THE COMPLETE BOOK OF THE - Turnbull Mfg. Co.

THE COMPLETE BOOK OF THE - Turnbull Mfg. Co.

THE COMPLETE BOOK OF THE - Turnbull Mfg. Co.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

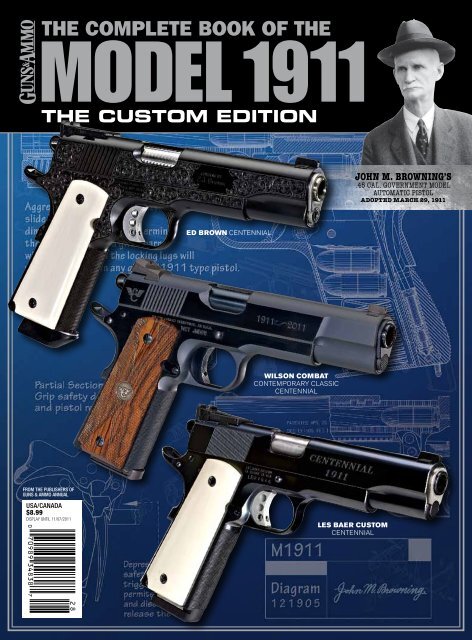

<strong>THE</strong> <strong>COMPLETE</strong> <strong>BOOK</strong> <strong>OF</strong> <strong>THE</strong>MODEL 1911The Custom EditionED BROWN CentennialWILSON COMBATCONTEMPORARY CLASSICCentennialFrom the Publishers ofGUNS & AMMO ANNUALUSA/CANADA$8.99Display until 11/07/2011LES BAER CUSTOMCENTENNIAL

OldNewbecomesWHEREagainGo inside the shop of Doug <strong>Turnbull</strong> to see howU.S. Model 1911s and M1911A1s are restored.Singer <strong>Mfg</strong>. <strong>Co</strong>. m1911a1(mfg 1941)Springfield armory 1911(mfg. 1914)By Eric R. Poole // Photos by Tracy HalpinRemington Arms <strong>Co</strong>. umc 1911(mfg 1918)<strong>Co</strong>lt 1911(mfg. 1913)Union switch & signal m1911a1(mfg. 1943)<strong>Co</strong>lt 1911 “black army”(<strong>Mfg</strong>. 1918)6 <strong>BOOK</strong> of the 1911gunsandammo.com

WHEREOld NewbecomesagainThis was the official “before” picture taken of the author’syounger Model 1911 (MFG. 1918) submitted to <strong>Turnbull</strong> <strong>Mfg</strong>.for restoration. It had been subject to at least two arsenalrebuilds and was a host of mismatched parts.“It can only be original once,” my dadwould often say. As early examplesof the U.S. Model 1911 start turningthe century mark, those of us whopossess a heavily used, refinished or obviouslyrebuilt 1911 struggle with the decisionwhether to preserve its weatheredcondition or restore it.“If it’s not documented to be historicallysignificant,” says Keith VanOrman,president of <strong>Turnbull</strong> Manufacturing<strong>Co</strong>mpany, “you should go ahead and let usrestore it.”I sent serial number 340611 and 605521to the expanding New York shop, anda few days later reality set in. There wasnothing particularly special about mypair of 1918-manufactured <strong>Co</strong>lt 1911s,something VanOrman’s team of researchersverified at the conclusion of the no-costevaluation and work estimate. In termsof value, I had a high opinion of my olderexample since it retained better than 85percent of its bluing and was found to beoriginal except for one part. But, like somany collectors who want to believe thatthey possess a rare and unique treasure,I thought they would be valued for morethan they’re actually worth.SHOP HISTORYDoug <strong>Turnbull</strong> and two employees beganrestoring antique, American-manufacturedfirearms in the back room of CreeksideGun Shop near Bloomfield, NewYork. They were starting to build a namefor themselves by accurately returningParker, L.C. Smith and Fox shotguns aswell as Winchester rifles made after 1873Once the U.S. entered World War I, productionof the 1911 increased dramatically. Atabout serial number 510,001 to the endof military production in 1945, the “UnitedStates Property” marking moved to the rightside of the receiver, just behind the slidestoppin.to factory-new condition.The operations moved to a4,000-square-foot facility in 1998 andexpanded by 3,000 square feet in 2001 toaccommodate the growing business drivenby their reputation and word of mouth. Asdemand from inside the industry for <strong>Turnbull</strong>’sfinishes increased, <strong>Turnbull</strong> Manufacturing<strong>Co</strong>mpany was created and brokeground adjacent to the original building tocreate a 6,400-square-foot facility with anew showroom. Today there are currently14 employees, including seven full-timegunsmiths and an in-house engraver.<strong>Turnbull</strong> Restoration obtained a federallicense to become a manufacturer offirearms and started creating its own lineof <strong>Co</strong>lt-style single-action revolvers andWinchester-style rifles. Every gunsmithholds each piece to a strict hand-fittingand -polishing process before subjecting itto <strong>Turnbull</strong>’s highly respected, periodcorrectfinishes. Much of its business istied to the vault-kept bluing and colorcase-hardening formulas, coveted by othermanufacturers and counterfeiters, usedfor specific serial-number ranges. Withrespect to the 1911 market, <strong>Turnbull</strong> hasfamously contributed the color case-hard-8 <strong>BOOK</strong> of the 1911gunsandammo.com

