SCHAAF GmbH

SCHAAF GmbH

SCHAAF GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>SCHAAF</strong><br />

Your partner for innovative solutions<br />

<strong>SCHAAF</strong> – Product quality and<br />

cooperation just as you like!

<strong>SCHAAF</strong> Germany<br />

7000 sqm for high-pressure hydraulic technology up to 4000 bar<br />

Accessories manufacturing and assembly<br />

Electrical assembly section and assembly line<br />

Hydraulic hose manufacturing and assembly<br />

Life time test benches<br />

Testing centre and test bunker<br />

Commercial Manager<br />

Commercial department<br />

Shipping dep. for the global market<br />

IT manager<br />

IT department<br />

Administration of quality<br />

management<br />

Material warehouse to<br />

enable express delivery.<br />

Reception<br />

Production management<br />

Quality department<br />

Development, organisation and sales<br />

Company management<br />

Development and design<br />

Order processing<br />

Technical sales (ERP, FEA and CAD-supported)<br />

Work planning (CAM-supported)<br />

Purchase<br />

CNC-large part manufacturing<br />

Production area with CNC high-tech<br />

machines for µm-precise production<br />

HighTech-assembly line<br />

CNC milling centres<br />

SEAL-TEC sealing technology centre<br />

<strong>SCHAAF</strong>-surface treatment<br />

Welding section<br />

Paint shop<br />

Joinery and<br />

fine-materials cutting<br />

Social area

Focus on <strong>SCHAAF</strong><br />

Know-how paired with High-Tech - the best foundation for successful systems.<br />

1 Commercial office<br />

2 Human resources office<br />

3 Commercial management<br />

4 IT-Department<br />

5 Reception<br />

6 Shipping<br />

7 Training zone / Conference room<br />

8 Electric department<br />

9 Quality assurance management<br />

10 Sawing center<br />

11 Material warehouse<br />

12 Managing director<br />

13 Purchase<br />

14 Hose production<br />

15 Design department<br />

16 Technical sales<br />

17 FEA department<br />

18 Process engineering<br />

Erkelenz,<br />

Germany<br />

1<br />

3<br />

5<br />

2<br />

4<br />

6<br />

9<br />

8<br />

7<br />

10<br />

13<br />

11<br />

12<br />

17<br />

15<br />

14<br />

16<br />

18

19 Radial drilling<br />

20 Conventional turning operation<br />

21 Assembly<br />

22 Test room monitoring<br />

23 Test bunker<br />

24 Deburring department<br />

25 Burnishing<br />

26 Showroom<br />

27 Production management / QA-Dept.<br />

28 Production<br />

29 Demonstration room<br />

30 Sealing manufacturing<br />

31 Welding section<br />

32 Joinery<br />

33 Teamwork<br />

Development<br />

The continuous adjustment of existing products to the latest<br />

technical standards is part of the daily process. Many new<br />

developed systems, which are subject to permanent<br />

endurance testing, are going to be released to the professional<br />

world in the near future. Visit us and get an idea of our<br />

development department and production facilities.<br />

22<br />

19<br />

20<br />

23<br />

21<br />

24<br />

27<br />

25<br />

26<br />

28<br />

29<br />

31<br />

32<br />

30<br />

33

Data and Facts<br />

Data and Facts<br />

<strong>SCHAAF</strong> produces in 3 shifts – 24 hours/day, 6 days/week<br />

The entire company has been certified in<br />

accordance with DIN ISO 9001 since 1997<br />

On average, around 1.8 tonnes of products<br />

leave the production facility each day<br />

95 % of all materials are immediately available from stock<br />

Almost 100 % of these are produced in-house<br />

24-hours express-delivery possible<br />

Due to the <strong>SCHAAF</strong> SEAL-TEC sealing technology centre,<br />

any type of seal and geometry can be produced quickly<br />

and individually, in the widest range of materials<br />

With its own Electrical and IT Dept., <strong>SCHAAF</strong> can<br />

provide tailored control system designs and adapt<br />

electro-hydraulic units to specific requirements<br />

Since 1990 the facilities have been enlarged by factor 20<br />

Service and Training<br />

<strong>SCHAAF</strong> will, if required, install and start up your hydraulic unit.<br />

