The Kaizen Japan Study Tour - Giappone-Italia

The Kaizen Japan Study Tour - Giappone-Italia

The Kaizen Japan Study Tour - Giappone-Italia

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

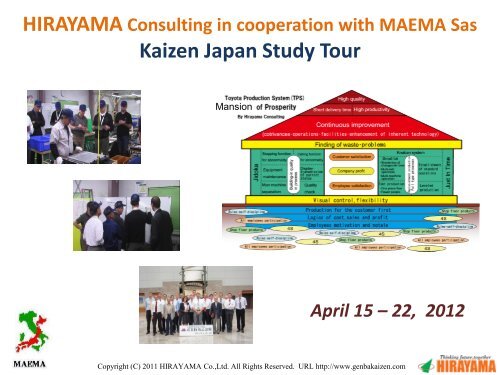

HIRAYAMA Consulting in cooperation with MAEMA Sas<br />

<strong>Kaizen</strong> <strong>Japan</strong> <strong>Study</strong> <strong>Tour</strong><br />

Mansion<br />

April 15 – 22, 2012<br />

Copyright (C) 2011 HIRAYAMA Co.,Ltd. All Rights Reserved. URL http://www.genbakaizen.com

<strong>The</strong> <strong>Kaizen</strong> <strong>Japan</strong> <strong>Study</strong> <strong>Tour</strong><br />

Why Does "<strong>The</strong> <strong>Kaizen</strong> <strong>Japan</strong> <strong>Study</strong> <strong>Tour</strong>" Work for You?<br />

While not only Europe but many regions around the world are suffering because of the severe and well-known financial and<br />

economic crisis, it is important to act for the recovery and future growth of the companies’ business. In <strong>Japan</strong>, after many<br />

years of sluggish expansion and natural disasters, many companies are actually increasing their competitiveness in the<br />

manufacturing field even in comparison with the low cost labor countries. TPS (Toyota Production System) led <strong>Kaizen</strong> in quality,<br />

productivity, cost and time reduction, environment friendly technologies… are improving company profits and image. That is<br />

why we think that a study and training tour, visiting some process and assembly industry plants of these<br />

<strong>Japan</strong>eseorganizations could help western companies to get some hints and lessons to learn.<br />

Characteristics of "<strong>The</strong> <strong>Kaizen</strong> <strong>Japan</strong> <strong>Study</strong> <strong>Tour</strong>"<br />

� Education and Assistance by Experts and Consultants with TPM and TPS Background<br />

� Seminars and <strong>Kaizen</strong> Training by ex Toyota Motor Managers and Trainers<br />

� Case Examples<br />

� Factory visits<br />

� Small-Group <strong>Tour</strong> to Lead Participants to Substantial Output<br />

Objectives of "<strong>The</strong> <strong>Kaizen</strong> <strong>Japan</strong> <strong>Study</strong> <strong>Tour</strong>"<br />

� To <strong>Study</strong> the Background and Structure of Toyota Production System and Other <strong>Japan</strong>ese Methodologies<br />

� To Share, Analyze and Solve Together Problems Participants May Have<br />

�To Have a <strong>Tour</strong> to <strong>The</strong> World's Highest Level Factories<br />

�To Learn about <strong>Japan</strong>ese Culture and the Background of its Excellent Production Systems<br />

Copyright (C) 2011 HIRAYAMA Co.,Ltd. All Rights Reserved. URL http://www.genbakaizen.com

