UT5200 Series - Corbin Russwin

UT5200 Series - Corbin Russwin

UT5200 Series - Corbin Russwin

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

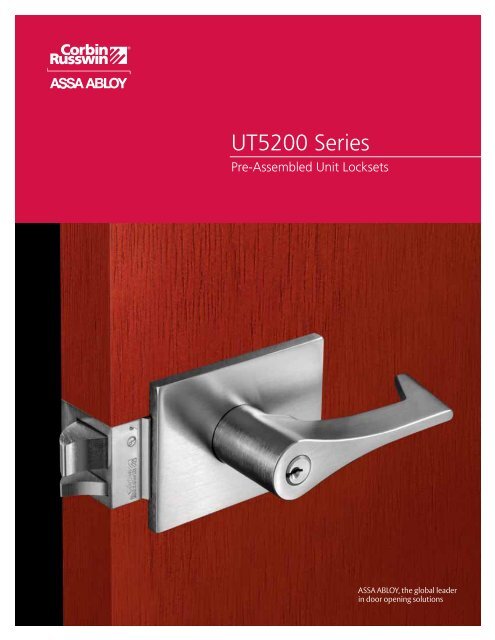

<strong>UT5200</strong> <strong>Series</strong>Pre-Assembled Unit Locksets

Applications<strong>UT5200</strong>Table of ContentsApplicationsThis lock has provided decadesof service in some of the world'smost prestigious buildings. Itspre-assembled, unitized construction isideal for projects where installation costsare to be minimized. Typical high-trafficcommercial, institutional and industrialapplications include:• Schools and universities• Office buildings• Hospitals• Municipal buildings• Historic buildingsAdvantages• Factory pre-assembled for quick,economical, one-piece installation: nojob site assembly required• 3/4" radius latchbolt, designed towedge more tightly into the strikewhen tampered with, while meeting allADA force-to-latch requirements.Applications......................... 2Features.............................. 3Functions............................. 4Trim Designs........................ 5Options and Accessories...... 6How to Order.......................8Helpful Terms.................... 10How to Specify.................. 11www.corbinrusswin.com<strong>UT5200</strong>.245090-7/13

Features<strong>UT5200</strong>FeaturesHandingSpecify hand. All functions are handed.Door Thickness1-3/4" (44mm) only.Backset2-3/4" (70mm) only.Lock ChassisOne-piece investment cast frame.Machined internal parts of steel, bronzeand stainless steel. Zinc dichromated forcorrosion resistance.FrontBeveled 1/8" (3mm) in 2" (51mm).LatchboltBrass, chrome plated, 3/4" (19mm) throwpivoted, swinging type.Auxiliary LatchDeadlocks latchbolt, preventingmanipulation when door is closed.StrikeWrought brass or bronze, ANSI strikewith nylon adjusting screw, standard.4-7/8" (124mm) x 1-1/4" (32mm) x 1-1/4"(32mm) lip to center.Optional strikes and lip lengths available;see pages 6 and 9.CylinderBrass, 6-pin, L4 keyway, 0-bitted standard.KeysTwo nickel silver standard.Keying Features AvailableMaster keyingConstruction master keyingVisual key controlConcealed key controlInterchangeable core (IC)SecuritySecurity (IC)Pyramid High SecurityPyramid High Security (IC)Pyramid SecurityPyramid Security (IC)Master ringWarrantyOne-year limited.Certification/ComplianceANSIMeets A156.2 <strong>Series</strong> 2000.Meets A117.1 Accessibility Code (leverdesign only).FederalMeets FF-H-106C.California State Reference Code(Formerly Title 19, California State Fire MarshalStandard)All levers with return comply; levers returnto within 1/2" (13mm) of door face.UL /ULCAll locks listed for A label and lesser classdoors, single or pair, maximum door size3'8" (111.7cm) x 7'2"(218.4cm)All locksets also listed for B label doors,single or pair, maximum door size 4' x8'. Letter F and UL symbol on lock frameindicate listing.Any retrofit or other field modification toa fire-rated opening can potentially impactthe fire rating of the opening, and <strong>Corbin</strong><strong>Russwin</strong>, Inc. makes no representations orPrecision machined internalparts ensure smooth operationand long lifewarranties concerning what such impactmay be in any specific situation. Whenretrofitting any portion of an existing fireratedopening, or specifying and installinga new fire-rated opening, please consultwith a code specialist or local code official(Authority Having Jurisdiction) to ensurecompliance with all applicable codes andratings.Finishes612 US10 Satin Bronze613 US10BInstallation of preassembled locksetrequires only tightening three throughbolts, significantly reducing costs andpotential for errorOxidized Bronze, oilrubbed, available lacquered625 US26 Bright Chromium Plated626 US26D Satin Chromium Plated626C—Satin ChromiumPlated withMicroShield ®3/4" throw latchbolt providessecurity and meets all force-tolatchrequirementsConventional, high security,interchangeable core andmaster ring cylinders availablefor keying flexibility45090-7/13<strong>UT5200</strong>.3