WHEREOld Newbecomesagainening, bone charcoal bluing and nitrebluefinishes to the Kimber Centennial(see page 26 of last year’s 2010 edition ofthe Guns & Ammo <strong>Co</strong>mplete Book of theModel 1911), as well as the exacting bluingcombination used on Bill Laughridge’shand-crafted tribute from Cylinder andSlide to the original Model 1911 (see page72 of this issue). Remington Arms, <strong>Co</strong>lt,Smith and Wesson, U.S. Firearms andmany gunsmiths around the world alsolook to <strong>Turnbull</strong> when the highest qualityand historical accuracy are necessary fortheir most important projects. Since thebusiness began in 1983, Doug <strong>Turnbull</strong>’sshop has restored or repaired more than5,600 firearms and manufactured morethan 200 new classics.SHOP VISIT<strong>Turnbull</strong> Manufacturing has restored inexcess of 1,000 1911s in all makes andmost variations. To fully understand whatgoes into the restoration of an importantpiece of history and experience one of my1911s undergoing part of the process, Imade a two-day road trip to Bloomfield,New York, from Illinois. I say “part of therestoration process” because as much as40 hours of labor go into each pistol. <strong>Turnbull</strong>restores about 50 1911s each year,but with this year marking the 100th anniversaryof the gun, the number of orderspatiently waiting inside <strong>Turnbull</strong>’s bankvault (yes, it’s from an actual bank) hasdoubled. Clients are being told to expect aseven- to nine-month turnaround.Touring the shop section of the new<strong>Turnbull</strong> facility, I walked through thedoors and was taken back to the memoryof my years sitting at a bench with thewarm smell of gun oil hovering in the air.The gunsmiths initially seemed unawareof my presence as they keenly focused onwhat they were doing within their ownpersonally organized space. One was workingon a side-by-side Fox shotgun, anotheron an old Winchester, and Mike Knowlesup front was working on polishing the gripsafety for one of my 1911s.In another room, a gunsmith/carpenterwas working on restoring an old Hawkinsshotgun recoil pad, but he was politeenough to take the time to discuss whatgoes into creating period-correct replacementsfor the different variations of 1911stocks. The truncated diamond pattern cutinto the walnut stocks of my 1918 pistolsfeature 14 diamonds per inch. RemingtonArms-UMC stocks were cut with 13 to13½ diamonds per inch, and Springfieldstocks were cut with finer checkering and15 diamonds per inch.Due to the large microscope positionedin the center of a sterile room, the nextroom visited within the shop appearedmore like a laboratory. Behind the microscopewas a thick-glassed engraver chiselingscrolls and flourishes into the slide ofa commercial 1911 manufactured in 1921.He was working on his last project to illustratehis mastery of the four different typesof engraving required to earn the highestrating from the Engraver’s Guild. He allowedme the opportunity to try my handunder the microscope, which only servedto impress me with his ability to steady hishand with a fine degree of flawless perfection.It was an unexpected talent from aman who indicated that he wears his thickeyewear to correct his 20/600 vision.Moving deeper into the shop, partsbins towered along a wall, and I carefullynoted the handwritten labels markingthe discriminatory variations of severalcomponents. As such an example, thereare nine types of front sights on 1911sand 1911A1s (military and commercialpistols), and within those types there arefour variations of the Type 8. How does<strong>Turnbull</strong> still find so many period-correctparts? “We have sources,” VanOrman says.“If we disassemble the project and discoverincorrect parts are on the gun, we workwith the customer to make it more periodcorrect. We also advise the customer asto what is correct and incorrect. Some replacementparts are original, while othersare modern, but we use the correct stamps,polishing, checkering, roll dies and inspectormarks to make it factory original. Wedo maintain a source for replacementparts, but I can’t mention from where.”Heading back to the older part of thefacility, a room to the right revealed anenormous collection of wooden stockblanks—more exhibition-grade wood thanI’ve ever seen in one room. Back and to theleft was an antique lathe that worked likeThomas Jefferson’s original copy machine.An indicator on the left travels across thecontours of an original stock, and a cutteron the right side mirrors its movement andforms the shape from a new blank. Littlewood is wasted, and the gunsmiths at<strong>Turnbull</strong> are seasoned veterans in selectingand accessing the best art from the grainthat each stock blank offers.The last room visited in the tourcontained a roomful of lathes and millingmachines, but my eyes were drawn to thewall of rollstamp dies as I realized that wasone of the company’s secrets in obtainingcorrect markings. One of the easiest ways10 <strong>BOOK</strong> of the 1911gunsandammo.com

