Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

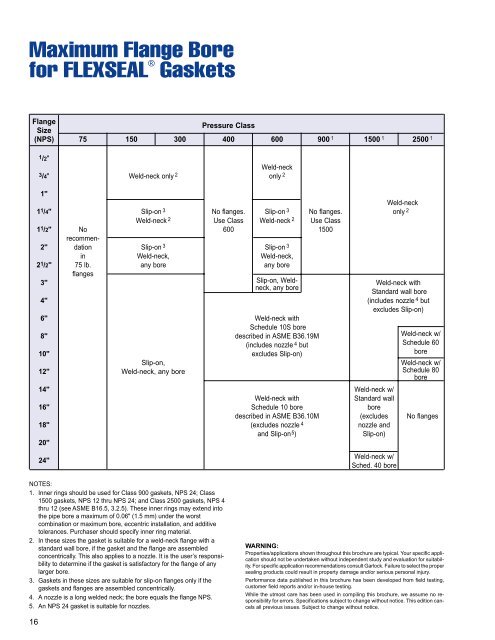

Maximum Flange Borefor FLEXSEAL ® GasketsFlangeSizePressure Class(NPS) 75 150 300 400 600 900 1 1500 1 2500 11/2"Weld-neck3/4" Weld-neck only 2 only 21"Weld-neck1 1 /4" Slip-on 3 No flanges. Slip-on 3 No flanges. only 2Weld-neck 2 Use Class Weld-neck 2 Use Class1 1 /2" No 600 1500recommen-2" dation Slip-on 3 Slip-on 3in Weld-neck, Weld-neck,2 1 /2" 75 lb. any bore any boreflanges3"Slip-on, Weld-Weld-neck withneck, any boreStandard wall bore4" (includes nozzle 4 butexcludes Slip-on)6" Weld-neck withSchedule 10S bore8" described in ASME B36.19M Weld-neck w/(includes nozzle 4 but Schedule 6010" excludes Slip-on) boreSlip-on, Weld-neck w/12" Weld-neck, any bore Schedule 80bore14" Weld-neck w/Weld-neck withStandard wall16" Schedule 10 bore boredescribed in ASME B36.10M (excludes No flanges18" (excludes nozzle 4 nozzle andand Slip-on 5 )Slip-on)20"24"Weld-neck w/Sched. 40 boreNOTES:1. Inner rings should be used for Class 900 gaskets, NPS 24; Class1500 gaskets, NPS 12 thru NPS 24; and Class 2500 gaskets, NPS 4thru 12 (see ASME B16.5, 3.2.5). These inner rings may extend intothe pipe bore a maximum of 0.06" (1.5 mm) under the worstcombination or maximum bore, eccentric installation, and additivetolerances. Purchaser should specify inner ring material.2. In these sizes the gasket is suitable for a weld-neck flange with astandard wall bore, if the gasket and the flange are assembledconcentrically. This also applies to a nozzle. It is the user’s responsibilityto determine if the gasket is satisfactory for the flange of anylarger bore.3. Gaskets in these sizes are suitable for slip-on flanges only if thegaskets and flanges are assembled concentrically.4. A nozzle is a long welded neck; the bore equals the flange NPS.5. An NPS 24 gasket is suitable for nozzles.WARNING:Properties/applications shown throughout this brochure are typical. Your specific applicationshould not be undertaken without independent study and evaluation for suitability.For specific application recommendations consult Garlock. Failure to select the propersealing products could result in property damage and/or serious personal injury.Performance data published in this brochure has been developed from field testing,customer field reports and/or in-house testing.While the utmost care has been used in compiling this brochure, we assume no responsibilityfor errors. Specifications subject to change without notice. This edition cancelsall previous issues. Subject to change without notice.16