ENGINES 9-2 FUEL SYSTEMS 9-6 TOP END 9-20 ... - S&S Cycle

ENGINES 9-2 FUEL SYSTEMS 9-6 TOP END 9-20 ... - S&S Cycle

ENGINES 9-2 FUEL SYSTEMS 9-6 TOP END 9-20 ... - S&S Cycle

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

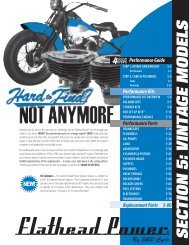

Parts forTwin Cam 88®CTOS&S Special Application (SA) B1 heads are intended for racing and radical street applications with high cfm requirements. For maximum versatility, SA B1 hare available in three stages of completion: unfinished, semi-finished, and fully machined. Due to the complex machining required to complete unfinishedsemi-finished heads, we recommend them only for professional engine builders with extensive machining capabilities. Fully machined SA B1 heads requirParts forEvolution®Parts forSportster® '86-'06finishing and final assembly. All SA B1 heads, regardless of part number oroptions, are shipped unassembled. This allows the builder to finish themexactly as required.Fitment❚❚ Available for modified Harley-Davidson® Evolution® big twinengines and 1986-’03 Sportster® models❚❚ For engines with a minimum cylinder bore of 4", and willaccommodate cylinder bores up to 41⁄2"VintageEnginesX-Wedge®Parts for Victory®,Off-road & MetricReplacementPartsTools &Shop SuppliesRacingProductsDealer Services& Promo ItemsWarranty &Company PolicyFeatures and Benefits❚❚ CNC machined and cast from 356 aluminum alloy and heattreatedto T6 specifications – maximum structural integrity andheat dissipation❚❚ Head bolt circles of 5.675" with 1⁄2" head bolts or 5.750" with7/16" head bolts can be used (S&S can match the industry's morecommon bolt patterns if requested or other patterns can bemachined if a print is provided)❚ ❚ Head gasket surface has sufficient material for machining – adjustcompression ratio without compromising structural integrity❚❚ Internal or external oil return passages are provided on fullymachined SA heads❚❚ Intake port utilizes a directional vane that routes the incomingfuel-air mixture around the valve stem and guide – minimizesturbulence and improve flow and cylinder fill• With minimal finish porting of a fully machined SA head, intakeflow is typically 195 cfm at 10" water and 0.700" liftvalve size is 1.750".• Intake port is located approx. .500" higher than stock – may ❚❚ Both cast iron and bronze valve guides are available. Cast guidescause interference problems with the top motor mount, particularlyare recommended for moderate duty and where longevity is ain rubber-mount chassisconsideration. Bronze guides can accommodate higher lifts and• SA intake port requires the use of a special intake manifold andare recommended for severe duty applications where longevitymounting hardware (not included – must purchase separately).is not a primary concern. See page 9-32 for S&S valve spring kitsThis manifold will be machined to customer specificatedrecommended for SA heads.manifold length and bore size. Port-to-port measurements must ❚❚ Combustion chamber in completely machined SA heads isbe supplied from mock-up or assembled engines. See page 7-4.similar to the closed, high-quench chamber used in 31⁄2" and• Professional porting is recommended in order to achieve the full35⁄8" bore Super Stock® heads. SA squish shelves are rounded topotential of these headsimprove combustion chamber dynamics in large displacement,high-revving engines. Heads may also be purchased with the❚❚ Exhaust Port has also been relocated in SA heads, requiring that acombustion chambers unmachined.special exhaust system be fabricated❚❚ Typical exhaust flow with minimal finish porting is 147 cfm at10" waterKit Contents❚❚ The valves, seats, and guides used in SA heads are compatible ❚❚ Completely machined front and rear cylinder heads with valvewith exotic fuels and are designed to withstand the high valveseats and guides installedspring pressures required for high rpm operation.❚❚ Additional parts which are not installed include: valves, seals,❚❚ Standard SA intake valve diameter is 2.100". Standard exhaustmanifold mounting hardware, and exhaust flanges.Order toll free 866-244-26739-28