Microwave Assist Laboratory Box Furnaces - Directories

Microwave Assist Laboratory Box Furnaces - Directories

Microwave Assist Laboratory Box Furnaces - Directories

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

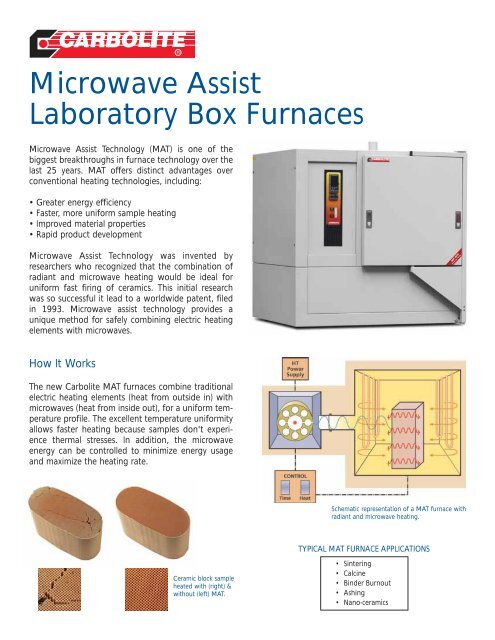

<strong>Microwave</strong> <strong>Assist</strong><strong>Laboratory</strong> <strong>Box</strong> <strong>Furnaces</strong><strong>Microwave</strong> <strong>Assist</strong> Technology (MAT) is one of thebiggest breakthroughs in furnace technology over thelast 25 years. MAT offers distinct advantages overconventional heating technologies, including:• Greater energy efficiency• Faster, more uniform sample heating• Improved material properties• Rapid product development<strong>Microwave</strong> <strong>Assist</strong> Technology was invented byresearchers who recognized that the combination ofradiant and microwave heating would be ideal foruniform fast firing of ceramics. This initial researchwas so successful it lead to a worldwide patent, filedin 1993. <strong>Microwave</strong> assist technology provides aunique method for safely combining electric heatingelements with microwaves.How It WorksThe new Carbolite MAT furnaces combine traditionalelectric heating elements (heat from outside in) withmicrowaves (heat from inside out), for a uniform temperatureprofile. The excellent temperature uniformityallows faster heating because samples don't experiencethermal stresses. In addition, the microwaveenergy can be controlled to minimize energy usageand maximize the heating rate.Schematic representation of a MAT furnace withradiant and microwave heating.TYPICAL MAT FURNACE APPLICATIONSCeramic block sampleheated with (right) &without (left) MAT.• Sintering• Calcine• Binder Burnout• Ashing• Nano-ceramics

C-Tech Innovations (UK) scaled up the <strong>Microwave</strong><strong>Assist</strong>ed Technology for the production of ceramicproducts, such as whitewares, bricks, and advancedceramics. This work was highly successful and provedthat there was a huge cost saving (~50%) because ofthe reduced energy consumption for equivalentproduct volumes. At the same time, tests proved thatthe MAT process resulted in higher quality ceramicproducts. Fast uniform heating was a key to newproducts and improved processing.Carbolite licensed the C-Tech patent in 2005 and hasrecently partnered with Ceralink, the North Americanlicensee. This new exciting technology will be offeredas both a standard and custom option, along with thecurrent range of Carbolite high specification laboratoryfurnaces.In a traditional furnace, the sample is heated from theoutside first, and heat is transferred to the centerthrough thermal conduction. This causes a thermalgradient (ΔT) in the sample, which produces unwantedthermal stresses. The effect is greater for largersamples and lower thermal conductivity materials. Tominimize the ΔT, traditional furnaces are heated slowly,leading to long cycle times. In addition, the outsideof the sample has more time at temperature, whichcan result in a variation in microstructure and propertiesthroughout the sample. In a pure microwave, thedielectric properties of ceramics cause them to heatvolumetrically through a kind of internal friction. Thesamples will heat internally, but cool from the surfacebecause the surrounding environment is cooler. Thisis known as an "inverse temperature profile" becausethe inside of the sample is hotter than the surface.Traditional heating or pure microwaves can producethermal gradients and stresses that result in cracksand flaws. In a MAT furnace these effects can be balanced,resulting in uniform heating of the sample. Inaddition, the sample only needs to be at maximumtemperature for a very short amount of time. As aresult, finer grain microstructures and nanostructurescan be obtained.Furnace TemperatureSample Outside TemperatureSample Inside Temperature Heated by MATSample Inside Temperature Heated by Conventional Furnace.Improved uniformity in a ceramic component when fired in a MATfurnace as compared to conventional and microwave only furnace.Graph illustrates faster MAT heating and finer grain uniformity.<strong>Microwave</strong> <strong>Assist</strong> <strong>Laboratory</strong> <strong>Box</strong> <strong>Furnaces</strong>Furnace Max. Internal Chamber Dimensions External Dimensions TC Element <strong>Microwave</strong> FurnaceModel Temp. Inches (mm) Inches (mm) Type Power Power Voltage(°C) Height Width Depth Height Width Depth (kW) (kW)MRF 12/23 1200 9.25 (235) 10.00 (255) 15.75 (400) 36.00 (915) 37.00 (935) 37.00 (935) R 5.0 1.8 208/240MRF 16/16 1600 9.25 (235) 8.00 (200) 14.25 (360) 36.00 (915) 37.00 (935) 37.00 (935) R 9.0 1.8 208/240www.carbolite.comsales@carbolite-usa.comTel: 800-543-6208