WHEREOld NewbecomesMore than 130 unique roll stamps hang on awall at <strong>Turnbull</strong> Manufacturing. From the scarceto the common, this unusual inventory is indicitiveof the shop’s capability in addressing anyrestoration.againbecause the restoration would depreciatethe pistol’s value.“The majority of our restorations arelower-condition, noncollectible 1911s,”says VanOrman. “These are typically$1,500 guns that bring the value to approximately$5,500 with $2,000 worth ofrestoration. It would be foolish to restore ahigh-quality gun.”When a 1911 comes in for a quote, itgets evaluated at no charge or obligation.A shop foreman takes a look at the gun,mechanically checks the condition (whichdoes not involve a test fire) and createsthink about is the work that has to bedone to most projects before they canbe blued,” says Tracy Haplin, marketingmanager for <strong>Turnbull</strong> Manufacturing. “Itusually has to be prepped and polishedbefore any marks are added. Historicallyspeaking, different parts got polished indifferent ways. There is more to what wedo than simply bluing. Some people tryto prep the pistol themselves, but mostof the guns need an entire restoration.Occasionally, we do get one in from agunsmith that has good prep work, andit can be simply blued for $250, but most<strong>Turnbull</strong>’s shop with an average conditionof 25 percent grade.Everything that leaves <strong>Turnbull</strong>’s shopis mechanically functional and ready to befired. It doesn’t usually see a gun submittedfor mechanical issues only; mostgunsmiths are approached for that sort ofwork. Although <strong>Turnbull</strong> Manufacturing<strong>Co</strong>mpany specializes in restorations, it willperform mechanical work while restoring agun. Once a gunsmith completes restoration,it goes through the hands of qualitycontrol before it is returned to the client,but it’s never test fired.to determine if a 1911 looks too good andhas ever been refinished is to carefullyinspect the markings. Gunsmiths willoften polish the slabs on the slide and theframe to reduce the effects of rust pitting,but in doing so the stamps and proofmarksare smoothed over and the depth of thelettering becomes shallow by the time a1911 is submerged in the bluing bath. Incases where a 1911 is pitted, a <strong>Turnbull</strong>gunsmith will completely remove any evidenceof pitting, smooth out the slab androllstamp the correct marking from one ofthe many dies the company has spent yearscollecting in order to produce an originalqualityresult.“We rarely see guns with too muchpitting. They were built quite well,” saysVanOrman. “We wouldn’t take on a projectif [rust] pitting were too deep.”Heading to the new showroom, Inoticed a locked door. “Is that where thebluing is done?” I asked.“Yes, but if I take you in there, I couldn’tlet you out,” I was told. The formula andprocess to achieve the correct blue and colorcase-hardening is a <strong>Turnbull</strong> secret keptclose to the chest. They won’t even explainhow it’s done. “The one thing that I canshare is that <strong>Co</strong>lt used coal, and <strong>Turnbull</strong>Manufacturing <strong>Co</strong>mpany uses propane forheating the ovens,” VanOrman indicated.