicle mounted computers.<br />

In addition, officers may view assessment<br />

video. Police vehicle locations are also<br />

tracked and displayed. These capabilities<br />

greatly improve the situational awareness<br />

of response forces.<br />

PIDS also interfaces with two legacy<br />

systems: (1) an Access Control System<br />

(ACS); and (2) existing Closed Circuit<br />

Television (CCTV) systems.<br />

System Requirements<br />

Key requirements that drove the system<br />

design are:<br />

Target Characteristics: These include the<br />

target types — person, vehicle, watercraft<br />

— and their cross-sectional area. In general,<br />

only the smallest target type needs to be<br />

specified, as the system is designed to<br />

detect and track such targets. This is typically<br />

a person, usually with a cross-sectional<br />

area of 0.5 m 2 to 1 m 2 . The target speed<br />

range should also be specified; a typical<br />

range is 0.1 m/s to 30 m/s.<br />

Operational Availability: This is expressed<br />

as the percentage of time the system is fully<br />

available to perform its mission. An A o of<br />

99.9 percent corresponds to a downtime of<br />

8.76 hours/year. The allowed downtime<br />

encompasses both total system failure and<br />

degraded mode operations, as well as periods<br />

of reduced system performance caused<br />

by extreme weather. Achieving a specified<br />

A o typically involves providing redundancy<br />

among system components, and providing<br />

overlapping sensor coverage.<br />

Feature<br />

Environmental Factors: Maximum rain<br />

rate is a key parameter impacting sensor<br />

performance and consequently A o .<br />

A selected rain rate is used in modeling<br />

sensor performance. Similar considerations<br />

apply to snow, fog and wind.<br />

Probability of Detection: The system is<br />

designed to detect targets with the specified<br />

characteristics under specified adverse<br />

weather conditions. Target detection zones<br />

are identified, usually around the facility<br />

perimeter. Within these zones, a minimum<br />

P d of 95 percent is maintained.<br />

Probability of False Alarm: False alarms<br />

are associated with sensor noise. P fa is<br />

specified on a sensor basis. A typical<br />

GSR P fa is 10 -6 .<br />

Nuisance Alarm Rate: Nuisance alarms are<br />

generated by the system detecting targets<br />

that do not satisfy the target characteristics.<br />

For example, a small dog or bird may be<br />

detected and tracked, even though it may<br />

not satisfy the required target characteristics.<br />

The NAR is usually expressed as an<br />

allowable number of nuisance alarms per<br />

detection zone, per specified time period.<br />

The achievable NAR is highly dependent on<br />

the facility environment.<br />

System Architecture and Design<br />

The PIDS implementation effort is dominated<br />

by the design and construction of the<br />

civil infrastructure necessary to support<br />

both the sensor network and the mobile<br />

communications. <strong>Raytheon</strong>’s approach to<br />

designing the physical system architecture<br />

begins with facility drawings augmented by<br />

site surveys. The drawings show where<br />

existing power and fixed communications<br />

nodes are located. These existing nodes are<br />

employed wherever possible to reduce<br />

implementation time and effort.<br />

Accurate sensor models for both radars and<br />

cameras (visible and infrared), expressed as<br />

P d versus range curves, are developed.<br />

These curves incorporate weather effects<br />

and target characteristics, along with<br />

Continued on page 8<br />

RAYTHEON TECHNOLOGY TODAY <strong>2007</strong> ISSUE 3 7

Feature<br />

Continued from page 7<br />

specific sensor characteristics. This modeling<br />

results in a maximum usable sensor range.<br />

The power and communications locations<br />

contained in the facility drawings are used<br />

with the sensor models to develop a sensor<br />

network layout. <strong>Raytheon</strong>’s Sensor Terrain<br />

Analysis Tool (STAT), which utilizes the P d<br />

versus range curves, terrain data including<br />

buildings, height restrictions and other<br />

topographic constraints, is employed for<br />

this purpose. STAT produces a color coded<br />

P d map of the entire facility. Low P d areas<br />

are corrected by adding additional sensors.<br />

The PIDS program was generalized to develop<br />

a system concept called the Integrated<br />

Security System for Airports (ISSA). Each<br />

subsystem is COTS-based, modular in design,<br />

with well defined interfaces. This supports<br />

future upgrades and expansions as new and<br />

improved products become available. The<br />

components and functions of each subsystem<br />

are described in the following.<br />

Intrusion Detection and Tracking<br />

Subsystem (IDTS): The IDTS functions as the<br />

surveillance sensor front end. Any type of surveillance<br />

sensor can be integrated, however,<br />

three principal sensor types are usually<br />

employed. (1) GSRs are employed in unobstructed<br />

areas as the principal means of<br />

detecting and tracking targets due to their<br />

excellent all-weather capabilities and low<br />

cost/m 2 surveillance and tracking capabilities;<br />

(2) Video motion detection–equipped CCTV<br />

and IR cameras are employed in areas with<br />

obstructions, typically near facility buildings<br />

and other types of structures; and (3) smart<br />

fence sensors are employed in low traffic<br />

areas as a supplementary means of intrusion<br />

detection. Surveillance sensor inputs are collected,<br />

processed and fused, and alarms are<br />

generated and transmitted to the command<br />

and control subsystem. ACS events are also<br />

processed within the IDTS and passed to the<br />

command and control subsystem.<br />

Intrusion Assessment Subsystem (IAS):<br />

The IAS provides video to assess intrusion<br />

events 24/7 in good and adverse weather<br />

conditions, thereby assisting users in determining<br />

the appropriate response. A combi-<br />

8 <strong>2007</strong> ISSUE 3 RAYTHEON TECHNOLOGY TODAY<br />

Perimeter Intrusion Detection System<br />

Block diagram of integrated security system for airports<br />

nation of visible light and IR cameras are<br />

employed to allow assessment in the full<br />

range of lighting and weather conditions.<br />

The cameras can be operated manually,<br />

automatically and in touring mode. In<br />

automatic mode, IDTS-generated position<br />

