Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

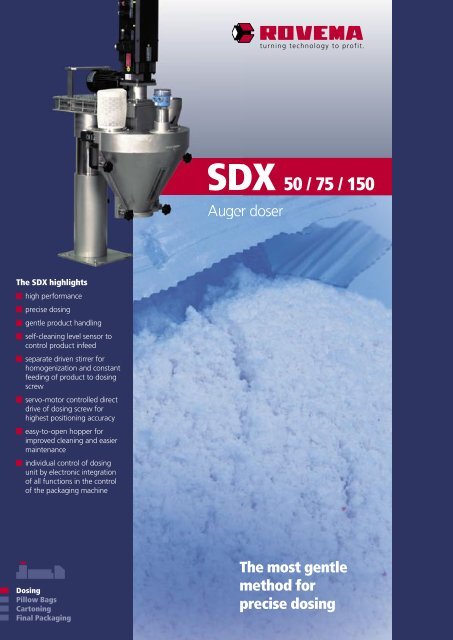

The SDX highlights<br />

■ high performance<br />

■ precise dosing<br />

■ gentle product handling<br />

■ self-cleaning level sensor to<br />

control product infeed<br />

■ separate driven stirrer for<br />

homogenization and constant<br />

feeding of product to dosing<br />

screw<br />

■ servo-motor controlled direct<br />

drive of dosing screw for<br />

highest positioning accuracy<br />

■ easy-to-open hopper for<br />

improved cleaning and easier<br />

maintenance<br />

■ individual control of dosing<br />

unit by electronic integration<br />

of all functions in the control<br />

of the packaging machine<br />

Dosing<br />

Pillow Bags<br />

Cartoning<br />

Final Packaging<br />

SDX 50 / 75 / 150<br />

Auger doser<br />

tur ning technology to profit.<br />

The most gentle<br />

method for<br />

precise dosing

SDX – rhe most<br />

gentle method for<br />

precise dosing<br />

ROVEMA<br />

Verpackungsmaschinen GmbH<br />

Industriestrasse 1<br />

D 35463 Fernwald<br />

Tel: ++49-641-409-0<br />

Fax: ++49-641-409-212<br />

info@<strong>rovema</strong>.de<br />

www.<strong>rovema</strong>.de<br />

ROVEMA<br />

Verpackungsservice GmbH<br />

Industriestraße 3<br />

D 35463 Fernwald<br />

Tel: ++49-641-94 00 20<br />

Fax: ++49-641-4 69 76<br />

info@rvs-gmbh.de<br />

www.<strong>rovema</strong>-verpackungsservice.de<br />

ROVEMA<br />

Verpackungsmaschinen Sp. Zo.o.<br />

ul. Odynca 51<br />

PL - 02-606 Warszawa<br />

Tel.: ++48-22 844 7748<br />

Fax: ++48-22 854 0446<br />

postmaster@<strong>rovema</strong>.atomnet.pl<br />

ROVEMA Iberica S.A.<br />

C/Mas d‘en Cisa, 5,<br />

Apdo. Correos N0 55<br />

E 08181 Sentmenat (Barcelona)<br />

Tel: ++34-93-7 15 46 00<br />

Fax: ++34-93-7 15 46 38<br />

<strong>rovema</strong>@<strong>rovema</strong>.es<br />

ROVEMA<br />

Packaging Machines L.P.<br />

650 Hurricane Shoals<br />

Road NW, Lawrenceville,<br />

GA 30045 U.S.A<br />

Tel: ++1-770-5 13 96 04<br />

Fax: ++1-770-5 13 08 14<br />

<strong>rovema</strong>@<strong>rovema</strong>.com<br />

www.<strong>rovema</strong>.com<br />

ROVEMA<br />

Packaging Machines Limited<br />

The Coach House<br />

The Firs, High Street<br />

GB-Whitchurch, Aylesbury<br />

HP 22 4 SJ<br />

Tel: ++44-12 96-64 20 60<br />

Fax: ++44-12 96-64 15 50<br />

sales@<strong>rovema</strong>.co.uk<br />

ROVEMA Benelux bv<br />

Everdenberg 9, 4902 TT<br />

Postbus 4357, 4900 CJ<br />

NL Oosterhout<br />

Tel: ++31-162-576 464<br />

Fax: ++31-162-576 465<br />

sales@<strong>rovema</strong>.nl<br />

ROVEMA Italia s.r.l.<br />

Via Marie Curie 10/A<br />

I 20026 Novate Milanese (MI)<br />

Tel: ++39-02 48 01 17 85<br />

Fax: ++39-02 48 00 82 59<br />

rit@<strong>rovema</strong>-italia.it<br />

SDX 50 / 75 / 150<br />

Auger doser<br />

T he<br />

he auger doser SDX 50/75/150 shows high performance and technical level.<br />

By the exact dosing even with diffi cult products it fulfi ls the economic demand of the<br />

user within the required legal standards. Almost every powdery or fi ne-grain product as<br />

coffee, sugar, herbs and spices, milk powder and chemicals can be handled.<br />

Product care and minimum tolerances<br />

The SDX dosing systems are able to dose even free-fl owing as well as viscous products at<br />

high performance.<br />

Gentle product handling, minimum fi lling tolerances and the avoiding of product damage<br />

are the most decisive demands to a modern dosing technology. Due to a long-term<br />

experience and the technical know-how ROVEMA meets<br />

these requirements.<br />

The principle<br />

(1) Product infeed (by transfer auger – as<br />

option – or directly into the hopper)<br />

(2) Driving motor actuates the stirrer.<br />

(3) Servo drive actuates the dosing auger.<br />

(4) Dosing auger admeasures the product in the<br />

required quantity.<br />

(5) Stirrer distributes the product in the hopper.<br />

Benefi ts and advantages of the SDX<br />

■ By the gyratory and high-polished auger screw the product is<br />

handled extremely gentle. While conventional milled and<br />

welded augers whirl the products, apply unwanted pressure and<br />

impact high friction causing product degradation and stress to<br />

the auger tube with ROVEMA augers the product is gently forwarded<br />

parallel to the screw axis. Moreover the closure systems<br />

are designed to the characteristics of the product thus ensuring<br />

an optimal dosing process.<br />

■ Another advantage is the very close dosing tolerances.<br />

These are far below the statutory tolerances specifi ed in current<br />

Weights and Measures legislation. Thus real product saving can<br />

be achieved by improving standard deviation – an investment<br />

will often pay for itself within one year.<br />

■ Since the auger rotation is continuously variable the<br />

precision of the fi lling weight dosing is supported additionally.<br />

■ Longevity and high availability are guaranteed by maintenance<br />

and wear-free drives.<br />

■ ROVEMA auger dosers can be used as a stand-alone unit or in<br />

combination with other machines as an integral part of<br />

ROVEMA systems technology.<br />

© 2007<br />

Technical details may be subject of alterations.<br />

1<br />

3<br />

The options<br />

Besides the technical experience<br />

and precision the strengths of the<br />

ROVEMA auger doser are mainly in<br />

the variety and thus in the consistent<br />

design of the dosing technology<br />

meeting the specifi c requirements<br />

of the customers.<br />

Available:<br />

2<br />

5<br />

4<br />

■ a wide range of auger format sets<br />

■ product specifi c closure systems<br />

■ devices for gas fl ushing systems<br />

■ aggregate for residual oxygen<br />

analysis<br />

■ tendency control<br />

Other options on request.<br />

tur ning technology to profit.<br />

SDX_GB/0307