Breakfast<br />

Plant <strong>Tour</strong><br />

<strong>Study</strong> Topic<br />

Day 1<br />

15th Sun<br />

�Arrive at Kansai<br />

International<br />

Airport (Osaka)<br />

�Transfer to Hotel<br />

� <strong>Tour</strong> Orientation<br />

& Dinner<br />

Day 2<br />

16th Mon<br />

Plant <strong>Tour</strong> �Free time<br />

Horiba Ltd.<br />

Day 3<br />

17 th Tue<br />

Day 4<br />

18th Wed<br />

Day 5<br />

19th Thu<br />

Day 6<br />

20th, Fri<br />

Day 7 & 8<br />

21 st— 22 nd Sat-Sun<br />

Breakfast Breakfast Breakfast Breakfast Breakfast Breakfast<br />

Sightseeing in<br />

Kyoto<br />

<strong>Study</strong> culture &<br />

heart of <strong>Japan</strong><br />

TPS Dojo<br />

Work-shop<br />

Training 1<br />

Standard work in<br />

TPS, Just in ttime<br />

Toyota Motor Daido steel Kokusan Denki<br />

Assembly plant,<br />

Center of TPS<br />

Optimal use of<br />

employees’<br />

capabilities<br />

Pursuit of<br />

advanced<br />

technologies<br />

Hitachi group<br />

Successfully<br />

introduced TPS<br />

system<br />

Lunch Lunch Lunch Lunch Lunch Lunch<br />

Every day<br />

Q&A<br />

Session -<br />

Dinner<br />

<strong>The</strong> <strong>Kaizen</strong> <strong>Japan</strong> <strong>Study</strong> <strong>Tour</strong> Schedule<br />

April 15 – 22 , 2012<br />

Leader of<br />

automotive<br />

emission<br />

measurement<br />

systems<br />

Tokai Shinei<br />

Electronics<br />

5S activity, Visual<br />

Management,<br />

<strong>Kaizen</strong> activities<br />

TPS Dojo<br />

Work-shop<br />

training 2<br />

<strong>Kaizen</strong> Technique<br />

by Motion analysis<br />

Nippon Steel Corp.<br />

No 1. Steel<br />

company<br />

� Schedule subjected to slight changes<br />

Copyright (C) 2011 HIRAYAMA Co.,Ltd. All Rights Reserved. URL http://www.genbakaizen.com<br />

Lecture, Discussion<br />

Q & A by<br />

Mr.Terasaki<br />

Former vice<br />

president of<br />

Kokusan Denki<br />

Sat. 21<br />

Sightseeing<br />

Hakone<br />

National park<br />

---<br />

Tokyo &<br />

Shopping<br />

----<br />

Dinner<br />

Sun. 22<br />

�Departure<br />

from Narita<br />

International<br />

Airport

Some Details about Plant Visits<br />

Horiba Co., Ltd.<br />

<strong>The</strong> <strong>Kaizen</strong> <strong>Japan</strong> <strong>Study</strong> <strong>Tour</strong> – Company Profile<br />

2 nd day - Monday<br />

HORIBA is a global group of companies that provides analytical and measurement<br />

equipments in fields that are indispensable to people’s lives, including environment,<br />

health, safety, and energy. HORIBA products hold No.1 or No.2 share positions in the global<br />

markets – for example, automotive emission measurement systems command an 80%<br />

share of the global market – accounting for approximately 60% of total sales.<br />

Prior to 2005 company’s growth was led by the Automotive Test Systems segment.<br />

In the subsequent five years, the company has been supported by the recovery and growth of<br />

the Semiconductor Instruments & Systems segment. Over the next five years, leading up to<br />

2015, company expects attractive profit contributions from the Medical Diagnostic Instruments<br />

& Systems segment.<br />

Date of Establishment : June, 1953<br />

Number of Employees : 5,202 employees (as of Dec, 2010)<br />

Sales Turnover: 119 Billion Yen (Dec, 2010)<br />

Net profit: 7.9 Billion Yen<br />

Products : Automotive test systems, Process & environmental, Medical diagnostics,<br />

Semiconductor, Scientific instruments , etc.<br />

Web URL : http://www.horiba.com<br />

Copyright (C) 2011 HIRAYAMA Co.,Ltd. All Rights Reserved. URL http://www.genbakaizen.com

<strong>The</strong> <strong>Kaizen</strong> <strong>Japan</strong> <strong>Study</strong> <strong>Tour</strong> – Company Profile<br />