Options and Accessories<strong>UT5200</strong>StrikesLipLength**Lip length for ANSI strikesmeasured from lip to centerANSI Curved LipBrass or bronze.4-7/8" (124mm) x 1-1/4"(32mm) x 1-1/4" (32mm) lip tocenter.Nylon set screw to adjustclearance.No optional lip lengths.Wrought box not available.To order with lockset, see Howto Order, pages 8 and 9. Toorder separately, specify 236L75x Finish.ANSI Straight Lipfor Extended LipEscutcheonBrass or bronze.4-7/8" (124mm) x 1-1/4"(32mm) x 15/16" (24mm) lip tocenter.Nylon set screw to adjustclearance.Furnished standard withextended lip escutcheon option.To order separately, specify610L43 x Finish.LipLength**Lip length for non ANSIstrikes measured from backof the strike to the lip.Curved Lip BoxBrass or bronze.3-1/4" (83mm) x 1-1/8" (29mm)x 2-1/8" (54mm).Nylon set screw to adjustclearance.Optional lip lengths (measuredfrom back of strike to edge oflip): 2" (51mm), 2-1/4" (57mm),2-1/2" (64mm), 2-3/4" (70mm),3" (76mm).To order with lockset, see Howto Order, page 9.To order separately, specify083L96 x Lip Length x Finish.For Extended LipEscutcheonBrass or bronze.3-1/4" (83mm) x 1-1/8" (29mm)x 1-13/16" (46mm) lip length.Nylon set screw to adjustclearance. Lip not curved.To order with lockset, see Howto Order, page 9.To order separately, specify293L14 x Finish.ANSI Straight Lip forPairs of DoorsBrass or bronze.4-7/8" (124mm) x 1-1/4"(32mm) x 1" (25mm) lip tocenter.Non-adjustable.To order with lockset, see Howto Order, pages 8 and 9.To order separately, specify610L44 x Finish.For Pairs of DoorsBrass or bronze. Non-adjustable3-1/4" (83mm) x 1-1/16"(27mm) x 1-13/16" (46mm).To order with lockset, see Howto Order, page 9.To order separately, specify82L67 x Finish.<strong>UT5200</strong>.645090-7/13

Options and Accessories<strong>UT5200</strong>CylindersStandard Cylinder.552" plug diameterBrass, 6-pin2 nickel silver keysFinishes: 606, 626.496" plug diameter PyramidInterchangeable Core.509" plug diameter conventional.552" plug diameter high securityBrass, 6-pin2 nickel silver keysFinishes: 612, 613, 625, 626.496" plug diameter PyramidMaster Ring Cylinder.552" plug diameterBrass, 6-pin2 nickel silver keysFinishes: 606, 626Conventional 6-Pin 2000-052 8000 2060-052Conventional 7-Pin N/A 8000-7 N/ASecurity 2010-052 8010 N/APyramid High Security 2020-052 8020 N/APyramid Security 2027-052 8027 N/ATo order optional cylinder with lockset, see How to Order, page 9.To order cylinder separately, specify Part No. x Keyway x Finish) (e.g., 2000-052 x L4 x 626).45090-7/13<strong>UT5200</strong>.7

How to Order<strong>UT5200</strong>Ordering ExamplesStock OrderQuantity <strong>Series</strong>/Function Trim Finish Hand100 UT5251 ESE 626 RHSplit Finish OrderWhere to findorderinginformation andQuick Codes<strong>Series</strong>/Function Page 4Trim Designs Page 5Finish Page 9Handing Page 9Strikes Page 9Miscellaneous Options Page 9Cylinder and Keying Page 9Quantity<strong>Series</strong>/FunctionTrimOutsideFinishInsideHand12 UT5251 ESE 626 625 RHContract / Detailed OrderQuantityKeyset<strong>Series</strong>/FunctionTrim Finish Hand Optional StrikeMisc.OptionsOptionalCylinderKeying24 AA1 UT5251 ESE 626 RHR SC200 M21 MR VKC3<strong>UT5200</strong>.845090-7/13