data automatically slave a camera to a<br />

moving target.<br />

Command and Control Subsystem<br />

(C2S): The C2S provides the operator interface<br />

and event management functions.<br />

Both a geographical map and a tabular list<br />

representation are displayed to the operator.<br />

Alarms from different sources are<br />

processed: access control system alarms,<br />

perimeter intrusion alarms, loss of communications<br />

alarms, low power alarms, tampering<br />

alarms, etc. Alarms are prioritized<br />

based on user defined rules. The highest<br />

priority alarm is always presented to the<br />

operator for action. The operator employs<br />

video from assessment cameras and standard<br />

operating procedures to validate the<br />

alarm and react appropriately in concert<br />

with security force personnel. The C2S also<br />

logs all operator actions and incident data.<br />

Communications Subsystem (CS): The CS<br />

connects all field components including<br />

sensors to computer resources located in<br />

server rooms. A high speed (1 Gbps or<br />

greater) Ethernet fiber optic network is<br />

employed, combining high bandwidth<br />

communications necessary for video transport<br />

with low communications latency.<br />

Mobile data and video communications<br />

with response forces are also provided.<br />

Power Subsystem (PS): The PS provides<br />

the power distribution system and<br />

Uninterruptible Power Supplies for all system<br />

components — interior and exterior.<br />

Video Management Subsystem (VMS):<br />

The VMS manages all video, including realtime<br />

display, replay, storage and archiving.<br />

The number of cameras, the video resolution<br />

and frame rate, and the video retention<br />

period are significant parameters that<br />

drive the required video storage capacity.<br />

Legacy CCTV systems are accessed through<br />

the VMS.<br />

In conclusion, <strong>Raytheon</strong> provides a total<br />

solution to our PANYNJ customer, including<br />

technology, civil infrastructure design and<br />

construction, and maintenance. In addition,<br />

the PIDS design, as generalized by the ISSA<br />

concept, is also applicable to protecting<br />

other critical transportation infrastructure,<br />

such as seaports and rail yards.<br />

Guy Germana<br />

guy_t_germana@raytheon.com<br />

Simon Hennin<br />

simon_j_hennin@raytheon.com<br />

Len Garcia<br />

leonard_garcia@raytheon.com

ENGINEERING PROFILE<br />

Guy Germana<br />

Senior Principal<br />

Engineer; NCS<br />

Airspace Management<br />

and Homeland<br />

Security<br />

Years with <strong>Raytheon</strong>: 10<br />

Q: Which programs<br />

are you working on?<br />

A: I’m working on<br />

several programs<br />

related to perimeter<br />

security. The<br />

LaGuardia Airport<br />

CCTV System will provide the airport police<br />

with a video surveillance capability. The Safe<br />

Haven program is a study contract to develop<br />

a security concept for rail yards. And I’m also<br />

writing a perimeter security section for the<br />

RTCA Airport Security guidelines.<br />

Q: How did you become involved with<br />

perimeter security?<br />

A: I worked on most major air traffic control<br />

systems — oceanic, en-route, and airport —<br />

for 20 years. I was ready for something new!<br />

Q: What are some of the challenges<br />

you’re facing?<br />

A: <strong>Raytheon</strong> is still expanding our Mission<br />

Systems Integration positions, so there are<br />

challenges there. Moving from the defense<br />

world to the commercial/civil world is also<br />

a big challenge.<br />

Q: Did anything in particular prepare you for<br />

your present role?<br />

A: My engineering educational background<br />

has helped me tremendously — thank you<br />

University of Maryland! The opportunity to<br />

manage several engineering projects has also<br />

helped tremendously.<br />

Q: What’s the secret to individual success<br />

at <strong>Raytheon</strong>?<br />

A: It’s really the basics — understanding what<br />

the customer wants, ensuring the customer<br />

understands and agrees to what <strong>Raytheon</strong> is<br />

providing, and managing change.<br />

Q: What about your job keeps you up at night?<br />

A: Figuring out how to deliver value to the<br />

customer, given their budget constraints.<br />

Q: What excites you about your job?<br />

A: I’m excited to have the opportunity to<br />

participate in a new and growing business<br />

area, and I enjoy working with the people<br />

involved. I’ve met quite a few smart people<br />

throughout the company.<br />

In the 30 years since <strong>Raytheon</strong> developed<br />

the AN/TRC-170 family of tactical<br />

troposcatter systems — and produced<br />

over 800 systems for the U.S. Army, Air<br />

Force and Marine Corps — little attention<br />

was given to the next generation.<br />

During the 1970s, troposcatter was the<br />

only means to convey megabit data at overthe-horizon<br />

distances up to several hundred<br />

kilometers since tactical SATCOM capacity<br />

was limited to critical C2. Over the last 25<br />

years, the focus on over-the-horizon highcapacity<br />

military communications shifted to<br />

SATCOM with continuous upgrades<br />

planned for the foreseeable future. Despite<br />

this rapid growth in SATCOM capability, the<br />

growth in information need-lines has been<br />

even greater, resulting in the need to lease<br />

expensive commercial SATCOM resources.<br />

While many of these high-capacity SAT-<br />

COM need-lines span ranges that are compatible<br />

with troposcatter operation, the<br />

AN/TRC-170 is often not used because it’s<br />

considered too large, too slow to setup,<br />

limited in data rate, and it requires specially<br />

trained operators.<br />

To exploit this opportunity, <strong>Raytheon</strong><br />

undertook an IRAD project starting in<br />

2005 to develop a prototype next generation<br />

troposcatter terminal. Ideally this new<br />

terminal would have many advantages over<br />

its predecessors: It would be no larger than<br />

a SATCOM terminal; it could be quickly set<br />

up; it required no special skills to operate;<br />

and it would provide data rates in excess<br />

of 20 Mbps.<br />

That next-generation terminal is the DART-T,<br />

or Dual-mode, All-band, Relocatable,<br />

Tactical–Terminal (DART-T). It has been produced<br />

in HMMWV-mounted, trailer-mounted<br />

and transit case (Flyaway) versions. To<br />

combine small size and ease of use with<br />