3rd & 4 th Day – Tuesday/Wednesday<br />

HIRAYAMA Training Center – TPS Dojo-<br />

Through this course you will<br />

① acquire the ability ,as manager & supervisor, to execute <strong>Kaizen</strong> by yourself<br />

② acquire TPS fundamental knowledge<br />

③ execute Genchi, Genbutsu principle and see actual work site of skills to detect MUDA, MURA and MURI<br />

④ experience and master <strong>Kaizen</strong> technique by executing motion analysis using the model production line<br />

<br />

Tuesday<br />

9:00-10:30 Introduction of TPS and <strong>Kaizen</strong> in Toyota way<br />

10:40-11:20 Explanation of standard work sheet & combination chart<br />

11:20-12:00 Finding problems from radiator assembly line<br />

Wednesday<br />

13:00-14:00 Detection of MUDA, MURA, MURI and group discussion<br />

14:15-15:30 Discussion<br />

15:30-16:30 Rebuilding and implementation of the line<br />

16:30-17:00 Summary, Q & A session<br />

Web URL : http://www.genbakaizen.com<br />

Copyright (C) 2011 HIRAYAMA Co.,Ltd. All Rights Reserved. URL http://www.genbakaizen.com

<strong>The</strong> <strong>Kaizen</strong> <strong>Japan</strong> <strong>Study</strong> <strong>Tour</strong> – Company Profile<br />

3rd day, Tuesday<br />

Tokai Shinei Electronics Industrial Co., Ltd.<br />

Gemba <strong>Kaizen</strong> examples by the effective cleaning power -5S is the principle of the successful company.<br />

Mr. Tanaka, president of the company sincerely promotes three basic principles: “Exchange greetings”,<br />

“Clean surroundings” and “Place shoes neatly side by side” which are the foundation of human<br />

resource cultivation. Company also pursues participative management through visible information<br />

system to all the employees.<br />

<br />

14:00-15:15 Introduction of the company + Lecture by Mr. Tanaka, president of TSK<br />

15:20-16:20 Production line tour<br />

16:30-17:00 Discussion, Q & A<br />

Date of Establishment : July 1, 1969<br />

Number of Employees : 120 employees (Consolidated base: 250 emp.)<br />

Products : Designing & Manufacturing of Printed Wiring Board, Single-sided PWB<br />

without plate TH. Multilayer PWB, Metal Mask, etc<br />

Web URL : http://www.tsk-pcb.co.jp<br />

Copyright (C) 2011 HIRAYAMA Co., Ltd. All Rights Reserved. URL http://www.genbakaizen.com

<strong>The</strong> <strong>Kaizen</strong> <strong>Japan</strong> <strong>Study</strong> <strong>Tour</strong> – Company Profile<br />

4th Day - Wednesday<br />

TOYOTA Motor Corporation<br />

Toyota Motor Corporation, <strong>Japan</strong>`s N°1 carmaker, manufactures cars, pickups, minivans, and SUVs which<br />

include<br />

such models as Camry, Corolla, 4Runner, Land Cruiser, Sienna, the luxury Lexus line, the Scion brand,<br />

and the hybrid brand. Toyota sells its vehicles in more than 170 countries and regions worldwide.<br />

Toyota`s primary markets for its automobiles are <strong>Japan</strong>, North America, Europe and Asia.<br />

Toyota also makes forklifts and manufactured housing, and offers consumer financial services.<br />

<strong>The</strong>y have a driving ambition to become greener. <strong>The</strong> company makes a hybrid-powered (gas & electric)<br />

