By C. GEORGE CHARLEShere was a time when the fellow whoT wanted a good .45 autoloader couldpick up an excellent military Colt or contractM1911lA1 at a pretty good price.They were inexpensive enough that economicallythere wasn't any point in buyinga new Spanish Star Model P. It's afact that even doggy militaries cost morethan a brand-new Star, when you canfind one.Actually, the Star design is an improvementupon the old Colt/Browningdesign, with a much more simplifiedframe and lockwork. It is this verv improvementand simplification of frameand lockwork that makes the Star mucheasier to shorten and lighten for combatuse. The parts that give the gunsmith fitsin the Colt don't even exist in the Star.Additionally, there is more leeway in theStar for butt modification.Now let's take a look at what can bedone to whittle that massive 37% ounce,8% inch long, 5'/z inch high gun down tomore manageable and concealable sizewithout detracting from its inherentgoodness and reliability.The hardest part to hide of any gun isthe butt and the .45 and .38 Super Starhave lots of butt. First off, field strip thegun and remove the grips and magazine.Notice the magazine safety (interruptor)positioned in the groove on the right sideof the frame behind the magazine well.Drift it out from the left side and throw itaway. A combat gun has no business witha magazine safety. Of course it is usefulin a household by a neophyte.Now look at the bottom half of the butt.Notice it is completely uncluttered withjust a metal shell into which the magazinefits. Everything below the mainspring anchorpin could be cut away and not interferea bit with the functioning but thatwould be cutting off too much thus makingthe handle too short for proper con-trol. Removing %" to ¥% from the buttis about right and there are two waysto do it.Simplest for the amateur is to saw andfile two lengths of 1/10" by %" steel stripto fit snuelv into the butt cutouts as-,shown. First, remove all other parts fromthe frame. Then, clean the joint surfacesthoroughly. Next flux and apply silversolder. Be sure you heat enough until itflows and a good joint is produced. Makesure these inserts are flush with the sidesof the butt inside so a magazine can enterfreely. This soldering can be handledwith a household propane torch or twoalthough an oxyacetylene torch will dothe job more easily.When cool, clean up the outer surfacesof the inserts. File if necessary. Then youcan flush and smooth with the frame butt.Screw the right grip back in place. Locateon the grip a new grip screw hole on linebetween the two existing and Ys" abovethe bottom hole. Level the frame with theright side up on the drill press table. Nowyou drill through the grip and both sidesof the frame in one shot. Remove the gripand tap both frame holes to accept theoriginal grip screws. Clean off the burrsinside and out as well as making certainthe screws turn in freely. Mark and drillthe screw hole in the left grip too.Now, with a properly secured seat forthe grips provided by the inserts, simplyscribe around the butt parallel to the bottomat the cutoff point. With a new highspeedsteel blade doused frequently withcutting fluid, you can hacksaw off theThe big star is a modified takeoff of theBrowningIColt .45 Government Model. Itcan also be done with the 9rnm or .38Super, all steel models.butt as near to the scribed lines as possible.Just remember to leave enough metalto file and grind it true to the mark. Thenew butt bottom surface should be flushwith the bottom of the silver solderedspacers or perhaps cutting slightly intothem. Note that if the spacers had notbeen installed, the butt would now be arelatively fragile open "U" of steel. Thespacers tie it all together and preventdistortion.Next, with files and your ever handyDremel Moto-Tool, duplicate the funnelingof the original butt around the inneredges of the new surface. These bevelsfacilitate rapid insertion of a freshmagazine and can well be carried evenfarther if you like. This is the simplestway.If you prefer and have welding equipmentthat you know how to use, youmight prefer doing it this way. First, youcan saw out a W section of the butt betweenthe mainspring anchor pin and thebottom paralleling the bottom line of theAMERICAN HANDGUNNER JULYIAUGUST <strong>1978</strong>