high performance, DART-T has achieved a<br />

number of technological firsts, including<br />

single antenna quad-diversity, Ku-band<br />

propagation, software definable advanced<br />

Feature<br />

The Next Generation of<br />

Troposcatter Systems<br />

An HMMWV-mounted DART-T is tested at<br />

Camp Pendleton.<br />

modulation, automatic antenna alignment<br />

and adaptive data rate.<br />

The DART-T Design<br />

To keep DART-T competitive in cost, it was<br />

decided to use proven components from<br />

rugged commercial-off-the-shelf (COTS)<br />

SATCOM terminals where possible. Hence,<br />

the terminal antenna is based on a single<br />

COTS 2.4m High-Wind Vertex/RSI antenna<br />

which has previously been adapted to<br />

HMMWV, trailer, and transit case transport.<br />

While high-performance tropo links often<br />

use larger antennas, going to higher RF<br />

frequency also gives a smaller antenna<br />

higher gain. Thus, a Ku-band capability<br />

was incorporated and a new angle diversity<br />

feed was developed, which provides two<br />

independent beams in elevation spaced by<br />

a little over one beamwidth. The use of<br />

angle diversity and dual transmitters (frequency<br />

diversity) allows DART-T to achieve<br />

quad-diversity with only a single antenna,<br />

while TRC-170 needs dual antennas for<br />

this performance — a large reduction in<br />

terminal “footprint.”<br />

Ku-band was previously rejected for<br />

troposcatter operation due to potential rain<br />

attenuation, but USAF/MITRE-sponsored<br />

Continued on page 10<br />

RAYTHEON TECHNOLOGY TODAY <strong>2007</strong> ISSUE 3 9

Feature Troposcatter Systems<br />

Continued from page 9<br />

testing in the 1990s showed that rain also<br />

enhanced the forward scatter, so the net<br />

effect was often neutralized. Since the<br />

COTS 2.4m antenna is motorized in elevation<br />

and azimuth pointing, algorithms were<br />

developed to allow the antenna to automatically<br />

search and acquire the signal from<br />

the distant terminal. This feature, combined<br />

with software that allows operators to<br />

estimate link performance before setup,<br />

nearly eliminates the special skill needed<br />

by an operator in the areas that are unique<br />

to troposcatter.<br />

Another innovation is a new state-of-theart<br />

modem developed at Radyne, which<br />

allows data rates up to 20 Mbps compared<br />

with the 4 Mbps maximum for TRC-170.<br />

This new modem also incorporates forward<br />

error correction coding and provides several<br />

dBs of system advantage even at TRC-170<br />

data rates. This software-definable modem<br />

allows any data rate in 1 bps increments<br />

rather than the handful of fixed rates<br />

previously available.<br />

Another major first for DART-T is the incorporation<br />

of Adaptive Data Rate, which<br />

allows the DART-T terminals to automatically<br />

adapt the data rate to the prevailing troposcatter<br />

path conditions. Previously, tropo<br />

data rates were set based on the maximum<br />

that could be supported 90 to 99 percent<br />

of the time, despite the fact that most of<br />

the time signal levels could be as much as<br />

20 dB higher. With Adaptive Data Rate, the<br />

DART-T always provides maximum throughput<br />

— an ideal solution to an IP-based network<br />

(all military nets are migrating to IP).<br />

DART-T Testing<br />

During 2006, DART-T Ku-band prototypes<br />

were successfully tested on an 83-mile troposcatter<br />

path at Otis Air Force Base, a 45mile<br />

diffraction/tropo path at Ft. Huachuca,<br />

and a 5-mile triple-diffraction path at Camp<br />

Pendleton. At Otis AFB, side-by-side testing<br />

was conducted against the TRC-170 V2<br />

(largest family member) on the same path,<br />

and performance was comparable on both<br />

systems at the same data rates. This was a<br />

10 <strong>2007</strong> ISSUE 3 RAYTHEON TECHNOLOGY TODAY<br />

Side-by-side DART-T and AN/TRC-170V2<br />

testing at Otis AFB<br />

A transit case DART-T at Ft. Huachuca<br />

Trailer Mounted DART-T at Ft. Monmouth<br />

clear indication that a viable tactical troposcatter<br />

system could be implemented at<br />

Ku-band, and that a much smaller terminal<br />

could exceed TRC-170 capabilities.<br />

Testing at Ft. Huachuca and Camp<br />

Pendleton demonstrated data rates to 20<br />

Mbps, which were error-free for long periods.<br />

Most of the time, performance was<br />

such that two parallel 20 Mbps streams, or<br />

40 Mbps total, could be transferred.<br />

Fred Unkauf<br />

manfred_g_unkauf@raytheon.com<br />

ENGINEERING PROFILE<br />

Douglas Johnson<br />

Program Manager;<br />

NCS Effects/Battle<br />

Management<br />

Systems Group<br />

Years with <strong>Raytheon</strong>: 25<br />

Q: What program<br />

are you working on<br />

these days?<br />

A: I’ve been working<br />

with AFATDS<br />

(Advanced Field<br />

Artillery Tactical Data<br />

System) programs for 16 years. During that<br />

time, I’ve held various positions; it usually<br />

changes every three years. The program is<br />

always evolving, so the work has never gotten<br />

monotonous.<br />

Q: How did you arrive at your current position?<br />

A: I started my career as a digital circuit designer.<br />

Then when digital design became less needed<br />

due to microelectronic design advances, I<br />

transitioned into system engineering. From<br />

there I got into program team leadership, project<br />

management, project engineering and finally<br />

program management.<br />

Q: What are some of the things that have allowed<br />

you to excel at <strong>Raytheon</strong>?<br />

A: There are a few. One is working for very<br />

supportive leaders who help guide my career<br />

and give me greater responsibility going forward.<br />

It’s also important to work with a very<br />

dedicated team. Another key is not being<br />

removed from my responsibilities when things<br />

don’t go as well as planned. I think it’s really<br />

important to have the opportunity to make<br />

decisions and then learn from your mistakes —<br />

that’s how you grow.<br />

Q: What part of your job concerns you the most?<br />

A: I’d say worrying about making all of our<br />

commitments. Maintaining a healthy work/life<br />

balance for me and everyone on the team is<br />

also a challenge.<br />

Q: What’s the most rewarding aspect of your job?<br />

A: Providing products the meet or exceed the<br />

users needs. And of course seeing soldiers get<br />

excited about the product — and really want to<br />

use it!

