Certificate of Analysis Send Method and Content ... - Supplier Portal

Certificate of Analysis Send Method and Content ... - Supplier Portal

Certificate of Analysis Send Method and Content ... - Supplier Portal

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

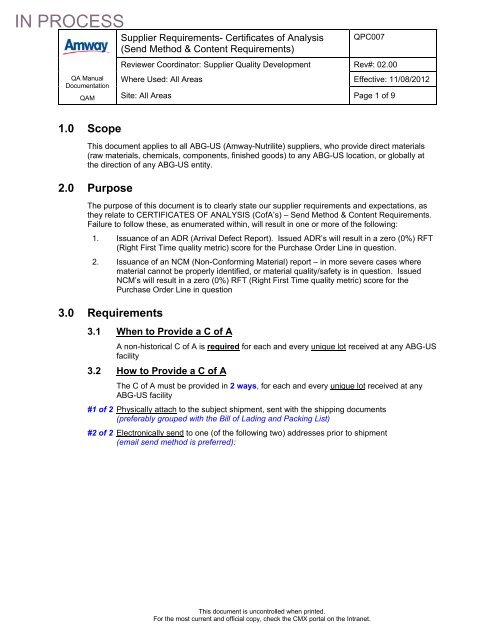

IN PROCESSQA ManualDocumentation<strong>Supplier</strong> Requirements- <strong>Certificate</strong>s <strong>of</strong> <strong>Analysis</strong>(<strong>Send</strong> <strong>Method</strong> & <strong>Content</strong> Requirements)QPC007Reviewer Coordinator: <strong>Supplier</strong> Quality Development Rev#: 02.00Where Used: All Areas Effective: 11/08/2012QAM Site: All Areas Page 1 <strong>of</strong> 91.0 ScopeThis document applies to all ABG-US (Amway-Nutrilite) suppliers, who provide direct materials(raw materials, chemicals, components, finished goods) to any ABG-US location, or globally atthe direction <strong>of</strong> any ABG-US entity.2.0 PurposeThe purpose <strong>of</strong> this document is to clearly state our supplier requirements <strong>and</strong> expectations, asthey relate to CERTIFICATES OF ANALYSIS (C<strong>of</strong>A’s) – <strong>Send</strong> <strong>Method</strong> & <strong>Content</strong> Requirements.Failure to follow these, as enumerated within, will result in one or more <strong>of</strong> the following:1. Issuance <strong>of</strong> an ADR (Arrival Defect Report). Issued ADR’s will result in a zero (0%) RFT(Right First Time quality metric) score for the Purchase Order Line in question.2. Issuance <strong>of</strong> an NCM (Non-Conforming Material) report – in more severe cases wherematerial cannot be properly identified, or material quality/safety is in question. IssuedNCM’s will result in a zero (0%) RFT (Right First Time quality metric) score for thePurchase Order Line in question3.0 Requirements3.1 When to Provide a C <strong>of</strong> AA non-historical C <strong>of</strong> A is required for each <strong>and</strong> every unique lot received at any ABG-USfacility3.2 How to Provide a C <strong>of</strong> AThe C <strong>of</strong> A must be provided in 2 ways, for each <strong>and</strong> every unique lot received at anyABG-US facility#1 <strong>of</strong> 2 Physically attach to the subject shipment, sent with the shipping documents(preferably grouped with the Bill <strong>of</strong> Lading <strong>and</strong> Packing List)#2 <strong>of</strong> 2 Electronically send to one (<strong>of</strong> the following two) addresses prior to shipment(email send method is preferred):This document is uncontrolled when printed.For the most current <strong>and</strong> <strong>of</strong>ficial copy, check the CMX portal on the Intranet.