How to Order<strong>UT5200</strong>Cylinder and KeyingConventional 6-pinLess cylinder(s)IC 6-pinDescription SpecifyIC 6-pin with temporary construction coreIC 6-pin less coreIC 7-pin (ESE trim only)IC 7-pin with temporary construction core(ESE trim only)(standard)LCC6CT6CL6C7CT7IC 7-pin less core (ESE trim only)CL7High SecurityHSHigh Security ICCHSMaster ringMR0-bitted with 2 blank keys(standard)Keyed randomKRConstruction master keyedCMKPyramid Security Fixed CorePSPyramid Security ICPCSPyramid High Security Fixed CorePHSPyramid High Security ICPCHSPyramid IC with Temporary ConstructionCoreCTPPyramid IC with TemporaryDisposable CoreCTPDPyramid IC Less CoreCLPIC 6-pin with Temporary ConstructionCore (Red)CT6RIC 6-pin with Temporary ConstructionCore (Blue)CT6BIC 6-pin with Temporary ConstructionCore (Green)CT6GIC 6-pin with Temporary Disposable CoreCT6DIC 7-pin with Temporary ConstructionCore (Red)CT7RIC 7-pin with Temporary ConstructionCore (Blue)CT7BIC 7-pin with Temporary ConstructionCore (Green)CT7GIC 7-pin with temporary Disposable CoreCT7DNo StampingVKC0Keys onlyVKC1Cylinders and keys (not for HS or CHS)VKC2Cylinders only (not for HS or CHS)VKC3Concealed key control (CKC)CKC cylinders with VKC keysCKC2CKC cylinders onlyCKC32 keys per lock (standard)More than 2 keysKY# (e.g., KY6)45090-7/13StrikesLip LengthANSICurved Lip Box*Curved Lip Specify Specify1-1/4" (32mm) (standard) N/A2" (51mm) N/A SC2002-1/8" (54mm) N/A SC2182-1/4" (57mm) N/A SC2142-1/2" (64mm) N/A SC2122-3/4" (70mm) N/A SC2343" (76mm) N/A SC300Lip LengthHandRight HandLeft HandRight Hand ReverseLeft Hand ReverseANSI* Straight Lipfor Door PairSpecifyFor Door Pair*Specify1-13/16" (46mm) SA136 SP136ANSI Straight LipLip Length for Extended LipEscutcheonStandard whenextended lip15/16" (24mm)escutcheon optionis specified*Lip is measured from back of strikeMiscellaneous OptionsDelrin insertSpanner head screwsLever to accept Best ® -type coreKnob to accept Best ® -type coreFor Extended LipEscutcheonSpecifyRHLHRHRLHRSX156Description SpecifyExtended lip escutcheon (for single door reverse bevel;630 finish to match 626 only)Knurling outside and insideKnurling outside onlyKnurling inside onlyAbrasive coat outside and insideAbrasive coat inside onlyAbrasive coat outside onlyLead-lined escutcheon (inside only)Unstaked lever retainerMicroShield Coating (626C only)FinishM01M02M08M10M11M20M21M22M23M24M25M28M33CDescriptionSpecifyUS10 Satin Bronze 612US10BDark Oxidized Satin Bronze,oil rubbed613US26 Bright Chromium Plated 625US26D Satin Chromium Plated 626Satin Chromium Plated with MicroShield 626CHanding<strong>UT5200</strong>.9

Helpful Terms<strong>UT5200</strong>Abrasive CoatHard granular material applied to aknob or lever to provide a non-sliptactile surface for the visually impaired.Auxiliary LatchboltA supplementary latch which, whenthe door is closed, automaticallydeadlocks the latchbolt. Protects thelatchbolt from forced retraction or"credit carding."BacksetThe distance from the front of thelock to the centerline of the cylinderor knob/lever hub.BevelThe angle of the edge of a door inrelation to the inside and outsidesurfaces of the stile. The mostcommon bevel for commercial doors is1/8" in 2".Box StrikeA strike equipped with an enclosurebehind the hole(s) for the latchboltand/or deadbolt. Protects the strikearea from mortar and cement.ChassisThe housing of a lockset, containingmost of the working parts.Curved Lip StrikeA strike with the lip curved to conformto the detail of the door frame.FrontThe part of a lock visible on the edgeof a door.HandThe direction a door swings.KnurlingA permanently applied tactile warningengraved in the metal of a knob orlever to warn the visually impaired ofdangerous conditions on the otherside of the door.LatchboltA lock component having a beveledend that projects from the lock frontbut may be forced back into thelockcase by end pressure or drawnback by action of the retractor. Whenthe door is closed, the latchboltprojects into a hole provided in thestrike, holding the door in the closedposition.Lead LinedPertains to a lockset whose trim has alining of lead to prevent the passageof radiation. Generally used in hospitalapplications.Lip of StrikeThe projecting part of a strike whichfirst engages the latch; may be curvedor straight.ReturnThe part of a lever handle whichangles or turns back toward theface of the door. Also, the distancebetween the end of the return of thelever and the surface of the door.StrikeA metal plate that is pierced orrecessed to receive the deadbolt orlatchbolt of a lock (sometimes called akeeper).ThrowThe distance that a lock's deadbolt orlatchbolt projects when in the lockedposition. The effective throw is thedistance that a latchbolt projects whendeadlocked.Wrought Strike BoxA metal box mounted behind thestrike to protect the strike openingfrom mortar or cement.Keying and Cylinder TermsConcealed Key Control (CKC)The marking of standard key symbolson a cylinder in a location which is notvisible once the cylinder is installed.Construction CoreAn interchangeable core fortemporary use during construction.It is replaced by the permanent corewhen construction personnel nolonger need access.Construction Master Keying (CMK)A cylinder preparation which allowstemporary access by constructionpersonnel.Control KeyA key used to remove and installinterchangeable cores.CylinderA lock component containing thecombination which determines whichkeys will operate.Interchangeable Core (IC)A cylinder which can be removed andinstalled quickly with a control key bynon-skilled personnel when rekeying isrequired.Key SectionThe cross-section of a key blade, asviewed from bow to tip.Key SymbolA letter/number combination in standardindustry format (e.g., 1AA, AA1, etc)which indicates exactly how a key orcylinder fits into a keying system.KeywayThe opening in a cylinder plugthrough which the key enters.Master KeyingPreparation of a cylinder to operatewith keys of different levels of access.Master Ring CylinderA cylinder which offers a wider rangeof keying.Visual Key Control (VCK)The marking of standard key symbolson keys and on the visible portion ofthe front of a cylinder.<strong>UT5200</strong>.1045090-7/13