“We know our bluing is correct based oncomparing it to guns that are in 98 percentcondition with a little bit of aging.”TO RESTORE, OR NOT TORESTORE? THAT IS <strong>THE</strong> QUESTIONOn several occasions <strong>Turnbull</strong> hasrejected work on high-condition 1911sa detailed quote. At this stage, nothingabout the gun has been disassembled.He considers what polishing or replacingof parts will likely need to occur beforeit’s even blued, then creates an estimate.After the client approves the work order,a gunsmith will disassemble the 1911 andexamine the need for any internal partsreplacement. The quote is amended withany unseen issues with the pistol, whichare addressed with the client before agunsmith continues. Each detail is brokendown on a line-item quotation.The typical restoration costs about$2,500 and requires extensive researchbefore beginning. The most commonmisunderstanding is when a client sendshis Model 1911 to be blued after seeinga price of $250 listed on the <strong>Turnbull</strong>Web site. “What they don’t necessarilyAfter nearly a century of service, serialnumber 605521 has been completelyrestored and appears exactly as it didthe day it left <strong>Co</strong>lt’s factory in late 1918.end up needing additional work.”Sharing space inside the <strong>Turnbull</strong> vaultare valuable materials including out-ofprintreferences, factory archival data anda library of pictures and notes gatheredfrom encounters with other originalsamples known to be historically correct.No detail is too small, and only <strong>Turnbull</strong>’srestoration services have proven the abilityto accurately reproduce every fine detail toexacting standards—proofmarks, inspectormarks, the number of lines in checkeringon different components, the sequenceof tactile diamonds cut into a <strong>Co</strong>lt stockslab in contrast to the lines of checkeringon a Remington or Springfield. Even thedirection and depth of the grain createdfrom final polishing to every componentgets critiqued.The most common restoration to a 1911is applied to an early <strong>Co</strong>lt M1911 U.S.Army, though the gunsmiths at <strong>Turnbull</strong>have completed a number of M1911A1projects. For those who are of the opinionthat allowing an original 1911 to besubject to restoration is sacrilege, considerthe fact that most 1911 projects arrive toARRIVALI purchased the pistols that I sent in forrestoration for just $500 apiece. Theyounger of the two was in especially roughcondition. A few short weeks after myvisit, both of my 1918-vintage 1911s weresigned for and unveiled in the office. It’seasy to understand why so many ownersof the early .45s are looking to <strong>Turnbull</strong>Manufacturing <strong>Co</strong>mpany for its restorationservices. My vintage 1911s now appearas if they just came off the original assemblytable. It is such an incredible feeling tothink back upon their condition monthsago, witness a day in their transformationand see what they have ultimately become.For a heavily worn or nonfunctioning,mismatched-parts gun without sometype of documented provenance, <strong>Turnbull</strong>’sservices can renew a 1911’s honorwhile creating an excellent investment.Occasionally, <strong>Turnbull</strong> Manufacturing<strong>Co</strong>mpany offers similar restoredpistols from its inventory or on customerconsignment for a price usually fallingbetween $4,500 and $5,500 (determinedby a number of factors). At the time ofthis writing, there is a Remington UMClisted for $6,250 and a <strong>Co</strong>lt Model 1911Black Army priced at $4,750. As high asthose prices might sound for a restored1911, <strong>Turnbull</strong> has no problem sellingthem. This is the only shop I knowwhere someone can send an honest antiqueto be restored without the risk ofdestroying its value. For more information,visit turnbullmfg.com.12 <strong>BOOK</strong> of the 1911 gunsandammo.comgunsandammo.com<strong>BOOK</strong> of the 1911 13

WHEREOld Newbecomesagain14 <strong>BOOK</strong> of the 1911 gunsandammo.comgunsandammo.com<strong>BOOK</strong> of the 1911 15