IN PROCESSQA ManualDocumentation<strong>Supplier</strong> Requirements- <strong>Certificate</strong>s <strong>of</strong> <strong>Analysis</strong>(<strong>Send</strong> <strong>Method</strong> & <strong>Content</strong> Requirements)QPC007Reviewer Coordinator: <strong>Supplier</strong> Quality Development Rev#: 02.00Where Used: All Areas Effective: 11/08/2012QAM Site: All Areas Page 2 <strong>of</strong> 9Business Line / Material Type / Location First Choice Second OptionFaxed to: 616-787-8981INCCHM@AMWAY.comChemicals / Raw Materials (Ada, MI)ATTN: Amway SCQA LabFaxed to: 616-682-4059INCPKG@AMWAY.comPackaging Components (Ada, MI)ATTN: Amway SQPQA LabFaxed to: 616-682-4072INCHT@AMWAY.comHome Tech Components (Ada, MI)ATTN: Amway SQPQA LabFaxed to: 616-682-4073INCBO@AMWAY.comFinished Goods / Buy-Outs (Ada, MI)ATTN: Amway SQPQA LabNutrilite Components Raw MaterialsRMCOA@AMWAY.com Finished Goods (Buy-Outs)(Buena Park, CA Lakeview, CATrout Lake, WA Quincy, WA Ada, MI)3.3 Emailed C<strong>of</strong>A’s (Subject Line Nomenclature)a) For items where the <strong>Supplier</strong> <strong>and</strong> Manufacturer are one <strong>and</strong> the same, the e-mailSubject Line for the C <strong>of</strong> A should include the following 4 components:<strong>Supplier</strong> Name ABG Item# ABG PO# Lot/Batch #b) For items supplied via a Distributor, the e-mail Subject Line for the C <strong>of</strong> A shouldinclude the following 5 components:Manufacture Name Distributor Name ABG Item# ABG PO# Lot/Batch #3.4 Control Limits versus Release Specificationsa) Control Limits are manufacturing control parameters for the production <strong>of</strong> the material,component or productb) To control unnecessary scrap or rework, the Control Limits should fall within the ReleaseSpecifications, <strong>and</strong> become increasingly narrow as production processes are optimized.c) C<strong>of</strong>A “Control Limits” should fall within the ABG Release Specifications, <strong>and</strong> not merelymatch them.3.5 C<strong>of</strong>A Header <strong>Content</strong> (Minimum Information, 11 or 12 fields )ABG Part Number/SKUManufacturer’s Trade Name (if applicable)Lab Test DateLab Approval/Release Authority (name)Lab Approval/Release Authority (contactinformation)Manufacturer NameManufacturer Location & Country <strong>of</strong> OriginManufacturer’s Lot/Batch NumberManufacturing DateShelf Life Days (from Mfg Date) or ExpirationDateThis document is uncontrolled when printed.For the most current <strong>and</strong> <strong>of</strong>ficial copy, check the CMX portal on the Intranet.

IN PROCESSQA ManualDocumentation<strong>Supplier</strong> Requirements- <strong>Certificate</strong>s <strong>of</strong> <strong>Analysis</strong>(<strong>Send</strong> <strong>Method</strong> & <strong>Content</strong> Requirements)QPC007Reviewer Coordinator: <strong>Supplier</strong> Quality Development Rev#: 02.00Where Used: All Areas Effective: 11/08/2012QAM Site: All Areas Page 3 <strong>of</strong> 9a) The complete ABG Part Number/SKUMust match ABG Purchase Order/PO LineMust match ABG SpecificationMust match Container Labelc) Manufacturer’s Trade Name – Common for raw materials, ingredient or chemical itemsMust match ABG Specification (if listed)Must match Container Label (only applicable if on ABG Spec)d) Manufacturer Name – (must be the Manufacturer’s name, not the Broker or Distributor)Must match ABG Specification (if listed)Must match the Container Labele) Manufacturer Location - City/State or City/Province are acceptable.Must match ABG Specification (if listed)Must match Container Labelf) Manufacturer Country <strong>of</strong> Origin – May be included as one line with ManufacturerLocationMust match ABG Specification (if listed)Must match Container Labelg) The unique manufacturer/vendor Lot/Batch Number. Lot traceability is required for eachcontainer.Must match Container Label In some rare cases, suppliers will be directed (by ABG Specification or Agreement) touse an 8-digit AMC lot code to replace their lot/batch number (please reference section4.1 for further guidance).h) Manufacturing Date - Month/Day/Year (MM/DD/YY) on which material is manufactured.If Julian-based, the manufacturer/vendor Lot/Batch number can be substituted forManufacturing Date.3.6 How to Determine Which Tests are Required on C<strong>of</strong>Aa) The tests required for each product or material are itemized within each ABGSpecification.b) All tests prefixed with ‘COA’ or (C), on the ABG Specification, are required to appear oneach C<strong>of</strong>A.c) Please refer to the ABG Specification examples (in Section 4.0) for further guidance.This document is uncontrolled when printed.For the most current <strong>and</strong> <strong>of</strong>ficial copy, check the CMX portal on the Intranet.

IN PROCESSQA ManualDocumentation<strong>Supplier</strong> Requirements- <strong>Certificate</strong>s <strong>of</strong> <strong>Analysis</strong>(<strong>Send</strong> <strong>Method</strong> & <strong>Content</strong> Requirements)QPC007Reviewer Coordinator: <strong>Supplier</strong> Quality Development Rev#: 02.00Where Used: All Areas Effective: 11/08/2012QAM Site: All Areas Page 4 <strong>of</strong> 93.7 C<strong>of</strong>A Test Information <strong>Content</strong> (Minimum Information, 6 or 7 fields )ABG preference is that the following information is presented horizontally:TestNameTest Unit <strong>of</strong>MeasureTest<strong>Method</strong>SpecificationRangeTestResultPass /Fail**a) For certain Durables Business Line items (engineered components), Ppk, Cpk, orSt<strong>and</strong>ard Deviation may be requiredb) ** Pass/Fail verification necessary to ensure an independent review <strong>of</strong> results bymanufacturer Release Authority.3.8 C<strong>of</strong>A Test ResultsALL line items on the C<strong>of</strong>A are required to meet their respective specification ReleaseLimits.4.0 References <strong>and</strong> Examples1. For LABEL / CONTAINER INDENTIFICATION requirements, please refer to theSHIPPING section <strong>of</strong> the ABG <strong>Supplier</strong> <strong>Portal</strong> (www.supplier.amway.com)2. For an ABG SPECIFICATION EXAMPLE, please refer to pages 4 through 7 <strong>of</strong> thisdocument.This document is uncontrolled when printed.For the most current <strong>and</strong> <strong>of</strong>ficial copy, check the CMX portal on the Intranet.