Sedan -the Prius- that is being snapped up in US and European markets.<br />

<strong>The</strong> company recorded revenues of $244 billions during the fiscal year of 2011, a decrease of 3.7% over 2010,<br />

and sales profit $3.6 billions, a decrease of 42% over the previous year.<br />

<br />

9:00-10:10 Toyota Assembly plant<br />

10:10-11:30 Transfer to the Exhibition Center<br />

10:30-11:30 Toyota Kaikan Exhibition Center<br />

11:45-12:30 Lunch at Restaurant “Socio” in Toyota Kaikan<br />

Date of Establishment : August, 1937<br />

Number of Employees : 69,478 employees<br />

Products : Automobile, Housing, Finance/Banking, etc.<br />

Web URL : http://www.toyota.co.jp<br />

Copyright (C) 2011 HIRAYAMA Co.,Ltd. All Rights Reserved. URL http://www.genbakaizen.com

Daido Steel Co., Ltd.<br />

<strong>The</strong> company is developing the steel for the practical mechanical structure centering on the co-development<br />

with automobile manufacturers for the purpose of promoting the manufacturer of the high function<br />

automobile parts. <strong>The</strong> company is also developing the materials with new functions by combination of<br />

manufacturing technologies of alloy designing, heat treatment and so on.<br />

Founded: August 19, 1916<br />

Incorporated: February 1, 1950<br />

Net Sales (consolidated basis) : 472,062 billion yen (FY2011). 298,769 billion Yen (non-consolidated)<br />

Number of Employees (consolidate basis): 10,272 employees, 3,239 (non-consolidated basis)<br />

Products in the Steel business: Automotive parts, industrial machinery parts, electrical machinery parts,<br />

welding, Electric and magnetic materials, Die forging , precise hot forging and others.<br />

Head office: Higashi-ku, Nagoya, Aichi Pref.<br />

<br />

Chita plant: Tokai city, Aichi pref.<br />

Hoshizaki plant: Minami-ku, Nagoya, Aichi pref.<br />

Shibukawa plant: Shibukawa city, Gunma pref.<br />

Web URL : www.daido.co.jp/e/<br />

<strong>The</strong> <strong>Kaizen</strong> <strong>Japan</strong> <strong>Study</strong> <strong>Tour</strong> – Company Profile<br />

5th Day - Thursday<br />

Copyright (C) 2007 HIRAYAMA Co.,Ltd. All Rights Reserved. URL http://www.genbakaizen.com

Nippon Steel Corp.<br />

<strong>The</strong> <strong>Kaizen</strong> <strong>Japan</strong> <strong>Study</strong> <strong>Tour</strong> – Company Profile<br />

5th Day - Thursday<br />

<strong>The</strong> history of the Nippon Steel Group goes back to 1857 when in Kamaishi, Nippon Steel successfully tapped<br />

steel from <strong>Japan</strong>’s first western style blast furnace.<br />

Nippon Steel Corporation was established in 1970 when Yawata Steel and Fuji Steel merged together. Its main<br />

business activities are related to Steelmaking, Engineering & Construction, Urban Development, Chemicals,<br />

New Materials, System Solutions. Its Head Office is located in Tokyo; its net sales are 4,109,774 million yen<br />

(Consolidated, FY2011); its employees are 16,150 (March 31, 2011).<br />

Nagoya Works<br />

<strong>The</strong> Nagoya Works is the only general base in the Chubu district that can meet a variety of needs.<br />

At the Nagoya Works, Nippon Steel Corp. has a setup that enables the company to offer a wide range of products<br />

including various steel sheets of thicknesses from 0.05 mm, which is thinner than paper, to 900 mm, and also<br />

seam-welded pipes.<br />

Date of Establishment : Established in September 1958 (as Tokai Iron & Steel Co., Ltd.)<br />

Number of Employees : 2,836<br />

Site Area: 6,230,000 m²<br />

Crude steel production: 6,281,000 tons (FY 2007)<br />

Web URL : http://www.nsc.co.jp/en/index.html<br />

Copyright (C) 2011 HIRAYAMA Co.,Ltd. All Rights Reserved. URL http://www.genbakaizen.com

Kokusan Denki Co., Ltd.<br />

<strong>The</strong> <strong>Kaizen</strong> <strong>Japan</strong> <strong>Study</strong> <strong>Tour</strong> – Company Profile<br />