How to Specify<strong>UT5200</strong>Suggested SpecificationAll locksets shall be <strong>UT5200</strong> <strong>Series</strong> Pre-Assembled Unit Locksets, as manufactured by <strong>Corbin</strong> <strong>Russwin</strong> ArchitecturalHardware, Berlin, Connecticut, USA.Locksets shall be the unit type, completely pre-assembled at the factory, requiring no dis-assembly to install on the door.Knobs/levers and escutcheons shall be part of the pre-assembled lockset.The lock frame, levers, escutcheons and bolts shall be made from non-ferrous metals. Escutcheons shall be forged brass,5/16" thick, and when installed on specified reverse bevel doors shall be the extended lip type to provide additionalsecurity. The latchbolt shall be extruded brass, pivoted swinging type with 3/4" throw. The cylinder shall be universalwith a horizontal keyway to assure correct orientation. Conventional, high security, interchangeable core and master ringcylinders shall be available.Lever handle designs shall return to within 1/2" of door surface.All locksets shall be listed by Underwriters Laboratories for A label and lesser class doors, single or pair, maximum doorsize 3'8" x 7'2". All locksets shall also be UL listed for B label doors, single or pair, maximum door size 4' x 8'.Certification:Federal Specification FF-H-106CANSI A156.2 <strong>Series</strong> 2000ANSI A117.1 Accessibility Code (lever handle trim)California State Reference Code, 1989 (formerly Title 19, California State Fire Marshal Standard) (lever handle trim)All locks, trim and cylinders shall be from one manufacturer.All locksets shall carry a one-year limited warranty.45090-7/13<strong>UT5200</strong>.11

In U.S.<strong>Corbin</strong> <strong>Russwin</strong>Architectural Hardware225 Episcopal RoadBerlin, CT 06037Phone: 800-543-3658Fax: 800-447-6714corbinrusswin.comIn CanadaASSA ABLOY DoorSecurity Solutions Canada160 Four Valley DriveVaughan, OntarioCanada L4K 4T9Phone: 800-461-3007For more information regarding <strong>Corbin</strong> <strong>Russwin</strong> Locksets,Exit Devices, Door Controls and Key Systems, contact yourauthorized <strong>Corbin</strong> <strong>Russwin</strong> Distributor or Sales Representative.MicroShield ®As part of their promise to provide innovative solutions to their customers, certain ASSA ABLOY Group brands offer the MicroShield® technology, a silver-based antimicrobial coatingdesigned to inhibit the growth of bacteria. MicroShield ® is a registered trademark of Yale Security Inc., an ASSA ABLOY Group company.<strong>Corbin</strong> <strong>Russwin</strong> and Design® is a registered trademark of <strong>Corbin</strong> <strong>Russwin</strong>, Inc., an ASSA ABLOY Group company. Other products’ brand names may be trademarks or registered trademarks of theirrespective owners and are mentioned for reference purposes only. These materials are protected under US copyright laws. All contents current at time of publication. <strong>Corbin</strong> <strong>Russwin</strong>, Inc., an ASSAABLOY Group company reserves the right to change availability of any item in this catalog, its design, construction, and/or its materials. Copyright © 2000, 2013 <strong>Corbin</strong> <strong>Russwin</strong>, Inc., an ASSA ABLOYGroup company. All rights reserved. Reproduction in whole or in part without the express written permission of <strong>Corbin</strong> <strong>Russwin</strong>, Inc. is prohibited.45090-7/13