Leveraging Technology to Realize<br />

Service-Oriented Architectures<br />

Service-Oriented Architecture (SOA) is<br />

a well-established strategy within the<br />

Department of Defense for meeting<br />

the transformational goals of net-centric<br />

warfare (NCW). By exposing capabilities to<br />

the Global Information Grid (GIG), the<br />

warfighter achieves information superiority<br />

through his ability to discover, view and act<br />

on information and capabilities previously<br />

hidden within systems, effectively breaking<br />

traditional stovepipes.<br />

This transformational goal can be realized<br />

without impacting functionality in the field<br />

through a phased migration strategy combining<br />

current technology with key technology<br />

insertions. <strong>Raytheon</strong> Effects/Battle<br />

Management Systems (E/BMS) has been<br />

migrating C2 systems of record and related<br />

products toward NCW SOA goals over the<br />

last 10 years.<br />

Migrating a Current Force System Into<br />

an SOA Environment<br />

Current force systems can be migrated into<br />

an SOA using several approaches ranging<br />

from exposing or adapting interfaces to<br />

refactoring the system architecture. On the<br />

Advanced Field Artillery Tactical Data<br />

System (AFATDS), we are using multiple<br />

approaches to achieve this migration.<br />

AFATDS is the Fire Support Command and<br />

Control (C2) system employed by the U.S.<br />

Army and U.S. Marine Corps units to provide<br />

automated support for planning, coordinating,<br />

controlling and executing fires and<br />

effects. It prioritizes targets received from<br />

various sensors and performs attack analysis<br />

using situational data combined with commander’s<br />

guidance. The result is timely,<br />

accurate and coordinated fire support<br />

options to engage targets using Army,<br />

Marine, Navy and Air Force weapon systems.<br />

Enhanced by an SOA, these capabilities<br />

will enable an expanded warfighter<br />

audience to make timely decisions for joint<br />

target engagement and synchronization.<br />

Figure 1. Web services that support the Joint Time Sensitive Targeting Thread<br />