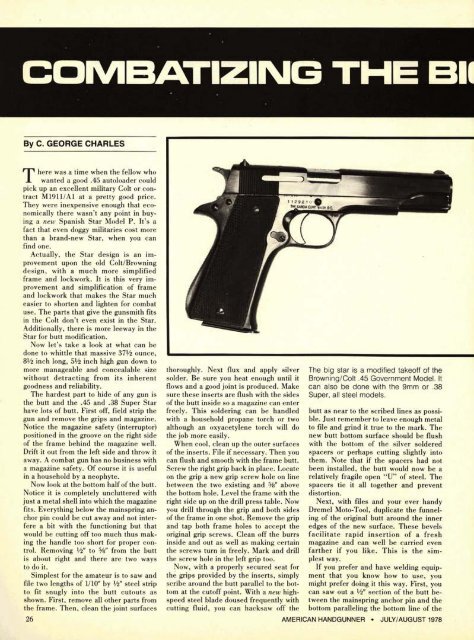

Now you see it trimmed down to manageablesize. Note the smaller butt, thesquared off trigger guard, and the combatsafety.butt. Then you can weld the cut off bottomback to the upper part. Rememberthat great care is required in aligning thetwo parts so the magazine will remaintrue. However, you can do this easilyenough with a spare magazine body andclamp and shims. A close fitting mandrelwould be best, but making one takesmore time than a single shortening jobcan justify.Regardless of the method you choose touse, it is necessary to clean the inside ofthe magazine well at the joints. This permitsthe magazines to enter and ejectfreely. Get rid of all heat scale and roughnessas well as surplus metal. Not onlymust magazines enter freely but theymust fall clear of their own weight whenthe catch is depressed. After filing, polishthe inside of the well with abrasive clothglued to shaped strips of wood.Now, with the slide on the frame andthe magazine catch in place, put one cartridgein a magazine and then insert ituntil the catch engages. Scribe aroundAMERICAN HANDGUNNER JULYIAUGUST <strong>1978</strong>the magazine body even with the butt andthen press the magazine in as far as it willgo. Use hand pressure only. Now againscribe around the body while it is heldthere.Next remove and disassemble themagazine completely. Make up a hardwoodplug to fit inside the body. Insertthe plug and clamp the magazine in yourvise. Now saw off the bottom W belowthe second or lowest scribe mark. Thensaw through the front of the body justbelow the first or highest scribe mark justback through the radius to the beginningof the flat sidewalls. Trim out this arcshapedpiece of metal and true up all cutedges with files.Insert a block of steel or aluminum thatis push fit in the magazine body. It can beseveral thicknesses of strip if necessary.Now clamp tightly in the vise. The visejaws must be true and the lowest scribemark must be flush and parallel withthem. Quickly bring the overhanging bitsof magazine sidewall to red heat, tap overoutward at right angles, down on visejaws with a smooth hammer that formsflanges just like the magazine possessedoriginally.Finish this by filing or grinding theedges of the flanges you've just producedso that the original floor plate will slidesmoothly over them. Remove the floorplate and flow low temp silver solder intothe seams where it is folded back on itselfto form the front tongue. As for themagazine spring, you just need to clip onecomplete coil off the bottom. Now bendthe last half-coil up as it was originally.Assemble the shortened magazine andinsert it in the shortened gun butt. Polishthe reworked area if necessary for freeinsertion and removal and make certainthe magazine catch engages properly.If the butt has been shortened by ourfirst method, the floor plate will extendwell beyond the front strap. Cut away thisexcess, flush with the front strap, thenradius all edges of the floorplate smoothlyso it won't snag hands or clothing. Now,back to the shortened butt. As it ischopped off abruptly in the curve of thebackstrap, it probably won't feel right inyour hand. Install the grips and saw themoff flush with the butt. Test how it feelsand do a little shooting, if necessary, tobe certain. If it feels okay, you justhave to file or grind the sharp edges to asmooth radius and your butt shapingis done.However, if it doesn't feel right, startfiling and grinding on the bulged backstrapuntil the gun feels and handlesright. I prefer to cut the hump off entirely,giving it the shape of a Colt .45 autowith the old flat mainspring housing.Now if you used the first butt shorteningmethod, you'll find that nearly all theswell at the bottom of the front strap willbe cut away. By the second method, itwill remain but there will be a step whereit joins the rest. There will be a dogleg atthe backstrap joint. Personally, I preferto eliminate this swell in any event. Itadds far more weight and bulk than itssmall amount of handling benefit isworth. Simply grind or file it off, fairingthe entire front strap into a straight line.When this is done, the second methodwill leave a small U-shaped notch wherethe original funneling cuts through. I likethis as it leaves a point of purchase wherethe front of the floorplate can be graspedif for some reason a magazine becomesstuck. For the same reason, when thefirst shortening method is used, I goahead and file a notch at the same pointafter the strap is straightened.27

- Page 1: " I THE AMERICANAUNOFFICIAL MAGAZIN

- Page 6 and 7: INDUSTRY INSIDERBy MASSAD F. AYOOB

- Page 8 and 9: -NIARLES C THOMAS-PUBLISHEI- I?r ?I

- Page 10 and 11: -'.. : ,,. . .{b-.$, \:..', -.,.IOO

- Page 12 and 13: SNUBmNOSEDREVOLVER1 FREE: Targets a

- Page 14 and 15: PA DISSENTING VIEW ON MAGAZINE SAFE

- Page 16 and 17: The New PistolcraftAt Jeff Cooper's

- Page 19 and 20: The Evolution ofModem PistolcraftBy

- Page 21 and 22: Sykes back in the 1930's. This prov

- Page 23 and 24: Charter544 Bi^gShot LoadsBy GEORGE

- Page 25: Throat opening can be done with cas

- Page 29 and 30: , .- - A --.-ng. As analternative,

- Page 31 and 32: Little is known of his second ventu

- Page 33 and 34: engaging the cartridge case groove

- Page 35 and 36: AMERICAN HANDGUNNER . JULYIAUGUST 1

- Page 37 and 38: II ShootingIll Law EnforcementPart

- Page 39 and 40: neared completion, factory manageme

- Page 41 and 42: Smith & Wesson Model 595107 Rear Si

- Page 43 and 44: By MASSAD F. AYOOBT THE time of the

- Page 45 and 46: when an automatic is adopted. One r

- Page 47 and 48: of WW 296 in CDM cases sparked by C

- Page 49 and 50: Zen, a td, lean, mustached western

- Page 51 and 52: Here's what makesDan Wesson revolve

- Page 53 and 54: Cutter T-1 is the most delicate of

- Page 55 and 56: standing Handgun Hunter Award is Da

- Page 57 and 58: INTRODUCTION TO 39/59(Continued fro

- Page 60 and 61: ''mentioning the fact that, with th

- Page 62 and 63: The .a57 MagnumHE .357 Magnum was d

- Page 64 and 65: Durable liaht weiaht cast aluminum

- Page 66 and 67: exceeds this record of rejection-af

- Page 68 and 69: 1 fire the first shot DA anyhammers

- Page 70 and 71: THE AMERICAN. . . the only magazine

- Page 72: When your 22 has to do more than it