IN PROCESSQA ManualDocumentation<strong>Supplier</strong> Requirements- <strong>Certificate</strong>s <strong>of</strong> <strong>Analysis</strong>(<strong>Send</strong> <strong>Method</strong> & <strong>Content</strong> Requirements)QPC007Reviewer Coordinator: <strong>Supplier</strong> Quality Development Rev#: 02.00Where Used: All Areas Effective: 11/08/2012QAM Site: All Areas Page 5 <strong>of</strong> 9“This document may contain confidential information <strong>and</strong> is considered proprietary information. Use <strong>of</strong> this document is covered bythe corporate agreement regarding confidentiality <strong>and</strong> intellectual property. This document is not to be shared with third parties orwith employees outside <strong>of</strong> normal business conduct without prior approval from the Director <strong>of</strong> Quality Assurance."ApprovalsTitle Name SignatureGroup Leader- SQD Chris Alder Reference Documentum.Group Leader- SCQA Jerry Visscher Reference Documentum.Group Leader- SCQA Kristina Parkanzky Reference Documentum.Group Leader- SCQA Gregor Stasik Reference Documentum.Group Leader- SCPQA Heath Paukette Reference Documentum.Group Leader- NQA Allison Zolnay Reference Documentum.Group Leader- NQA Amy Caplette Reference Documentum.Author Cara Fritsma Reference DocumentumThis document is uncontrolled when printed.For the most current <strong>and</strong> <strong>of</strong>ficial copy, check the CMX portal on the Intranet.

IN PROCESSQA ManualDocumentation<strong>Supplier</strong> Requirements- <strong>Certificate</strong>s <strong>of</strong> <strong>Analysis</strong>(<strong>Send</strong> <strong>Method</strong> & <strong>Content</strong> Requirements)QPC007Reviewer Coordinator: <strong>Supplier</strong> Quality Development Rev#: 02.00Where Used: All Areas Effective: 11/08/2012QAM Site: All Areas Page 6 <strong>of</strong> 9This document is uncontrolled when printed.For the most current <strong>and</strong> <strong>of</strong>ficial copy, check the CMX portal on the Intranet.

IN PROCESSQA ManualDocumentation<strong>Supplier</strong> Requirements- <strong>Certificate</strong>s <strong>of</strong> <strong>Analysis</strong>(<strong>Send</strong> <strong>Method</strong> & <strong>Content</strong> Requirements)QPC007Reviewer Coordinator: <strong>Supplier</strong> Quality Development Rev#: 02.00Where Used: All Areas Effective: 11/08/2012QAM Site: All Areas Page 7 <strong>of</strong> 9This document is uncontrolled when printed.For the most current <strong>and</strong> <strong>of</strong>ficial copy, check the CMX portal on the Intranet.

IN PROCESSQA ManualDocumentation<strong>Supplier</strong> Requirements- <strong>Certificate</strong>s <strong>of</strong> <strong>Analysis</strong>(<strong>Send</strong> <strong>Method</strong> & <strong>Content</strong> Requirements)QPC007Reviewer Coordinator: <strong>Supplier</strong> Quality Development Rev#: 02.00Where Used: All Areas Effective: 11/08/2012QAM Site: All Areas Page 8 <strong>of</strong> 9This document is uncontrolled when printed.For the most current <strong>and</strong> <strong>of</strong>ficial copy, check the CMX portal on the Intranet.

IN PROCESSQA ManualDocumentation<strong>Supplier</strong> Requirements- <strong>Certificate</strong>s <strong>of</strong> <strong>Analysis</strong>(<strong>Send</strong> <strong>Method</strong> & <strong>Content</strong> Requirements)QPC007Reviewer Coordinator: <strong>Supplier</strong> Quality Development Rev#: 02.00Where Used: All Areas Effective: 11/08/2012QAM Site: All Areas Page 9 <strong>of</strong> 9This document is uncontrolled when printed.For the most current <strong>and</strong> <strong>of</strong>ficial copy, check the CMX portal on the Intranet.