Shortly after AFATDS was fielded in 1996,<br />

<strong>Raytheon</strong> and the Army product manager<br />

for the Fire Support Command and Control<br />

(PdM FSC2) office collaborated to develop<br />

the Effects Management Tool (EMT) to provide<br />

AFATDS capabilities to remote users. At<br />

that time, a client-server architecture using<br />

Common Object Request Broker<br />

Architecture (CORBA) Interface Definition<br />

Language (IDL) was created, establishing<br />

the foundation for our subsequent SOA<br />

migration strategy.<br />

As NCW concepts emerged, Advanced<br />

Concept Technology Demonstrations<br />

(ACTD) exercises and experiments focused<br />

on realizing the tenets of NCW and SOA<br />

primarily through Web-service technology.<br />

In 2004, AFATDS began transitioning the<br />

CORBA IDL interface to Web services, as<br />

well as defining new Web services as part<br />

of the Family of Interoperable Operational<br />

Pictures (FIOP) initiative and the Joint Forces<br />

Feature<br />

Command (JFCOM), J9 Joint Fires Initiative<br />

(JFI) Limited Objective Experiment (LOE).<br />

These services were further refined through<br />

participation in various other activities and<br />

experiments that focused primarily on the<br />

Joint Time Sensitive Targeting (TST) Thread.<br />

The relationship of the AFATDS Web services<br />

to the TST thread is depicted in Figure 1.<br />

By leveraging these experimental results,<br />

the AFATDS program has already fielded<br />

selected Web services. Moreover, it will field<br />

enough Web services in its next major<br />

release (early 2008) to completely replace<br />

the original CORBA IDL.<br />

Incremental Migration Strategy to<br />

Realize SOA Goals<br />

The creation of Web services by itself does<br />

not fully realize an SOA. Additional aspects<br />

include defining meta-data for search and<br />

Continued on page 12<br />

RAYTHEON TECHNOLOGY TODAY <strong>2007</strong> ISSUE 3 11

Feature<br />

Continued from page 11<br />

discovery, integration with infrastructure<br />

services, scaling up to support many users,<br />

and the eventual retiring of the system in<br />

lieu of services on high-performance<br />

servers. The AFATDS program has addressed<br />

these aspects through a multiphase migration<br />

strategy that’s currently in progress.<br />

Our migration strategy consists of several<br />

architectural changes implemented over<br />

several discrete phases. One of the first<br />

changes created a remote Java 2 Enterprise<br />

Edition (J2EE)-compliant Web application<br />

server. This remote server provides all<br />

AFATDS Web services and can be deployed<br />

12 <strong>2007</strong> ISSUE 3 RAYTHEON TECHNOLOGY TODAY<br />

on a separate high-performance Windows<br />

server, thus off-loading the Web service<br />

processing burden from the AFATDS C2<br />

platform.<br />

The next change makes AFATDS itself capable<br />

of being deployed on a high-performance<br />

Windows server. To accomplish this,<br />

AFATDS is being modified to run on a server<br />

without a local operator. This step<br />

requires additional Web services to provide<br />

the data and functionality needed for the<br />

Graphical User Interface (GUI). A single<br />

Java-based thick client — combining the<br />

GUI with EMT — will be created that can<br />

Figure 2. Integration of Fires and Targeting capabilities within the DIB<br />

Service-Oriented Architectures<br />

be configured based on user role and skill<br />

level. A related change adds a thin-client<br />

capability to support edge users. Any user<br />

with appropriate privileges will be able to<br />

access fires and effects services via a Fires<br />

Portal using a standard commercial browser.<br />

The final phase of our migration strategy<br />

transforms AFATDS into a collection of<br />

services that can be separately shared or<br />

replaced within a total net-centric environment.<br />

During this phase, selected components<br />

are separated and designed to meet a<br />

well defined and publicized interface.<br />

Eventually, all capabilities will be available

as separate services (or be replaced by<br />

equivalent services) to provide a Networked<br />

Fires C2 capability.<br />

Using Technology Insertion to Bring New<br />

Capabilities Into an SOA Environment<br />

In addition to transforming current force<br />

systems, additional SOA capabilities can be<br />

created by combining current technologies<br />

with new product development. In one<br />

case, we developed an SOA-based product<br />

that presents critical warfighter information<br />

by combining data from multiple current<br />

force systems. The Joint Target Manager<br />

(JTM) was created to provide net-centric<br />

Web service and role-based GUI access to<br />

tactical targeting information collected from<br />

current force systems such as AFATDS,<br />

Theater Battle Management Core System<br />

(TBMCS), and Cursor on Target (CoT). As<br />

part of its SOA adaptation, JTM also provides<br />

a Web service interface for access by<br />

other warfighter applications, a browser<br />

interface for remote warfighters, and a GUI<br />

for local warfighters.<br />

In another case, we added new capabilities<br />

taken from current applications into a<br />

developing SOA environment. The<br />

Distributed Common Ground System<br />

(DCGS) program recognized the need for a<br />

new architecture to address warfighter<br />

intelligence collection gaps and to support<br />

system-of-systems integration within a distributed<br />

enterprise environment. The resulting<br />

network-centric architecture is based on<br />

SOA and J2EE technologies. The centerpiece<br />

of this architecture is the DCGS<br />

Integration Backbone (DIB) and the DIB’s<br />

Meta-Data Framework (MDF). Multiple DIBs<br />

can be federated, thus providing an enterprise-wide<br />

environment where producers<br />

and consumers can publish data and subscribe<br />

to and receive data appropriately.<br />

The DCGS-Navy program office also recognized<br />

the need to integrate ISR and Fires C2<br />

capabilities. This resulted in both customerfunded<br />

and enterprise campaign efforts<br />

that brought Fires C2 and related capabilities<br />

into the DIB enterprise to reduce<br />

sensor-to-effects timelines and increase<br />

situational understanding.<br />

After analyzing DIB integration levels and<br />

the AFATDS interface, we selected Level 2<br />

Resource Adapters as the most appropriate<br />

integration level. Level 2 Resource Adapters<br />

provide a facade between the DIB and an<br />

existing system. The Resource Adapter uses<br />

existing system interfaces, performs data<br />

translations, and uses the MDF interfaces<br />

for data insertion and extraction to/from<br />

the DIB. This path was selected because<br />

AFATDS already provided Web services, supplying<br />

exposed operations via Web Services<br />

Description Language (WSDL) and XML<br />

schemas. JTM was also integrated into the<br />

DIB using a similar approach, thus bringing<br />

Fires C2 and Targeting capabilities into the<br />

DIB (see Figure 2).<br />

In other cases, we brought new capabilities<br />

to the DIB by including an Enterprise<br />

Service Bus (ESB) to provide messaging and<br />

mediation services between the DIB and the<br />

Advanced Communications Service (ACS).<br />

The tactical message/XML transformations<br />

provided by ACS facilitated the integration<br />

