touch probes - Marposs

touch probes - Marposs

touch probes - Marposs

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

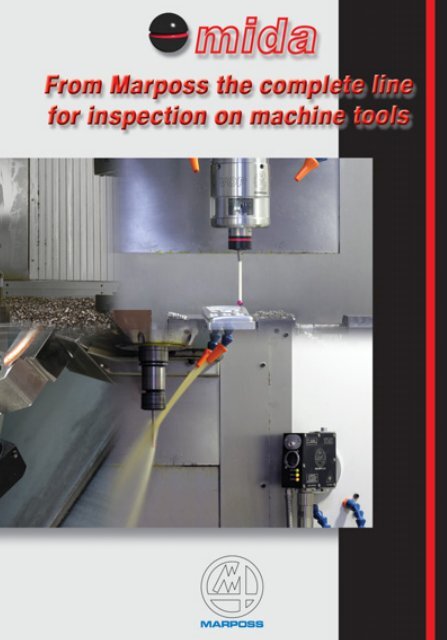

<strong>Marposs</strong> has developed the Mida line of products to perform partinspection, tool setting and machine monitoring applications on machinetools.Mida systems feature various signal transmission options, enabling<strong>Marposs</strong> to supply the best application for all measuring requirementson machine tools.Mida products are designed to withstand the harshest conditionsin the machine environment whilst at the same time assuring thehighest measuring precision.Part probing Tool setting Machine monitoringMachining centresMilling machinesLathesTurning centresGlass / marbleworking machinesTool grindersGrindersContact probe/plugoptical/radio transm.Contact probeoptical/radio transm.Contact probeoptical/radio transm.Contact proberadio transm.Contact probehard wired transm.Contact probehard wired transm.Contact probe/laseroptical/radio transm.Contact probe/laseroptical/radio transm.Arms with contact probeLaserLaserContact probehard wired transm.Contact probehard wired transm.Tool monitoringVibration monitoringTool monitoringVibration monitoringTool monitoringVibration monitoringTool monitoringVibration monitoringTool monitoringVibration monitoringTool monitoringVibration monitoring

PART PROBINGTOOL SETTINGtwin probeCOMPLETE PART PROBINGAND TOOL CHECK APPLICATIONEfficient combined toolcheck and part probingapplication for use onmachining centres andmilling machines• Available withradio or opticaltransmission• Fully controlled by asingle interface, completelywireless.• Ultra-compact applications in the case of the optical version usedtogether with the (Ø18 mm) receiver

PART PROBINGWRSRADIO TRANSMISSIONPART PROBING SYSTEMand large machine tools,• The WRP45 versionfeatures reduceddimensions - 45 mmmilling machines•large MC and lathes• 2.4 GHz radio transmission frequency for ranges of up to 15 m• Long transmission range - up to 15 m• Exceptional operating autonomy, up to 1500 hours in continuous use• Modular system in orderto satisfy a wide range ofrequirements• 79 channels 4 sub-channelsprovide incredible operatingquantity in the sameenvironment

PART PROBINGE83LOPTICAL TRANSMISSION PART PROBINGSYSTEM FOR LATHESDesigned for use on lathes:• Long transmission range• Modular system in orderto satisfy a widerange of customerrequirements• Compact size of individualcomponents• Multi probe mode, up to 4 <strong>probes</strong> on the same machine

<strong>touch</strong> <strong>probes</strong> - T seriesTHE IDEAL PROBE RANGEFOR FLAT SURFACESflat) surfaces.•2σ ≤ 0.5 μm• Excellent results withlong stylii•and rapid machine accelerations• Extensions for reaching hardto access points• Compatibility with all <strong>Marposs</strong>modular systems formaximum operating flexibility

<strong>touch</strong> <strong>probes</strong> - TT seriesTHE IDEAL PROBE RANGE• High over travel for increate probe protection• Extensions for reaching hard toaccess points• Compatibility with all <strong>Marposs</strong>modular systems for maximumoperating flexibilitydimensional) surfaces• Repeatability 2σ ≤ 1 μm• Multi-directional repeatability,irrespective of <strong>touch</strong> directions• Excellent results with complexand heavy styli

TOOL SETTINGTS lineRANGE OF PROBESFOR CONTACT TOOL CHECKCapable of performing presetting, lengthand diameter measurements, integritychecks and tool wear compensation.The range features the following models:• TS30, hard wired with integratedinterface, can be used to measuretool length and diameter even whenrotating•The whole range features:• Repeatability 2σ ≤ 1 μm• Immunity to machine vibrations• Collision protectionTS30OTS30WRTSNew radio transmission probe. Whencoupled with the WRS spindle probe, theyform a complete part probing and tool checksystem with a single interface.