Upon request, <strong>SCHAAF</strong> will train your technicians in the operation,<br />

maintenance and dismantling of units - at our premises and, of course,<br />

on site anywhere in the world.<br />

Documentation<br />

Each delivery is accompanied by documentation<br />

prepared according to the latest requirements and<br />

most stringent regulations.<br />

High-precision Test Bench<br />

Upon request, <strong>SCHAAF</strong> will perform precise variance comparison tests<br />

of the pressure, force or stroke and torque of each bolt tensioner and<br />

hydraulic nut. Fatigue-strength test benches are constantly in use to<br />

determine the service life and material quality of the products. We are<br />

pleased to perform also customer-specific tests.<br />

A yearly output of 20,000 <strong>SCHAAF</strong> hydraulic high-pressure tools<br />

is delivered worldwide. The <strong>SCHAAF</strong> installation team is ready to<br />

go into action on-the-spot everywhere at extremely short notice.<br />

Advisory Service<br />

Designers and engineers are at your disposal right<br />

from the beginning in order to achieve an optimum<br />

solution for you.<br />

Certificates, Approval Requirements<br />

Upon request, you receive certificates covering the<br />

materials used and tests performed.<br />

Quality Assurance<br />

The entire company is certified according to<br />

DIN EN ISO 9001. All products are carefully planned,<br />

manufactured, checked for conformity with the requirements,<br />

and supplied ready for use.<br />

1977 Established in Erkelenz by Mr. Martin Schaaf<br />

1988 Erection of a new 400 sqm company building<br />

1990 Takeover by Dipl.-Ing. Ralf Köllges<br />

1997 Certification of the entire company in<br />

accordance with DIN EN ISO 9001<br />

1999 Erection of a new 1,600 sqm company building<br />

2002 Extension of the company building by 600 sqm<br />

2005 Addition of a 1,800 sqm production facility<br />

2007 Extension of sales network in Southwest Asia<br />

2009 Production and office extension of 3,000 sqm<br />

2010 Establishment of <strong>SCHAAF</strong> (Taicang) Co. Ltd and<br />

movement into the new production facility with<br />

700 sqm area in Taicang, China<br />

2011 Start of production in China

Sophisticated and flexible<br />

<strong>SCHAAF</strong>‘s quality management is impressive throughout the entire production process<br />

A consequent company<br />

policy creates trust<br />

The company philosophy of <strong>SCHAAF</strong> <strong>GmbH</strong> & Co. KG<br />