of existing systems with key Meta-Data<br />

Catalogue (MDC) Web-based objects.<br />

Summary<br />

Because SOA capabilities greatly increase<br />

the warfighter’s effectiveness, they are a<br />

key factor in Department of Defense procurements<br />

today. C2 systems require SOA<br />

compatibility to stay relevant to today’s<br />

defense strategies. AFATDS is an important<br />

multi-service current force program actively<br />

migrating toward the net-centric environment,<br />

and JTM is an example of a new<br />

warfighter capability made possible by<br />

leveraging SOA access.<br />

Strategies to migrate current force systems<br />

to SOA through technology insertion not<br />

only preserve the government’s investment<br />

in current systems, but also offer a clear<br />

path for new tools that benefit the<br />

net-centric warfighter using the<br />

unprecedented data and capability<br />

access allowed by SOA.<br />

John Schlundt<br />

john_a_schlundt@raytheon.com<br />

Dale Anglin<br />

dale_e_anglin @raytheon.com<br />

John Lindquist<br />

john_t_lindquist @raytheon.com<br />

ENGINEERING PROFILE<br />

Leonard Brown<br />

Manager of<br />

Prototype Capabilities<br />

Development for C2<br />

Solutions Team; NCS<br />

Effects/Battle Management<br />

Systems Group<br />

Years with <strong>Raytheon</strong>: 26<br />

Q: Which programs are<br />

you working on?<br />

A: I’ve been doing<br />

command and controlrelated<br />

business development<br />

for the last two<br />

years. Previously, I worked with the AFATDS<br />

program, doing advanced technology development<br />

for 10 years.<br />

Q: What inspired you to work with this program?<br />

A desire to apply state-of-the-art technologies<br />

to existing capabilities to enhance warfighter<br />

C2 effectiveness. This spans improving<br />

communications, user interfaces and overall<br />

ease-of-use, to making broader application<br />

of C2 capabilities and transitioning them<br />

more rapidly to the users.<br />

Q: What makes the AFATDS program successful?<br />

A: The AFATDS program is a rare example<br />

of a successful collaboration among the user,<br />

customer and contractor that has enabled the<br />

product to evolve to meet the user’s needs.<br />

The AFATDS development team continues to<br />

apply disciplined system, software and test<br />

engineering to all functionality enhancements.<br />

As a consequence, they’ve created a firm<br />

technology base that can be applied to solve<br />

problems in many other capability areas.<br />

Q: Why have you excelled in your present role?<br />

A: I have always enjoyed seeing ideas turn into<br />

reality. I experienced this as a young engineer<br />

developing robotics, and continued to enjoy it<br />

through the varied communications, IFF and<br />

C2 tools to which I have contributed.<br />

Q: What’s your primary goal as a manager?<br />

A: We have many bright people here with great<br />

ideas. My personal goal in my role as a manager<br />

has always been to enable those people to apply<br />

their ideas to our development opportunities.<br />

Q: How can <strong>Raytheon</strong> maximize the potential<br />

of individual employees?<br />

A: Ensure that everyone understands our<br />

business road map and how their efforts fit into<br />

that road map. Also ensure that individuals<br />

with good ideas that don’t obviously fit the<br />

road map still have the opportunity to bring<br />

those ideas to the forefront — because they<br />

may very well help evolve the road map.<br />

RAYTHEON TECHNOLOGY TODAY <strong>2007</strong> ISSUE 3 13

Feature<br />

Centaur Program Rapidly Calculates<br />

Weapon-Firing Data<br />

The Centaur<br />

Program<br />

answers<br />

critical multi-service<br />

(U.S. Army, U.S.<br />

Marine Corps) requirements<br />

to rapidly calculate<br />

cannon and mortar weaponfiring<br />

solutions in training and combat. This<br />

is possible because of the development,<br />

acceptance and deployment of its Centaur<br />

Technical Fire Direction (TFD) System.<br />

Using a commercial-off-the-shelf personal<br />

digital assistant (PDA), the Centaur program is<br />

a modern, lightweight handheld product that<br />

safely and accurately calculates firing data<br />

for rapid deployment units (airborne, airmobile,<br />

light infantry and amphibious forces)<br />

during the early phases of forced entry<br />

operations and during split-unit operations<br />

such as artillery raids or leap-frog movement.<br />

Centaur is also used as an independent<br />

means of validating the primary tactical/<br />

technical fire control system, TFD solutions.<br />

The primary system is <strong>Raytheon</strong> Advanced<br />

Field Artillery Tactical Data System (AFATDS).<br />

It calculates weapon and munition-specific<br />

aiming information, allowing fire missions<br />

to be rapidly and safely fired en route and/<br />

or immediately upon occupation of a firing<br />

position, prior to the arrival and setup of<br />

AFATDS. This additional capability allowed<br />

Centaur to replace the 20+ year-old backup<br />

computer system (BUCS), which had not<br />

been supported for more than a decade.<br />

Centaur is the first and only fielded system<br />

to ever calculate both combat and training<br />

safety data, then compare individual<br />

weapon firing solutions to the safety constraints<br />

to identify potential safety violations.<br />

Centaur automates the previously<br />

manual method of calculating safety information<br />

during live-fire training exercise to<br />

prevent training accidents. It is unique in its<br />

ability to consider nonstandard conditions<br />

in all its safety calculations. Further, working<br />

closely with customer subject matter experts,<br />

<strong>Raytheon</strong> developed the Digital Safety<br />

Computation Rules, which are now being<br />

extended and used to evolve published military<br />

doctrine and/or unit procedures.<br />

14 <strong>2007</strong> ISSUE 3 RAYTHEON TECHNOLOGY TODAY<br />

The Next-Generation Centaur<br />

The Centaur contract was initiated in April<br />

2002. Version 1.0 began fielding in<br />

February 2004 and is now in use during<br />

combat operations by U.S. Army and<br />

Marine Corps warfighters in both Iraq and<br />

Afghanistan. Version 1.1 is currently being<br />

fielded to new and retrofit units, and has<br />

become a part of the joint artillery school<br />

curriculum. A third version (Version 2.0),<br />

which has completed development, has a<br />

targeted materiel release of October <strong>2007</strong>.<br />

Enhanced capability in Version 2.0 includes<br />

digital communications (when using a<br />

Rugidized PDA with a <strong>Raytheon</strong> TacLink<br />

3000 modem), the latest Digital Safety<br />

Computation Rules, and incorporation of<br />

additional munitions and the 120 mm<br />

Rifled Towed Mortar weapon system.<br />

Digital communications includes the reception<br />

of the Meteorological MIL-STD-6017<br />

message over a MIL-STD-188-220c network<br />

and also TACFIRE communications to the<br />

Gun Display Unit (GDU) located on the cannons.<br />

Reception of the Centaur system by<br />

military units can best be described as<br />

“enthusiastic adoption” with some units<br />

purchasing their own hardware to get<br />

ahead of the official fielding schedule.<br />

Centaur is a model acquisition program<br />

that reflects a true government-industry<br />

partnership. The “user” representative<br />