TOOL SETTINGmida laser pNON CONTACT LASERTOOL CHECK SYSTEMfor presetting, performing lengthand diameter measurements onrotating tools, identification, wearcompensation, integrity checks,tool breakage, and machine axesthermal drift compensation• Available in compact ormodular versions• Optimum repeatability,2σ ≤ 0.2 μm• Tool diameter measurements up to 30 μm• Focused laser beam guaranteesmaximum measurementaccuracy• Exclusive, patented tunnel effect(ATE) protection system• Maximum measurementaccuracy, even in the presenceof coolant• Machine table support includes

TOOL SETTINGmida laser 75HPHIGH PRECISION LASERTOOL CHECK SYSTEMThe perfect response to the requirementsfor micro-machined high-precisionparts with low surface roughness. Usedfor presetting, performing length anddiameter measurements on rotatingtools, identification, wear compensation,integrity checks, tool breakage, andmachine axes thermal drift compensation• Optimum repeatability, 2σ ≤ 0.2 μm• Tool diameter measurements to 10 micron• Reduced laser beam diameter allows maximum independence fromtool geometry• Exclusive, patented tunnel effect (ATE) protection system• Maximum measurementaccuracy, even in thepresence of coolant• Machine table supportincludes built-in toolcleaning kit

TOOL SETTINGTBDNON CONTACT LASERTOOL BREAKAGE CHECK SYSTEMTBD (Tool Breakage Detector), newlaser triangulation device for toolbreakage controls• Extremely fast and sensitive• Capable of monitoring a widerange of tool diameters down to0.2 mm• Capable of detecting tools at arange of distances from 0.3 to2 m• Functions at all multiple rotationspeeds from 200 and 1000 rpm,up to 5000 rpm

TOOL SETTINGT18LCONTACT TOOL CHECK PROBEFOR LATHESTouch probe for tool controlson lathes and turning centres,capable of performingpresetting, tool length anddiameter measurements, wearcompensation and tool integritychecks.• Repeatability 2σ ≤ 1 μm• Wire transmission• High protection against hostile machine environments

TOOL SETTINGA90KRANGE OF PROBES FOR CONTACTTOOL CHECK ON LATHESCompact applications for performing tool length measurements, offsetcalculations, wear compensation andtool breakage checks on lathes. They areequipped with a contact for each <strong>touch</strong>direction.• Repeatability 2σ ≤ 1 μm• Wire transmission• High reliability• Immunity to machine vibrations• High protection against hostilemachine environments

TOOL SETTINGmida setRANGE OF ARMS FOR CONTACTTOOL CHECK ON LATHESThe range of removable arms for presetting tools on lathes.• Repeatability 2σ ≤ 5• Wide range of sizesavailable• Takes up minimumspace when not inuse

TOOL SETTINGmida tool eyeRANGE OF MANUALLY OR ELECTRICALLYOPERATED ARMS• Repeatability 2σ ≤ 5 μm• Wide range of sizes availableThe motor operated version:• Can be used to is possibleto perform automaticmeasurement cycles• Drastically reduces toolchecking times• Enables correction of thermaldrift• When not in use, the probeis placed in special box thatguarantees optimum protection

PART PROBINGTOOL SETTINGstyli and accessoriesACCESSORIES FOR APPLICATIONSWITH TOUCH PROBES<strong>probes</strong> in order to satisfyevery possible machinerequirement or customerspecification:• Various different stylusforms and lengths• Wide range of adapters,extensions and supports

PART PROBING3D Shape InspectorSOFTWARE FOR 3D INSPECTIONOF WORKPIECES SHAPEwithout removing it from themachine.• Simplified part reworkingmanagement• Interactive measurementpoint selection• Preparation of customerdefinedreportsKinematic management with3/4/5 configurable axesCompatible with the vastmajority of CNC

mida softwareSOFTWARE PACKAGES FOR CONTACTOR LASER PROBING<strong>Marposs</strong> has developed software packagesfor all its part and tool contact andnon-contact control systems, for everytype of machine tool. They areextremely user friendly and makethe <strong>Marposs</strong> systems easier touse, streamlining themeasurement cycleprogramming processand optimisingproductionefficiency, interms of speedand quality.• 3D Inspection of the part• Tool setting with contact<strong>probes</strong>• Tool setting with MidaLaser

PART PROBINGTOOL SETTINGmida softwareThe table indicates the availability of measuring cycles for each CNC type.For CNC not listed below, please contact your nearest <strong>Marposs</strong> office.FANUCAND SIMILAR •SIEMENS840D-810D-828DSIEMENS840CSIEMENS802DMAZATROLHEIDENHAINFAGOR8050-8070SELCA3000-4000D.ELECTRONZ32ECSSERIES WINOKUMAMACHINING CENTRESPart probing √ √ √ √ √ × × × × ×Part 3D inspection √ √ √ √ √ ΔContact tool setting √ √ √ × × × × ×Laser tool setting √ √ √ √ √ √ √ √ √ √LATHES ANDTURNING CENTRESPart probing √ √ √ √ √ × √Contact tool setting √ √ √ ×Laser tool setting √ √ √Legenda:√ = available×= already available in CNC original softwareΔ = available only for THINC CNC model• = Brother, Haas, Makino, Mitsubishi, Yasnac