is based on a consequently operated quality policy and<br />

a continuously promoted process of improvement. Welldefined<br />

fundamentals and quality aims are deep-seated<br />

within the company. They assure that <strong>SCHAAF</strong> products<br />

and services meet the claims of national and international<br />

norms and standards, compulsory definitions and the<br />

specific needs and requirements of our customers.<br />

At <strong>SCHAAF</strong> <strong>GmbH</strong> & Co. KG, the customer<br />

takes the centre stage. Excellent consulting and<br />

efficient determination of the customers wishes and<br />

reqiurements, in consideration of the field of application,<br />

are indispensable pre-conditions in order to satisfy<br />

the customer and to create trust. Safety, functionality,<br />

reliability, operation, performance, healthiness,<br />

<strong>SCHAAF</strong> China<br />

Since 2011 <strong>SCHAAF</strong> manufactures on 700 sqm under<br />

German supervision in Taicang close to Shanghai. After<br />

2 years of preparation with a sales office in Shanghai,<br />

the trained personnel is ready for all kinds of demands.<br />

Due to severe surveillance, the quality policy is continued<br />

in addition with the asian conditions. Construction and<br />

development is going to remain in the German headquarter<br />

in Erkelenz. Further extension of the production area<br />

and the distribution network is in planning stage.<br />

ecologically sensitiveness, comfort, design, material,<br />

delivery time, servicable life, service, and maintenance<br />

are essential parametres to the effort to offer and deliver<br />

the ideal solution for the customer quick and flexible.<br />

Planned and certified:<br />

Quality management create convincing quality image<br />

In order to achieve the optimum for our customers<br />

and, thus, assure the existence and the success of the<br />

company, <strong>SCHAAF</strong>‘s executive management focusses<br />

on the quality of the daily performance, the internal and<br />

external collaboration and on the resulting products<br />

and services. The quality of all <strong>SCHAAF</strong> products<br />

is systematically planned, finished and certified.<br />

The continuously updated quality management system,<br />

being monitored and evaluated by the executive<br />

management, animates the <strong>SCHAAF</strong> quality premise<br />

and generates the outstanding quality image of the<br />

company. <strong>SCHAAF</strong> quality products are only approved<br />

for application and are deliverd to the customer, if the<br />

proof is given, that they fulfil the requirements to 100%.<br />

<strong>SCHAAF</strong> staff:<br />

Quality conscious action - continuous improvement<br />

The personnel management at <strong>SCHAAF</strong> is driven by<br />

the idea, that only qualified and quality conscious<br />

employees can assure a high efficiency in the fields<br />

of product development and manufacturing. The<br />

executive management is convinced, that each and<br />

every <strong>SCHAAF</strong> staff member is part of ensuring and<br />

achieving the company‘s goals. Furthermore, the<br />

company is not satisfied by achieving a goal, but willing<br />

to continuously improve thinking and performing.<br />

Thus, the executive management offers every<br />

single staff member the necessary free spaces<br />

and trainings to meet the requirements, to maintain<br />

the quality management system and constantly<br />

work on the improvement of the company.<br />

This is how a remaining customer trust in the<br />

abilities of the <strong>SCHAAF</strong> performance is granted.<br />

Therefore, <strong>SCHAAF</strong> implements a leading position<br />

and guarantees a long lasting job security.<br />

Production facility in Taicang - China Office in Taicang Managing director in Taicang<br />

...

We are High-Pressure<br />

Products, developed and manufactured by <strong>SCHAAF</strong>, shown by some examples<br />

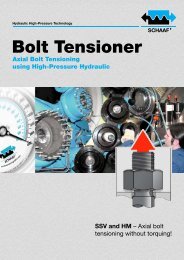

Bolt Tensioners<br />

Simultaneous torsion-free generation of<br />

pretensioning force in several bolts.<br />

Fields of Application<br />

General mechanical engineering<br />

Shipbuilding<br />

Metal industry<br />

Structural and civil engineering<br />

Refineries, chemical industry<br />

Powerplant technology<br />

Wind power industry<br />

Research technology<br />

Onshore / Offshore<br />

Hydr. high-pressure<br />

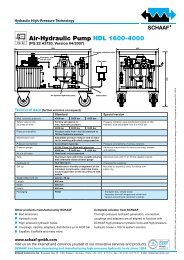

pumps, control systems<br />

Hydraulic pumps up to 4000 bar.<br />

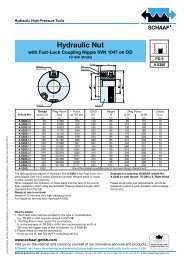

Hydraulic Nuts<br />

Axial force is generated and can immediately be checked at any time.<br />

Pictograms of the <strong>SCHAAF</strong> product groups (PG)

A-LOC Roll Ring Locking System<br />

Material-adjusted axial clamping –<br />

centering and tightening with only one tool.<br />

EcoRolls<br />

The cost-effective<br />

composite rolls<br />

Best in Technology<br />

Out of more than 3000 suppliers <strong>SCHAAF</strong> received the<br />

award „Best in Technology“ from MAN Diesel & Turbo SE.<br />

In the last 30 years over 8000 orders for the companies of<br />

MAN Diesel & Turbo SE were executed.<br />

Oil press fit<br />

Fully automatic generation and<br />

loosening of oil press fits.<br />

Mounting Documentation System<br />

For safe processing Bolt tensioning force<br />

generation. Optionally as mobile unit, with<br />

Tool-Service-Indicator (TSI) and<br />

Tool-Management-System (TMS).<br />

High-pressure<br />

Hydraulic Accessories<br />

Standard versions and special designs.<br />

Internationally / multilingual for you.<br />

Staff:<br />

Internet:<br />

Presentations:<br />

Animations:<br />

DVD-Interactive:<br />

Represent. countries:<br />

ExpaBolt, ExpaTen<br />

The ideal connection for torque and<br />

shear force transmission.<br />

GripLoc<br />

The optimum connection<br />

for shafts and axles

<strong>SCHAAF</strong> <strong>GmbH</strong> & Co. KG<br />

Bruesseler Allee 22<br />

41812 Erkelenz - Germany<br />

Telephone: +49 - 24 31 - 9 77 70-0<br />

Fax: +49 - 24 31- 9 77 70-77<br />

E-Mail: info@schaaf-gmbh.com<br />

Internet: www.schaaf-gmbh.com<br />

<strong>SCHAAF</strong>.e_0310_indd_online · Errors excepted.<br />

Data will change as developments occur.<br />

Copyright as per standard ISO 16016.