(TCM FSC3, Fort Sill, Okla.) is responsible<br />

for articulating and validating all system<br />

requirements. The product manager’s office<br />

(PM Battle Command, Ft. Monmouth, N.J.)<br />

executes the contract options and manages<br />

the cradle-to-grave life cycle.<br />

Recognizing Outstanding Performance<br />

During initial Centaur development, all<br />

three elements (TCM, PM and <strong>Raytheon</strong>)<br />

collaborated to clearly define the requirements<br />

and expectations. As such, the TCM<br />

assigned an artillery officer, as part of training<br />

with industry, to work for a year on<br />

Centaur. This foundation was leveraged<br />

into solid control of work scope, cost and<br />

schedule. Additionally, active duty soldiers<br />

and Marines were brought in to directly<br />

influence functionality and test Centaur<br />

capabilities during program development.<br />

Jeffrey Weiss (left), U.S. Army product director,<br />

Handheld Systems, and Douglas Johnson,<br />

<strong>Raytheon</strong> NCS E/BMS program manager,<br />

Handheld Products, accept the DoD Top 5<br />

Program Award for the Centaur Program at<br />

the NDIA Systems Engineering Conference.<br />

The end result is a highly regarded and<br />

user-friendly product delivered below cost<br />

and ahead of schedule. In fact, the government’s<br />

Customer Performance Assessment<br />

Report (CPARS) rated <strong>Raytheon</strong>’s work performance<br />

on Centaur (on AFATDS Contract)<br />

for 2004 and 2005 as “Exceptional” — a<br />

perfect score.<br />

The Centaur Handheld Technical Fire<br />

Direction system also received a DoD Top 5<br />

Program Award for 2005. This award<br />

recognizes the successful implementation<br />

of systems engineering best practices<br />

resulting in program success.<br />

The Centaur artillery fire direction system is<br />

a valuable addition to the fires and effects<br />

capabilities of U.S. forces. It ensures that<br />

cannon and mortar delivery systems have<br />

available attack options immediately upon<br />

insertion into the combat area by land, sea<br />

or air. Further, even if the primary tactical<br />

and technical computing system is unavailable,<br />

cannon and mortar delivery systems<br />

remain a viable attack option.<br />

Centaur technology (small form factor,<br />

easy-to-use functionality) opens up several<br />

opportunities for <strong>Raytheon</strong>, including direct<br />

or foreign military sales of Centaur.<br />

Specifically, the adaptation of Centaur technology<br />

by <strong>Raytheon</strong> should enable the capture<br />

of adjacent markets (for small form<br />

factor computer/communications) such as<br />

gun control system, logistics personnel<br />

communications, others needing situational<br />

awareness/communication on the battlefield,<br />

and commercial first responder<br />

type applications.<br />

Douglas Johnson<br />

douglas_a_johnson@raytheon.com

LEADERS CORNER<br />

Dr. Peter Boland<br />

Vice President<br />

Corporate Engineering<br />

Recently Technology Today talked<br />

with Peter Boland, vice president of<br />

corporate Engineering, about the<br />

role of Engineering at <strong>Raytheon</strong> and the<br />

challenges it faces in driving growth.<br />

He also discussed his career at <strong>Raytheon</strong>,<br />

the value of diversity, and what earlycareer<br />

engineers can do to advance in<br />

the company.<br />

TT: What role do <strong>Raytheon</strong>’s engineers<br />

play in the success of the company?<br />

PB: <strong>Raytheon</strong>’s engineers contribute to<br />

the company in two main areas. The first<br />

is innovation. <strong>Raytheon</strong> is known as a<br />

technology company. It’s expected that<br />

<strong>Raytheon</strong> is always on the leading edge of<br />

technologies in our markets. We depend<br />

on our engineering staff and our technology<br />

staff to keep <strong>Raytheon</strong> at the forefront<br />

of technology and innovation.<br />

The other major category, especially in<br />

today’s environment, is program performance.<br />

If <strong>Raytheon</strong> is going to continue to<br />

grow, and if our customers are going to<br />

become an advocate of <strong>Raytheon</strong> on various<br />

programs, especially the area of<br />

Mission Systems Integration, <strong>Raytheon</strong> has<br />

to perform very well on its programs. In<br />

addition, we have to make sure that we<br />

keep all of our promises to our customers.<br />

In doing so, it is critical for the engineering<br />

staff, who is the engine of the success<br />

of these programs, to understand precisely<br />

what responsibilities they have, as well as<br />

being accountable for the work they do.<br />

TT: Why is accountability so important?<br />

PB: I firmly believe that <strong>Raytheon</strong> has<br />

world-class people in Engineering. Where<br />

we sometimes fall short is in the area of<br />

accountability. The challenge for leadership,<br />

management and supervisors is to continually<br />

hone this great talent by providing clear<br />

processes, standards and expectations.<br />

That discipline will enable us to serve our<br />

customers to our fullest potential.<br />

One of the ways to do that is by focusing<br />

more on Performance Excellence. We need<br />

to make sure we understand things like<br />

contractual requirements, and better manage<br />

our subs and suppliers. We really need<br />

to treat our subs, suppliers and partners as<br />

just another <strong>Raytheon</strong> IPT. As a result, many<br />

of our key goals in Engineering address the<br />

need for accountability, continuous learning<br />

and process discipline. If we can excel in<br />

these areas, I believe we will be unbeatable.<br />

TT: So will engineers also have to<br />

become Performance Excellence or<br />

Quality professionals?<br />

PB: No, not exactly, but they need to help<br />

drive these processes. At the end of the<br />

day, program leadership and leadership<br />

teams aren’t the only ones responsible for<br />

Performance Excellence, Engineering is<br />

too. If we don’t do get behind it, it’s not<br />

going to get done the way it should.<br />

TT: What other challenges does<br />

Engineering face?<br />

PB: An upcoming challenge for <strong>Raytheon</strong><br />

is going to be maintaining growth during<br />

the inevitable decline in U.S. defense<br />

spending. When this happens, a potential<br />

area of growth is in the Mission Systems<br />

Integration or the MSI arena.<br />

This will require Engineering to do several<br />

things. One, it requires that we do systems<br />

engineering to a much higher level than<br />

we have done in the past. And, [it<br />

requires] that we develop requirements<br />

from the systems level, from the mission<br />

systems level, all the way down to components<br />

and parts that we supply.<br />

Increased MSI work will also require that<br />

<strong>Raytheon</strong> have a larger number of partners<br />

— meaning we’ll be dealing with a<br />

larger number of subcontractors and<br />

suppliers. We are going to need to learn<br />

how to manage such organizations outside<br />

of our own environment, much better<br />

than we do today, if we’re really going to<br />

grow in that arena.<br />

That will necessitate better program management<br />

skills, better technical skills, more<br />

discipline and following our own processes,<br />