PART PROBINGTOOL SETTINGMACHINING CENTRESPart probingPart 3D inspectionContact tool settingLaser tool setting• Protected part positioning• Calibration• Bore and boss measure• Two bores/bosses measure• Three/four bores/bosses measure• Web and pocket measure• Single surface measure• Inner-outer corner measure• Angle measure• Probe aligning for multiple axes• Stock measure• Calibration• Point programming• Geometric body programming• Graphical simulation of path• Measurement reports• 3/4/5 axes management• All popular CAD file format management• Most CNC supported• CNC or external PC installation• Calibration, measure, integrity inspection on tool lengthand tool diameter• Calibration• Length and radius gauging of axial and not axial tools• Checking for tool breakage• Cutting edges integrity check on tool’s straight profile• Cutting edges integrity check on tool’s round profile• Gauging of the radius of tool’s cutting edge• Presetting for disk mill and boring bar• Axis thermal drift compensation• Tool circular sector checkLATHES ANDTURNING CENTRESPart probingContact tool settingLaser tool setting• X - Z axis calibration• Protected positioning• X - Z axis single <strong>touch</strong> measure• Z axis rib and groove measure• Diameter measure• Web/pocket bore/boss measure• C axis measure with centre search• Tool probe calibration• Automatic tool measure• Presetting for standard tool• Presetting for neutral tool• Presetting for threading tool• Presetting for external and internal groove tool

MONITORINGSYSTEMSMMS lineMONITORING SYSTEMS FOR MACHINE TOOLThese systems are the ideal solution for improving the efficiency ofthe mechanical machining processes while maintaining high qualitystandards. The part machining process is monitored continuouslyso that it can be interruptedimmediately in the event of ananomaly without having to waitfor a check at the end of theline, and enables the user tooptimise the cutting parametersin order to improve the qualityof the machined surface.Tool controls• Tool breakage• Tool wear for replacement/sharpening only if necessary• Tool unbalancingProcess controls• Cutting forces• Loads on drives• Cutting parameters and machine vibrations

MONITORINGSYSTEMSMMS lineIn addition to monitoring theprocess, our systems also checkthe state of the machine tool so thatit is possible to carry out preventivemaintenance on worn parts beforemore serious breakages occur, thusavoiding the much higher costsresulting from the need to carryout repairs and the consequencesof prolonged downtime. Also, inthe event of a collision, the axesstop moving instantly, preventingstructural damage to the machineMachine/spindle controls• Wear and tear of mechanical parts• Dilatation of mechanical parts• Working temperatures• Collisions

www.marposs.comTo download a pdf copyof this catalogueTo visit the <strong>Marposs</strong> websitewww.marposs.com

MARPOSS in the world<strong>Marposs</strong> Headquarters - Bologna (Italy)<strong>Marposs</strong> Germany - Weinstadt<strong>Marposs</strong> U.S.A. - Auburn Hills<strong>Marposs</strong> Japan - Tokyo<strong>Marposs</strong> China - Nanjing

AUSTRALIAAUSTRIABRAZILCANADACESKÁREPUBLIKA andSLOVENSKAREPUBLICACHINADEUTSCHLANDESPAÑAFRANCEGREAT BRITAINHONG KONGINDIAISRAELKNOXFIELDWIENER NEUDORFSÃO PAULOCURITIBASÃO LEOPOLDOTORONTOPRAHANANJINGBEIJINGCHONGQINGGUANGZHOUKUNSHANSHANGHAISHENYANGSHENZENWUHANWEINSTADTCHEMNITZFRANKFURT / MAINHANNOVERKREFELDMÜNCHENBARCELONASAN SEBASTIANRUEIL MALMAISONBRIGNAISCOVENTRYHONG KONGIMT MANESARBANGALORECHENNAIJAMSHEDPURPUNEYAVNEITALIAJAPANKOREA - R.O.K.MALAYSIAMEXICOPOLSKAROMANIARUSSIASCHWEIZSINGAPORESLOVENIJASOUTH AFRICASRBIJA I CRNAGORASVERIGETAIWANTHAILANDTÜRKIYEU.S.A.For a detailed address list:www.marposs.comBENTIVOGLIOMILANOTORINOTOKYONAGAOKATOYOTATOYAMAOSAKAHIROSHIMASEOULULSANCHANGWON-CITYGUNSANKUALA LUMPURATIZAPÁN DE ZARAGOZAQUERETAROSALTILLO COAHUILAPOZNANBRASOVMOSKVASAMARABELPSINGAPORENOVA GORICAJOHANNESBURGKIKINDAKARLSKOGATAICHUNG CITYBANGKOKISTANBULAUBURN HILLS

RADIO & OPTICALSPINDLE PROBESLASER TOOL SETTING© Copyright 2007-2012 <strong>Marposs</strong> - D6C03800G0 - ed. 11/2012CONTACT TOOLSETTINGMACHINE MONITORINGSYSTEMS