American Handgunner May/June 1978

American Handgunner May/June 1978

American Handgunner May/June 1978

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

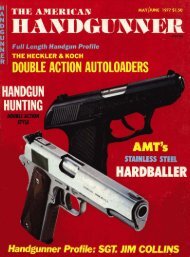

tandai 'd accuracy set up by Swenson. The Government Model1s given full house treatment and fitted with a .22 conversionunit and a .38/44 barrel and bushing for multi-purpose use.surface was needed. The secret of thetechnique is not the chrome itself but thepreparation of the surface, which must beflawless. The surface is hydro-honed withdiamond dust to prepare it for the mattefinish. When the chrome is applied it isonly Yioths to 5/~oths of '/ioooth of an inchthick. Certain allowances are made to allowfor clearances in close fitting areas.The plating is sent to a custom platinghouse which Armand has used for over adecade. The next most popular finish isthe standard old blue job which is all donein the shop. Nearly 90% of the pistols goingthrough the shop are ordered with theHard White Chrome finish.The squared-off trigger guard was pioneeredby Armand Swenson, applyingthe knowledge gained in altering bolts andtriggers on military rifle actions. The techniqueinvolves heating the trigger guard tothe correct temperature, then forging it tothe desired shape and contour. This allhad to be done without disturbing thecharacter of the frame, for heating it toomuch, or cooling it incorrectly, couldcause the temper to be lost or, even worse,.warp the frame.f^it. - . -Steps in installing the S&W "K"model rear sight. The commercialslide (right) is milled (center)and completed job is shown at left.After this is done the surfaces are finishedout and checkered to match thefront strap of the frame. This feature is appliedonly to the steel frame models. Thesquared-off trigger guard has done muchto popularize the two-hand hold with thebig auto.Perhaps the most famous Swenson inventionseen today, since it is sold separatelyand assembled on the many stan-ambidextrous thumb safety. For years'.*.Swenson built these by hand. He began byextending the standard thumb safety for4ease of operation. Later, he redesignedthe long safety for the right side of theframe. It utilized the same shaft that extendedfrom the thumb safety through theframe to hold the grip safety in place onthe frame. The early models featured asquare pin at the end of the shaft on theright side of the frame that mated with ablind square hole on the left safety lever.The lever was held in place on the shaft bythe right hand grip panel which had to bealtered to allow the lever to work freelyunder it.Lately, Armand has gone to a stainlesssteel investment casting which featuresthe connecting grip safety pin being assembledby a tongue and groove system.There are several other ways to connectthem, and the above mentioned and everyother system have been patented by Swenson.The unit is sold to the public and requiressome handfitting to insure that thesafety properly engages the sear.Armand also sells the regular extendedthumb safety which is a single unit that replacesthe regular Colt or G. I. version~this goes for $25.00, while the dual purposemodel is around $38.50 in kit form.All are investment cast from highest qualitystainless steel.One of Armand's pioneer features wasthe installation of the "K" model S & Wrear sight on the .45 slide. The techniquehas changed little, with shear pins now beingadded for strength. The sight must beset correctly in the slide for proper frontsight application.Alone with the sight installation is theuucustom stippling or matting on the slide.This not only offers a non-glare surfacebut looks damned good, in my opinion.Aside from the outer cosmetic featureswhich are readily noticeable, all Swenson' Y., ; AMERICAN HANDGUNNEf^tl. ..'i..