6th Day - Friday<br />

Kokusan Denki is known as HITACHI Group, producing magnetos for aircraft domestically in 1931.<br />

Taking advantages of applied technologies of electromagnetic and production technologies that have been<br />

developed since its establishment, Kokusan Denki has always led the industries while aggressively entering into<br />

such fields as various engine electric appliances, small-size and high-precision electric motors.<br />

Its products are being used by customers of various fields, including motorcycles, automobiles,<br />

outboard motors, agricultural machinery, ATM (automated teller machine) and etc.<br />

<br />

9:30-10:15 Introduction of the company + explanation of <strong>Kaizen</strong> activities<br />

10:15-11:15 Production line tour<br />

HIRAYAMA Consultant – Mr. Terasaki (Ex-President of Kokusan Denki)<br />

11:15-12:00 Q&A Session<br />

Date of Establishment : 10 July, 1931<br />

Number of Employees : 710 employees<br />

Products : Engine Ignition Systems, Electric Motors, Alternators & Welders<br />

Web URL : http://www.kokusandenki.co.jp<br />

Copyright (C) 2011 HIRAYAMA Co.,Ltd. All Rights Reserved. URL http://www.genbakaizen.com

Hitachi, Ltd.<br />

Company Position Experience<br />

Kokusan Denki, Ltd.<br />

(Electric Appliances<br />

for Motorcycle &<br />

Multipurpose Engine,<br />

Motor,<br />

Generator)<br />

India Nippon Electricals,<br />

Ltd.<br />

[INE]<br />

(Joint Corporation with<br />

Kokusandenki in India)<br />

<strong>The</strong> <strong>Kaizen</strong> <strong>Japan</strong> <strong>Study</strong> <strong>Tour</strong> – Lecture Consultant Profile<br />

Consultant : Akashi TERASAKI<br />

Senior Manager of Prototype Mfg.<br />

Dpt.<br />

Senior Manager of Production<br />

Engineering Dpt.<br />

Chief Manager of KAIZEN<br />

Promotion Center<br />

Managing Director &<br />

Senior Manager<br />

Chief Manager of KAIZEN<br />

Promotion Center<br />

Director<br />

・ Assumption of Chief Manager of KAIZEN Promotion Center in 1991<br />

・ Promoted the Improvement Activity in Automotive Products Division in<br />

Hitachi<br />

・ Received the Grand Prix Award of Improvement consecutive 3 years<br />

from 1993 to 1995<br />

・ [Result of JIT Activity for 3 years]<br />

Productivity 194% Up Manpower Reducing 37% Down<br />

Space Reducing 40% Down Defect Reducing 52% Down<br />

Inventory Reducing 16% Down Lead Time 71% Down<br />

Changeover Time 37% Down Down Time of Facilities 42% Down<br />

・ Transferred to Kokusandenki, Ltd., subsidiary company of<br />

Hitachi, in 1995<br />

・ Directed the “Actual KAIZEN Improvement Activity” in<br />

Kokusandenki<br />

・ Prepared to make the 100% of Hitachi Improvement Know How<br />

・ And started “Terasaki Way Improvement”<br />

・ Assumption of Director of INE in 1991<br />

・ Directed the “Actual Improvement Activity” at 5 companies of INE<br />

group<br />

・ Received the Grand Prix Award of Improvement in 1997 and the<br />

result of improvement was in the spotlight in the world<br />

Kokusan Dennki , Ltd. President ・ Directed the “Actual KAIZEN Improvement “<br />

Copyright (C) 2011 HIRAYAMA Co.,Ltd. All Rights Reserved. URL http://www.genbakaizen.com