as well as ensuring that our detailed<br />

processes get flowed down to all of our<br />

partners and contractors, etc.<br />

That’s going to be a significant challenge<br />

for our engineers, and we’re working very<br />

hard in that direction right now with the<br />

Engineering staff, program management,<br />

Supply Chain and Performance Excellence<br />

organizations.<br />

It requires a slightly different skill set than<br />

most of our engineers have today. They<br />

need to understand how to adapt to it. In<br />

fact, we’ve been training engineers in<br />

those areas. They’ve been very willing and<br />

excited about moving forward in that area.<br />

TT: Can you provide some examples of<br />

how Engineering is working to improve<br />

our MSI capability and skills?<br />

PB: Systems engineering is essential to<br />

our growth. To emphasize that, I have<br />

brought one of the company’s most senior<br />

and experienced systems engineers onto<br />

my staff, Brian H. Wells. Although Brian is<br />

<strong>Raytheon</strong>’s chief systems engineer, a key<br />

responsibility he has is to grow our systems<br />

engineering capabilities through people,<br />

learning, accountability and mentoring.<br />

Brian is working closely with the Systems<br />

Engineering Council to develop common<br />

competency models, improve our processes<br />

and develop people at all levels. He is<br />

working with the corporate learning<br />

organization and local universities to<br />

improve systems engineering learning. At<br />

every opportunity, as Brian traverses our<br />

businesses, he makes sure to visit with<br />

systems engineering leadership to instill<br />

the merits of process discipline and both<br />

functional and individual accountability.<br />

Continued on page 16<br />

RAYTHEON TECHNOLOGY TODAY <strong>2007</strong> ISSUE 3 15

LEADERS CORNER<br />

Continued from page 15<br />

Once Brian has his arms around making<br />

<strong>Raytheon</strong> a world-class systems engineering<br />

house, he will expand those efforts to other<br />

engineering disciplines.<br />

For <strong>Raytheon</strong> to truly be an MSI, we need<br />

our businesses to be able to work as one<br />

company. That means that in addition to a<br />

common core process — IPDS — we need to<br />

have as many common tools as is rational.<br />

Engineering is pursuing an initiative to move<br />

toward a common Product Life Management<br />

(PLM) suite of tools to make “design anywhere,<br />

build anywhere, support anywhere”<br />

a reality. The foundation of this suite is a<br />

common Product Data Management (PDM)<br />

system. Today, <strong>Raytheon</strong> has almost 30 different<br />

PDM tools as an artifact of the legacy<br />

companies. Many of these are archaic and no<br />

longer supported. We have selected a common<br />

tool and are in the process of planning a<br />

strategy to implement it across the company.<br />

Other initiatives that will help include developing<br />

a common approach to Health<br />

Management Systems — loosely defined as<br />

prognostics, a common strategy for RF<br />

spectrum management; working with<br />

Performance Excellence to improve our<br />

Supplier Rating System; and working with<br />

the <strong>Raytheon</strong> Six Sigma community, supporting<br />

the implementation of a Green Belt<br />

Program, to name just a few.<br />

TT: There have been some exciting CMMI ®<br />

milestones in the businesses. Is that also<br />

part of this strategy?<br />

PB: Absolutely. CMMI is a very powerful<br />

tool to help ensure efficiency, reduce variability<br />

and ensure the same excellent standards<br />

of quality from project to project and<br />

location to location. The businesses have<br />

done a commendable job of achieving<br />

higher appraisal levels, which have enormous<br />

benefits for the company — giving<br />

us the ability and agility to design anywhere<br />

and build anywhere. This year, NCS<br />

achieved Level 5 across all of its business’<br />

sites for systems, software and hardware<br />

engineering — an astonishing achievement.<br />

Most other businesses have been appraised<br />

at level 3 or 4. We’re well on our way to<br />

our future goal of reaching CMMI Level 5<br />

across the entire Engineering function.<br />

TT: Switching gears, you have had quite a<br />

varied career at <strong>Raytheon</strong>. What do you<br />

attribute your success to?<br />

16 <strong>2007</strong> ISSUE 3 RAYTHEON TECHNOLOGY TODAY<br />

PB: Well, it started with a solid foundation.<br />

The reason I became an engineer is that I<br />

was fortunate in that my father was an<br />

educator. He taught math and science, and<br />

he instilled in me an interest in these subjects.<br />

We always had puzzles when I was a<br />

kid. We were always fixing things around<br />

the house. And I just became very interested<br />

and curious about those kinds of things.<br />

He encouraged me to become an engineer<br />

and to continue my education in that direction,<br />

by being very supportive. I was lucky<br />

in that regard, because I had parents who<br />

had the ability to encourage me and coach<br />

me, if you will, in becoming an engineer.<br />

Earlier this year, I celebrated my 38th<br />

anniversary with <strong>Raytheon</strong>. I’ve enjoyed<br />

working here all these years, because<br />

<strong>Raytheon</strong> has provided an encouraging and<br />

exciting environment for me to operate in.<br />

Yes, I’ve had a varied career at <strong>Raytheon</strong>.<br />

When I first joined the company, I worked<br />

in several different organizations and programs.<br />

I saw various forms of engineering,<br />

test engineering, analysis, and did design<br />

work. I got to see those designs actually<br />

built and tested and come to fruition. I was<br />

also able to work with customers to ensure<br />

that we met their requirements.<br />

Through the years, <strong>Raytheon</strong> also encouraged<br />

me to further my education. I went to<br />

graduate school under <strong>Raytheon</strong>’s<br />

advanced studies program, and I was able<br />

to get my master’s degree and eventually,<br />

my Ph.D. through that program.<br />

<strong>Raytheon</strong> has been great to me. I’ve gotten<br />

to see many different businesses and many<br />

different functions. Although I was a<br />

mechanical engineer when I first came to<br />

<strong>Raytheon</strong>, I’ve done electrical engineering<br />

work, and I’ve done some systems engineering<br />

work. So, over the years <strong>Raytheon</strong><br />

has provided the environment where engineers<br />

are encouraged to be the best they can.<br />

TT: As you know, the <strong>Raytheon</strong> environment<br />

values diversity of all kinds. How does<br />

diversity relate to Engineering?<br />

PB: In many ways, but let me highlight<br />

two. The first is in diversity of thought. As I<br />

mentioned, we have great, smart people at<br />

<strong>Raytheon</strong>. But sometimes that confidence<br />

and ability could be perceived as arrogance.<br />

We are not as open as we need to be to<br />

other people’s ideas, perspectives and<br />

input. As a result, programs can get dis-<br />

Q&A With Peter Boland<br />

jointed, team health suffers, and we might<br />

not be effectively collaborating to come up<br />

with the best solution for the customer.<br />

The second reason an inclusive environment<br />

is important to Engineering is that<br />