<strong>Tour</strong> Details<br />

Dates – One whole week, from April 15 to April 22<br />

<strong>The</strong> participants will arrive at the Kansai Airport (Osaka) on Sunday. If they arrive in the morning as group, they will<br />

go to the Hotel by Hirayama coach, have lunch, visit some interesting spots, and attend the <strong>Tour</strong> introduction and<br />

evening dinner. On the return trip, participants will depart from Narita Airport (Tokyo) on Sunday. It is possible to<br />

add some extra days before or after the <strong>Tour</strong>, for personal reasons. Hirayama staff will help from the logistic<br />

standpoint but the expenses will be paid personally.<br />

Participation Fee (To pay one month before the tour starting)<br />

<strong>The</strong> fee includes :<br />

� Hotel Accommodation for 7 nights, included Internet access<br />

� 7 breakfasts, 7 lunches, 7 dinners<br />

� Arrangements for factory visits escorted by Hirayama Staff<br />

� Transportation during the tour, including company visits and sightseeing<br />

� Education materials and text books<br />

� Interpreter’s fee during the training program and factory visits<br />

� Hirayama Staff assistance and cultural technical inputs during the tour<br />

<strong>The</strong> fee excludes :<br />

• Travel to and from <strong>Japan</strong> (Airfare)<br />

• Transportation to and from the airport in <strong>Japan</strong> (if not in the same group)<br />

• Travel insurance and alcohol drinks during meals or elsewhere<br />

• Incidentals (telephone calls, additional drinks, laundry, etc.)<br />

Cancellation Policy<br />

• 15 days prior to the starting date of the tour No charge<br />

• 7 – 14 days prior to the starting date of the tour 30% of the tour fare<br />

• 6 – 3 days prior to the starting date of the tour 50% of the tour fare<br />

• 2 days prior to the starting date of the tour 100% of the tour fare<br />

Copyright (C) 2011 HIRAYAMA Co.,Ltd. All Rights Reserved.

Registration<br />

Name(s) and title :<br />

# of Participants : Company(s) :<br />

Address : City : State :<br />

Postal Code : Country :<br />

Phone : Fax : Email :<br />

Flight Schedule : Arrival Time Departure Time(Date)<br />

For Application:<br />

Maema S.a.s. di Manisera & C.<br />

Via Verrocchio 154 - 25124 Brescia – Italy<br />

Tel/Fax ++39 030 2305952 - Mob. 335 6748968 - E-mail: maema@giappone-italia.it<br />

Application and full payment (to Hirayama bank account): one month before departure<br />

---------------<br />

Organization<br />

HIRAYAMA Consulting - Shinagawa Place 6F, 1-8-40 Konan, Minato-ku, Tokyo 108-0075 <strong>Japan</strong><br />

Phone +81-3-5783-3571 - Fax: +81-3-3548-1445<br />

Manager Noboru Takeuchi - E-mail: noboru-takeuchi2@hirayamastaff.co.jp<br />

Copyright (C) 2011 HIRAYAMA Co.,Ltd. All Rights Reserved.

Organization<br />

HIRAYAMA Consulting<br />

Shinagawa Place 6F<br />

1-8-40 Konan, Minato-ku<br />

Tokyo 108-0075 <strong>Japan</strong><br />

TEL:+81-3-5783-3571<br />

FAX:+81-3-5783-3572<br />

www.genbakaizen.com<br />

<strong>Study</strong> <strong>Tour</strong> Manager<br />

Noboru Takeuchi<br />

noboru-takeuchi2@hirayamastaff.co.jp<br />

-----------<br />

<strong>The</strong> <strong>Kaizen</strong> <strong>Japan</strong> <strong>Study</strong> <strong>Tour</strong> – Contact<br />

Mansion of Prosperity<br />

Maema S.a.s. di Manisera & C.<br />

Via Verrocchio 154 - 25124 Brescia – Italy<br />

Tel/Fax ++39 030 2305952 - Mob. 335 6748968 - E-mail: maema@giappone-italia.it<br />

Please feel free to contact us for further questions.<br />

Copyright (C) 2011 HIRAYAMA Co.,Ltd. All Rights Reserved. URL http://www.genbakaizen.com